Académique Documents

Professionnel Documents

Culture Documents

Saic N 2035

Transféré par

aamirapiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Saic N 2035

Transféré par

aamirapiDroits d'auteur :

Formats disponibles

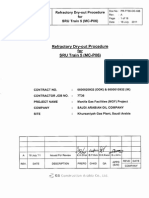

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER

Review Installation Procedure for Fireclay Bricks

SAIC-N-2035

PROJECT TITLE

WBS / BI / JO NUMBER

EQUIPMENT ID NUMBER(S)

EQUIPMENT DESCRIPTION

LAYOUT DRAWING NUMBER

REV. NO.

SCHEDULED INSPECTION DATE & TIME

ACTUAL INSPECTION DATE & TIME

SYSTEM ID.

MH's SPENT

TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO INSPECTION LEVEL

CONTRACTOR INSPECTION LEVEL

REFERENCE

WORK PERMIT REQUIRED?

PASS

FAIL

General Requirements (Note: This Checklist applies to Fireclay Brick Refractories Only per SAES-N-130)

A1

The procedure is project specific and identifiable by Budget Item (BI) or

Job Number, Contract Number & Project title.

Sch Q,

Section 3.1

A2

A) An approval section exists to document adequacy prior to use.

B) A revision control section exists to

document procedure changes.

(ISO 9001:2000, Para. 4.2.3a)

Sch Q,

Section 3.1

A3

An attachment section exists listing applicable QC forms & records.

(ISO 9001:2000, Para. 4.2.4a)

Sch Q,

Section 3.1

A4

Procedure Scope covers fireclay bricks used for bridges and dividing

walls in boilers, sulfur recovery unit equipment and process heaters.

SAES-N-130,

Para. 1.1

A5

Procedure list under References:

A) SAES-N-100, SAES-N-130.

B) SA Std Drawings AD-036393, sheet 1 through 28 as applicable for

Boiler Installations

C) SA Form 175-328110

C) Applicable International Standards i.e. API STD 560, API RP 936 &

ASTM Standards applicable to the refractory scope of work.

SAES-N-100,

Sec. 3

A6

Definitions are listed & match SAES-N-100/130, Section 4, and API RP

936, Section 3 & Appendix A (Glossary of Terms).

SAES-N-100,

Section 3 & 4

A7

Procedure covers Quality Control Key Elements of API RP 936

(Documents, material & applicator qualifications, installation monitoring,

as-installed tests, pre-dryout inspection, dryout & post dryout inspection.

See Attachment 1.

SAES-N-100,

Para. 3.2

A8

Procedure is a "Marriage" of requirements of Refractory Manufacturer,

the Equipment Manufacturer, & applicable SA standards (SAES-N-130).

See Note 1.

SAES-N-130,

Para. 5.2

A9

Procedure Responsibility section states:

A) Refractory Installer is responsible for installing

refractory systems per SA STDs (SAES-N-100/130) & specific

requirements of Refractory Manufacturer and the Equipment

Manufacturer.

B) Equipment Manufacturer is

responsible for preparing fully detailed engineering drawings of

refractory system (also referenced in procedure).

SAES-N-130,

Section 5

A10

Procedure states that "Refractory Installation" work will not begin until

Refractory work procedures have been approved by Company.

Page 1 of 9

PLANT NO.

EC / PMCC / MCC NO.

QUANTITY INSP.

SAUDI ARAMCO ACTIVITY NUMBER

A.

MECH-

CONTRACTOR / SUBCONTRACTOR

PURCHASE ORDER NUMBER

ACCEPTANCE CRITERIA

QR NUMBER

15-Dec-09

EQPT CODE

SAUDI ARAMCO TIP NUMBER

ITEM

No.

30-Jun-08

DATE APPROVED

Sch. Q, Att. IV,

Para 2.1 & Table

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER

Review Installation Procedure for Fireclay Bricks

PROJECT TITLE

SAIC-N-2035

WBS / BI / JO NUMBER

ITEM

No.

ACCEPTANCE CRITERIA

REFERENCE

B.

Materials Section (Procedure lists material requirements, storage & handling controls)

B1

Material Handling & Storage section details fireclay brick protection

(Handling & Stacking) measures to prevent mechanical damage.

SAES-N-130,

Para. 7.1

B2

The Refractory Manufacturer's precautions for material handling &

storage, as specified on the MSDS sheets, are strictly followed (stated).

