Académique Documents

Professionnel Documents

Culture Documents

IJETED Desig of TAR-libre

Transféré par

Michael DouglasCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

IJETED Desig of TAR-libre

Transféré par

Michael DouglasDroits d'auteur :

Formats disponibles

International Journal of Emerging trends in Engineering and Development

ISSN 2249-6149

Issue1, Vol. 2

Design and Optimization of a Thermo

Acoustic Refrigerator

Bheemsha1, Ramesh Nayak. B 2, Pundarika.G3

1- Associate Professor, Dept of Mechanical Engineering, B M S College of Engineering, Bull Temple Road,

Bangalore-560019, Karnataka, India

2- Associate Professor, Dept of Industrial Engineering and Management,B M S College of Engineering, Bull

Temple Road,Bangalore-560019, Karnataka, India

3- Principal, Government Engineering College, Ramanagara-562159, Karnataka, India

Abstract

The work reported here deals with the design and optimisation of a thermo acoustic

refrigerator (TAR) as an attempt to address the future generation environment friendly energy

systems. The literature survey gives a complete picture on the history of thermo acoustics and

the work carried out in the field of thermo acoustics till today. The motivation of the design of

thermo acoustic refrigerator explains the reasons for carrying out the work illustrating its

benefits and how the performance of the TAR in future can be made efficient in comparison

with the performance of a conventional refrigerator. The general linear theory of thermo

acoustics is used as a basis for the design taking simplified assumptions into consideration of

the design. Optimization is carried out using MATLAB. The optimisation of different

components is carried out to improve the performance and minimise losses in the thermo

acoustic refrigerator. For a cooling power of 10 watts, the stack COP was optimized and

found to be 2.4948. The acoustic losses in the small diameter resonator tube were minimized

by taking the optimized value of the diameter ratio (D2/D1) equal to 0.43.

Keywords: Thermoacoustic, Stack, Heat exchangers, Resonator tube, Buffer volume

___________________________________________________________________________

1 Introduction

1.1 A Standing-Wave Thermo Acoustic Refrigerator

The configuration of standing-wave thermo acoustic refrigerators is simple. A

standing-wave TAR comprises a driver, a resonator, and a stack. The practical device also

RS Publication

Page 47

International Journal of Emerging trends in Engineering and Development

ISSN 2249-6149

Issue1, Vol. 2

utilizes two heat exchangers; however, they are not necessary for creating a temperature

difference across the stack. The parts are assembled as shown in Figure 1.

Fig. 1 Configuration of a standing-wave thermoacoustic refrigerator

The driver, which is often a modified electro dynamic loudspeaker, is sealed to a

resonator. Assuming the driver is supplied with the proper frequency input, the resonator will

respond with a standing pressure wave, amplifying the input from the driver. The standing

wave drives a thermo acoustic process within the stack. The stack is so called because it was

first conceived as a stack of parallel plates; however, the term stack now refers to the thermo

acoustic core of a standing-wave TAR no matter the cores geometry. The stack is placed

within the resonator such that it is between a pressure antinode and a velocity antinode in the

sound wave. Via the thermo acoustic process, heat is pumped toward the pressure antinode.

The overall device is then a refrigerator or heat pump depending on the attachment of heat

exchangers for practical application.

A temperature gradient can be created along the stack with or without heat

exchangers. The exchangers merely allow a useful flow of heat. If the hot end is thermally

anchored to the environment and the cold end connected to a heat load, the device is then a

refrigerator. If the cold side is anchored to the environment and the load applied at the hot

end, the device operates as a heat pump. In any case, a few simple parts make up the thermo

acoustic device, and no sliding seals are necessary.

