Académique Documents

Professionnel Documents

Culture Documents

Gas & Electric Boiling Pans

Transféré par

Netico85Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Gas & Electric Boiling Pans

Transféré par

Netico85Droits d'auteur :

Formats disponibles

OPTIMUM 700 & 900

GAS & ELECTRIC

BOILING PANS

BUILDERS SPECIFICATIONS

Part D: Maintenance instructions

- WARRANTY In order to guarantee this equipment, we recommend that you comply with the

MANUFACTURERS INSTRUCTIONS in this manual.

However if you can not undertake the required maintenance operations, our installation

and service network is available to provide you with a personalized contract.

- WARNING -

The product delivered to you complies with current standards. If any modifications

are made the manufacturer cannot accept any responsibility whatsoever. The

manufacturer can not be held responsible in the event of an incorrect use of the

appliance.

Keep your documents.

3BE390582NM

Page 2

3BE390582NM 10/07

TABLE OF CONTENTS

GAS & ELECTRIC

BOILING PANS

1

ELECTRIC DIAGRAMS..............................................................................................................................3

1.1

1.2

GAS CIRCUITS ..........................................................................................................................................8

2.1

2.2

SPRING ADJUSTMENT .....................................................................................................................................31

ADJUSTMENT OF LID OPENING......................................................................................................................31

OTHER PARTS NECESSARY FOR AFTER SALES ..............................................................................32

7.1

7.2

PT100 PROBE ....................................................................................................................................................29

LID ADJUSTMENT...................................................................................................................................31

6.1

6.2

LIST OF GASES / PRESSURES AUTHORIZED ACCORDING TO CATEGORIES AND COUNTRIES ..........24

CHANGING FROM ONE GAS TO ANOTHER:..................................................................................................25

GAS FLOW RATES AND POWERS ..................................................................................................................26

CHART OF NOZZLES and air adjustment .........................................................................................................26

VERIFICATION OF THE TEMPERATURE PROBES ..............................................................................29

5.1

60 LITRE OPTIMUM 700 BOILING PANS .........................................................................................................17

60, 110 and 150 LITRE OPTIMUM 900 BOILING PANS ...................................................................................19

250 LITRE VINDIS 900 BOILING PAN...............................................................................................................21

ADAPTATION OF THE APPLIANCE FROM ONE GAS TO ANOTHER.................................................24

4.1

4.2

4.3

4.4

GAS CIRCUIT .......................................................................................................................................................8

PILOT BURNER SUB-ASSEMBLY ....................................................................................................................14

HYDRAULIC CIRCUIT .............................................................................................................................17

3.1

3.2

3.3

GAS BOILING PANS ............................................................................................................................................3

ELECTRIC BOILING PAN ....................................................................................................................................4

APPLIANCE ASSEMBLY ...................................................................................................................................32

ELECTRIC CIRCUIT OF ELECTRIC BOILING PANS .......................................................................................37

FRONT LINE PARTS ...............................................................................................................................41

8.1

8.2

GAS BOILING BOILING PANS ..........................................................................................................................41

ELECTRIC BOILING PANS................................................................................................................................41

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 3

3BE390582NM 10/07

1 ELECTRIC DIAGRAMS

1.1 GAS BOILING PANS

1.1.1

DIRECT HEATING BOILING PANS

Ignition push button

Electric igniter

Ignition electrode

Tank filling switch

Cold water solenoid valve

Hot water solenoid valve

1.1.2

BAIN MARIE BOILING PAN

Safety indicator

Filling solenoid valve of the

double jacket

Water level probe

a: : is closed in the absence

of a flame in the double

jacket

b: closes for 70 seconds after

the closure of "a" if the water

level has not been reached

c: opens when "b" closes

Ignition push button

Electric igniter

Ignition electrode

Tank filling switch

Cold water solenoid valve

Hot water solenoid valve

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 4

1.1.3

3BE390582NM 10/07

LIST OF PARTS

Pos.

Aa

Bn

E1

E2

Hs

S1

Se

Yr

Yec

Yef

Designation.

Bain marie Boiling pan monitor card

Water level probe

2 point igniter

Ignition electrode

Safety indicator

Tank filling switch

Ignition push button

Double jacket solenoid valve

Hot water solenoid valve

Cold water solenoid valve

Quantity.

1

1

1

1

1

1

1

1

1

1

Code

170764

145 032

308 465

308 480

308 010

300 770

300 157

144 674

144 937

144 937

1.2 ELECTRIC BOILING PAN

1.2.1

BASIC DIAGRAM

DIRECT HEATING BOILING PAN.

Heating contactor

Voltage indicator On

Tank filling switch

Cold water solenoid valve

Hot water solenoid valve

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 5

3BE390582NM 10/07

BAIN MARIE BOILING PAN

Suppressor

Heating contactor

Voltage indicator On

Safety indicator

Double jacket filling solenoid

valve

Water level probe

a: is closed in the absence of

a flame in the double jacket

b: it closes after 70 seconds

after the closure of "a" if the

water level has not been

reached

c: it closes if the temperature in

the double jacket is lower

than 111C (B1)

Tank filling switch

Cold water solenoid valve

Hot water solenoid valve

1.2.2

POWER DIAGRAM

DIRECT HEATING BOILING PAN. 110 litres

Three-phase 230 Volts

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 6

3BE390582NM 10/07

Three-phase 400 Volts

60, 110 and 150 litre BAIN MARIE BOILING PAN

Three-phase 230 Volts

Three-phase 400 Volts

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 7

3BE390582NM 10/07

250 litre BAIN MARIE BOILING PAN

Three-phase 400 Volts

1.2.3

LIST OF PARTS

Pos.

Aa

Ar

B1

Bn

Designation.

Filling card

Energy trimmer

Temperature probe PT100

Water level probe

Hm

Hs

S1

Yr

Yec

Yef

Zr

Voltage indicator On

Safety indicator

Water switch

Filling solenoid valve

Hot water solenoid valve

Cold water solenoid valve

Suppressor

Pos.

Designation.

Kr

Heating contactor

Resistances

Immersion heaters

MA 60 BM

220V

400V

1

1

1

-

MA 60

1

1

1

1

1

1

1

1

1

1

1

MA 110

1

1

1

1

1

1

1

1

1

1

1

MA 110 CD

220V

400V

1

1

6

6

-

MA 150

1

1

1

1

1

1

1

1

1

1

1

MA 250

1

1

1

1

1

1

1

1

1

1

1

Code

170764*

301 200

301 479

145 032

301 456

308 334

308 010

300 770

144 674

144 937

144 937

300 769

MA 110/150 BM MA 250

220V

400V

400V

1

1

1

3

3

1

Code

300 697

300 698

300 699

300 700

302 195

303 127

303 123

303 130

Note: The card 170764 is delivered as After Sale Service with two wires (black and white) which are to be

connected to a gas boiling pan. In the case of an electric boiling pan, cut the two wires as close as

possible to the card.

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 8

3BE390582NM 10/07

2 GAS CIRCUITS

2.1 GAS CIRCUIT

2.1.1

60 LITRE DIRECT HEATING BOILING PANS

Designation.

Air ring diameter 19 (See chart of nozzles)

Air ring diameter 22,5 (See chart of nozzles)

3 flame SIT pilot flame burner holder

Mounted button for size 10 pin

Gas intake tube sub-assembly

3 flame pilot burner sub-assembly

Mounted 60 litre boiling pan burner subassembly

Black tight cap

Sealing gasket

Black push button diameter 12

2 outlet 230V igniter with ground wire

Complete gas tap

Gas control Lexan

Electric ignition Lexan

Gas nozzle (See chart of nozzles)

Nozzle holder

Gas burner

Brass union for double wall, diameter 6

Bent brass connector 12 1/2 female

Black silicone button gasket

Code

027367Q

027367R

027682M

151733

171167

171169

171170

300062

300063

300157

308465

310140

310741

310750

311131

311146

311164

317862

317999

366370

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 9

2.1.2

3BE390582NM 10/07

60 LITRE BAIN MARIE BOILING PANS

Designation.