SAES-N-130,

Para. 7.2

B3

Target walls with flame impingement on both sides are constructed of

high-duty firebrick, at least 1538C (2800F) rating. (API 560, Par.

11.1.7)

SAES-N-130,

Para. 1.1

B4

Material of metallic shelves used for support of firebricks in process

heaters (selected on surface temperature) shall be specified in

procedure

Note: The support material shall be rated for surface temperature (as

calculated and shown in equipment data sheet) plus 10C.

(API 560, Par. 11.2.8)

SAES-N-130,

Para. 6.4

B5

Fibrous refractory material (Ceramic fiber to pack expansion joint gaps)

comes in strip form (Continuous roll), not in a loose bulk form.

SAES-N-130,

Para. 6.2

C.

Preparations & Pre-Installation Inspection Requirements (Procedure)

C1

Types of materials supplied are checked upon receipt including the data

sheets & specific mixing instructions for materials (mortars, bricks).

C2

Refractory Manufacturer's safety precautions & MSDS sheet are

available & are "to be strictly followed".

C3

Documents (IFC detailed drawings & specifications) have been

approved and are checked by the Inspector prior to installation of brick.

C4

Equipment for Mixing is checked & available as follows (as stated):

A) Number and type of mixers are adequate.

B) A back up mixer is available.

C) A Brick saw is available.

D) Set-up location is acceptable relative to work location

E) Equipment cleanliness is acceptable.

D.

Installation Section Content Requirements

D1

Firebricks for specific equipment meet requirements specified in

SAES-N-100 Table 3 "Mandatory Refractory Systems":

SAES-N-130,

Para. 8.3

SAES-N-130,

Para. 8.3

SAES-N-130,

Para. 8.3

SAES-N-130,

Para. 8.3

SAES-N-100,

Para. 9.1

See Note 2.

D2

Fired Process Heater refractory is installed per the API 560, Section 11

specific requirements, unless otherwise specified.

See Note 3.

Page 2 of 9

SAES-N-100,

Para. 3.2

30-Jun-08

DATE APPROVED

15-Dec-09

QR NUMBER

MECH-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

Review Installation Procedure for Fireclay Bricks

PROJECT TITLE

ITEM

No.

SAIC NUMBER

SAIC-N-2035

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

During installation, Inspection is performed for the following (as stated):

D3

A) Verify all dimensions are per detail drawings.

B) Verify construction joints installed as required per drawings & codes

C) Verify plumbness and straightness is per detail drawings.

D) Verify the integrity of bricks (complete or sections) used.

SAES-N-130,

Para. 8.3

(SA

Checklist)

E.

Expansion Joint Requirements

E1

Expansion joints exist in both vertical and horizontal directions of walls,

at wall edges, around burner tiles & doors. See Note 4.

SAES-N-130,

Para. 6.1

E2

Walls, arches & floors allow for proper expansion of parts & multilayer

bricks have staggered joints that are not continuous through the lining.

(API 560, Para. 11.1.3)

SAES-N-130,

Para. 1.1

E3

Target walls with flame impingement on both sides (Bricks are laid dry or

mortared joints) have expansion joint gaps packed with ceramic fiber

strips having a service temp rating equal to brick. (API 560, Para. 11.1.7)

SAES-N-130,

Para. 1.1

E4

Floor bricks are not mortared & have a 13 mm expansion gap on a 1.8

meter interval (gaps are packed with fibrous strip refractory material).

SAES-N-130,

Para. 6.2

F.

Support Requirements (Tie-backs & Lintels)

F1

Brick lining on vertical flat casing is tied back (minimum 15% of bricks) &

supported by structural steel framing members with tie members

constructed of austenitic alloy material.

SAES-N-130,

Para. 6.3

F2

Tie backs are not required when the radius of the curvature of cylindrical

casing keys the bricks.

SAES-N-130,

Para. 6.3

F3

Brick lining is supported by metal support lintels (shelves) welded to

casing & centered a maximum of 1.8 meters (6 ft.) vertically with shelves

slotted to allow for thermal expansion.

SAES-N-130,

Para. 6.4

G.

Installation of Firebricks & Tiles (API 560 Fired Process Heaters Specific Requirements)

G1

Radiant chamber walls of gravity construction shall not exceed 7.3

meters in height & are made of high-duty fireclay brick.

