Académique Documents

Professionnel Documents

Culture Documents

Embed D Epic Proj

Transféré par

Amit RaiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Embed D Epic Proj

Transféré par

Amit RaiDroits d'auteur :

Formats disponibles

JOURNAL OF DISPLAY TECHNOLOGY, VOL. 8, NO.

4, APRIL 2012

219

The Compact Systems Design Based on DMD and

the Straight Line 2-Channel LED for a Mobile

Embedded Pico Projector

Sung Chul Shin, Yunsuk Jung, Tae-Jeong Ahn, Sang Sik Jeong, Seung-Gyu Lee, and Kwang-Yeol Choi

AbstractWe have successfully designed the most compact mobile embedded pico projector system, with an optical module size

of up to 2.1 cc (20.6 16.4 6.2 mm), compared with the liquid

crystal on silicon (LCoS) based projector system, which has an engine size of 10 cc. The most compact pico projector system, with

a reduction in size of about 25%, can be obtained. It consists of

a projected optical system based on field lens type with 0.2 nHD

(640 360) digital micromirror device (DMD) panel and an illumination part of the 2 channel type with 2 in1 LED source. It can be

obtained the available display image size about 560 inches with

uniformity over 70%, brightness 8 lm at LED power consumption

1 W and contrast ratio 1700:1 in the dark room.

Index TermsDLP, field lens, led, mobile, phone, pico, projector.

high brightness according to our consumer insight is required

10 lm in house space.

In the case of the liquid crystal on silicon (LCoS) panel type,

the size of a pico projector module with a normal reflective

structure can be up to 10 cc, and its system has low optical efficiency and low contrast by LCoS panel property.

In this paper, the pico projector system including electric

board is designed with a slight thickness of 6.9 m and small

volume size of 3.5 cc, using the 2-channel illumination combination system and the field lens projected optical system. The

RGB 2-in-1 LED light source and the 0.2 digital micromirror

device (DMD) panel are used to implement high efficiency (8

lm@3.5 cc) and high image quality (1700:1, nHD: 640 360).

I. INTRODUCTION

II. PICO PROJECTOR DISPLAY SYSTEM

MOBILE DEVICE can implement various multimedia

service functions as a smart phone, which is an integrated terminal that is equipped with PC functions. On the other

hand, consumers want to obtain information in real-time regardless of the time zone, be able to carry the terminal in their

hands regardless of the place, and view the image on a wider

screen. However, conventional mobile devices cannot display a

large sized image like a TV can. As a result, a project structure

was presented that has been integrated into mobile devices, as

a means of displaying a large sized image while providing mobility. This structure has been developed as a sub-display function of the mobile device.

The pico projector in mobile devices has been shown to significantly display a larger image size in mobile life space. First,

the pico projector should be designed as a thin and small-size

module that considers the thickness of the mobile phone and

that uses the same method of integrating a camera module into

the phone. For example, the required thickness of the module of

our companys feature phone is less than 7 mm. Also, the mobile

embedded pico projector should provide high brightness and

contrast at a low power consumption, which is supported by the

mobile device, so that users can recognize an image without inconvenience in an outdoor mobile spaces environment. So, the

Manuscript received April 12, 2011; revised June 10, 2011 and August 16,

2011; accepted August 17, 2011. Date of current version March 28, 2012.

The authors are with the Future Device R&D Lab., Advanced Research Institute, LG Electronics, 16 Woomyeon-dong, Seocho-gu, Seoul 137-724, Korea

(e-mail: sungchul.shin@lge.com; yunsuk.jung@lge.com; ace.ahn@lge.com;

sangsik.jeong@lge.com; seunggyu1.lee@lge.com; kwangyeol.choi@lge.com).

Color versions of one or more of the figures are available online at http://

ieeexplore.ieee.org.