Air ring diameter 19 (See chart of nozzles)

Air ring diameter 22,5 (See chart of nozzles)

3 flame SIT pilot burner holder

Mounted button for size 10 pin

Gas intake tube sub-assembly

3 flame pilot burner sub-assembly

Mounted burner sub-assembly for 60 litre boiling pans

Black tight cap

Sealing gasket

Black push button diameter 12

Red indicator 230/400V, complete

2 outlet 230V igniter with ground wire

Complete gas tap

Gas control Lexan

Electric ignition Lexan

Boiling pan indicator Lexan

Gas nozzle (See chart of nozzles)

Nozzle holder

Gas burner

Brass union for double wall, diameter 6

Bent brass connector 12 1/2 female

Black silicone button gasket

Code

027367Q

027367R

027682M

151733

171167

171169

171170

300062

300063

300157

308010

308465

310140

310741

310750

310760

311131

311146

311164

317862

317999

366370

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 10

2.1.3

3BE390582NM 10/07

110 ET 150 LITRE DIRECT HEATING BOILING PANS

Designation.

Air ring diameter 19 (See chart of nozzles)

Air ring diameter 22,5 (See chart of nozzles)

Burner plate

Boiling pan burner ramp

Burner for 110-150 litre boiling pans, complete

Mounted button for size 10 pin

Gas intake tube sub-assembly

Black tight cap

Sealing gasket

Black push button diameter 12

2 outlet 230V igniter with ground wire

Complete gas tap

Gas control Lexan

Electric ignition Lexan

Gas nozzle (See chart of nozzles)

Gas burner

Ring connector 12-3/4 FF

Brass union for double wall, diameter 6

Black silicone button gasket

Code

027367Q

027367R

027378N

134223

138264

151733

171167

300062

300063

300157

308465

310140

310741

310750

311131

311164

317253

317862

366370

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 11

2.1.4

3BE390582NM 10/07

110 LITRE BOILING PANS AND 150 LITRES BAIN MARIE

Designation.

Air ring diameter 19 (See chart of nozzles)

Air ring diameter 22,5 (See chart of nozzles)

Burner plate

Boiling pan burner ramp

Complete burner for 110-150 litre boiling pans

Mounted button for size 10 button 10

Gas intake tube sub-assembly

Black tight cap

Sealing gasket

Black push button diameter 12

Red indicator 230/400V, complete

2 outlet 230V igniter with ground wire

Complete gas tap

Gas control Lexan

Electric ignition Lexan

Boiling pan indicator Lexan

Gas nozzle (See chart of nozzles)

Gas burner

Ring connector 12-3/4 FF

Brass union for double wall, diameter 6

Black silicone button gasket

Code

027367Q

027367R

027378N

134223

138264

151733

171167

300062

300063

300157

308010

308465

310140

310741

310750

310760

311131

311164

317253

317862

366370

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 12

2.1.5

3BE390582NM 10/07

250 LITRE DIRECT HEATING BOILING PANS

Designation.

Ramp locking fastener

Air adjustment ring

Lock washer

3 flame SIT pilot burner reflector

Burner tube sub-assembly 450 in length

Left/right secondary burner tube

210-250 litre boiling pans burner ramp

Mounted button for size 10 pin

Gas intake tube sub-assembly

Gas tube sub-assembly to tap / burner

Mounted burner for 250 litre direct heating boiling pans

Equipped pilot burner sub-assembly

Black tight cap

Sealing gasket

Black push button diameter 12

2 outlet 230V igniter with ground wire

Complete gas tap

Gas control Lexan

Electric ignition Lexan

Gas nozzle (See chart of nozzles)

Ring connector 12-3/4 FF

Brass union for double wall, diameter 6

Black silicone button gasket

Stainless steel clamp

Stainless steel screw TH 5 x 10

Code

022506M

022596M

022600M

027598O

132717

134004 / 134005

134035

151733

171168

171239

171247

171251

300062

300063

300157

308465

310141

310741

310750

311131

317253

317862

366370

385032

388105

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 13

2.1.6

3BE390582NM 10/07

250 LITRE BAIN MARIE BOILING PANS

Designation.

Ramp locking fastener

Air adjustment ring

Lock washer

3 flame SIT pilot burner reflector

Burner tube sub-assembly, 450 in length

Left/right secondary burner tube

210-250 litre boiling pan burner ramp

Mounted button for size 10 pin

Gas intake tube sub-assembly

Tap / burner gas tube sub-assembly

Mounted burner for 250 litre bain marie boiling pans

Equipped pilot burner sub-assembly

Black tight cap

Sealing gasket

Black push button diameter 12

Red indicator 230/400V, complete

2 outlet 230V igniter with ground wire

Complete gas tap

Gas control Lexan

Electric ignition Lexan

Boiling pan indicator Lexan

Gas nozzle (See chart of nozzles)

Ring connector 12-3/4 FF

Brass union for double wall, diameter 6

Black silicone button gasket

Stainless steel clamp

Stainless steel screw TH 5 x 10

Code

022506M

022596M

022600M

027598O

132717

134004 / 134005

134035

151733

171168

171240

171248

171251

300062

300063

300157

308010

308465

310141

310741

310750

310760

311131

317253

317862

366370

385032

388105

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 14

3BE390582NM 10/07

2.2 PILOT BURNER SUB-ASSEMBLY

2.2.1

60 LITRE BOILING PANS

Designation.

1200 long electrode wire

Ignition electrode M4

3 flame series 160 pilot burner without nut

Pilot burner nozzle diameter 41 (see chart of nozzles)

Pilot burner nozzle diameter 25 (see chart of nozzles)

Bicone pour tube diameter 6

1200 mm long series 200 thermocouple

Pilot burner nozzle diameter 30 (see chart of nozzles)

Pilot burner nozzle diameter 45 (see chart of nozzles)

Bicone nut for tube diameter 6 mm

Thermocouple fixation nut

Ignition electrode fixation nut

Code

307998

308480

310272

310273

310274

310275

310277

311171

311172

317978

317979

317980

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 15

2.2.2

3BE390582NM 10/07

110 AND 150 LITRE BOILING PANS

Designation.

Thermocouple distance bushing

Pilot burner nozzle (see chart of nozzles)

Ignition electrode holder

1200 long electrode wire

Ignition electrode M4

Pilot burner nozzle diameter 40 (see chart of nozzles)

Pilot burner

1300 long thermocouple, connector M9

Pilot burner nozzle reference A26 (see chart of nozzles)

Pilot burner tube connector, diameter 6

Ignition electrode fixation nut

Thermocouple split screw

Code

027467M

132886

140377

307998

308480

310091

310092

310145

310155

317104

317980

367994

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 16

2.2.3

3BE390582NM 10/07

250 LITRE BOILING PANS

Designation.

Pilot burner holder

500 long electrode wire

Ignition electrode M4

Pilot burner series 160 3 flame without nut

Pilot burner nozzle diameter 41 (see chart of nozzles)

Pilot burner nozzle diameter 25 (see chart of nozzles)

Bicone for tube diameter 6

1200 mm long series 200 thermocouple

Pilot burner nozzle diameter 45 (see chart of nozzles)

Bicone nut for tube diameter 6 mm

Thermocouple fixation nut

Ignition electrode fixation nut

Code

022699M

307999

308480

310272

310273

310274

310275

310277

311172

317978

317979

317980

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 17

3BE390582NM 10/07

3 HYDRAULIC CIRCUIT

3.1 60 LITRE OPTIMUM 700 BOILING PANS

3.1.1

DIRECT HEATING BOILING PAN.