The walls shall have a base width a minimum of 8% of the wall height &

a maximum height to width ratio of 5 to 1.

The walls of firebrick shall be self-supporting and the wall base rests

directly on the steel floor, not on other refractory.

(API 560, Par. 11.2.2).

SAES-N-130,

Para. 1.1

G2

Gravity walls are of mortared construction. Mortar used is non-slagging,

air-setting & chemically compatible with adjacent refractory, including the

rated temperature of the brick.

(API 560, Para.11.2.3)

SAES-N-130,

Para. 1.1

Page 3 of 9

30-Jun-08

DATE APPROVED

15-Dec-09

QR NUMBER

MECH-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER

Review Installation Procedure for Fireclay Bricks

SAIC-N-2035

PROJECT TITLE

WBS / BI / JO NUMBER

ITEM

No.

ACCEPTANCE CRITERIA

30-Jun-08

DATE APPROVED

REFERENCE

G3

Vertical expansion joints are provided at gravity wall ends and required

intermediate locations. All expansion joints are kept open & free to

move.

If the expansion joint is formed with lapped brick, no mortar is used. it

shall be, a dry joints.

(API 560, Para.11.2.4)

SAES-N-130,

Para. 1.1

G4

Expansion joint gaps are packed with ceramic fiber strips with a service

temperature rating equal to or greater than brick. (API 560, Para. 7.1.7)

SAES-N-130,

Para. 1.1

H.

Quality Control & Responsibility (Inspection, Testing & Repairs)

H1

Inspection & Testing is performed per SA Inspection Form 175-328110 &

SAES-N-130 procedure. use SATR-N-2001.

SAES-N-130,

Para. 8.1

H2

ASTM C134 production testing (Size and Bulk Density, Squareness and

Warpage of Firebricks) was performed per SA Insp. Form 175-328110

Line 23 with certificates available.

SAES-N-100

Sec. 3.2

H3

Repair methods are in accordance with original installation procedure &

where needed, additional supports are installed (as stated).

SAES-N-130,

Para. 8.2

QR NUMBER

15-Dec-09

MECH-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

REMARKS:

REFERENCE DOCUMENTS:

1.

2.

3.

4.

Schedule Q -- Quality Requirements (Project Specific)

SAES-N-100 -- Refractory Systems (30 Jan 2007)

SAES-N-130 -- Installation Requirements-Fireclay Bricks (30 Jan 2007)

API Standard 560 -- Fired Heaters for General Refinery Service (Aug 2007)

5. API RP 936 -- Refractory Installation Quality Control Guidelines - Inspection & Testing Monolithic Refractory Lining & Materials (Nov 2008 Edition)

ATTACHMENTS:

1. Attachment 1, API RP 936 Table 1

2. Attachment 2, SA Inspection Requirement Form 175-328110 (Refractories)

NOTES: 1. Contractor's refractory installation procedure must follow the SA mandatory specific installation procedure SAES-N-130. Contractor can

copy & paste much of the SA refractory procedure into his own procedure. However, Refractory & Equipment Manufacturer requirements must also

be incorporated into the procedure (per SAES-N-130, Para. 5.2 for procedure section)

2. Use Table 3 Mandatory Refractory Systems of SAES-N-100 (Not Attached) for Receipt & Pre-installation inspection checks of firebricks.

3. Incorporate API 560 general/specific requirements & utilize API 560 Section 7 as a checklist during Heater construction. (This is Not Attached).

Process Heater refractory procedures may be submitted separately from other equipment refractory procedures with a heater installation package.

Ensure SAES-N-100, Table 3 & Notes (Not attached) are incorporated in procedure to check Process Heater Refractory materials on installation.

Contractor / Third-Party

Saudi Aramco

Construction Representative*

PMT Representative

Work is Complete and Ready for Inspection:

Name, Initials and Date:

QC Inspector

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

PID Representative

Performed Inspection

Work / Rework May Proceed

Name, Initials and Date:

Name, Initials and Date:

QC Supervisor

Proponent and Others

Quality Record Approved:

Name, Sign and Date:

T&I Witnessed

Name, Initials and Date:

Name, Organization,

Initials and Date:

Page 4 of 9

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER

Review Installation Procedure for Fireclay Bricks

SAIC-N-2035

PROJECT TITLE

ITEM

No.

