Académique Documents

Professionnel Documents

Culture Documents

Trigger 3

Transféré par

angel1230 évaluation0% ont trouvé ce document utile (0 vote)

86 vues1 pageblueprints gunsmithing

Titre original

trigger 3

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentblueprints gunsmithing

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

86 vues1 pageTrigger 3

Transféré par

angel123blueprints gunsmithing

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

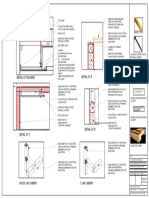

141"'/64

die

3/16 deep

3/32

1 1/8

3/16

iTI"\- # 10-32

#30 drill

3 places.for rivets.

(Use the sideplafe

fora drill template.)

I I-I 2 places

~ 1/4 D

1/8

FRONT SPACER BLOCK

mat'l - Aluminum or CRS

1 required

Face "l" (see text)

drill

REAR SPACER BLOCK

mat'l - Aluminum or CRS

In this trigger system, the trigger

and the sear are separate parts. The

trigger bar supports the front lip of

the sear (refer to Figure 3) in a manner

that the sear is prevented from

rolling forward, so the sear notch

(a part of the striker in the bolt) is

prevented from moving forward to

fire the cartridge. When the shooter

pulls the trigger rearward, the pivoted

top end of the trigger bar moves out

from under the sear nose, allowing

the sear to roll over forward under

the pressure of the striker spring.

With the striker notch moved

forward, the sear is returned to the

upright position by the sear spring.

The trigger spring in the upper

hole in the front spacer block with

a tensioning screw provides an

adjustable trigger tension, and

returns the trigger to its upright

position under the sear nose when

the trigger is released after firing.

2 places for rivets.

(Use the side plate

for a drill template.)

When the bolt is withdrawn after

firing, the sear notch rides over the

top leg of the sear, forcing the sear

down, pushing the rear end of the

system housing downward, allowing

the bolt assembly to go rearward.

As the sear notch passes rearward

over the sear top, it allows the sear

and the housing to rise again into

position in front of the sear notch.

When the bolt is again moved forward

chambering the fresh cartridge, the

sear notch is again held back in

cocked position by the sear for

the next firing.

An over-travel screw in the rear

spacer stops the trigger after it has

released the sear and prevents

excessive rearward travel of the

trigger pull. The engagement

adjustment screw in the bottom of

the front spacer block adjusts the

amount of engagement of the trigger

with the sear, preventing an overlong

trigger pull. The W' holes in the side

plates allow easier adjustment of

engagement and provide access for

lubrication. Engagement of the

trigger bar with the sear nose by only

about 0.020" permits a smooth but

abrupt let-off for firing.

The trigger assembly is not subjected

to heavy forces by recoil caused

by firing, but the trigger and sear

are required to securely prevent

the accidental firing of the rifle

due to any bump or jolt in

any direction.

The adjustment must all be able

to securely prevent release of the

firing mechanism - tested before

ever loading the firearm. Test it

thoroughly, jolted and bumped

solidly, in all possible directions,

with the chamber empty while the

striker notch is engaged to make

sure the firing mechanism cannot

accidentally release. Also, safety

requires you occasionally do this

test to make sure the trigger system

is safe before taking the weapon

to the field for shooting.

Now, Let's Make One

But first, one or two notes. Since

this sear/trigger combination is all

that prevents the rifle from firing,

it must be carefully made of

adequate aluminum or steel and

the engagement faces need to be

hardened steel. The failure of any

stressed part can allow an accidental

firing, so be sure of your work. The

housing does not directly receive

firing stresses; the forces applied

within the assembly are all of low

magnitude. Wear on the trigger bar

and sear can result in failure, and

these parts should be hardened steel

at their contact parts.

Since Mausers have been made by

many manufacturers, and to many

specifications from customers, it is

mandatory that you first verify all the

measurements given to make sure

they will fit properly and do their

functions as designed. I have found

variations from one maker to another

and you may too. And, the sear must

engage fully with the striker notch.

Now, let's proceed. This is not a

complicated mechanism, but each part

has its function, so study how they

interact before starting to cut metal.

October/November2001

27

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- US Tap and Drill Bit Size TableDocument2 pagesUS Tap and Drill Bit Size Tableangel123Pas encore d'évaluation

- Ps Magazine m79Document4 pagesPs Magazine m79angel123100% (1)

- Starrett Inch Metric Tap DrillDocument1 pageStarrett Inch Metric Tap DrillCesar P Ayon100% (3)

- Mossberg Brownie Grip Frame-1Document1 pageMossberg Brownie Grip Frame-1angel123100% (2)

- Mossberg Maverick 88 ReceiverDocument1 pageMossberg Maverick 88 Receiverangel123Pas encore d'évaluation

- Photos by Author October/November2001Document1 pagePhotos by Author October/November2001angel123Pas encore d'évaluation

- Mossberg Brownie BarrelDocument1 pageMossberg Brownie Barrelangel12350% (2)

- Beretta 21a Frame Left Side CutsDocument1 pageBeretta 21a Frame Left Side Cutsangel123Pas encore d'évaluation

