Académique Documents

Professionnel Documents

Culture Documents

Process Simulator Effective in De-Ethanizer Tower Revamp - Oil & Gas Journal

Transféré par

CraigUnderwoodTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Process Simulator Effective in De-Ethanizer Tower Revamp - Oil & Gas Journal

Transféré par

CraigUnderwoodDroits d'auteur :

Formats disponibles

Process simulator effective in de-ethanizer tower revamp - Oil & Gas J...

1 of 5

http://www.ogj.com/articles/print/volume-100/issue-12/processing/pro...

Login or Register using

SUBSCRIBE: MAGAZINE | NEWSLETTERS

Home Process simulator effective in de-ethanizer tower revamp

Looking for past issues? Click here.

03/25/2002

Revamping an existing plant to increase production with minimum investment is important in today's process industries.

Revamping a process plant is more complex than building a new plant. Revamps require a thorough knowledge and

expertise of detailed material and energy balances.

1

A process simulator is a powerful tool for identifying bottlenecks to achieve higher capacity. For some pieces of

equipment like pumps, compressors, heat exchangers, etc., revamping is relatively straightforward. For example,

replacing the impeller on a centrifugal pump or installing an additional pump in parallel to achieve higher capacity.

A distillation column, on the other hand, is a major cost component and simply replacing it during a revamp is not

2

acceptable. Existing column performance must be understood and analyzed in a distillation column revamp.

Process simulators are an extremely useful tool to perform revamps with considerable ease. A simulator has an

extensive thermodynamic model database, unit operations library, and pure component databank for modeling the

process.

This article presents a case history of using a process simulator as a tool for revamping an existing distillation column

to establish additional throughput without a major hardware change.

The column was revamped for additional throughput by combining feed precooling and providing a side reboiler. This

concept requires minimal hardware changes for columns excessively loaded at stripping section. The key to a

successful revamp lies in setting the appropriate location and side reboiler duty.

This exercise demonstrates how a process simulator can help analyze column profiles and locate the side reboiler.

Distillation revamp

A revamp should increase column throughput. The new throughput will increase column traffic and, consequently, limit

the reboiler and condenser. There are various revamping options available to overcome these constraints.

A simple and generally used approach is to use structured packing or high efficiency trays to handle additional column

traffic and provide additional surface area to overcome the reboiler and condenser bottlenecks. A more careful analysis

of the existing column may give insight on alternate revamping strategies that will lead to an optimum design.

Hydraulic loads in the stripping and rectification sections may vary substantially. If a column is typically hydraulically

loaded more in the stripping section and less in the rectification section, adding heat at an intermediate tray between

the feed and reboiler can help redistribute the load; column throughput can be enhanced without replacing internals.

Side reboiler

3

Using a side reboiler is useful for columns loaded relatively heavily in the stripping section. The heat load between the

rectification and stripping sections can be balanced by varying the feed temperature. Feed preheating decreases

reboiler duty and increases condenser duty while feed precooling has the opposite effect. Component physical

properties influence the sensitivity of heat load variations with respect to feed temperature.

With a side reboiler:

Feed is precooled.

Condenser heat load decreases.

Vapor-liquid traffic in the rectifying section decreases.

Vapor-liquid traffic in the stripping section increases.

Reboiler heat load increases.

19/08/2014 8:12 PM

Process simulator effective in de-ethanizer tower revamp - Oil & Gas J...

2 of 5

http://www.ogj.com/articles/print/volume-100/issue-12/processing/pro...

A side reboiler placed between the feed point and bottom tray reduces the tray load below the point where heat is

added. It will also, to some extent, increase the tray load above the heat addition point.

With top section traffic reduced due to feed precooling and bottom section traffic reduced due to a side reboiler, column

throughput can be increased so that column traffic, condenser heat duty, and reboiler heat duty remain the same.

When using this approach for a distillation revamp, the trick is to specify the side reboiler location and fix the heat

addition rate that will give maximum overall capacity increase. This is a trial-and-error procedure with no simple

formula.

Problem definition

In an LPG recovery scheme, ethane

is removed from the main feed

stream in a de-ethanizer column

followed by a LPG column. LPG is

the overhead product in the LPG

column and the bottoms are mainly

C +. Fig. 1 shows the flow scheme.

5

A column with the feed stream

shown in Table 1 was considered.

The revamp study was performed

on the de-ethanizer column. These

specifications for overhead and

bottom streams were fixed:

Click here to enlarge image

Ethane with 0.5 wt % propane in the overhead.

Bottom stream with 0.5 wt % ethane.