Before introducing quantitative thermo acoustic theory, a simplified qualitative

Lagrangian explanation of the thermo acoustic refrigeration cycle is helpful. Consider a parcel

of gas in a channel between two plates, as in Figure 2, where the gas is acted upon by an

acoustic standing wave. To keep things simple, the acoustic wave is considered a square wave

and no losses are taken into account. There is a relatively small temperature gradient imposed

on the walls of the channel such that the top is hot and the bottom cold. The thermo acoustic

process can be conceptually simplified into four steps.

RS Publication

Page 48

International Journal of Emerging trends in Engineering and Development

ISSN 2249-6149

Issue1, Vol. 2

Fig. 2 Thermoacoustic cycle

First, the gas parcel undergoes adiabatic compression and travels up the channel due to

the acoustic wave. The pressure increases by twice the acoustic pressure amplitude, so the

temperature of the parcel increases accordingly. At the same time, the parcel travels a distance

that is twice the acoustic displacement amplitude. Then the second step takes place. When the

parcel reaches maximum displacement, it is has a higher temperature than the adjacent walls,

assuming the imposed temperature gradient is sufficiently small. Therefore, the parcel

undergoes an isobaric process by which it rejects heat to the wall, resulting in a decrease in

the size and temperature of the gas parcel. In the third step, the second half-cycle of the

acoustic oscillation moves the parcel back down the temperature gradient. The parcel

adiabatically expands as the pressure becomes a minimum, reducing the temperature of the

gas. The gas reaches its maximum excursion in the opposite direction with a larger volume

and its lowest temperature. Finally, in step four, the parcels temperature has become lower

than the local wall temperature (again assuming a small temperature gradient) so that heat

flows from the wall to the gas parcel. The process then repeats so that small amounts of heat

can be transported up the temperature gradient along the wall. Although the actual thermo

acoustic process is much more complicated than this idealized description, this view of

thermo acoustics yields a few useful ideas. Each gas parcel can only move a small amount of

heat over a small temperature difference in this manner, so to move the heat across a larger

temperature difference or move more heat (increase the power output), the situation must be

modified. To move heat over a larger temperature difference, the length of the channel can be

extended to allow more gas parcels to participate in moving the heat. Then, the temperature

gradient is the same, but the total temperature difference increases. If the goal is to move

RS Publication

Page 49

International Journal of Emerging trends in Engineering and Development

ISSN 2249-6149

Issue1, Vol. 2

more heat, then adding more channels in parallel will effectively increase the heat capacity of

the gas so that the cooling/heating power of the process is increased. Alternatively, the

working gas parameters can be modified so that its temperature fluctuates over a wider range,

or the acoustic pressure can be increased to achieve the same effect.

If the temperature gradient perfectly matches the adiabatic temperature change in the

gas, then there is no heat transfer in the second and fourth steps; the necessary temperature

distribution is called the critical temperature gradient. If the gradient is smaller than this

value, then the cycle will perform a heat pumping action; however, if the gradient is larger

than the critical value, then the cycle will produce work in the form of an acoustic oscillation.

Therefore, both thermo acoustic engines (TAEs) and thermo acoustic refrigerator (TARs) utilize the

same process, differing only in the temperature boundary condition. When losses are

considered, the critical temperature gradient becomes a critical range rather than a single

value so that no useful work is done in this range; acoustic power is absorbed and heat is

moved down the temperature gradient. As stated above, this Lagrangian view of thermo

acoustics is extremely simplified.

2 Design of Thermo Acoustic Refrigerator

A thermo acoustic refrigerator consists of an acoustic driver/speaker with a housing

attached to a gas filled resonator tube in which a stack and two heat exchangers are placed and

a vacuum vessel in which the resonator is contained. The system is constructed in such a way

that all components are independent so that specific parts can be exchanged when the design

changes or for other reasons. In the following section, the design and construction of the

different parts will be described in detail. A schematic illustration of a thermo acoustic

refrigerator is as shown in Figure 3.