Digital Object Identifier 10.1109/JDT.2011.2165934

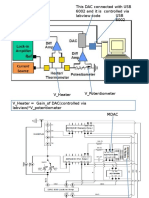

As shown in Fig. 1, we selected the field lens projected optical

system for integration with the mobile device, because compared to the reflected mirror structure this kind of optical system

opts to reduce the thickness of the system.

Generally, DMD panels can be grouped into one of two types

of pixel structure (a diamond square or a Manhattan square) [1].

A DMD chip has on its surface several hundred thousand microscopic mirrors arranged in a rectangular array which correspond

to the pixels in the image to be displayed. As shown in Fig. 1, the

mirrors can be individually rotated at 10 12 , to an on or off

state. The 0.2 DMD panel has a Manhattan square pixel shape

and is operated diagonally each pixel. As a result, the beam is

projected from the bottom of the diagonal of the panel toward

the center. Which is to say, the beam is projected in a three-dimensional direction. Therefore, the optical axis of the -coordinate coming out of the illumination combination system is located under the center of the panels active area, and the position

difference affects the thickness. Therefore, the mirror reflection

structure [Fig. 2(b)] cannot properly reduce the thickness of the

system module, because the reflection mirror is located at the

same position with the optical axis of the illumination combination system. Whereas, the field lens structure [Fig. 2(a)] can

reduce the difference between the optical axis coming out of

the illumination combination system and the center of the active panel area, because the positive lens, which has an optical

axis that is shifted upwards from the center of the active panel

area, is positioned before the panel.

It is assumed that the project for the mobile device is put on

the table and the image is projected to the displayed the screen,

as the field lens is designed with an upward projection structure

(100% projection offset). Of course, efficient and optimal design

1551-319X/$31.00 2012 IEEE

220

JOURNAL OF DISPLAY TECHNOLOGY, VOL. 8, NO. 4, APRIL 2012

Fig. 1. DMD principle with Manhattan square pixel type. a. DMD operation principle; b. DMD with Manhattan square pixel.

Fig. 2. LED DLP pico projector display systems by reflected mirror type and field lens type. (a) Reflected mirror type. (b) Field lens type.

is required, as some of the reflected mirror, which reflects the

beam coming out of the lighting combination system, can interfere with the beam ray coming out of the field lens. To achieve

efficient and optimal design, the collimated lens positioned in

front of the FEL (Fly Eye Lenses for uniform irradiance distribution on DMD panel) can be moved to the -axis, so that the

illumination combination system can be moved upwards in relation to the shifted distance and the overall thickness can be

reduced. As shown in Fig. 2, the field lens structure can reduce

thickness by more than 1 mm, compared to a reflected mirror

type. The actual optical module size for a field lens type can be

up to 2.1 cc (20.6 16.4 6.2 mm .

The projector illumination system generally has the

3-channel structure that collimates and combines the Lambertian distribution of each RGB light source as shown in Fig. 3

[2]. Even though it has a 2-channel structure, it is an L structure. Therefore, there is not actually much of a difference in the

spatial reduction of size (up to 4.7 cc), as the LED is always

positioned to the -axis length directionthe vertical incident

angle to the FEL side, compared with the 3-channel structure.

However, as shown in Fig. 2, by using the 2-in-1 LED that is

included in a single package the -axis direction length could

be reduced significantly by positioning the LED 2 chips, which

have a different wavelength, with the straight line 2-channel

illumination combination system structure. The most compact

pico projector system, with a reduction in size of about 25%,

can be obtained: We have successfully improved the size of the

compact system, making it about three times smaller than the

LCoS pico projector system, and reducing its thickness to less

than 7 mm, compared with 9 mm for the LCoS pico projector.

Generally, the 2-channel LED is composed of a green LED

and a red/blue LED, in order to secure the green LED chip area,

which has a higher brightness ratio [3]. In this system, the red

LED and the green/blue LED were positioned separately by two

considered factors. One factor is that the inefficient red LED

generates a lot of heat, and affects the blue chip, which is positioned in the same LED package. This results in a difficulty in

stabilizing the color uniformity and light source efficiency. The

other factor is that the colors blue and green belong to the same

neighboring wavelength band in the color combination system,

which combines of the light sources and sends them to one light

source path on optical axis. Simple reflection/transmission filter

structure coating can then be performed and high light efficiency

can be obtained.