The simulation used single-pass Glitsch valve trays in

the rectifying section and two-pass Glitsch valve trays

in the stripping section.

More than 600 job

openings are now

online, watch videos

and learn more!

The distillation column had 40 theoretical stages

excluding the condenser and reboiler. Feed entered at

Tray 20. This was the optimum feed location.

Click Here to Watch

The de-ethanizer was swaged below the feed; the top

section was 0.95 m diameter and the bottom section

was 1.7 m diameter, with a tray spacing of 0.5 m in both

sections.

Click here to enlarge image

Column top pressure was 30 kg/sq cm, feed rate was

40,000 kg/hr, and feed temperature was 65C. The simulation used the Peng-Robinson thermodynamic method. After

achieving the required specifications, further studies were performed with this model as the base case.

Surfactant Synthesis Specialist

Tower simulation

A detailed analysis of the base case revealed that

the column was heavily loaded in stripping section

(Fig. 2). This was due to various factors.

Solvay

Country: United States

The applications and markets serviced by Solvay

Novecare enterprise surfactants are Coatings, Home

Latent heat in the reboiler vapor is substantially lower

than the overhead. Liquid molecular weight

increases in the stripping section up to the bottom

tray, resulting in lower vapor velocity and tray

loading. With higher fluid temperature, however,

liquid density is lower resulting in higher tray loading.

The net overall result is increased tray loading

between the feed and column bottom.

Personal Care, Agrochemicals, Industrial, ...

Sr. Product Line Manager-Turbo/Recip,

Global Technology

Dresser-Rand

Country: United States

Dresser-Rand is searching for candidates to fill

important Product Management positions in the

areas of Turbo products and Reciprocating

Click here to enlarge image

products. Candidates must have significant

experience in

Search More Job Listings >>

19/08/2014 8:12 PM

Process simulator effective in de-ethanizer tower revamp - Oil & Gas J...

3 of 5

http://www.ogj.com/articles/print/volume-100/issue-12/processing/pro...

The column profile for this simulation case is tabulated in Table 2.

Flooding at the feed tray was 51%, and it steadily increased towards

the bottom. The bottom tray flooding was 79.8%, the recommended

maximum for the column.

The top section was not hydraulically loaded (Fig. 2). The mass flow

rate of liquid in the rectifying section was 12,000 to 16,000 kg/hr

whereas the mass flow rate of liquid in stripping section was 60,000

to 75,000 kg/hr.

Click here to enlarge image

A further increase in throughput was not possible due to flooding

limitations. The loading pattern, however, shows that if we could uniformly balance hydraulic load in the stripping

section, it would be possible to revamp the column such that traffic in the stripping section's bottom trays would be

similar to traffic before the revamp. Supplying intermediate heat in the stripping section at a suitable location would

achieve this goal.

Feed precooling or preheating before it enters the column can also alter vapor-liquid traffic. However, feed preheat or

precool will not help in altering the relative load in a section. Feed precooling accompanied with a side reboiler can,

however, substantially increase column throughput.

Feed was precooled to 40C. to lower the condenser duty and

column rectification section loading. Table 3 shows the results.

Click here to enlarge image

Condenser duty

was 22% lower

(Table 4)

compared to the

base case.

There was a

corresponding

increase of

15.5% in the

reboiler duty.

Click here to enlarge image

Fig. 3 shows that stripping section loads increase with flooding,

reaching an unacceptable value of 91.6%. Flooding on the top tray

was 57.5%.

Adding an intermediate heat source below the feed tray will reduce

the traffic below it.

Click here to enlarge image

Intermittent heat addition

The heat duty from a side reboiler must be determined by trial-and-error. A first estimate of the side reboiler duty uses

the net differential duty between the base case and revamp case. Since the revamp case, however, was itself a

function of side reboiler duty and location, it was extremely difficult to arrive at an initial estimate.

We observed that the total duty required for the revamp case was not equal to the base case plus a differential duty. It

was a little less if heat was added at an intermittent location and was sensitive to where the heat was added.

For this case, the side reboiler added 1 million

kcal/hr. A study was performed to evaluate the

reduction in reboiler duty by varying the side reboiler

location. Fig. 4 shows the results. There is no

significant reduction in reboiler duty when the side

reboiler is placed in the rectifying section. So, further

studies varied the side reboiler location in just the

stripping section.

The side reboiler was tried at Tray 25, 30, and 35.

The condenser and reboiler duties, and column

flooding at each stage were studied for each run.

Fig. 5 shows the results.