- Beretta 21a Frame P CutDocument1 pageBeretta 21a Frame P Cutangel123Pas encore d'évaluation

- Beretta 21a Frame Right Side CutsDocument1 pageBeretta 21a Frame Right Side Cutsangel123Pas encore d'évaluation

- Beretta 21a Frame (Side Holes)Document1 pageBeretta 21a Frame (Side Holes)angel123Pas encore d'évaluation

- Beretta 21a Frame (Overall Size Dims)Document1 pageBeretta 21a Frame (Overall Size Dims)angel12350% (2)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Partition 4 With DetailsDocument1 pagePartition 4 With DetailsRONAK RATHODPas encore d'évaluation

- E539 High Intake Manifold Air Temperature.Document3 pagesE539 High Intake Manifold Air Temperature.Teo Sil Cas100% (1)

- PSP LabDocument5 pagesPSP LabShaban SattiPas encore d'évaluation

- American International University-Bangladesh: Faculty of Engineering (EEE)Document7 pagesAmerican International University-Bangladesh: Faculty of Engineering (EEE)SifatPas encore d'évaluation

- McGraw-Edison SPI Lighting Power Drawer CCL Series Brochure 1982Document40 pagesMcGraw-Edison SPI Lighting Power Drawer CCL Series Brochure 1982Alan MastersPas encore d'évaluation

- Fastener Identification Guide - For Bolts and StudsDocument162 pagesFastener Identification Guide - For Bolts and StudsIgorToporskyPas encore d'évaluation

- 15 Intake and ExhaustDocument16 pages15 Intake and Exhaustwanderlei669085Pas encore d'évaluation

- Kia Picanto 2018Document9 pagesKia Picanto 2018Jean Sc RivasPas encore d'évaluation

- Technical Scope For Modification of The LVAC Switchboard in NCS2Document5 pagesTechnical Scope For Modification of The LVAC Switchboard in NCS2SudeepDPoojaryPas encore d'évaluation

- Chapter 2-Transformers PDFDocument103 pagesChapter 2-Transformers PDFkessam92100% (1)

- Structural Glazing: Submitted To:-Submitted By: Ar. Gourav Agrawal Chhaya, Tanvi, Suraj, Prakash, SumanDocument19 pagesStructural Glazing: Submitted To:-Submitted By: Ar. Gourav Agrawal Chhaya, Tanvi, Suraj, Prakash, Sumanshreenu211204Pas encore d'évaluation

- Electrical Wiring - Introduction ExoraDocument30 pagesElectrical Wiring - Introduction ExoraTobeng60% (20)

- DC Generator MCQ Question and AnswerDocument5 pagesDC Generator MCQ Question and AnswerRubab MalikPas encore d'évaluation

- Autodata Training - Course Guide - 2020Document24 pagesAutodata Training - Course Guide - 2020MMR100% (2)

- 3rd FloorDocument1 page3rd FloorJopheth RelucioPas encore d'évaluation

- LacettiDocument3 pagesLacettizozo0424Pas encore d'évaluation

- HMC6 Protection and Power Management: Zhengzhou Smartgen Technology Co.,LtdDocument77 pagesHMC6 Protection and Power Management: Zhengzhou Smartgen Technology Co.,LtdVinhPas encore d'évaluation

- AEG PS White Paper Led Dimming Nov2011 DC FormatDocument21 pagesAEG PS White Paper Led Dimming Nov2011 DC FormatSahil MittalPas encore d'évaluation

- Rewinding of Single Phase Induction MotorsDocument2 pagesRewinding of Single Phase Induction Motors2023seee004Pas encore d'évaluation

- Type C Porcelain: Cutouts and Cutout-Arrester CombinationsDocument20 pagesType C Porcelain: Cutouts and Cutout-Arrester Combinationsaisya mutia syafiiPas encore d'évaluation

- Gilera Fuoco - 500ie OWNERS PDFDocument96 pagesGilera Fuoco - 500ie OWNERS PDFMindaugas VizbarasPas encore d'évaluation

- 2002 Nissan Pathfinder 41673Document62 pages2002 Nissan Pathfinder 41673AndrikAlfredoAbadReinosaPas encore d'évaluation

- 1.4 Lecture Notes-4 (DR)Document5 pages1.4 Lecture Notes-4 (DR)Anil Kumar SinghPas encore d'évaluation

- Manual BTS - enDocument32 pagesManual BTS - enBruno Ferreira RodriguesPas encore d'évaluation

- Areva PDFDocument16 pagesAreva PDFallen smithPas encore d'évaluation

- TMR Din Rail TimerDocument2 pagesTMR Din Rail TimerRabindra SinghPas encore d'évaluation

- SG50 Curtain Walling System: Experts in AluminiumDocument2 pagesSG50 Curtain Walling System: Experts in Aluminiumtheking111111111Pas encore d'évaluation

- NFPA 70 - 2020 Handbook ErrataDocument2 pagesNFPA 70 - 2020 Handbook ErrataMernaPas encore d'évaluation

- Breaker UL1066PrintDocument362 pagesBreaker UL1066PrintGaurav MaithilPas encore d'évaluation