Designation.

Mixing tap concept ME100 valve heads

Flexible polyester braided hose in EPDM M1/2 M3/8, 450 mm in length

Code

313137

316135

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 18

3.1.2

3BE390582NM 10/07

BAIN MARIE BOILING PAN

Designation.

Premounted generator/double jacket filling probe

Filling electronic card

Plastic distance piece 6/6, 9.5 in height

Mixing tap concept ME100 with valve heads

Standard fixation holder for water solenoid valve

Safety valve for bain-marie boiling pan

Flexible reinforced hose

Flexible polyester braided hose in EPDM, M1/2 M3/8, 450 mm in length

Brass square head plug 1/4, with size 8 square

Legris male branch connector

Pressure series ring connector - male - 1/2 12

Temperature resistant gasket, diameter 16 x 24, 2 mm thick 20/27

Probe bushing

Stainless steel tightening clamp, diameter 12/20

Galvanized square elbow 8/13MF

1 way 1 x 5 L/min solenoid valve

Ring connector 12-3/4 FF

Code

145032

170764

307897

313137

314348

315715

316112

316135

317888

317932

317982

318045

368350

317676

317114

144674

317253

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 19

3BE390582NM 10/07

3.2 60, 110 and 150 LITRE OPTIMUM 900 BOILING PANS

3.2.1

DIRECT HEATING BOILING PAN.

Designation.

Welded boiling pan spout

1 way solenoid valve, 1 x 10 L/min

Mounted button for size 6 pin, complete

4 position switch

Water supply Lexan

Standard fixation holder for water solenoid valve

Flexible reinforced tube

Stainless steel tightening clamp, diameter 12/20

Plastic double female clamp size 15/17.2

Base nut + bicone nut + bicone diameter 14

Equal branch Y-shape connector, diameter 10

Gasket

Code

134221

144937

151731

300770

310759

314348

316112

317676

317834

317947

318304

366452

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 20

3.2.2

3BE390582NM 10/07

BAIN MARIE BOILING PAN

Designation.

Welded boiling pan spout

1 way solenoid valve 1 x 5 L/min

1 way solenoid valve 1 x 10 L/min

Premounted generator/double jacket filling probe

Mounted button for size 6 pin, complete

Electronic filling card

4 position switch

Plastic distance piece 6/6, 9.5 in height

Water supply Lexan

Standard fixation holder for water solenoid valve

Bain-marie boiling pan safety valve

Flexible reinforced tube

Galvanised square elbow 8/13MF

Ring connector 12-3/4 FF

Stainless steel tightening clamp diameter 12/20

Plastic double female clamp 15/17.2

Brass square head plug 1/4 with size 8 square

Male Legris connector

Base nut + bicone nut + bicone diameter 14

Pressure series ring connector - male - 1/2 12

Temperature-resistant gasket, diameter 16 x 24, 2 mm thick 20/27

Equal branch Y-shape connector, diameter 10

Gasket

Probe bushing

Code

134221

144674

144937

145032

151731

170764

300770

307897

310759

314348

315715

316112

317114

317253

317676

317834

317888

317932

317947

317982

318045

318304

366452

368350

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 21

3BE390582NM 10/07

3.3 250 LITRE VINDIS 900 BOILING PAN

3.3.1

DIRECT HEATING BOILING PAN.

Designation.

1 way solenoid valve 1 x 10 L/min

Mounted button for size 6 pin, complete

Spout, height 50 under the outlet

4 position switch

Water supply Lexan

Standard fixation holder for water solenoid valve

Flexible reinforced tube

Flexible sanitary hose 1 bent connector, length 1350

Low pressure flexible hose, length 900, male & fixed 1/2

Reduced nipple 20/27F-15/21M

Stainless steel tightening clamp, diameter 12/20

Double female plastic clamp 15/17.2

Equal branch Y-shape connector, diameter 10

Brass counter nut with base, size 15 x 21

Fibre gasket 15/21

Fibre gasket 20/27

Gasket

Code

144937

151731

155831

300770

310759

314348

316112

316140

316152

317083

317676

317834

318304

318314

366248

366288

366452

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 22

3.3.2

3BE390582NM 10/07

GAS BAIN MARIE BOILING PAN

Designation.

1 way Solenoid valve 1 x 5 L/min / 1 way 1 x 10 L/min

Premounted generator/double jacket filling probe

Mounted button size 6 pin, complete

Spout, height 50 under outlet

Electronic filling card

4 position switch

Plastic distance piece 6/6, height 9.5

Water supply Lexan

Standard fixation for water solenoid valve

Bain-marie boiling pan safety valve

Flexible reinforced tube

Sanitary flexible hose, 1 bent connector, 1350 in length

Low pressure flexible hose, 900 in length, male fixed 1/2

Reduced nipple 20/27F-15/21M

Galvanised elbow 8/13MF

Ring connector 12-3/4 FF

Stainless steel tightening clamp, diameter 12/20

Double female plastic clamp 15/17.2

Brass square head plug 1/4 with size 8 square

Male Legris connector

Pressure series ring connector - male - 1/2 12

High-temperature gasket, diameter 16 x 24, 2 mm thick 20/27

Equal branch Y-shape connector, diameter 10

Brass counternut with base 15 x 21

Fibre gasket 15/21 / fibre gasket 20/27

Gasket

Probe bushing

Code

144674 / 144937

145032

151731

155831

170764

300770

307897

310759

314348

315715

316112

316140

316152

317083

317114

317253

317676

317834

317888

317932

317982

318045

318304

318314

366248 / 366288

366452

368350

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 23

3.3.3

3BE390582NM 10/07

ELECTRIC BAIN MARIE BOILING PAN

Designation.

Code

1 way solenoid valve 1 x 5 L/min / 1 way 1 x 10 L/min

Premounted generator/double jacket filling probe

Mounted button for size 6 pin, complete

Spout, height 50 under outlet

Electronic filling card

4 position switch

Plastic distance piece 6/6, height 9.5

Water supply Lexan

Standard fixation holder for water solenoid valve

Bain-marie boiling pan safety valve

Flexible reinforced tube

Sanitary flexible 1 bent connector, 1350 in length

Galvanized square elbow 8/13MF

Ring connector 12-3/4 FF

Stainless steel tightening clamp, diameter 12/20

Double female plastic clamp 15/17.2

Brass square head plug with size 8 square

Male Legris connector

Pressure series ring connector - male - 1/2 12

Temperature-resistant gasket, diameter 16 x 24, 2 mm thick 20/27

Equal branch Y-shape connector, diameter 10

Brass base counternut 15 x 21

Fibre gasket 15/21

Gasket

Probe bushing

144674 / 144937

145032

151731

155831

170764

300770

307897

310759

314348

315715

316112

316140

317114

317253

317676

317834

317888

317932

317982

318045

318304

318314

366248

366452

368350

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 24

3BE390582NM 10/07

4 ADAPTATION OF THE APPLIANCE FROM ONE GAS TO ANOTHER

Generalities:

In the following chapters, the different gases are referenced by their international codification:

G20

G25

G30

G31

NATURAL GAS Group H . (Methane, Lacq gas)

NATURAL GAS Group L . (Groningue type gas)