The 2-in-1 LED can affect color uniformity, as two LED chips

with different wavelengths are positioned in a single package.

Therefore, two kinds of structures were used to combine two different wavelengths in two LEDs uniformly in the illumination

combination system. The one structure positions the Y-direction cylindrical FEL between the collimated lens and the color

combiner, so that the collimated beam can arrive uniformly in

the FEL plane of incidence. This has the advantage of using the

SHIN et al.: COMPACT SYSTEMS DESIGN BASED ON DMD

221

Fig. 3. LED DLP Field lens type pico projector system with the 3-channel and the 2-channel.

Fig. 4. Wwedge X-plate color combiner design for color uniformity. (a) X-plate color combiner type. (b) Wedge X-plate color combiner type.

conventional color combiner as it is. However, more space is

required for the cylindrical FEL components. As a result, optical transmitted efficiency deterioration and material cost increase effects are expected. The other structure is a color combiner as shown in Fig. 4, and a wedge X-plate structure, optimizes a wedge tilting angle, so that the reflection coating with

each different wavelength coming from the front and rear side of

the wedge plate can be matched on the FEL plane of incidence.

When an x-plate is used to combine the 2-in-1 LED color, it horizontally appeared the uninformed color distribution like color

gray gamut. However, we have successfully obtained color uniformity of over 70% by applying a wedge X-plate.

The system arranged the 0.7 0.7 mm 2-in-1 LEDs chip total

dimension ratio in a way that is similar to the 0.2 DMD panels

dimension ratio of 16:9 so that a practical high light efficiency

that is in accordance with the principle of etandue can be attained. In addition, as the beam is transferred from the FEL to

the DMD plane by the reflected mirror component, which is

tilted in a three dimensional space, the active light area on the

display panels plane is rotated when the beam rays coming out

of the illumination combination system are sent to the panel at

the desired incidence angle. Consequently, as shown in Fig. 5,

compensation rotation was applied to LED and FEL to efficiently match the active square area ratio of the panel.

Table I shows the optical specification of projection lens. The

optical projected lens system is designed with four glass lenses

and two plastic lenses for the standard specification of a 30-inch

image size at a 1150 mm object distance. Then, the optical per-

formance is optimized at a 5 60 inch image size by setting the

focus adjustment range. When the total effective RGB LED light

intensity is 35 lm@W, the simulated brightness intensity is secured up to 10 lm (@ANSI uniformity 70%), and color temperature

targets 7000 (

,

, @ color

in the optical illumination system.

uniformity

The effective size of the optical module was only set to 2.1 cc

(20.6 16.4 6.2 mm) to design the ultra-small pico projector.

III. SYSTEM PROTOTYPE

Fig. 6 shows the structural diagram of the mobile embedded

pico projector prototype. The actual size of the mechanical engine module of the mobile embedded pico projector system prototype was measured as 3.5 cc (23.9 21.3 6.9 mm), including the DMD panel. Basically, the device has a mounted

structure that is based on an all-in-one body. Optical parts are

mounted first and then are covered with a flat plate. Therefore,

the heat that is generated by the LED is transmitted to the LED

presser that covers the LED metal PCB, and an all-in-one body

is mounted directly, and is transmitted to the mobile device body

again. The temperature measurement graph in Fig. 6 shows that

the phone sets temperature (about 39 ) satisfies the temperature

requirement of the touchable surface standard EN563: 48 .

The cooling experiment result estimated that heat transmission

was stabilized in the all-in-one mount structure [5].

