Académique Documents

Professionnel Documents

Culture Documents

Topic 5 Industrial Load Monitoring and Controls

Transféré par

jayxcellCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Topic 5 Industrial Load Monitoring and Controls

Transféré par

jayxcellDroits d'auteur :

Formats disponibles

11/24/2014

Industrial Load Monitoring

and Controls

BEF 44903 Topic 5

Outlines

Load Monitoring System

Load Voltage Monitoring and Control

Load Frequency Monitoring and Control

Load Shedding in Industrial Power

Systems

2

11/24/2014

Load Monitoring System

Load Monitoring System

Why Load Monitoring System (LMS) in industry?

ForFutureDesignorUpgrade

Usedatatocheckissuesand

problems

Usedatatoredesign

systemtobemoreefficient

Analyse

energy

consumption

Diagnosefor

powerquality

Control

energyflow/

equipment

Interface

withEnergy

Management

System

4

11/24/2014

Load Monitoring System

Benefits of Load Monitoring System to Industry:

Technical

Maintaingoodpowerquality

Minimise faultrisk

Minimise maintenanceworks

Prolongequipment/deviceslifespan

g q p

p

Nontechnical

Reduceadministrationandmaintenancecost

Betterenergyplanningandmanagement

Environmentallyfriendly

Load Monitoring System

How to categorise industrial electrical loads?

Non

interruptible

loads

Interruptible

loads

Shouldberunwithoutinterruptionincertain

processes.

Examples:lighting,firealarmsystems,security

cameras,ventilation,elevators,escalatorsand

mostlyproductionmachinery.

Thoseloadsthatarenotaffectproductivityorlevel

ofcomfortwhenturnedoffforacertainperiodof

time.

11/24/2014

Load Monitoring System

What should be monitored in industry?

Mechanical

Parameters

Electrical

Parameters

kW,kVAr,V,I

Disturbances,PF,Harmonics,

Disturbances

PF Harmonics

Sags,Swell,Transient,

Equipmentstatus,

temperature,ventilation,

Load Monitoring System

MonitoringA

Area

Where to monitor the electrical loads?

Mainswitchboard

Distributionswitchboard

Distribution switchboard

Mainraiser

Subdistributionboard

MCC

8

11/24/2014

Load Monitoring System

Monitoring Device 1: Phase control relays

Dedicated mainly to processes

integrating 3-phase motors.

Phase control relays monitor:

Themotorfault

preventionsolution

Phase sequence

Loss of one or more phases

U b l

Unbalance

llevell

Voltage level between phases or between

phases and neutral

Load Monitoring System

Monitoring Device 2: Voltage control relays

Voltage control relays monitor input

voltage level compared to a high or low

threshold preset values.

Voltage control relays monitor:

Thepowersupply

faultprevention

solution

Phase and Line-to-line voltages

P k and

Peak

d RMS values

l

Undervoltage

Overvoltage

10

11/24/2014

Load Monitoring System

Monitoring Device 3: Current control relays

Theloadfault

preventionsolution

Measurement of under and overcurrent.

Continous monitoring of the operation of

electrical and mechanical loads such as

motors and resistors.

These control relays are for applications

in fields as varied as ventilation, pumping,

and conveying.

11

Load Monitoring System

Monitoring Device 4: Frequency control relays

Frequency control relays monitor positive

or negative frequency variation.

Monitor over and underfrequency.

Thenetwork

frequencyfault

preventionsolution

12

11/24/2014

Load Monitoring System

Monitoring Device 5: Level control relays

Thefilling,draining

andmonitoring

solution

Level control relays are used to monitor or

maintain levels, mainly of liquids.

Level control is usually achieved with float

switch fitted contacts which change state

according to the position of the float

switch

switch.

13

Load Monitoring System

Monitoring Device 6: Pump control relays

Pump control relays control pumps (single

or 3-phase) using discrete control inputs

and monitor current (dry operation and

overload protection) and the state of

supply phases.