BUTANE

PROPANE

4.1 LIST OF GASES / PRESSURES AUTHORIZED ACCORDING TO CATEGORIES

AND COUNTRIES

Countries

Austria

Finland

Sweden

Denmark

Belgium

Categories

II2H3B/P

II2H3B/P

I2E+

I3+

Germany

II2ELL3B/P

I3P

Spain United Kingdom

Ireland - Portugal - Italy

Greece

Spain

II2H3+

France

II2E+3+

I2H

II2H3P

II2E+3B/P

II2E+3P

Luxemburg

II2E3B/P

II2E3P

Netherlands

II2L3B/P

II2L3P

Norway

I3B/P

Gases

G 20

G 30 and G 31

G 20

G 30

G 31

G 20 / G 25

G 30 / G 31

G 20

G 25

G 30 / G 31

G 31

G 20

G 30 / G 31

G 20

G 20

G 31

G 20 / G 25

G 30 / G 31

G 20 / G 25

G 30 / G 31

G 20 / G 25

G 31

G 20

G 30 / G 31

G 20 / G 25

G 31

G 25

G 30

G 31

G 25

G 31

G 30

G 31

Pressures (mbar)

20

50

20

28-30

30

20/25

28-30/37

20

20

50

50

20

28-30/37

20

20

50

20/25

28-30/37

20/25

50

20/25

50

20

50

20/25

50

25

28-30

30

25

50

28-30

30

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 25

3BE390582NM 10/07

4.2 CHANGING FROM ONE GAS TO ANOTHER:

According to the country of the installation and the category of the equipment (indicated on the firm

plate), the changeover from one gas to another may require 2 operations:

CI

RA

Change of nozzles

Adjustment of primary air

(See paragraph 4.4)

(See paragraph 4.4)

PROCEDURE:

On the firm plate, check:

- The category (ies) of the equipment.

- The gas and pressure for which it is adjusted.

In the following chart, select:

- The country concerned.

- The gas and the category of the appliance (see above).

- The gas and the pressure for which the appliance is going to be adjusted.

- Note and carry out the required operations.

- Replace the adjustment plate and mark the new gas used.

C0UNTRIES

Austria

Finland - Sweden

Denmark

Belgium

Germany

Spain Italy

United Kingdom

Ireland Switzerland

Portugal

Spain - Switzerland

France

Luxemburg

Netherlands

Norway

GAS OF ORIGIN

(or new gas)

Gas

P(mbar)

G 20

20

G 30

50

G 20

20

G 30

28-30

G 20

20

G 30

28-30

G 20

20

G 20 or G 31

20

G 30

50

G 20

20

G 25

20

G 30

50

G 20

20

NEW GAS

(or gas of origin)

Gas

P(mbar)

G 30 or G 31

50

G 31

50

G 30 or G 31

30/30

G 31

30

G 25

25

G 31

37

G 25

20

G 30 or G 31

50

G 25

20

G 31

50

G 30 or G 31

28-30/30

G 30

28-30

G 31

37

G 20

G 20

G 20 or G 25

G 30

G 20 or G 25

G 20 or G 25

G 20

G 20

G 25

G 30

G 25

G 30

20

20

20/25

28-30

20/25

20/25

20

20

25

28-30

25

30

G 31

G 25

G 30 or G 31

G 31

G 30 or G 31

G 31

G 30 or G 31

G 31

G 30 or G 31

G 31

G 31

G 31

50

25

28-30/37

37

50

50

50

50

28-30/30

30

50

30

CATEGORY

II2H3B/P

II2H3B/P

I2E+

I3+

II2ELL3B/P

I3P

II2H3+

II2H3P

II2E+3+

II2E+3B/P

II2E+3P

II2E+3B/P

II2E+3P

II2L3B/P

II2L3P

I3B/P

OPERATIONS

NECESSARY and

AUTHORIZED

CI RA

Nothing

CI RA

Nothing

Nothing

Nothing

CI

CI RA

CI RA

CI

Change of

category (see *)

CI RA

Nothing

CI RA

Nothing

CI RA

Nothing

CI RA

CI

CI RA

CI

CI RA

Nothing

CI

Rien

* The category change is only to be carried out under the responsibility of the Company T.G.C.P. or our local agent.

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 26

3BE390582NM 10/07

4.3 GAS FLOW RATES AND POWERS

See paragraph 1: TECHNICAL CHARACTERISTICS (Instructions for installation)

4.4 CHART OF NOZZLES and air adjustment

NOTE:

- The burners called "main burners" are simple tubes.

- The burners said "secondary burners" are burners equipped with the interignition ramp.

60 litre boiling pans

GAS

Designation

Pressure

Family

Type

(mbar)

Natural

gas

G.P.L

G 20 / G 25

G 25

G 25***

G 30 or G 31

Pilot burner

Natural

gas

G.P.L

G 30 or G 31*

G 31**

G 20 / G 25

G 25

G 30 or G 31

Idle flame

adjustment

screw

Natural

gas

G.P.L

20 / 25

20

25

28-30

30 or 37

50

50

20 / 25

20

28-30

30 or 37

50

20 / 25

20

28-30 or 37

50

Burner

G 30 or G 31

G 20 / G 25

G 25

G 30 or G 31

G 30 or G 31

INJECTEURS

Diameter

d

Qty

Code

(1/100e)

(mm)

1

1

1

1

250

280

260

165

19

19

19

22.5

311 131-250

311 131-280

311 131-260

311 131-165

1

1

1

1

1

145

155

41

45

30

19

19

-

311 131-145

311 131-155

310 273

311 172

311 171

1

1

1

1

1

25

135

150

85

80

310 274

310 179

310 188

310 282

310 309

* Configuration only valid in Austria for 50 mbar propane

** Configuration not valid in Austria

*** Configuration only valid in the Netherlands.

RA: Air adjustment

Air adjustment is carried out by means of the distance

d specified in the previous chart.

d

19

22.5

Code

027367Q

027367R

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 27

3BE390582NM 10/07

110 and 150 litre boiling pans

GAS

Designation

Burner

Pilot burner

Idle flame

adjustment

screw

Pressure

Family

Type

(mbar)

Natural

Gas

G.P.L

G 20 / G 25

G 25

G 25***

G 30 or G 31

Natural

gas

G.P.L

G 30 or G 31*

G 31**

G 20 / G 25

G 25

G 30 or G 31

Natural

gas

G.P.L

G 30 or G 31

G 20 / G 25

G 25

G 30 or G 31

20 / 25

20

25

28-30

30 or 37

50

50

20 / 25

20

28-30

30 or 37

50

20 / 25

20

28-30 or 50

30 or 37 or 50

NOZZLES

Diameter

d

Qty

Code

(1/100e)

(mm)

2

2

2

2

260

290

270

165

19

19

19

22.5

311 131-260

311 131-290

311 131-270

311 131-165

2

2

1

1

1

145

155

Ref: A26

Ref: A26

40

19

19

-

311 131-145

311 131-155

310 155

310 155

132 886

1

1

1

1

Ref: K14

230

300

115

310 091

310 284

310 194

310 178

* Configuration only valid in Austria for 50 mbar propane.

