Académique Documents

Professionnel Documents

Culture Documents

Normalizing

Transféré par

Saurabh S. Dhakras100%(1)100% ont trouvé ce document utile (1 vote)

78 vues2 pagesThe Importance of Normalizing

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThe Importance of Normalizing

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

100%(1)100% ont trouvé ce document utile (1 vote)

78 vues2 pagesNormalizing

Transféré par

Saurabh S. DhakrasThe Importance of Normalizing

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

THE HEAT TREAT DOCTOR

rial H

Daniel H. Herring | 630.834.3017 | heattreatdoctor@industrialheating.com

TH

The Importance of Normalizing

Why bother normalizing? is a question frequently asked

of The Doctor. Why indeed? Lets learn more.

Why Normalize?

Normalizing imparts both hardness and strength to iron and

steel components. In addition, normalizing helps reduce internal stresses (Fig. 1) induced by such operations as forging, casting, machining, forming or welding. Normalizing also improves

microstructural homogeneity and response to heat treatment

(e.g. annealing or hardening) and enhances

stability by imparting a thermal memory for

subsequent lower-temperature processes. Parts

that require maximum toughness and those

subjected to impact are often normalized.

When large cross sections are normalized, they

are also tempered to further reduce stress and

more closely control mechanical properties.

Normalizing is typically performed in order

to:

Improve machinability

Improve dimensional stability

Modify and/or rene the grain structure

Produce a homogeneous microstructure

Reduce banding

Improve ductility

Provide a more consistent response when hardening or case

hardening

By way of example, many gear blanks are normalized prior

to machining so that during subsequent hardening or case

hardening dimensional changes such as growth, shrinkage or

warpage will be better controlled.

Soak periods for normalizing are typically one hour per

inch of cross-sectional area but not less than two hours at temperature. It is important to remember that the mass of the part

or the workload can have a signicant inuence on the cooling rate and thus on the resulting microstructure. Thin pieces

cool faster and are harder after normalizing than thicker ones.

By contrast, after furnace cooling in an annealing process, the

hardness of the thin and thicker sections are about the same.

Low-carbon steels typically do not require normalizing. If

these steels are normalized, however, no harmful effects result.

Castings with relatively uniform wall thickness and section sizes

are usually annealed rather than normalized. Other castings, especially those having a complex shape or interconnected thick

and thin sections and are thus prone to high levels of residual

stresses, benet from normalizing. The microstructure obtained

by normalizing depends on the composition of the castings

(which dictates its hardenability) and the cooling rate.

How it Works

The normalizing of steel (Fig. 2) is carried out by heating approximately 100F (38F) above the upper critical temperature

(Ac3 or Acm) followed by cooling in air to room temperature,

or at no greater than one-bar pressure using nitrogen if the

process is being run in a vacuum furnace.

Normalizing is often considered from both a thermal and a

microstructural standpoint. In the thermal sense, normalizing

is austenitizing followed by a relatively slow cool. In the microstructural sense, the areas of the microstructure that contain

about 0.80% carbon are pearlitic, while areas of low carbon

are ferritic.

1400

Normalizing

1000

Quench and tempered at 550C

800

Temperature

Nominal stress , MPa

Austenite ( - iron)

Quench

1200

Normalized

600

Annealed

+ Fe3C

400

+ Fe3C

+ Fe3C

Hypoeutectoid steel

Hypereutectoid steel

200

0

0

10

15

20

Nominal strain, (%)

25

Fig. 1. Stresses induced by heat treatment (SAE 1045)[1]

16 April 2008 - IndustrialHeating.com

30

35

0.83

2.00

%C

Fig. 2. The normalizing process[2]

rial H

Effect of Normalizing on Physical Properties

Annealing and normalizing do not present a signicant difference on

the ductility of low-carbon steels. As the carbon content increases,

however, annealing levels off, with respect to a property such as elongation, around 20%. On the other hand, the ductility of the normalized high-carbon steels continues to drop to the 12% level (Fig. 3).

The tensile strength (Fig. 4) and the yield point (Fig. 5) of the normalized steels are higher than the annealed steels. Normalizing and

annealing do not show a signicant difference on the tensile strength

and yield point of the low-carbon steels. Normalized high-carbon

steels, however, exhibit much higher tensile strength and yield point

than those that are annealed.

Low- and medium-carbon steels produce similar hardness levels

when normalized or annealed. However, when high-carbon steels are

normalized, they maintain higher levels of hardness than those that

are annealed (Fig. 6).