Thepump

managementand

monitoringsolution

14

11/24/2014

Load Monitoring System

Monitoring Device 7: Speed control relays

Theoperatingrate

monitoringsolution

Dependent on rotation or movement

speed, the pulse rate supplied to the relay

varies. By monitoring the pulse rate, the

relays control over or underspeed.

The applications include monitoring of

rotation speed

speed, transporter or conveyor

belt speed, pump rotation, etc.

15

Load Monitoring System

Monitoring Device 8: Temperature control

relays

Temperature control relays monitor the

temperature in control or pulley rooms to

check that it remains within the regulated

limits.

Thetemperature

controlsolution

16

11/24/2014

Load Voltage Monitoring and

Control (LVMC)

LVMC is normally used in industry to constantly monitor

three phase voltages of motor circuit in order to avoid

any harmful power line conditions.

Voltage ratings of the various buses in the industrial

power system should be within the permissible limits for

satisfactory operation of all electrical equipment.

Voltage level in IPS is much depends on the fluctuation

of reactive power (Q) due to the motor loadings

loadings.

The task of voltage control is closely associated with

fluctuating load conditions and corresponding

requirements of reactive power compensation.

17

Load Voltage Monitoring and

Control

Load

Control

Voltage

LVMC

CT

18

11/24/2014

Load Voltage Monitoring and

Control

Feederr

E

Z S RS jX S

IS

jX L I L

L V RI

L

jVX

VR

IL

Load

S L PL jQL

Voltageregulation canbedefinedasthe

proportionalchangeinvoltagemagnitude

attheloadbusduetochangeinload

current(sayfromnoloadtofullload). 19

IL

Load Voltage Monitoring and

Control

The voltage drop is caused due to feeder impedance

carrying the load current as illustrated in the Figure. The

voltage regulation (VR) is given by,

VR

E V V

V

V

In absence of compensator, the source and load currents

are same and the voltage drop due to the feeder is given

by,

V E V Z S I L

where Z S RS jX S

20

10

11/24/2014

Load Voltage Monitoring and

Control

The relationship between the load powers and its voltage

and current is,

S L V I L PL jQL

*

Substituting IL and ZS yields,

P jQL

V RS jX S L

R P X S QL

X P RS QL

S L

j S L

V

V

VR jVX

21

Load Voltage Monitoring and

Control

From previous equations,

R P X S QL X S PL RS QL

E V S L

j

V

V

In magnitude basis,

R P X S QL X S PL RS QL

E V S L

V

V

Rearrange the equation,

V 4 2R S PL X S Q L E 2 V 2 R S2 X S2 Q L2 PL2 0

22

11

11/24/2014

Load Voltage Monitoring and

Control

Voltage change ( V )

depends upon the real

and reactive power flow

of the load and the value

of the feeder impedance.

A compensator should

be added in parallel with

the load as shown in the

Figure to improve the

voltage regulation, i.e.,

Feeder

E

Z S RS jX S

IS

E V

Load

Comp.

V

QC

S L PL jQL

IL

IC

23

Load Voltage Monitoring and

Control

The net reactive at the load bus is now,

QN QC QL

From previous equations,

R P X S QN X S PL RS QN

E V S L

j

V

V

IC

IS

IL

jX S I S

RS I S

24

12

11/24/2014

Load Voltage Monitoring and

Control

The above equation implies that,

R P X S QN X S PL RS QN

E V S L

V

V

Rearrange the equation,

2

S

X S2 Q N2 2V 2 X S Q N V 2 R S PL

X S2 PL2 E 2V 2 0

Thus the solution of above equation is as following,

QN

4ac

2a

25

Load Voltage Monitoring and

Control

Methods of voltage control:

Excitation Control of Generators

Shunt Capacitors

Synchronous Condensers

Tap-Changing Transformers

26

13

11/24/2014

Load Voltage Monitoring and

Control

Excitation Control of Generators

The induced emf of synchronous generator (E) depends

upon the excitation current (field current).

The terminal voltage V of synchronous generators are

given by V = E IX.

The generators have excitation and automatic voltage

regulation systems (AVR). The function of this systems

are:

To control the load under steady state operating conditions

To regulate voltage under fault conditions

To enable sharing of reactive power.