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

Quality Record Approved:

Name, Sign and Date:

REFERENCE

30-Jun-08

DATE APPROVED

15-Dec-09

QR NUMBER

MECH-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

Y = YES

N = NO F = FAILED

Name, Organization,

Initials and Date:

*Person Responsible for Completion of Quality Work / Test

Page 5 of 9

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

Review Installation Procedure for Fireclay Bricks

SAIC NUMBER

SAIC-N-2035

30-Jun-08

DATE APPROVED

15-Dec-09

Attachment 1 -- API RP 936 Table 1

Page 6 of 9

QR NUMBER

MECH-

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER

Review Installation Procedure for Fireclay Bricks

SAIC-N2035

30-Jun-08

DATE APPROVED

15-Dec-09

Attachment 2 -- SA Form 175-328110 (Refractories)

Page 7 of 9

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER

Review Installation Procedure for Fireclay Bricks

Page 8 of 9

SAIC-N2035

30-Jun-08

DATE APPROVED

15-Dec-09

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER

Review Installation Procedure for Fireclay Bricks

Page 9 of 9

SAIC-N2035

30-Jun-08

DATE APPROVED

15-Dec-09

Vous aimerez peut-être aussi

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistaamirapiPas encore d'évaluation

- SATIP-X-400-01 Rev 5Document3 pagesSATIP-X-400-01 Rev 5aamirapiPas encore d'évaluation

- SAIC-X-3002 Rev 5Document3 pagesSAIC-X-3002 Rev 5aamirapiPas encore d'évaluation

- Saic N 2037Document5 pagesSaic N 2037aamirapiPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Storage & Preservation of Fireclay Bricks & Mortar SAIC-N-2038 15-Dec-09 MechDocument1 pageSaudi Aramco Inspection Checklist: Storage & Preservation of Fireclay Bricks & Mortar SAIC-N-2038 15-Dec-09 MechaamirapiPas encore d'évaluation

- Saes N 140Document10 pagesSaes N 140aamirapiPas encore d'évaluation

- Refractory Dry-Out Procedure For SRU Train 5 (MC-P06) Rev-ADocument107 pagesRefractory Dry-Out Procedure For SRU Train 5 (MC-P06) Rev-Aaamirapi100% (2)

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechDocument5 pagesSaudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechaamirapiPas encore d'évaluation

- Saic N 2033Document5 pagesSaic N 2033aamirapiPas encore d'évaluation

- Saic N 2031Document4 pagesSaic N 2031aamirapi100% (1)

- Saic N 2034Document4 pagesSaic N 2034aamirapiPas encore d'évaluation

- Saic N 2036Document6 pagesSaic N 2036aamirapiPas encore d'évaluation

- Saic N 2034Document4 pagesSaic N 2034aamirapiPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Pre-Application Inspection of Castable & Brick Refractory SAIC-N-2024 15-Dec-09 MechDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Application Inspection of Castable & Brick Refractory SAIC-N-2024 15-Dec-09 Mechaamirapi100% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saic N 2029Document6 pagesSaic N 2029aamirapi100% (1)

- Saudi Aramco Inspection ChecklistDocument7 pagesSaudi Aramco Inspection ChecklistaamirapiPas encore d'évaluation

- Saic N 2028Document4 pagesSaic N 2028aamirapi100% (1)

- Test - SHEM - 07.05 (ANSWER SHEET.) : Employ Name ID# Department SignDocument1 pageTest - SHEM - 07.05 (ANSWER SHEET.) : Employ Name ID# Department SignaamirapiPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistaamirapi100% (2)

- MD4 203 D 7150 340 9003 009 - AwcDocument1 pageMD4 203 D 7150 340 9003 009 - AwcaamirapiPas encore d'évaluation

- Saes N 120Document13 pagesSaes N 120aamirapi100% (1)

- Saes N 110Document17 pagesSaes N 110aamirapi100% (1)

- Plateform Deleted Hence This Gate Also Not RequiredDocument1 pagePlateform Deleted Hence This Gate Also Not RequiredaamirapiPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saes N 100Document16 pagesSaes N 100aamirapiPas encore d'évaluation

- Daelim: General NotesDocument1 pageDaelim: General NotesaamirapiPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Rough CostDocument1 pageRough CostKannanPas encore d'évaluation