Fig. 3 Thermoacoustic refrigerator experimental setup

RS Publication

Page 50

International Journal of Emerging trends in Engineering and Development

ISSN 2249-6149

Issue1, Vol. 2

2.1 Design Strategy

The stack is considered as the heart of any thermo acoustic system. It can be seen that these

systems have very complicated expressions which cannot be solved, which necessitates the

use of approximations. The coefficient of performance of the stack for example which can be

defined as the ratio of heat pumped by the stack to the acoustic power dissipated in the stack.

A simplified expression is derived from the short stack and boundarylayer approximation

[1]. However, even after the approximation, the expression looks complicated. They contain a

large number of parameters such as working gas, material and geometrical parameters of the

stack. It is difficult to deal with so many parameters in engineering. However, one can reduce

the number of parameters by choosing a group of dimensionless independent variables. Some

dimensionless parameters can be deduced directly. Others can be defined from the boundarylayer and short stack assumptions [1, 2]. The parameters of paramount importance in thermo

acoustics, which are contained in the work flow and heat flow expressions are given in Table

1 and 2.

Table 1 Operating and working gas variables

Operational variables

Working gas properties

Operating frequency

Dynamic viscosity

Average pressure PM

Thermal conductivity K

Dynamic pressure amplitude PO

Sound velocity a

Mean temperature TM

Ratio of isobaric to isochoric specific heat

Temperature gradient TM

Mach number M

Specific heat CP

Drive ratio D

Gas density m

Cooling power QC

Prandtl number

The goal in the design of a thermo acoustic refrigerator is to meet the requirements of

a given cooling power QC and a given low temperature TC. These requirements are added to

the operation parameters as shown in Table 1. The low temperature T C is shown indirectly in

the form of Temperature gradient TM.

RS Publication

Page 51

International Journal of Emerging trends in Engineering and Development

ISSN 2249-6149

Issue1, Vol. 2

Table 2: Normalised and non-dimensional design parameters

Non-Dimensional Parameters

Normalised thermal penetration Depth

Normalised Stack center position xsn

Normalised Stack Length Lsn

Normalised Acoustic power loss in Small Diameter resonator tube

Normalised Cold heat exchanger position from the driver end xchn

Normalised Hot heat exchanger position from the driver end xhhn

Normalised Length of Cold heat exchanger L chn

Normalised Cold heat exchanger position from the driver end Lhhn

Acoustic Mach Number M

The boundary layer and short stack approximations assume the following [1, 2]:

i.

The reduced acoustic wavelength is larger than the stack length /2 very much

greater than LS, so that the pressure and velocity can be considered as constant over

the stack and that the acoustic field is not significantly disturbed by the presence of

the stack.

ii.

The thermal and viscous penetration depth is smaller than the spacing in the stack x

and V are very much less than y0 .This assumption leads to the simplification

of Rotts functions, where the complex hyperbolic tangents can be set equal to one.

iii.

The temperature difference is smaller than the average temperature TM very much

greater than TM, so that the thermo physical properties of the gas can be considered

as constant within the stack.

2.2 Design Operating Conditions

For this investigation a design of refrigerator for a temperature difference of TM

=60K and a cooling power of 10 watts was chosen. In the following, the selection of some

operating parameters, the gas and stack materials was discussed.

2.3. Design Assumptions

The assumptions made in the design process are:

1. The thermal conduction (i.e. heat leak from cold side to the hot side) along both the

RS Publication

Page 52

International Journal of Emerging trends in Engineering and Development

ISSN 2249-6149

Issue1, Vol. 2

stack material and the gas in the stack is neglected.

2.

The stack is short compared to the wavelength of the acoustic standing wave.

3. The temperature difference across the stack is a small fraction of the mean

temperature of the stack and gas.