27

Load Voltage Monitoring and

Control

Excitation Control of Generators

28

14

11/24/2014

Load Voltage Monitoring and

Control

Shunt Capacitors

Shunt capacitors are usually switched in during high

loads. Static shunt capacitors are installed near the load

terminals in industries.

Most of the industrial loads (induction motors,

transformers, welding sets, furnaces) draws inductive

current of poor power factor (0.3 to 0.6 lag).

The shunt capacitors provide leading VARs there by the

total KVA loading of substation transformer and the

current is reduced.

Switching in shunt capacitor should improve the bus

voltage if the compensation is effective.

29

Load Voltage Monitoring and

Control

Synchronous Condensers

Synchronous condensers are over excited synchronous

motors installed in the power system to deliver the

reactive power.

These synchronous phase modifiers are located near to

the load in order to improve the voltage profile of the

industrial power system.

The main advantage of synchronous phase modifiers are

the ability to deliver the reactive power that can be

adjusted, unlike static shunt capacitors.

30

15

11/24/2014

Load Voltage Monitoring and

Control

Tap-Changing Transformers

The voltage control of industrial distribution systems is

obtained basically by tap-changing. Tap changers are

either on-load or off load tap changers.

By changing the turns ratio of the transformer, the

voltage ratio and the secondary voltage is changed and

voltage control is obtained.

The voltage control of the range +15% to -15

15 % can be

achieved by tap changing transformers

31

Load Frequency Monitoring

and Control

In any electric system, the active power (P) has to be

generated at the same time as it is consumed.

Power generated must be maintained in constant

equilibrium with power consumed / demanded, otherwise

a power deviation occurs.

Disturbances in this balance, causing a deviation of the

system frequency.

32

16

11/24/2014

Load Frequency Monitoring

and Control

33

Load Frequency Monitoring

and Control

Frequency deviations occur due to the following reasons:

Disturbance / outage of generation or load.

Stochastic imbalances in normal operation. These can occur due

to the continuous variations of demand

Deterministic Frequency Deviations e.g. ramping at the hour

shift

Network splitting

34

17

11/24/2014

Load Shedding in Industrial

Power Systems

Cost of industrial electricity is based on two components:

1.

1 The amount used (consumption)

2. The intensity of its use (demand)

The demand is determined as the highest measured

intensity within a certain period of time, usually monthly.

Load shedding is a mechanism to help manage the way

electricity is used in an industry to reduce the peak

demand, significantly reducing monthly utility costs.

35

Load Shedding in Industrial

Power Systems

Load shedding is defined as the amount of load that must

almost instantly be removed from a power system to keep the

remaining portion off the system operational.

The load shed processes automatically sense overload

conditions, then shed enough load to relieve the overloaded

equipment before there is loss of generation, line tripping,

equipment damage, or a chaotic random shutdown of the

system.

Common disturbances that triggers the load shedding to

response:

Faults

Severe Overloaded

Loss of generation

Switching errors, etc.

36

18

11/24/2014

Load Shedding in Industrial

Power Systems

Overloads may be differentiated by what is overloaded:

1.

1 Those in which there is a real power shortage and in which the

prime mover torque cannot meet the load torque and the

generation begins to decelerate.

2. Those in which there is a reactive power shortage. This is

manifested as voltage drops in line and transformer reactances

that prevent power delivery to loads

37

Load Shedding in Industrial

Power Systems

PVorQVcurve

38

19

11/24/2014

Load Shedding in Industrial

Power Systems

Advantages of load shedding to industry:

Reduces peak demand, thereby

reducing electricity costs

Minimise power blackout risk

due to severe fault/ overload

Maintains standard frequency

and voltage levels

39

Load Shedding in Industrial

Power Systems

When a power system is exposed to a disturbance, its

dynamics and transient responses are mainly controlled

through two major dynamic loops:

Excitation (including AVR) loop that will control the generator

reactive power and system voltage.

Prime-mover loop,

p which will control the g

generator active p

power

and system frequency

40

20

11/24/2014

Load Shedding in Industrial

Power Systems

Several types of loads drop out if there is a serious

undervoltage:

Motor Starters will drop out if voltage reaches 50-75% of

rated.