- DSS Lecture Note 3 - Lateral Loads - Wind LoadDocument49 pagesDSS Lecture Note 3 - Lateral Loads - Wind LoadMrSamspartPas encore d'évaluation

- GloQ-T428 Bulk Density PDFDocument6 pagesGloQ-T428 Bulk Density PDFRafa Gallagher McCartney PadillaPas encore d'évaluation

- The Master Guide To Construction BiddingDocument58 pagesThe Master Guide To Construction BiddingRafael Yap G.67% (3)

- Asghal PVLDocument118 pagesAsghal PVLEslam ElramlyPas encore d'évaluation

- KirbyCorporateBrochureDocument36 pagesKirbyCorporateBrochureThilan SenarathnePas encore d'évaluation

- First Floor Plan Rev-3 Opt-1Document1 pageFirst Floor Plan Rev-3 Opt-1jagadeshPas encore d'évaluation

- Img 20190425 0002Document1 pageImg 20190425 0002syahmi adliPas encore d'évaluation

- Operation Liftboat FourDocument6 pagesOperation Liftboat Fourmyusuf_engineer100% (1)

- Astm C 1260 PDFDocument9 pagesAstm C 1260 PDFjorgesilva84Pas encore d'évaluation

- PRIMAMAJU R® Steel Datasheet PDFDocument2 pagesPRIMAMAJU R® Steel Datasheet PDFkongkokkingPas encore d'évaluation

- LOI Compro International Exchange House OfficeDocument61 pagesLOI Compro International Exchange House Officemuhammad rachmadiPas encore d'évaluation

- The History of Project ManagementDocument650 pagesThe History of Project Managementjose diaz100% (6)

- Alternative Construction SystemsDocument50 pagesAlternative Construction SystemsYigezu YehombaworkPas encore d'évaluation

- ITP Projek JalanDocument14 pagesITP Projek Jalanzindha100% (1)

- Seven PDFDocument124 pagesSeven PDFDayana PinedoPas encore d'évaluation

- AD 436 - Section Classification of A Flat Plate, January 2020Document1 pageAD 436 - Section Classification of A Flat Plate, January 2020symon ellimacPas encore d'évaluation

- نسخة من All Videos SummaryDocument2 pagesنسخة من All Videos SummaryشمسخلفالسحابPas encore d'évaluation

- Contractor Quality Control (CQC) Plan: Project NameDocument29 pagesContractor Quality Control (CQC) Plan: Project Name徐漫书Pas encore d'évaluation

- ITP For Injection Work of Basement Walls: King Abdullah Financial District (KAFD) Cluster J1Document5 pagesITP For Injection Work of Basement Walls: King Abdullah Financial District (KAFD) Cluster J1amirskbkbk0% (1)

- A3-Bill of Quantities (BOQ)Document10 pagesA3-Bill of Quantities (BOQ)Wael Sayed omarPas encore d'évaluation

- Pi-Typical Masonary Wall Details-5516!10!101aDocument1 pagePi-Typical Masonary Wall Details-5516!10!101akrishanPas encore d'évaluation

- Proposed Sewage Treatment Plant of Domestic Waste 5CmD (Design and Build) .1Document2 pagesProposed Sewage Treatment Plant of Domestic Waste 5CmD (Design and Build) .1John Axl LajomPas encore d'évaluation

- ITB-3094 RequirmentsDocument1 pageITB-3094 RequirmentsTony HaddadPas encore d'évaluation

- Bill of Quantity: Baner Lifespaes LLPDocument1 pageBill of Quantity: Baner Lifespaes LLPSales AlufacadesPas encore d'évaluation

- Introduction To High Speed Railway Bridges in ChinaDocument33 pagesIntroduction To High Speed Railway Bridges in Chinazhou jiePas encore d'évaluation

- ODA (P&BS) Rules 2020 PDFDocument152 pagesODA (P&BS) Rules 2020 PDFAnshuman RathPas encore d'évaluation

- Deshamanya Geoffrey Manning BawaDocument14 pagesDeshamanya Geoffrey Manning BawahrithwikPas encore d'évaluation

- Heating Equipment Sizing FormDocument2 pagesHeating Equipment Sizing FormBenouna FertPas encore d'évaluation

- Comparative Analysis of RC Irregular Buildings Designed According ToDocument9 pagesComparative Analysis of RC Irregular Buildings Designed According ToChristian SesoPas encore d'évaluation