Click here to enlarge image

Adding heat at an intermediate location decreased

the loading below the heat addition tray and

increased the loading above it. As the heat addition

location was lowered, loading on the trays above the

heat addition point was not as great.

Fig. 5 shows that maximum flooding in the stripping

section reaches 82% when heat was added on Tray

35. This is more than the maximum flooding in the

base case; so this heat addition point was not

19/08/2014 8:12 PM

Process simulator effective in de-ethanizer tower revamp - Oil & Gas J...

4 of 5

http://www.ogj.com/articles/print/volume-100/issue-12/processing/pro...

accepted.

When heat was added on Tray 30, maximum

flooding in stripping section was 74.9%, lower than

maximum flooding for the base case.

In the rectifying section, maximum flooding was

59.6%, lower than maximum flooding for the base

case by 25.1%.

Click here to enlarge image

When heat was added at Tray 25, maximum flooding

in the stripping section was 71%. Maximum flooding

was 70% in the rectifying section, 12% lower than

the maximum flooding for the base case.

Adding heat at Tray 25 gave more margin for flooding than Tray 30, when compared to the base case. Tray 25 was

chosen as the optimum head addition point.

Revamp case

After side reboiler duty and location were finalized, column runs were performed to evaluate additional throughput. The

feed rate was gradually increased and column parameters were analyzed.

At a throughput of 47,500 kg/hr, column hydraulic performance and duties were fairly close to the base case. Flooding

in the column was compared to the base case.

Fig. 6 shows column flooding before and after the

revamp.

Since intermediate heat is added on Tray 25, the

maximum flooding point in the bottom section (Tray

24) is 80%. This matches closely with maximum

flooding of 79.8% in bottom section (Tray 39) for the

base case.

Maximum flooding in the revamped top section is

75.3%, well below the maximum flooding of 79.5%

for the base case.

Click here to enlarge image

Condenser duty for the base case was 1.055 million

kcal/hr and the condenser duty after the revamp

remains at 1.06 million kcal/hr (Table 4). Reboiler

duty before and after the revamp was 2.51 and 2.55

million kcal/hr, respectively.

The study revealed that there was no need to

change the existing reboiler and condenser surfaces after the revamp. The column traffic limiting points were also

maintained so that the internals did not have to be changed after the revamp.

Precooling the feed from 65 to 40 C. and adding 1 million kcal/hr of heat using a side reboiler at Tray 25 increased

distillation column throughput by 18% without affecting product specifications.

Role of the simulator

We performed a similar exercise with different combinations of heat duty and heat addition points. We observed that

the overall column throughput increase was less than 18% for all other cases.

4-6

This type of study is practically impossible to perform without the use of a process simulator.

This case study is a classic example that stresses the importance of process simulators for revamping distillation

columns or other complex operations within a process plant.

References

1. Sloley, A., and Fraser, A.C.S., "Consider modeling tools to revamp existing process units," Hydrocarbon

Processing, June 2000, pp. 57-63.

2. Fair, J.R., and Seibert, A.F., "Understand distillation-column debottlenecking options," Chemical Engineering

Progress, June 1996, pp. 42-48.

3. Nye, J.O., Herzog, K., and Cheaney, S., "Use a side reboiler to increase tower capacity," Hydrocarbon

Processing, September 1999, pp 51-56.

4. Kister, H.Z., "Troubleshoot distillation simulations," Chemical Engineering Progress, June 1995, pp. 63-75.

5. Kister, H.Z., "Distillation design," McGraw-Hill, New York, 1992.

6. Dimian, A., "Use process simulation to improve plant operations," Chemical Engineering Progress, September

1994, pp. 58-66.

The authors

Atul Choudhari is a senior process engineer at Kvaerner Powergas India Ltd., Mumbai, India. His

experience of more than 9 years includes flowsheet simulations and process optimization for

petrochemicals, fine chemicals, and hydrocarbon processes. Choudhari also has experience in various

debottlenecking and distillation revamping projects. He received his BS in chemical engineering from

Marathwada University, Aurangabad, India.

Pradnya Gune is a principal process engineer at Kvaerner Powergas India Ltd., Mumbai, India. She has

more than 10 years of process engineering experience in the field of petrochemicals and fine chemicals.

Gune previously worked for Reliance Industries Ltd. She is a graduate engineer from the University of

Mumbai, Department of Chemical Technology.