Discharge lighting extinguishes at about 80-90% of rated

voltage, and may or may not automatically restart.

Adjustable speed drives (ASD) drops out at about 8090% of rated voltage.

Similar to ASDs, other rectifier or thyristor based power

supplies may drop out at about 80-90% of rated voltage.

41

Load Shedding in Industrial

Power Systems

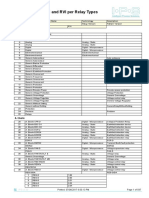

Types of Load Shedding Scheme:

Conventional

BreakerInterlock

Scheme

Intelligent

IntelligentLoad

Shedding(ILS)

Underfrequency

RelayScheme

PLCBasedLoad

Shedding

42

21

11/24/2014

Load Shedding in Industrial

Power Systems

Breaker

Interlock

I t l k

Scheme

43

Load Shedding in Industrial

Power Systems

Drawbacks of Breaker Interlock Scheme:

Difficult to change load priority since the actions for load

shedding are hardwired and the amount of load shedding is

calculated for the worst-case scenario

Only one stage of load shedding is available

Often results in shedding more loads than necessary

The operation of this type of load-shedding scheme will most

likely shut the entire industrial facility down in a non-orderly

manner

Plant restarting may be delayed because of the requirement

to shut down and then restart other remote facilities that have

been affected by the loss of the main facility, before the main

facility can be started

44

22

11/24/2014

Load Shedding in Industrial

Power Systems

Under

frequency

frequency

Relay

Scheme

45

Load Shedding in Industrial

Power Systems

Frequency relays do not detect disturbances but react to

either a rapid change in frequency or gradual frequency

deterioration.

The load shedding scheme is activated by frequency

decaying stages.

46

23

11/24/2014

Load Shedding in Industrial

Power Systems

If the amount of load shed in the first stage is insufficient

and the frequency continues to decay, the system

frequency

q

y will reach the next set p

point,, and additional

load shedding will be initiated.

Each additional stage introduces a delay in the loadshedding process.

47

Load Shedding in Industrial

Power Systems

Drawbacks of under frequency load shedding scheme:

Slow response time of frequency relays (time for the

frequency to reach relay settings and time delay setting

for relay)

Incorrect load may be dropped causing undesirable

blackouts

Analysis knowledge is lost

48

24

11/24/2014

Load Shedding in Industrial

Power Systems

Maximumanticipatedoverload

Maximum anticipated overload

Numberofloadsheddingstages

Sizeofloadshedateachstage

Proceduresandcriteriain Frequencysettings

designingunder

Timedelays

frequencyloadshedding

Locationofthefrequencyrelays

Location of the frequency relays

scheme

49

50

25

11/24/2014

Load Shedding in Industrial

Power Systems

Total load to be shed:

P

f

d 1

1 P

50 pu

PD

f

1 d 1

50

d = load reduction factor

P = relative overload

f = frequency variation

f0 = System frequency

Frequency variation during the load shedding:

f

d 1

P

d

f0

1 P

51

Load Shedding in Industrial

Power Systems

Programmable Logic Controller-Based Load Shedding

The application of controllers in industrial load management

and curtailment schemes started in the early 1980s.

Load shedding is initiated based on the system frequency

deviations or other triggers.

The circuit breaker tripping can be programmed based on the

system

y

loading,

g available g

generation, and other specific

p

logics.

Each subsystem is equipped with a controller that is

programmed to shed a preset sequence of loads.

This static sequence is continued until the frequency returns

to a normal condition.

52

26

11/24/2014

Load Shedding in Industrial

Power Systems

Intelligent Load Shedding (ILS)

An ILS system is necessary to improve response time,

time

accurately predict the system frequency decay, and

make a fast, optimum, and reliable load-shedding

decision.

An ILS engine is a training knowledge base using

carefully selected transient-stability cases from offline

system studies and simulations

simulations.

System dynamic responses, including frequency and

voltage variations to different types of disturbances, are

among the outputs of the knowledge base.