The projected lens system part is separated from the main

body for focus adjustment according to the projection distance

and has a cylinder guide structure that enables the user to move

222

JOURNAL OF DISPLAY TECHNOLOGY, VOL. 8, NO. 4, APRIL 2012

Fig. 5. Rotated LED/FEL design for high optical efficiency on DMD by field lens.

TABLE I

OPTICAL SPECIFICATION OF PROJECTION LENS

the back focal on the optical axis while mounting the projection

lenses as shown in the 3D view of Fig. 6.

The result of the image quality measurement from the prototype shows that brightness at 1.5 W total power consumption

was 8 lm at 70% ANSI uniformity, and 1700:1 contrast ratio

in the dark room. On average the color temperature K was

,

). In the review

measured as 8000 (

of the prototype, the wedge x-plate was segmented with three

parts (a red-reflected coating plate filter, green/blue each reflected coating wedge plate filter, and a reflected coating prism),

as shown in Fig. 4(b). So, there was some loss of optical illumination due to the limited coating condition according to the

plate filters tilting angle and the center bonding area of the combined part. And, in the estimation of the components, it was

found that the optical system efficiency of the projection lens

was low compared with the simulation value, because the lens

D-cut boundary area was not homogenous by birefringence. It

was analyzed that the light intensity loss (compared with the

simulation) could be compensated, if the wedge x-plate coating

within the cone angle range and the bonding of combined parts

are stabilized, and that D-cut projected lens efficiency can be improved in the mold manufacturing process. Fig. 7 shows the pico

projector module prototype integrated with the mobile device.

IV. CONCLUSION

In this study, an ultra-small LED DLP pico projector system

was designed with the dimensions 23.0 mm (width) 21.9 mm

(length) 6.9 mm (thickness) ( 3.5 cc), and its prototype was

produced using a straight line 2-channel LED structure. It means

that the actual whole size of the mechanical engine module

based on DMD and the straight line 2-channel LED for a mobile embedded pico projector is reduced about 25%, especially

thickness has less than 7 mm for embedding a mobile phone.

This projector system can provide a good efficiency [ 23%, 8

SHIN et al.: COMPACT SYSTEMS DESIGN BASED ON DMD

223

Fig. 6. Structural diagram and thermal test of the engine module.

Fig. 7. Mobile embedded projection device. (a) Pico projector module. (b) Mobile embedded projector demo.

Fig. 8. Development of all-in-one type engine & driver development.

lm @ANSI uniformity 70%) and a good quality image (contrast 1700:1, nHD (640 360)] with the total power consumption 1.5 W. It seems obvious that the pico projector system device has the advantage of being able to be integrated into already

conventional mobile devices, as the small engine module is provided that is less than 7 mm in thickness. Furthermore, the 3.5

cc volume structure with its practical regular hexahedron and

compact shape, would support integration with a mobile device,

and would allow for easy application to portable devices such as

laptops and console games. If the driving circuit board is manufactured in a three dimension shape, and if an all-in-one type

could be developed that covers the engine module, as shown in

Fig. 8, a detachable accessory product (e.g., a charging gender)

for the mobile device could also be widely marketed.

The brightness and resolution of the pico projector system

depend heavily on the light source and the micro display panel.

Therefore, if an LED light source and a micro display panel

can be developed successfully, a pico projector that implements

over 15 lm brightness and provides high-quality resolution

could then be developed without any great effort. However, a

major concern would be developing a highly efficient system

that can minimize the systems size optimally in consideration

of its thickness. This is because the systems limited thickness

affects the panel size, light source size, and the lens components active aperture.

In the next step, we will internally evaluate several reliable

engine module tests for a mobile embedded pico projector. (e.g.,

drop test, dust test, vibration teat, etc.)

REFERENCES

[1] Texas Instruments Incorporated, Introduction to Digital Micro Mirror

Device (DMD) Technology, Appl. Rep. DLPA008, Jul. 2008.