** Configuration not valid in Austria

*** Configuration only valid in the Netherlands.

RA: Air adjustment

Air adjustment is carried out by means of the distance

d specified in the previous charts.

d

19

22.5

Code

027367Q

027367R

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 28

3BE390582NM 10/07

250 litre boiling pans

GAS

Designation

Burner

Pressure

Type

NOZZLES

Qty Diameter

d

(1/100e)

(mm)

Code

Family

Type

(mbar)

Burner

Natural

Gas

G 20 / G 25

20 / 25

G 25

20

G 25***

25

G 30 or G 31

28-30

G 31

37

G 30 or G31*

50

G 31**

50

20 / 25

20

28-30 or 50

30 or 37 or 50

20 / 25

20

28-30 or 37

50

BP

BS G/D

BP

BS G/D

BP

BS G/D

BP

BS G/D

BP

BS G/D

BP

BS G/D

BP

BS G/D

-

6

1/1

6

1/1

6

1/1

6

1/1

6

1/1

6

1/1

6

1/1

1

1

1

140

155/150

155

170/165

145

160/160

95

110/105

95

110/105

85

90/90

90

100/95

41

45

25

3

3

3

3

3

3

6.5

6.5

5

5

4.5

4.5

4

4

-

311 131-140

311 131-155/150

311 131-155

311 131-170/165

311 131-145

311 131-160/160

311 131-95

311 131-110/105

311 131-95

311 131-110/105

311 131-85

311 131-90/90

311 131-90

311 131-100/95

310 273

311 172

310 274

1

1

1

1

290

320

160

150

310 191

310 192

310 195

310 188

G.P.L

Pilot burner

Natural

Gas

G.P.L

G 20 / G 25

G 25

G 30 or G 31

Idle flame

adjustment

screw

Natural

gas

G.P.L

G 20 / G 25

G 25

G 30 or G 31

G 30 or G 31

BP: Main burner

BSG: Left secondary burner

BSD: Right secondary burner

* Configuration only valid in Austria for 50 mbar propane.

** Configuration not valid in Austria

*** Configuration only valid in the Netherlands.

RA: Air adjustment

Air adjustment is carried out by means of the distance

d specified in the previous chart.

Remarks:

- If the flame is poor and yellow: this means a lack of primary air. In this case, push the ring towards the

burner (increase distance d).

- If the flame is nervous and shows a tendency to jump: this is the sign of an excess of primary air.

In this case, shift away the burner ring (diminish the distance d).

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 29

3BE390582NM 10/07

5 VERIFICATION OF THE TEMPERATURE PROBES

5.1 PT100 PROBE

Component of the PT100 probe

PT100

Temperature probe composed of a resistance probe with the value of 100 ohms for a temperature of 0,

138.5 ohms for a temperature of 100. The variation of the resistance depending on the temperature is linear.

The reading of the resistance gives directly the measured temperature. The probe is not polarised. The probe

is lengthened by a copper wire.

Correspondence of temperature in C and Resistance in for PT100 probe

C

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

210

220

0

100.00

103.90

107.79

111.67

115.54

119.40

123.24

127.07

130.89

134.70

138.50

142.29

146.06

149.82

153.58

157.31

161.04

164.76

168.46

172.16

175.84

179.51

183.17

1

100.39

104.29

108.18

112.06

115.93

119.78

123.62

127.45

131.27

135.08

138.88

142.66

146.44

150.20

153.95

157.69

161.42

165.13

168.83

172.53

176.21

179.88

183.53

2

100.78

104.68

108.57

112.45

116.31

120.16

124.01

127.84

131.66

135.46

139.26

143.04

146.81

150.57

154.32

158.06

161.79

165.50

169.20

172.90

176.57

180.24

183.90

3

101.17

105.07

108.96

112.83

116.70

120.55

124.39

128.22

132.04

135.84

139.64

143.42

147.19

150.95

154.70

158.43

162.16

165.87

169.57

173.26

176.94

180.61

184.26

4

101.56

105.46

109.35

113.22

117.08

120.93

124.77

128.60

132.42

136.22

140.02

143.80

147.57

151.33

155.07

158.81

162.53

166.24

169.94

173.63

177.31

180.97

184.63

5

101.95

105.85

109.73

113.61

117.47

121.32

125.16

128.98

132.80

136.60

140.39

144.17

147.94

151.70

155.45

159.18

162.90

166.61

170.31

174.00

177.68

181.34

184.99

6

102.34

106.24

110.12

113.99

117.85

121.70

125.54

129.37

133.18

136.98

140.77

144.55

148.32

152.08

155.82

159.55

163.27

166.98

170.68

174.37

178.04

181.71

185.36

7

102.73

106.63

110.51

114.38

118.24

122.09

125.92

129.75

133.56

137.36

141.15

144.93

148.70

152.45

156.19

159.93

163.65

167.35

171.05

174.74

178.41

182.07

185.72

8

103.12

107.02

110.90

114.77

118.62

122.47

126.31

130.13

133.94

137.74

141.53

145.31

149.07

152.83

156.57

160.30

164.02

167.72

171.42

175.10

178.78

182.44

186.09

9

103.51

107.4

111.28

115.15

119.01

122.86

126.69

130.51

134.32

138.12

141.91

145.68

149.45

153.20

156.94

160.67

164.39

168.09

171.79

175.47

179.14

182.80

186.45

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 30

3BE390582NM 10/07

How to read the chart:

To find the resistance corresponding to the temperature of 164C.

Find the intersection of the line 160C and the col umn 4C.

The reading shows 162.53 Ohms.

Check

PT100

Check probe resistance with an ohmmeter gauged at 200 ohms (less than 107 ohms for 20).

Check the probe insulation between one of the leads and the metal part with the ohmmeter gauged at

20 megohms (a value over 10 megohms).

Check the continuity between the screen and the metal part of the probe.

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 31

3BE390582NM 10/07

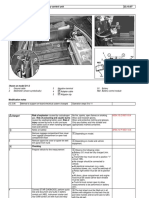

6 LID ADJUSTMENT

6.1 SPRING ADJUSTMENT

This adjustment enables to increase or diminish the closing or opening strength of the lid.

- Remove the collector cover.

- On the back of the appliance, unscrew the blind nut to loosen the spring or tighten to stretch it. Put the lid

in open position to limit the strengths.

Blind nut

- Carry out this operation on both springs and both sides of the appliance.

6.2 ADJUSTMENT OF LID OPENING

This adjustment enables to increase or diminish the opening angle of the lid.

- Remove the collector cover.

- Unscrew the lock nut of the lid opening thrust. Screw on or loosen the adjustment screw to diminish or

increase the lid opening angle and screw on the nut.

The factory adjustment enables lid opening to the maximum.

Adjustment

screw

Locking

nut

- Carry out this intervention on both sides of the appliance.

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 32

3BE390582NM 10/07

7 OTHER PARTS NECESSARY FOR AFTER SALES

7.1 APPLIANCE ASSEMBLY

7.1.1

60 LITRE VINDIS 700 BOILING PANS

Designation.

60 litre drainage grid

Right / left outer panels

Front upper panel to 60 and 150 litres

Top plug

Welded hub subassembly

Lid bearing cover

60 litre boiling pan lid

Bonnet logo

Drainage tap to boiling pan 40/49

Drainage tap trimming ring

Threaded rod M8 x 330

Disc pin

Pivot

Plastic leg

Tensile spring with stainless steel insert diameter 30 x 200

Trimming ring stainless steel securing spring, diameter 2

Stainless steel nut HU 8

Flat stainless steel washer M8

Stainless steel screw TRL 5 x 16

Blind stainless steel nut H8

Stainless steel nut with grooved base M8

Code

027517O

027716M / 027716O

027729N

038203W

155697

171289

171292

308938

313048

313050

368358

368616

368617

384649

385051

385052

388061

388065

388102

388285

389543

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 33

7.1.2

3BE390582NM 10/07

60 LITRE VINDIS 900 BOILING PANS

Designation.

Code

027517O

027716N / 027716P

027729N

038203W

155697

171289

60 litre drainage grid

Right / left out panels

60 and 150 litre front upper panel

Top plug

Welded hub sub-assembly

Lid bearing cover

60 litre boiling pan lid

171293

Bonnet logo

Boiling pan drainage tap 40/49

Drainage trimming ring

Threaded rod M8 x 330

Disc pin

Pivot

Plastic leg

Tensile spring with stainless steel insert, diameter 30 x 200

Trimming ring stainless steel securing spring, diameter 2

Stainless steel nut8

Flat stainless steel washer M8

Stainless steel screw TRL 5 x 16

Blind stainless steel nutH8

Stainless steel nut with grooved base M8

308938

313048

313050

368358

368616

368617

384649

385051

385052

388061

388065

388102

388285

389543

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 34

7.1.3

3BE390582NM 10/07

110 LITRE BOILING PANS

Designation.