53

Load Shedding in Industrial

Power Systems

Functional block diagram of an ILS system:

54

27

11/24/2014

Load Shedding in Industrial

Power Systems

The ILS implementation diagram:

55

Load Shedding in Industrial

Power Systems

56

28

11/24/2014

Load Shedding in Industrial

Power Systems

57

Load Shedding in Industrial

Power Systems

The operation logic flow chart of

expert system for load shedding

58

29

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Sandeep Maram THESIS Final UpdatedFebDocument81 pagesSandeep Maram THESIS Final UpdatedFebKenneth YanulaquePas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Topic 4 Industrial Power QualityDocument45 pagesTopic 4 Industrial Power QualityjayxcellPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Simulation Model of A Digital Controller For DC Motor Speed ControlDocument8 pagesSimulation Model of A Digital Controller For DC Motor Speed ControljayxcellPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Power Electronic Module - Chapter 5Document36 pagesPower Electronic Module - Chapter 5jayxcellPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Topic 2 Industrial Distribution EquipmentDocument39 pagesTopic 2 Industrial Distribution EquipmentjayxcellPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Power Electronic Module - Chapter 3Document34 pagesPower Electronic Module - Chapter 3jayxcellPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Planning Industrial Power Distribution SystemsDocument34 pagesPlanning Industrial Power Distribution SystemsjayxcellPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Topic 3 Industrial Energy ManagementDocument26 pagesTopic 3 Industrial Energy ManagementjayxcellPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- DESIGNING THE PROPORTIONAL (P) AND PROPORTIONAL-INTEGRAL (PI) CONTROLLERS Control SystemDocument7 pagesDESIGNING THE PROPORTIONAL (P) AND PROPORTIONAL-INTEGRAL (PI) CONTROLLERS Control SystemjayxcellPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- Power Electronic Module - Chapter 4Document31 pagesPower Electronic Module - Chapter 4jayxcellPas encore d'évaluation

- Power Electronic Module - Chapter 1Document27 pagesPower Electronic Module - Chapter 1jayxcell100% (1)

- Power Electronic Module - Chapter 2Document43 pagesPower Electronic Module - Chapter 2jayxcellPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Tools and Technique Resolving Issues of Food Price Increase Due To Raw Material Price Increase in Malaysia.Document6 pagesTools and Technique Resolving Issues of Food Price Increase Due To Raw Material Price Increase in Malaysia.jayxcellPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Choice of Site For Geothermal Power PlantDocument4 pagesChoice of Site For Geothermal Power PlantjayxcellPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Solution To Curb Fuel Hike Price and Illegal Immigrant Issues.Document9 pagesSolution To Curb Fuel Hike Price and Illegal Immigrant Issues.jayxcellPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Introduction)Document21 pagesIntroduction)Hasnolhadi Samsudin100% (1)

- Solution To Curb Fuel Hike Price and Illegal Immigrant Issues.Document6 pagesSolution To Curb Fuel Hike Price and Illegal Immigrant Issues.jayxcellPas encore d'évaluation

- Pasta Bolognese With CheeseDocument2 pagesPasta Bolognese With CheesejayxcellPas encore d'évaluation

- Pasta Bolognese With CheeseDocument2 pagesPasta Bolognese With CheesejayxcellPas encore d'évaluation

- Xone Port NetworksDocument53 pagesXone Port NetworksjayxcellPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- DITE01Document41 pagesDITE01jayxcellPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Unit 4 Micro Controller 8051Document20 pagesUnit 4 Micro Controller 8051Anbalagan Guru100% (1)

- TSX 172 3428 v1.4 Telemecanique ManualDocument70 pagesTSX 172 3428 v1.4 Telemecanique ManualAiman EbraheemPas encore d'évaluation

- Chapter 4 Programmable Logic Devices Cplds With VHDL Design Copyright 2006Document28 pagesChapter 4 Programmable Logic Devices Cplds With VHDL Design Copyright 2006Tint Swe OoPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Infrared Sensor Detects Obstacles Using 555 Timer CircuitDocument5 pagesInfrared Sensor Detects Obstacles Using 555 Timer CircuitGirijaKaushikPas encore d'évaluation