4. The heat and work flow are steady state.

5. The viscosity at the boundary layer is assumed to be zero.

2.4 Design Procedure

A total of 5 basic components have to be designed, of which stack is the most

important. Its not only the most critical component when it comes to the functioning of the

thermo acoustic refrigerator, but also has a determining effect on the design and dimensioning

of all remaining components. In order to begin with the design of the stack, first the values of

all parameters are obtained and finalized. Sometimes direct values are not available. Values at

particular temperatures are accurately available and using appropriate formulae, the values at

operating temperatures can be calculated. The temperature gradient TM is indicative of the

range of temperatures within which the system is going to be operating. Given the lowest

temperature TC and the highest TH one can obtain the operating temperature range which is

nothing but TM.

(1)

Assuming that the maximum operating temperature is 45 oC; and minimum -15oC, a

temperature difference of 60 oC was obtained. In an effort to simplify calculations a

concentrated effort has been put into converting all parameters into dimensionless form so

that computations are simpler. This is achieved by normalising them. Hence TM is converted

into TMN, the normalised mean temperature difference by dividing with mean temperature

TM. Assuming mean temperature to be 300 K, a value of 0.2 is obtained.

(2)

2.5 Dynamic Pressure

The dynamic pressure amplitude PO is limited by the following three factors:

1. The maximum force of the driver

2. Non-linearities

3. Drive ratio

RS Publication

Page 53

International Journal of Emerging trends in Engineering and Development

ISSN 2249-6149

Issue1, Vol. 2

The acoustic ach number can be defined as,

(3)

The acoustic Mach number for noble gases has to be limited to 0.1 in order to avoid

any nonlinear effects [1]. Correspondingly, the drive ratio has to be less than 3%. The value of

2% was chosen.

2.6 Average Pressure and Drive Ratio

After fixing the temperatures, the average pressure was calculated. Since the power

density in the thermo acoustic device is proportional to the average mean pressure P M and

drive ratio

. Hence it is preferable to choose PM and drive ratio D as large as possible.

This is determined by the mechanical strength of the resonator. On the other hand K, the

thermal penetration depth is inversely proportional to the square root of P M. So a high

pressure results in a small K and small stack plate spacing. This makes the construction

difficult. Taking into account these effects and also making the preliminary choice for Helium

as the working gas, the maximal pressure is 12 bars and drive ratio should be D less than 3%

[2]. An average mean pressure of 10 bars and drive ratio 2% was chosen. To minimize the

heat conduction from the hot side of the stack to the cold side, a holder made of Ertacetal

material with low thermal conductivity was used.

Drive ratio D = 2%

Hence

Hence the maximum dynamic pressure amplitude is limited to P 0 = 0.2 bar

2.7 Sound Speed

Speed of sound is given by the expression

(4)

When a sound wave travels through an ideal gas, the longitudinal wave is expected to

be polytrophic or adiabatic and therefore the pressure and volume obey the relationship

(5)

RS Publication

Page 54

International Journal of Emerging trends in Engineering and Development

ISSN 2249-6149

Issue1, Vol. 2

= 1.67 for Helium

The association with the sound wave happens so quickly that there is no opportunity

for heat to flow in or out of the volume of air. This is the adiabatic assumption. Density of gas

is

(6)

Now,

(7)

Therefore speed of sound is

(8)

The ideal gas relationship:

(9)

(10)

This can also be written as [3]

(12)

The conditions for these relationships are that the sound propagation process is adiabatic and

the gas obeys the ideal gas laws.

R = 8.314 J/ mol-K and M = 0.004002602 kg/ mol

Hence, for a mean absolute temperature of 300 K the sound speed is found to be

RS Publication

Page 55

International Journal of Emerging trends in Engineering and Development

ISSN 2249-6149

Issue1, Vol. 2

2.8 Frequency

As the power in the thermo acoustic device is a linear function of the acoustic

resonance frequency [2] an obvious choice is thus a high resonance frequency. On the other

hand k is inversely proportional to the square root of the frequency which again implies a

stack with very small plate spacing. Making a compromise between these two effects and the

fact that the driver resonance has to be maintained to the resonator resonance for high

efficiency of the driver, the frequency of 400Hz was chosen [2].