In Conclusion

Normalizing is a process that improves part quality and plays an important role in controlling dimensional variation in hardening and

case hardening. Normalizing should be done whenever dimensional

stability is important or when manufacturing operations are expected

to impart signicant amounts of stress into the material. Normalizing

helps avoid many heat-treating problems. IH

References

1. Rapid Product Deployment Research Centre (http: rpdrc.ic.polyu.edu.hk)

2. School of Engineering Technologies, Farmingdale State College (www.

lu.farmingdale.edu)

Additional related information may be found by searching for these (and

other) key words/terms via BNP Media SEARCH at www.industrialheating.

com: normalizing, austenitizing, pearlitic, ferritic, annealing, quenched

18 April 2008 - IndustrialHeating.com

Elongation, % in 2 in. gage length

45

40

35

30

25

Annealing

20

15

10

Normalizing

5

0

0

0.5

1

Carbon content, % C

1.5

Fig. 3. Normalizing and ductility[2]

180

Tensile strength, 1,000 psi

160

Normalizing

140

120

100

Annealing

80

60

40

20

0

0

0.5

1

Carbon content, % C

1.5

Fig. 4. Normalizing and tensile strength[1]

120

100

Yeild point, 1,000 psi

TH

Normalizing vs. Annealing

Normalizing differs from annealing in that the metal is heated to a

higher temperature and then removed from the furnace for air cooling rather than furnace cooling. For many manufacturing engineers

there is often a great deal of confusion as to when to specify normalizing and when to call out annealing. There is a logical reason for this

because, in many instances, the procedure for normalizing and that of

annealing are one and the same. For example, very-low-carbon steel

can be almost fully annealed by heating above the transformation

range and cooling in air.

In normalizing, the cooling rate is slower than that of a quenchand-temper operation but faster than that used in annealing. As a

result of this intermediate cooling rate, the parts will possess a hardness and strength somewhat greater than if annealed but somewhat

less than if quenched and tempered. The slower cooling rate means

normalized sections will not be as highly stressed as quenched sections. Thus, normalizing is a treatment where a moderate increase in

strength is achieved without undue increase in stress.

Normalizing

80

60

Annealing

40

20

0

0

0.5

1

Carbon content, % C

1.5

Fig. 5. Normalizing and yield strength[1]

350

Brinell hardness number, BHN

50

300

Normalizing

250

200

Annealing

150

100

50

0

0.5

1

Carbon content, % C

Fig. 6. Normalizing and hardness[1]

1.5

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

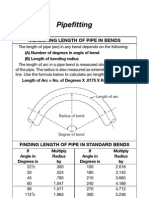

- Measuring Length of Pipe in BendsDocument1 pageMeasuring Length of Pipe in Bendsamacathot06100% (1)

- Ferrite and Austenite Grain StructuresDocument148 pagesFerrite and Austenite Grain StructuresFelipe Arce100% (2)

- Chinese To DinDocument7 pagesChinese To DinDamla KaymakçıPas encore d'évaluation

- Zinc Coating Thickness Effects On Hot Dip Galvanized Steel Corrosion Rates at A Severe Marine SiteDocument7 pagesZinc Coating Thickness Effects On Hot Dip Galvanized Steel Corrosion Rates at A Severe Marine Sitepbp2956100% (1)

- BP Energy Outlook 2019Document73 pagesBP Energy Outlook 2019Pedro Mentado100% (1)

- Procurement Strategy 1Document13 pagesProcurement Strategy 1Saurabh S. DhakrasPas encore d'évaluation

- Basic Heat TreatmentDocument12 pagesBasic Heat Treatmentpramod_goswamiPas encore d'évaluation

- Alloying of SteelDocument3 pagesAlloying of SteelSaurabh S. DhakrasPas encore d'évaluation

- How To PrepareDocument3 pagesHow To PrepareSaurabh S. DhakrasPas encore d'évaluation

- Vanessa PDFDocument4 pagesVanessa PDFosnaider chamorro cardenasPas encore d'évaluation

- Tata Magizinc EnglischDocument4 pagesTata Magizinc EnglischIbtissam EL HaiPas encore d'évaluation

- Laboratorio Nº2 Hidrometalurgia: Lixiviación en ColumnasDocument17 pagesLaboratorio Nº2 Hidrometalurgia: Lixiviación en ColumnasIsidora Martin TriviñoPas encore d'évaluation

- Thermanit 22/09 Solid Wire For Joining Duplex Stainless SteelsDocument1 pageThermanit 22/09 Solid Wire For Joining Duplex Stainless SteelsbrayanPas encore d'évaluation