110 litre drainage grid

Right / left outer panels

110 litre front upper panel

Top plug

Welded round boiling pan lid

Welded hub sub-assembly

Lid bearing cover

Bonnet logo

Boiling pan drainage tap 40/49

Drainage trimming ring

Threaded rod M8 x 330

Disc pin

Pivot

Plastic leg

Tensile spring with stainless steel insert, diameter 30 x 200

Trimming ring stainless steel securing spring, diameter 2

Stainless steel nut HU 8

Flat stainless steel washer M8

Stainless steel screw TRL 5 x 16

Blind stainless steel nut H8

Stainless steel nut with grooved base M8

Code

027517M

027716N / 027716P

027729M

038203W

138305

155696

171289

308938

313048

313050

368358

368616

368617

384649

385051

385052

388061

388065

388102

388285

389543

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 35

7.1.4

3BE390582NM 10/07

150 LITRE BOILING PANS

Designation.

150 litre drainage grid

Right / left outer panels

60 and 150 litre front upper panel

Top plug

Welded round boiling pan lid

Welded hub sub-assembly

Lid bearing cover

Bonnet logo

Pan drainage tap 40/49

Drainage trimming ring

Threaded rod M8 x 330

Disc pin

Pivot

Plastic leg

Tensile spring with stainless steel insert diameter 30 x 200

Trimming ring stainless steel securing spring, diameter 2

Stainless steel nut HU 8

Flat stainless steel washer M8

Stainless steel screw TRL 5 x 16

Blind stainless steel nut H8

Stainless steel nut with grooved base M8

Code

027517N

027716N / 027716P

027729N

038203W

138305

155696

171289

308938

313048

313050

368358

368616

368617

384649

385051

385052

388061

388065

388102

388285

389543

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 36

7.1.5

3BE390582NM 10/07

250 LITRE PANS

Designation.

250 litre drainage grid

Right / left outer panels

250 litre upper front panel

250 litre boiling pan lid

Welded hub sub-assembly

Lid bearing cover

Bonnet logo

Boiling pan drainage tap 40/49

Drainage trimming ring

Threaded rod M8 x 330

Disc pin

Pivot

Connecting strip

Plastic leg

Tensile spring with insert steel stainless diameter 30 x 200

Trimming ring stainless steel securing spring, diameter 2

Stainless steel nut HU 8

Flat stainless steel washer M8

Stainless steel screw TRL 5 x 16

Blind stainless steel nut H8

Stainless steel nut with grooved base M8

Code

027584N

027716N / 027716P

027729P

138300

155697

171289

308938

313048

313050

368358

368616

368617

368628

384649

385051

385052

388061

388065

388102

388285

389543

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 37

7.2

3BE390582NM 10/07

ELECTRIC CIRCUIT OF ELECTRIC BOILING PANS

7.2.1

60 LITRE BOILING PANS

Designation.

Indicator lamp fixation

Mounted button for size 6 pin, complete

Three-pole contactor 25A 230V 50/60 Hz

Three-pole contactor 40A 230V 50/60 Hz

Suppressor relay

Simmerstat

Temperature probe

Immersion heater 8 kW 230V

5-pole connecting strip 400V 32A

Plastic gland nut PG13

Gland neoprene gasket PG13

Plastic gland PG 29

Red indicator 230/400V, complete

Green indicator 230/400V, complete

Electric inlet label

Control Lexan

Gasket

Gasket to capacity resistance + immersion heater

Characteristics

400V

230V

Code

027754M

151731

300697

300699

300769

301200

301479

303127

306086

307875

307876

307888

308010

308334

308825

310749

366452

366461

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 38

7.2.2

3BE390582NM 10/07

110 LITRE DIRECT HEATING BOILING PANS

Designation.

Heating body

Reflector

Resistance locking strip

Comb

Assembly lock key

Indicator lamp fixation

Mounted chromium-plated button to size 6 pin, complete

Chassis 110 litre electric subassembly

Three-pole contactor 25A 230V 50/60 Hz

Three-pole contactor 32A 230V 50/60 Hz

Suppressor relay

Simmerstat

Boiling pan heating resistance, 2500W 230V

5-pole connecting strip 400V 32A

Plastic gland nut PG13

Gland neoprene gasket PG13

Plastic gland

Green indicator 230/400V, complete

Electric inlet label

Control Lexan

Insulation plate to 100 litre electric boiling pan

Gasket

Characteristics

400V

230V

Code

027113N

027115M

027117M

027119M

027121N

027754M

151731

171414

300697

300698

300769

301200

302195

306086

307875

307876

307877

308334

308825

310749

362169

366452

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 39

7.2.3

3BE390582NM 10/07

110 AND 150 LITRE BAIN MARIE BOILING PANS

Designation.

Indicator lamp fixation

Mounted chromium-plated button for size 6 pin, complete

Three-pole contactor 32A 230V 50/60 Hz

Three-pole contactor 50A 230V 50/60 Hz

Suppressor relay

Simmerstat

Temperature probe

Immersion heater 6 kW 230V

5-pole connecting strip 400V 32A

Junction block M 10/10

Grey junction block M 10/10

Plastic gland nut PG13

Gland neoprene gasket PG13

Plastic gland PG 29

Red indicator 230/400V, complete

Green indicator 230/400V, complete

Electric supply label

Control Lexan

Gasket

Gasket to capacity resistance + immersion heater

Characteristics

400V

230V

230V

230V

400V

Code

027754M

151731

300698

300700

300769

301200

301479

303123

306086

307736

307739

307875

307876

307888

308010

308334

308825

310749

366452

366461

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 40

7.2.4

3BE390582NM 10/07

250 LITRE BOILING PANS

Designation.

Indicating lamp fixation

Premounted generator/double jacket filling probe

Mounted button for size 6 pin, complete

Three-pole contactor 40A 230V 50/60 Hz

Suppressor relay

Simmerstat

Probe PT100 diameter 4, 350 in length

Immersion heater 24 kW, length 570 with bulb passage

12-pole connecting strip 400V 40A

Gland

Plastic gland nut PG13

Gland neoprene gasket PG13

Plastic gland

Red indicator 230/400V, complete

Green indicator 230/400V, complete

Electric supply label

Control Lexan

Stainless steel screw clamp size7 x 11

Gland gasket, diameter 8 x 4 x 4

Gasket

Gasket to capacity resistance + immersion heater

Characteristics

Code

027754M

145032

151731

300699

300769

301200

301456

303130

306087

307681

307875

307876

307877

308010

308334

308825

310749

317908

366424

366452

366461

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Page 41

3BE390582NM 10/07

FRONT LINE PARTS

8.1 GAS BOILING BOILING PANS

Designation.

Code

2 outlet 230V igniter with ground wire

Black push button diameter 12

Electronic filling card

4 position switch

Ignition electrode M4

1 way solenoid valve 1 x 5 L/min / 1 way 1 x 10 L/min

Pilot burner nozzle

Pilot burner nozzle diameter 25 / diameter 30

Pilot burner nozzle diameter 40 / diameter 41

Pilot burner nozzle diameter 45

Pilot burner nozzle reference A26 (code 310155)

Temperature-resistant gasket, diameter 16 x 24, 2 mm thick, 20/27

Tensile spring with stainless steel insert, diameter 30 x 200

Boiling pan drainage tap 40/49

Complete gas tap

Premounted generator/double jacket filling probe

Bain-marie boiling pan safety valve

1300 long thermocouple, connector M9

Series 200 1200 mm long thermocouple

Pilot burner

Pilot burner series 160 3 flame without nut

Red indicator 230/400V, complete

308465

300157

170764

300770

308480

144674 / 144937

132886

310274 / 311171

310091 / 310273

311172

A26

318045

385051

313048

310140 / 310141

145032

315715

310145

310277

310092

310272

308010

8.2 ELECTRIC BOILING PANS

Designation.