2.9 Working Gas

After fixing the above values, its time to choose the working gas. It should not be

chemically reactive and should also have a high thermal conductivity. Owing to these reasons,

helium is chosen. It is a noble gas and hence not reactive and has a high thermal conductivity

[3]. It also has the highest sound velocity of all inert gases. Furthermore helium is cheap in

comparison with other noble gases. A gas with a high thermal conductivity is used since k is

proportional to the square root of the thermal coefficient (k).

Having chosen Helium, its properties have to be noted down. Sometimes, accurate

values at desired temperatures are not available necessitating the use of formulae to

extrapolate those values to arrive at the values at the required temperature. Hence the

following formulae are used to arrive at accurate values. Thermal conductivity of helium at

required temperature is given by [3]

(13)

The value of bk is 0.72 for Helium. At 300K the thermal conductivity is 0.1513 W/mK.

The specific heat ratio

for a mono-atomic gas like helium is 5/3 [3]. Specific heat is

found to be 5192.872 [3]. Gas density of helium is 1.626 kg/m3 calculated using the formula

[3].

(14)

(15)

Prandtl number is a dimensionless parameter characterizing the ratio of kinematic viscosity to

thermal diffusivity, which is a very important parameter to study the behaviour of gases in

thermo acoustic devices. The Prandtl number is given by [3]

RS Publication

Page 56

International Journal of Emerging trends in Engineering and Development

ISSN 2249-6149

Issue1, Vol. 2

(16)

The prandtl number written in terms of thermal and viscous penetration depth is

(17)

Viscous friction has a negative effect on the performance of a thermo acoustic system.

Decreasing the prandtl number generally increases the performance of a thermo acoustic

device. Kinetic gas theory has shown that the prandtl number for monatomic gases is about

0.2. Lower prandtl number can be realized using noble gases like Helium and coefficient of

performance of refrigerator can be maximized. The value of

can be obtained from either

equation. They yield the same answer. Prandtl number of 0.6835 is obtained for pure Helium

gas [4-7].

(18)

(19)

A value of V = 0.0987 mm and K = 0.11941 mm was got by calculations.

3 Optimisation of the Thermo Acoustic Refrigerator

In mathematics and computer science, optimization or mathematical programming

refers to choosing the best element from some set of available alternatives.

3.1. Dimensionless Optimization

The motive behind optimization is to improve the performance of the thermo acoustic

refrigerator and to minimize the losses occurring in various components of thermo acoustic

refrigerator. Optimization is done to get the maximum co-efficient of performance taking

practical aspects into consideration.

Dimensionless Optimization (DO) is used in design problems, and consists of the following

steps:

Rendering the dimensions of the design dimensionless

Selecting a local region of the design space to perform analysis on.

RS Publication

Page 57

International Journal of Emerging trends in Engineering and Development

ISSN 2249-6149

Issue1, Vol. 2

Creating an I-optimal design within the local design space.

Forming response surfaces based on the analysis.

Optimizing the design based on the evaluation of the objective function, using the

response surface models.

First, the standing wave thermo acoustic refrigerator was designed for a cooling power of 10

watts and the required dimensions of the components of thermo acoustic refrigerator were

calculated. Secondly, a MATLAB program was devised for the design equations of thermo

acoustic refrigerator. This MATLAB program was used to optimise the design of thermo

acoustic refrigerator to get the optimum co-efficient of performance by minimizing the total

losses in the stack, cold and hot heat exchangers, small and large diameter resonator tube.

Finally, the various values for stack length and stack centre position were got from this. From

the values obtained it was tabulated in Microsoft excel and using scatter option the graph of

COPSTACK versus Lsn for various Xsn values were plotted to locate the maximum value of

COPSTACK. From the maximum value of COPSTACK were noted the corresponding

dimensions for stack and heat exchangers.