- Aluminum-Beryllium Alloys For Aerospace Applications: Materion Corporation Materion Beryllium & Composites 14710Document7 pagesAluminum-Beryllium Alloys For Aerospace Applications: Materion Corporation Materion Beryllium & Composites 14710roshniPas encore d'évaluation

- World: Jawaharlal Nehru Technological University HyderabadDocument11 pagesWorld: Jawaharlal Nehru Technological University HyderabadlavanyaPas encore d'évaluation

- Influences of Martensite Morphology and Precipitation On Bendability in Press-Hardened SteelsDocument8 pagesInfluences of Martensite Morphology and Precipitation On Bendability in Press-Hardened SteelsLuca CoralloPas encore d'évaluation

- Corrosion of Metals: PittingDocument26 pagesCorrosion of Metals: Pittingfreeuser3Pas encore d'évaluation

- EMSE 201 - Introduction To Materials Science and EngineeringDocument3 pagesEMSE 201 - Introduction To Materials Science and EngineeringblessingjohnPas encore d'évaluation

- Temper EmbrittlementDocument5 pagesTemper EmbrittlementClaudia Patricia Magaña RabanalesPas encore d'évaluation

- PM Process Advantages for Manufacturing Complex Metal PartsDocument4 pagesPM Process Advantages for Manufacturing Complex Metal PartsAndri YanPas encore d'évaluation

- C4C1.0303 SteelNumber ChemicalcompositionequivalentpropertiesDocument2 pagesC4C1.0303 SteelNumber Chemicalcompositionequivalentpropertiesharis osmanagicPas encore d'évaluation

- Aspl 2011 PDFDocument29 pagesAspl 2011 PDFRajkumar APas encore d'évaluation

- Time-Temperature-Transformation (TTT) DiagramDocument1 pageTime-Temperature-Transformation (TTT) DiagramGunvir SinghPas encore d'évaluation

- ALS7501 01 Sucker Rods Brochure PDFDocument8 pagesALS7501 01 Sucker Rods Brochure PDFedinson saenzPas encore d'évaluation

- ITAConfpaperDocument13 pagesITAConfpaperjmezapPas encore d'évaluation

- Program Schedule WebDocument13 pagesProgram Schedule WebGuru75Pas encore d'évaluation

- Powder Components Heat Treatment PDFDocument47 pagesPowder Components Heat Treatment PDFsmani170Pas encore d'évaluation

- The Effect of Carbon Content On The C A Ratio of As-Quenched Martensite in Fe-C AlloysDocument6 pagesThe Effect of Carbon Content On The C A Ratio of As-Quenched Martensite in Fe-C AlloysAlexis Guzmán MéndezPas encore d'évaluation

- Boe Linien en 090616onlinedoppelseite PDFDocument19 pagesBoe Linien en 090616onlinedoppelseite PDFxavicojmPas encore d'évaluation

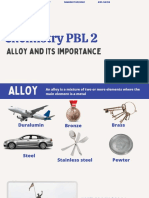

- Chemistry PBL 2 AlloyDocument10 pagesChemistry PBL 2 AlloyNAWARAH FARZANAH BINTI SEMILAH MoePas encore d'évaluation

- Sensitization of AISI 304 and Reversing of Corrosion 2012Document13 pagesSensitization of AISI 304 and Reversing of Corrosion 2012Adnan SaadiPas encore d'évaluation

- Materials and Processes For The Third-Generation Advanced High-Strength SteelsDocument10 pagesMaterials and Processes For The Third-Generation Advanced High-Strength SteelsMathews LimaPas encore d'évaluation

- proceedingofInternationalConferenceIC RAMSD20181 CompressedDocument52 pagesproceedingofInternationalConferenceIC RAMSD20181 CompressedSRIGUSTI REGA MUGIAPas encore d'évaluation

- Phase Diagrams:: The Iron-Iron Carbide (Fe-Fe3C) Diagram or Iron-Carbon (Fe-C) Equilibrium DiagramDocument46 pagesPhase Diagrams:: The Iron-Iron Carbide (Fe-Fe3C) Diagram or Iron-Carbon (Fe-C) Equilibrium DiagramUsman FarooqPas encore d'évaluation

- Micro Constituents of Iron and SteelDocument1 pageMicro Constituents of Iron and SteelAshwani KansaraPas encore d'évaluation

- Widmanstätten StructuresDocument3 pagesWidmanstätten StructuresdantegimenezPas encore d'évaluation