224

JOURNAL OF DISPLAY TECHNOLOGY, VOL. 8, NO. 4, APRIL 2012

[2] S. J. Park, S. M. Kim, and C. S. Won, Design considerations for picoprojector based on LCoS and 3-LEDs, in 2011 IEEE Int. Conf. on

Consumer Electron. (ICCE), 2011, pp. 805806.

[3] S. Morgott, S. Groetsch, W. Schnabel, and D. Wiener, LED light

sources for mobile embedded projection, in Proc. SPIE 7723, 2010,

vol. 77230.

[4] E. Piehler, Carl Zeiss Jena GmbH, , Germany, System in which light

is directed from a light source onto a surface, U.S. Patent 6 439 726,

Aug. 27, 2002.

[5] P. Marks, Projector phones: Cool app or visual pollution, The New

Scientist, vol. 201, no. 2697, pp. 1819, 2009.

Sung Chul Shin received the Ph.D. degree in engineering from University of

Warwick, Warwick, U.K., in 2004.

He is currently with the Advanced Device (AD) Gr, Future Device R&D Lab.,

Advanced Research Institute, LG Electronics, Seoul, Korea, as a chief research

engineer.

Yunsuk Jung received the M.A. degree in electronic & electrical engineering

from Pohang University of Science and Technology, Korea, in 2007.

She is currently with the Advanced Device (AD) Gr. Future Device R&D

Lab., Advanced Research Institute, LG Electronics, Seoul, Korea, as an junior

research engineer.

Tae-Jeong Ahn received the M.S. degree in mechanical engineering from

Hanyang University in Korea in 2000.

He is currently with the Advanced Device (AD) Gr. Future Device R&D Lab.,

Advanced Research Institute, LG Electronics, Seoul, Korea, as a chief research

engineer.

Sang Sik Jeong received the M.A. degree in Electronic Engineering from

Dongguk University in Korea in 1990.

He is currently with the Advanced Device (AD) Gr. Future Device R&D Lab.,

Advanced Research Institute, LG Electronics, Seoul, Korea, as Part leader and

a principal Research Engineer.

Seung-Gyu Lee received the M.A. degree in Physical Education from Seoul

National University in Korea in 2005.

He is currently with the Advanced Device (AD) Gr, Future Device R&D Lab.,

Advanced Research Institute, as group leader and a research follower.

Kwang-Yeol Choi is currently with Future Device R&D Lab., Advanced Research Institute, LG Electronics, Seoul, Korea, as laboratory director and a principal research engineer since 2010.

Vous aimerez peut-être aussi

- Radiative Heat Transfer in Fibrous Insulations-Part I: Analytical StudyDocument6 pagesRadiative Heat Transfer in Fibrous Insulations-Part I: Analytical StudyAmit RaiPas encore d'évaluation

- This DAC Connected With USB 6002 and It Is Controlled Via Labview Code USB 6002Document2 pagesThis DAC Connected With USB 6002 and It Is Controlled Via Labview Code USB 6002Amit RaiPas encore d'évaluation

- Syllabus INEN 514 Winter 2017Document4 pagesSyllabus INEN 514 Winter 2017Amit RaiPas encore d'évaluation

- U (r, θ, ϕ) = r A − sin2θ) + cos θ (1 + sin2θ) ) r A − sin2θ) + cos θ (1 + sin2θ) )Document1 pageU (r, θ, ϕ) = r A − sin2θ) + cos θ (1 + sin2θ) ) r A − sin2θ) + cos θ (1 + sin2θ) )Amit RaiPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Oracle Jrockit Mission Control Lab GuideDocument17 pagesOracle Jrockit Mission Control Lab GuideashuhegdePas encore d'évaluation

- 8J Summary SheetDocument2 pages8J Summary Sheet박찬우Pas encore d'évaluation

- Cif Purge Plug Systems en 3Document3 pagesCif Purge Plug Systems en 3abdeljalil elbadrPas encore d'évaluation

- Measurement Advisory Committee Summary - Attachment 3Document70 pagesMeasurement Advisory Committee Summary - Attachment 3MauricioICQPas encore d'évaluation