Code

Electronic filling card

4 position switch

Three-pole contactor 25A 230V 50/60 Hz

Three-pole contactor 32A 230V 50/60 Hz

Three-pole contactor 40A 230V 50/60 Hz

Three-pole contactor 50A 230V 50/60HZ

1 way solenoid valve 1 x 10 L/min

1 way solenoid valve 1 x 5 L/min

Temperature-resistant gasket, diameter 16 x 24, 2 mm thick 20/27

Gasket to capacity resistance + immersion heater

Suppressor relay

Boiling pan resistance 2500W 230V

Tensile spring with stainless steel insert diameter 30 x 200

Boiling pan drainage tap40/49

Simmerstat

Probe PT100 diameter 4, 350 in length

Premounted generator/double jacket filling probe

Immersion heater 24 kW, 570 long with bulb passage

Bain-marie boiling pan safety valve

Immersion heater 6 KW 230V

Immersion heater 8 kW 230V

Red/green indicator 230/400V, complete

170764

300770

300697

300698

300699

300700

144937

144674

318045

366461

300769

302195

385051

313048

301200

301456

145032

303130

315715

303123

303127

308010 / 308334

BONNET CIDELCEM GRANDE CUISINE

Sige social:

Rue des Frres Lumire - Z.I Mitry Compans

77292 MITRY MORY Cedex

Vous aimerez peut-être aussi

- En Manual GT-500Document56 pagesEn Manual GT-500Adrian Petre100% (1)

- User Manual LG (Cleaner)Document32 pagesUser Manual LG (Cleaner)Serg SergPas encore d'évaluation

- Heating and hot water installation manualDocument28 pagesHeating and hot water installation manualLucianIonitaPas encore d'évaluation

- Whirlpool HDW 1011 WG-GBDocument31 pagesWhirlpool HDW 1011 WG-GBmariuszkonopkaPas encore d'évaluation

- VantageDocument36 pagesVantagehsaeed786Pas encore d'évaluation

- Suburban FURNACE - Service-and-Training-Manual-11-05-2015Document40 pagesSuburban FURNACE - Service-and-Training-Manual-11-05-2015Adam KnightPas encore d'évaluation

- Thema F: Installation and Servicing InstructionsDocument28 pagesThema F: Installation and Servicing InstructionsjuanitoingPas encore d'évaluation

- E ATMOS c31Document56 pagesE ATMOS c31Ion CîmpeanuPas encore d'évaluation

- Hotpoint WF101 Service ManualDocument30 pagesHotpoint WF101 Service ManualSeena Zharaa100% (1)

- RS68-120 MLN ManuelDocument28 pagesRS68-120 MLN ManuelUmar MajeedPas encore d'évaluation

- Whirlpool Awo D 6202 DDocument54 pagesWhirlpool Awo D 6202 Dcatalinsky0% (1)

- RLS 70-100-130 - eDocument28 pagesRLS 70-100-130 - eJosep Alexander Gutierrez ReyesPas encore d'évaluation

- Whirlpool Awe 7516 WDocument42 pagesWhirlpool Awe 7516 Wdumitru2014Pas encore d'évaluation

- User and Maintenance Manual: EnglishDocument12 pagesUser and Maintenance Manual: EnglishPricopPas encore d'évaluation

- PC100 PC200 DS300 en CircuitsDocument13 pagesPC100 PC200 DS300 en Circuitsulovrencic100% (1)

- 8997 4782 00 Diagrams and Drawings PDFDocument53 pages8997 4782 00 Diagrams and Drawings PDFDave ArmasPas encore d'évaluation

- Riello RG5D Burner ManualDocument11 pagesRiello RG5D Burner ManualjadetorresPas encore d'évaluation

- Manual Boiler Sussman ES-60 PDFDocument24 pagesManual Boiler Sussman ES-60 PDFsistemas_pivegPas encore d'évaluation

- DB EKHVX EN tcm135-186767 PDFDocument21 pagesDB EKHVX EN tcm135-186767 PDFdino_pPas encore d'évaluation

- Format - Zip GBDocument26 pagesFormat - Zip GBIonela MaraPas encore d'évaluation

- Installation and servicing guide for Ideal Classic SE FF boilersDocument44 pagesInstallation and servicing guide for Ideal Classic SE FF boilersbladeblowerPas encore d'évaluation

- Bedienungsanleitung Speicher Druzice OKC NTR HVDocument32 pagesBedienungsanleitung Speicher Druzice OKC NTR HVThe Inquiring MindPas encore d'évaluation

- Panasonic Microwave nnct878 Service ManualDocument35 pagesPanasonic Microwave nnct878 Service Manualwinos100% (2)

- LG Split Type Air Conditioner Complete Service ManualDocument74 pagesLG Split Type Air Conditioner Complete Service ManualArt Del R Salonga85% (75)

- Whirlpool Awe 7516 1 FlorinelDocument43 pagesWhirlpool Awe 7516 1 Florinelargatu florin100% (1)

- User Manual: S.S. LG-10 Thru LG-30Document44 pagesUser Manual: S.S. LG-10 Thru LG-30EddyPas encore d'évaluation

- Whirlpool Awe 6616 W PDFDocument41 pagesWhirlpool Awe 6616 W PDFflorin071Pas encore d'évaluation

- Steam - Generator Maxi 60 GhidiniDocument12 pagesSteam - Generator Maxi 60 GhidiniEttore FrattonePas encore d'évaluation

- Convectoare de Pardoseala Isan Dynamic, Practic - Catalog 2011Document44 pagesConvectoare de Pardoseala Isan Dynamic, Practic - Catalog 2011Liviu ToaderPas encore d'évaluation

- Suburban RV FURNACES SERVICE MANUALDocument40 pagesSuburban RV FURNACES SERVICE MANUALCheryl Ray95% (41)

- 10Document72 pages10Dixon Javier Cortes TapiaPas encore d'évaluation

- JBC Classic Catalog - Engl2014Document20 pagesJBC Classic Catalog - Engl2014Scott ShafferPas encore d'évaluation

- Isomax: This Is A Cat I2E+ ApplianceDocument32 pagesIsomax: This Is A Cat I2E+ AppliancePéter BegidsánPas encore d'évaluation

- Format Sime Boiler ManualDocument21 pagesFormat Sime Boiler Manualadysanro100% (1)

- Boiler Knight XL IOMDocument80 pagesBoiler Knight XL IOMlevilydaPas encore d'évaluation

- Uh Svx01a en - 09032008 (Trane Unit Heaters)Document60 pagesUh Svx01a en - 09032008 (Trane Unit Heaters)kayelePas encore d'évaluation

- Bosch Greenstar ZWBR 7-25 A23 Gcno.46-311-44 Boiler Installation and Service ManualDocument36 pagesBosch Greenstar ZWBR 7-25 A23 Gcno.46-311-44 Boiler Installation and Service ManualMerlin1950Pas encore d'évaluation

- AO Smith Service HandbookDocument72 pagesAO Smith Service HandbookMinhnghia360Pas encore d'évaluation

- Modular S - Monobloc - T1350UKDocument20 pagesModular S - Monobloc - T1350UKGogaPas encore d'évaluation