Click here to

enlarge

image

S. K. Saxena is a senior engineering manager (process), head of process for Kvaerner

Powergas India Ltd., Mumbai, India. He has also worked for Synthetics & Chemicals Ltd.,

Humphrey & Glasgow Ltd., Engineers India Ltd., Bechtel Group Inc., and Petrofac

International Ltd. in various capacities. Saxena has more than 25 years experience in

19/08/2014 8:12 PM

Process simulator effective in de-ethanizer tower revamp - Oil & Gas J...

5 of 5

http://www.ogj.com/articles/print/volume-100/issue-12/processing/pro...

process design, troubleshooting, and operations. His experience covers refining,

Click here to petrochemicals, and fine chemicals. He has a masters in chemical engineering (design).

enlarge

image

Click here to

enlarge

image

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

US should avoid military motives for LNG exports

03/24/2014 The US natural gas industry should remind House Republicans that geopolitical power works best

in silence, that bluster dissipates influence.

IEA: Global oil demand revised upward on stronger data

03/24/2014 Global oil demand in 2013 rose by 1.3 million b/d year-over-year to 91.3 million b/d, according to

the latest, near-complete set of demand data for...

BPTT adds to reserves at Angelin offshore Trinidad and Tobago

03/24/2014 BP Trinidad & Tobago's (BPTT) Ocean Bottom Cable Seismic (OBCS) has already added

significant proved reserves to its Angelin gas discovery in 8...

Chevron to increase production, maintain capex level through 2017

03/24/2014 Chevron Corp. will increase production by 20% through 2017 without raising capital expenditures,

executives said Mar. 11 at the company's annual se...

Stay Connected

1455 West Loop South

Houston, Texas 77027

(713) 621-9720

Copyright 2013: PennWell Corporation

All Rights Reserved.

Home

Events

Magazine Subscription

About Us

General Interest

Market Connection

Newsletter Subscription

PennWell

Exploration & Development

White Papers

Book Store

View All Pennwell Websites

Drilling & Production

Webcasts

Privacy Policy

View All Pennwell Events

Processing

RSS

Terms & Conditions

Site Map

Transportation

PennEnergy Jobs

Contact Us

Webmaster

Unconventional

Equipment

Advertise

Research

Mobile

19/08/2014 8:12 PM

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Toyota NR Series EnginesDocument18 pagesToyota NR Series EnginesHortodoxocs50% (2)

- 140KDocument63 pages140KRuben Chumacero100% (3)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Bi Toroid Transformer DiscussionDocument781 pagesBi Toroid Transformer DiscussionLuisLazoPas encore d'évaluation

- HDPE EloallitasaDocument34 pagesHDPE EloallitasaCraigUnderwood100% (1)

- HDPE EloallitasaDocument34 pagesHDPE EloallitasaCraigUnderwood100% (1)

- SHS Core - Earth and Life Science CGDocument13 pagesSHS Core - Earth and Life Science CGShendy AcostaPas encore d'évaluation

- L1 - Introduction To AlcoaDocument58 pagesL1 - Introduction To AlcoaCraigUnderwoodPas encore d'évaluation

- Improve Control: Level LoopsDocument8 pagesImprove Control: Level LoopsCraigUnderwoodPas encore d'évaluation

- Gate Questions On MosfetDocument16 pagesGate Questions On MosfetEsakkiPonniah100% (1)

- Innovations in LNG TechnologyDocument15 pagesInnovations in LNG TechnologyCraigUnderwoodPas encore d'évaluation

- Merlin Gerin Masterpact (00689992a) PDFDocument161 pagesMerlin Gerin Masterpact (00689992a) PDFyerut0130100% (4)

- Ethylene BalanceDocument29 pagesEthylene BalanceCraigUnderwood100% (2)

- Large Span Timber StructuresDocument34 pagesLarge Span Timber StructuresAnonymous 8f2veZf100% (1)

- 25 HP & 20 HP Solar Pump QuatationDocument5 pages25 HP & 20 HP Solar Pump QuatationAmodPas encore d'évaluation

- ABBDocument133 pagesABBIulian Luncan100% (3)

- HJ-March National Voucher Voucher PDFDocument2 pagesHJ-March National Voucher Voucher PDFCraigUnderwoodPas encore d'évaluation

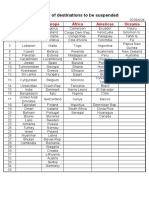

- List of Destinations To Be Suspended: Asia Europe Africa Americas OceaniaDocument1 pageList of Destinations To Be Suspended: Asia Europe Africa Americas OceaniaCraigUnderwoodPas encore d'évaluation