- Project AgreementDocument6 pagesProject AgreementRowin DizonPas encore d'évaluation

- KST GlueTech 44 enDocument80 pagesKST GlueTech 44 enLeandro RadamesPas encore d'évaluation

- CoreJava Ratan CompleteMarerial PDFDocument398 pagesCoreJava Ratan CompleteMarerial PDFSivaShankar100% (7)

- EN 1991-1-4 NA enDocument4 pagesEN 1991-1-4 NA enanuj3936100% (1)

- ASTM F 412 - 01a Standard Terminology Relating To Plastic Piping Systems1Document13 pagesASTM F 412 - 01a Standard Terminology Relating To Plastic Piping Systems1JORGE ARTURO TORIBIO HUERTAPas encore d'évaluation

- 3-Axially Loaded Compresion Members PDFDocument37 pages3-Axially Loaded Compresion Members PDFKellen BrumbaughPas encore d'évaluation

- Mechanical Workshop Practice ReportDocument6 pagesMechanical Workshop Practice ReportMuhd AkmalPas encore d'évaluation

- Section 05120 Structural Steel Part 1Document43 pagesSection 05120 Structural Steel Part 1jacksondcplPas encore d'évaluation

- Determination of The Solubility Product Constant of Silver AcetateDocument8 pagesDetermination of The Solubility Product Constant of Silver AcetateSara Al AzemPas encore d'évaluation

- Teradata Installation: Installation Steps For WindowsDocument4 pagesTeradata Installation: Installation Steps For WindowsjupudiguptaPas encore d'évaluation

- ProceedingsDocument656 pagesProceedingsgkgjPas encore d'évaluation

- Cisco Network DiagramDocument1 pageCisco Network DiagramĐỗ DuyPas encore d'évaluation

- 4.10) Arch Shaped Self Supporting Trussless Roof SpecificationsDocument11 pages4.10) Arch Shaped Self Supporting Trussless Roof Specificationshebh123100% (1)

- BM 81004 MuvDocument52 pagesBM 81004 MuvHamza Abbasi AbbasiPas encore d'évaluation

- Noise Optimization in Sensor Signal Conditioning Circuit Part IDocument37 pagesNoise Optimization in Sensor Signal Conditioning Circuit Part Iyzhao148Pas encore d'évaluation

- Solar Pond - Awesome PDFDocument26 pagesSolar Pond - Awesome PDFKartik MahajanPas encore d'évaluation

- DSP45 12aDocument5 pagesDSP45 12aDaniel BarbuPas encore d'évaluation

- Production of Isopropyl Palmitate-Experimental StudiesDocument12 pagesProduction of Isopropyl Palmitate-Experimental Studiesikaw_3Pas encore d'évaluation

- 01 GeoStrucAnal Cylinder Elastic PDFDocument12 pages01 GeoStrucAnal Cylinder Elastic PDFSiddhant KaushikPas encore d'évaluation

- BurnerDocument4 pagesBurnerAhmed Mohamed KhalilPas encore d'évaluation

- Gathering Network RequirementsDocument30 pagesGathering Network RequirementsAmin ZangetsuPas encore d'évaluation

- Honeywell P7640B1032 Differential Pressure Sensors PDFDocument2 pagesHoneywell P7640B1032 Differential Pressure Sensors PDFMarcello PorrinoPas encore d'évaluation

- SF6 Novec 4710Document4 pagesSF6 Novec 4710Fidya Eka PrahestiPas encore d'évaluation

- 27C ChainDocument19 pages27C ChainyanaziPas encore d'évaluation

- Transmicion de CF 500, CF 600 PDFDocument337 pagesTransmicion de CF 500, CF 600 PDFgusspeSPas encore d'évaluation

- Vibration - Electrical or Mechanical - EASADocument3 pagesVibration - Electrical or Mechanical - EASAGilbPas encore d'évaluation