- Example Risk Assessment For A Motor Vehicle ShowroomDocument4 pagesExample Risk Assessment For A Motor Vehicle Showroomdogankku100% (1)

- QWupdateDocument9 pagesQWupdatekgskgmPas encore d'évaluation

- Ee321 Chap01 ReviewDocument60 pagesEe321 Chap01 ReviewMohamed Ouail CHARAOUIPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Installation Manual for JUMONG General X-Ray MachineDocument50 pagesInstallation Manual for JUMONG General X-Ray MachineDaniel Parada Vanegas100% (3)

- Ruska MakeDocument42 pagesRuska Makechandushar1604Pas encore d'évaluation

- Cutting Plotter FC8600-60/75/100/130/160: Service ManualDocument152 pagesCutting Plotter FC8600-60/75/100/130/160: Service ManualOtavio MirandaPas encore d'évaluation

- Analog Integrated Circuits Lab ManualDocument133 pagesAnalog Integrated Circuits Lab Manualprabhu4scribdPas encore d'évaluation

- 01 Laboratory Exercise Lorejo JomreyDocument3 pages01 Laboratory Exercise Lorejo JomreyJimboy LorejoPas encore d'évaluation

- hEX SDocument2 pageshEX SjmiguelcdPas encore d'évaluation

- Garage Door OpenerDocument7 pagesGarage Door OpenerPlaban Pratim BhuyanPas encore d'évaluation

- Leica TCS SP8 Technical Documentation - EN - 08 - 2015Document12 pagesLeica TCS SP8 Technical Documentation - EN - 08 - 2015ccPas encore d'évaluation

- Krohne IFC 010 ManualDocument67 pagesKrohne IFC 010 ManualDnyaneshwar PatilPas encore d'évaluation

- Amazon Fire TV Ebook PDFDocument22 pagesAmazon Fire TV Ebook PDFTilak ReddyPas encore d'évaluation

- 08-EE310 Electromechanical Level Measuring System Operation ManualDocument25 pages08-EE310 Electromechanical Level Measuring System Operation ManualJohnny Liu JohnnyPas encore d'évaluation

- Best Practices in ElasticsearchDocument5 pagesBest Practices in ElasticsearchGangadhar AmbatiPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- AR09MSWXCWKXCVDocument2 pagesAR09MSWXCWKXCValcorrefaccionesPas encore d'évaluation

- Convert Seismological Data and Analyze WaveformsDocument72 pagesConvert Seismological Data and Analyze WaveformsYayanMi'rojulHusniPas encore d'évaluation

- Primavera P6 Exercise Worksheet Rev 1.04 2016-09-12Document38 pagesPrimavera P6 Exercise Worksheet Rev 1.04 2016-09-12RAKESH RANJANPas encore d'évaluation

- TS Flash Writer Manual - Rev1.04Document5 pagesTS Flash Writer Manual - Rev1.04taehyun KimPas encore d'évaluation

- AEV JK HEMI Harness InstallationDocument10 pagesAEV JK HEMI Harness InstallationBryanPas encore d'évaluation

- 1 - Format of Six Weeks Training ReportDocument5 pages1 - Format of Six Weeks Training ReportDeepak MehtaPas encore d'évaluation

- Parts Book P20-P50/51-P75/76-P315 Gear Pumps and Motors: Distributor ProgramDocument37 pagesParts Book P20-P50/51-P75/76-P315 Gear Pumps and Motors: Distributor ProgramEddy OrtegaPas encore d'évaluation

- Unit 4 Complaints Dec. 17Document16 pagesUnit 4 Complaints Dec. 17Alvaro Duran VillarroelPas encore d'évaluation

- CSL 2020 New 11 PromaxDocument1 pageCSL 2020 New 11 PromaxKenneth GonzalesPas encore d'évaluation

- IPS-ENERGY - Available Relay ModelsDocument597 pagesIPS-ENERGY - Available Relay Modelsbrahim100% (2)

- Extreme NXT PDFDocument2 pagesExtreme NXT PDFShawnPas encore d'évaluation