- As 1548-2008 - Fine Grained, Weldable Steel Plates For Pressure EquipmentDocument37 pagesAs 1548-2008 - Fine Grained, Weldable Steel Plates For Pressure EquipmentCraigUnderwoodPas encore d'évaluation

- As 1548-2008 - Fine Grained, Weldable Steel Plates For Pressure EquipmentDocument37 pagesAs 1548-2008 - Fine Grained, Weldable Steel Plates For Pressure EquipmentCraigUnderwoodPas encore d'évaluation

- Profile On The Production of Low Desnsity Polyethylene (Ldpe)Document25 pagesProfile On The Production of Low Desnsity Polyethylene (Ldpe)CraigUnderwoodPas encore d'évaluation

- Profile On The Production of Low Desnsity Polyethylene (Ldpe)Document25 pagesProfile On The Production of Low Desnsity Polyethylene (Ldpe)CraigUnderwoodPas encore d'évaluation

- Burrup Industiral EstateDocument2 pagesBurrup Industiral EstateCraigUnderwoodPas encore d'évaluation

- Che415 Explosion HazardsDocument63 pagesChe415 Explosion HazardsCraigUnderwoodPas encore d'évaluation

- Notes FlamephotometryDocument19 pagesNotes FlamephotometryKaFiAliMirzaPas encore d'évaluation

- FTPDocument10 pagesFTPMichael ParkerPas encore d'évaluation

- SBSBattery VRLA Tubular Gel VRZ Series PDFDocument1 pageSBSBattery VRLA Tubular Gel VRZ Series PDFAleiska Victoria Gómez BetancourthPas encore d'évaluation

- The Basic Parts of A GeneratorDocument4 pagesThe Basic Parts of A GeneratorFionah Mae PraderoPas encore d'évaluation

- Biogass DigesterDocument9 pagesBiogass DigesterHasnain AshrafPas encore d'évaluation

- Data Sheet For HV Motor: 4935-30001-21-EL-DS-1050Document3 pagesData Sheet For HV Motor: 4935-30001-21-EL-DS-1050Pinaki SharmaPas encore d'évaluation

- Atal Aicte Online Faculty Development Programme (FDP)Document6 pagesAtal Aicte Online Faculty Development Programme (FDP)indranildasPas encore d'évaluation

- Case Study - BoilerDocument17 pagesCase Study - BoilerMohd Shafuaaz KassimPas encore d'évaluation

- Fujitsu AOU48RLXFZ Design and Technical ManualDocument312 pagesFujitsu AOU48RLXFZ Design and Technical Manuale-ComfortUSA100% (2)

- Living Eco VIIDB202Document28 pagesLiving Eco VIIDB202jovanoxPas encore d'évaluation

- Reciprocating PumpDocument6 pagesReciprocating PumpManish SoniPas encore d'évaluation

- Presentation Textile PhysicsDocument7 pagesPresentation Textile PhysicsNipu SenPas encore d'évaluation

- Week018-019 Presentation Sounds PPT PART 1 PhysicsDocument31 pagesWeek018-019 Presentation Sounds PPT PART 1 PhysicsRouie john dizon100% (1)

- A en 05806 00Document10 pagesA en 05806 00Saravanan MathiPas encore d'évaluation

- Human Energy Requirements - FaoDocument2 pagesHuman Energy Requirements - FaoKaren MazariegosPas encore d'évaluation

- Flexible Disc Couplings: TB Wood's Form-Flex & Torsiflex-IDocument52 pagesFlexible Disc Couplings: TB Wood's Form-Flex & Torsiflex-Ioscar.pabaPas encore d'évaluation

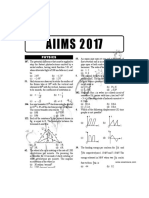

- AIIMS Solved Paper 2017Document30 pagesAIIMS Solved Paper 2017Jagmohan SinghPas encore d'évaluation

- Xylux Lr3: High Output Emergency LED Luminaire Suitable For 10.8 Lux ApplicationsDocument4 pagesXylux Lr3: High Output Emergency LED Luminaire Suitable For 10.8 Lux ApplicationsAtiqPas encore d'évaluation

- Alpha Argus GuidelineDocument33 pagesAlpha Argus GuidelineToto CutugnoPas encore d'évaluation

- 69NT40-561-001 To 199: Container RefrigerationDocument136 pages69NT40-561-001 To 199: Container RefrigerationMAYMODERN STEELPas encore d'évaluation

- Performance Verification For Platinum Resistance ThermometersDocument4 pagesPerformance Verification For Platinum Resistance Thermometersfawmer61Pas encore d'évaluation