- 1228 Technox3 840 BT-Use and Maintenance Manual (En)Document32 pages1228 Technox3 840 BT-Use and Maintenance Manual (En)Cristi SoarecePas encore d'évaluation

- 1 A-50m Hydronic Heating Plumbing ProductsDocument39 pages1 A-50m Hydronic Heating Plumbing ProductsZach ZelkPas encore d'évaluation

- LAW 420 LAW 520: Service ManualDocument46 pagesLAW 420 LAW 520: Service ManualquangppPas encore d'évaluation

- Boiler Operation and Installation ManualDocument24 pagesBoiler Operation and Installation ManualbzvzPas encore d'évaluation

- Operation Manual for Blasting Machines and TestersDocument18 pagesOperation Manual for Blasting Machines and TestersVictor Yucás100% (1)

- Boiler Manual Electrosteam LgsDocument34 pagesBoiler Manual Electrosteam LgsErik GámezPas encore d'évaluation

- Rational 101 Service Manual (2008-2011) PDFDocument48 pagesRational 101 Service Manual (2008-2011) PDFManuel Heras Castilla76% (17)

- Saunier Duval Thema F 23 e Installation Manual 121307Document28 pagesSaunier Duval Thema F 23 e Installation Manual 121307psuguyPas encore d'évaluation

- User Manual: LG-10 Thru LG-30Document33 pagesUser Manual: LG-10 Thru LG-30JaimePas encore d'évaluation

- Eternity T Installation GuideDocument28 pagesEternity T Installation GuidepsicodePas encore d'évaluation

- 2004 Owners Guide BeachcomberDocument30 pages2004 Owners Guide Beachcomberkdm004Pas encore d'évaluation

- Technical Catalogue: AC Induction Three-Phase MotorsDocument60 pagesTechnical Catalogue: AC Induction Three-Phase MotorsCyrus CameleonPas encore d'évaluation

- Manual de Instalacion PFHDocument36 pagesManual de Instalacion PFHingfcontrerasPas encore d'évaluation

- 598-SBP-125-G-8 Bar Technical and Commercial Quotation Adk SolutionsDocument7 pages598-SBP-125-G-8 Bar Technical and Commercial Quotation Adk SolutionsBeò FhathastPas encore d'évaluation

- Technical Service Guide: Profi Le Bottom Mount RefrigeratorsDocument56 pagesTechnical Service Guide: Profi Le Bottom Mount RefrigeratorsJim HarmkePas encore d'évaluation

- Twinflo Service ManualDocument36 pagesTwinflo Service ManualGreg ReynekePas encore d'évaluation

- Power Electronics Design: A Practitioner's GuideD'EverandPower Electronics Design: A Practitioner's GuideÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Electric Gas Lighting How to Install Electric Gas Ignition ApparatusD'EverandElectric Gas Lighting How to Install Electric Gas Ignition ApparatusÉvaluation : 3 sur 5 étoiles3/5 (1)

- Ignition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.D'EverandIgnition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Évaluation : 3 sur 5 étoiles3/5 (4)

- Turning Frequency in Adult Bedridden Patients To Prevent Hospital-Acquired Pressure Ulcer: A Scoping ReviewDocument12 pagesTurning Frequency in Adult Bedridden Patients To Prevent Hospital-Acquired Pressure Ulcer: A Scoping ReviewfajaqaPas encore d'évaluation

- Indian Standard: Hexagon Head Bolts, Screws and Nuts of Product Grades A and BDocument11 pagesIndian Standard: Hexagon Head Bolts, Screws and Nuts of Product Grades A and BJignesh TrivediPas encore d'évaluation

- Consumer Behavior, Market Segmentation and Marketing PlanDocument57 pagesConsumer Behavior, Market Segmentation and Marketing PlanShubhamPas encore d'évaluation

- DHRM 3 SyllabusDocument10 pagesDHRM 3 SyllabusCherokee Tuazon RodriguezPas encore d'évaluation

- D37H-08A ManualDocument56 pagesD37H-08A Manuallijie100% (1)

- ZetaPlus EXT SP Series CDocument5 pagesZetaPlus EXT SP Series Cgeorgadam1983Pas encore d'évaluation

- Tiotropium Bromide: Spiriva Handihaler, Spiriva RespimatDocument9 pagesTiotropium Bromide: Spiriva Handihaler, Spiriva RespimatAssem Ashraf KhidhrPas encore d'évaluation

- Autoridad Myles Munroe Poder de La El Proposito y PDF Autoridad Myles MunroeDocument5 pagesAutoridad Myles Munroe Poder de La El Proposito y PDF Autoridad Myles MunroeMaricarmen MorenoPas encore d'évaluation

- Dada and Buddhist Thought - Sung-Won Ko PDFDocument24 pagesDada and Buddhist Thought - Sung-Won Ko PDFJuan Manuel Gomez GarcíaPas encore d'évaluation

- Tauros TBM Guidance SystemDocument3 pagesTauros TBM Guidance SystemMiloš StanimirovićPas encore d'évaluation

- Link L5 Assessment AKDocument11 pagesLink L5 Assessment AKJoanna MajczykPas encore d'évaluation

- Promoting Gusaling Museo Through ModernizationDocument15 pagesPromoting Gusaling Museo Through Modernizationdesiree choi100% (1)

- Checking battery control unitDocument3 pagesChecking battery control unitjuanPas encore d'évaluation

- Laplace Transform solved problems explainedDocument41 pagesLaplace Transform solved problems explainedduchesschloePas encore d'évaluation

- Duct Seal: Multi Cable and Pipe Sealing SystemDocument8 pagesDuct Seal: Multi Cable and Pipe Sealing SystemSri VarshiniPas encore d'évaluation

- Data Sheet 6EP1457-3BA00: InputDocument4 pagesData Sheet 6EP1457-3BA00: InputSeyyed Amir MohmmadiPas encore d'évaluation

- Piano Chords PracticeDocument30 pagesPiano Chords PracticeEd Vince89% (9)

- Handout 4-6 StratDocument6 pagesHandout 4-6 StratTrixie JordanPas encore d'évaluation

- Excel File - Business Computing - End Term (To Be Shared Vide Email)Document301 pagesExcel File - Business Computing - End Term (To Be Shared Vide Email)Aman SankrityayanPas encore d'évaluation

- Anuj Singh ResumeDocument4 pagesAnuj Singh ResumeAnuj BaghelPas encore d'évaluation

- Protecting The Pianist's Hand: The Carrezando Touch and MoreDocument6 pagesProtecting The Pianist's Hand: The Carrezando Touch and MoreAdrianPas encore d'évaluation

- She Walks in BeautyDocument6 pagesShe Walks in Beautyksdnc100% (1)

- Three Laws of RoboticsDocument2 pagesThree Laws of RoboticsBav VAansoqnuaetzPas encore d'évaluation

- AMX-3 Prom AdaptorDocument18 pagesAMX-3 Prom AdaptorEmmanuel RamirezPas encore d'évaluation

- 2015 StoneAge - LowresDocument51 pages2015 StoneAge - LowresAZLAN ABDULLAIPas encore d'évaluation

- Sense Organs Lesson PlanDocument16 pagesSense Organs Lesson PlanBernard DayotPas encore d'évaluation

- Lesson Plan For DemoDocument7 pagesLesson Plan For DemoShiela Tecson GamayonPas encore d'évaluation

- Shorthand TheoryDocument75 pagesShorthand Theorysubhashcb100% (3)

- Plumbing Layout and SpecificationsDocument1 pagePlumbing Layout and SpecificationsLiza P. PaculanangPas encore d'évaluation

- Gram Negative Rods NonStool Pathogens FlowchartDocument1 pageGram Negative Rods NonStool Pathogens FlowchartKeithPas encore d'évaluation