The acoustic power loss in small diameter tube (Wsrs) was minimised by plotting the graph of

diameter ratio (D2/D1) with respect to Wsrs. The least value of acoustic power loss was found

and the value of diameter ratio (D2/D1) corresponding to least value of acoustic power loss

was found out.

3.2. Optimization of the stack geometry

In the performance calculations, the data shown in table 3 are used.

Table 3 Parameters used in the performance calculations

Operation parameters

Pm =10 bar

RS Publication

Gas parameters

a = 1019.1047 m/sec.

Tm = 300K

= 0.6835

Tmn = 0.2

= (5/)

= 0.02

= 400Hz,

= 2.46615m-1

B = 0.75

kn

= (2/3)

Page 58

International Journal of Emerging trends in Engineering and Development

ISSN 2249-6149

Issue1, Vol. 2

Fig. 4 Performance calculations for the stack, as function of the normalized length and normalized stack centre position

Figure 4 shows the performance calculations as function of the normalized stack

length Lsn, for different normalized stack positions xn. The normalized position xn = 0,

corresponds to the driver position (pressure antinode). In all cases the COP shows a

maximum. For each stack length there is an optimal stack position. As the normalized length

of the stack increases, the performance peak shifts to larger stack positions, while

performance decreases. This behaviour is to be understood in the following way: A decrease

of the centre position of the stack means that the stack is placed close to the driver. This

position is a pressure antinode and a velocity node which will be discussed in the acoustic

concepts [4-7].

From the fact that sin (kx) is zero where cos (kx) is maximum and vice versa, it

follows that pressure antinodes are always velocity nodes and vice versa; the pressure and

velocity are spatially 90 degrees out-of-phase. The frequency of the acoustic standing wave is

determined by the type of gas, the length L of the resonator and the boundary conditions. A

RS Publication

Page 59

International Journal of Emerging trends in Engineering and Development

ISSN 2249-6149

Issue1, Vol. 2

quarter-wavelength resonator is suitable. But a half-wavelength resonator can also be used.

This depends on how the standing wave fits in the tube. A half-wavelength resonator has two

closed ends, so that the velocity is zero at the ends and the pressure is maximal (antinodes).

The resonance modes are given by the condition that the longitudinal velocity vanishes at the

ends of the resonator is used.

Hence,

(20)

Where,

(21)

In this case it is found that the first (fundamental) mode which is usually used in

thermo acoustic devices, corresponds to L = /2, ergo the name half-wavelength resonator.

For a quarter-wavelength resonator, one end is open and the other end is closed.

This requires a pressure node at the open end, hence

cos kL = 0

(22)

(n = 1, 2, ,)

(23)

so that

The fundamental mode corresponds to L = /4, ergo the name quarter-wave resonator.

The refrigerator shown in Figure 5 is assumed to be a half-wavelength device. Thus, in

the resonance tube, the pressure and velocity distributions will be obtained indicated in

Figure.5

Equation (24) shows that the viscous losses are proportional to the square of the

acoustic velocity. Thus decreasing the velocity will result in a decrease of the losses and

hence a higher COP. The effect of the position of the stack in the standing wave is discussed.

RS Publication

Page 60

International Journal of Emerging trends in Engineering and Development

ISSN 2249-6149

Issue1, Vol. 2

In this section, the effect of the position of the stack in the standing-wave thermo acoustic

devices will be illustrated. In Figure 5 some important length scales are also shown: the

longitudinal lengths, wavelength = 2L, gas excursion x1, stack length LS, and the mean stack

position from the pressure antinode xS, and the transversal length: spacing in the stack

2 k.For audio frequencies, and typically for thermo acoustic devices

(25)

Fig. 5 Model of a thermoacoustic refrigerator. a) An acoustically resonant tube containing a gas, a stack of parallel plates and two heat

exchangers. An acoustic driver is attached to one end of the tube and the other end is closed. Some length scales are also shown: the gas

excursion in the stack x1, the length of the stack LS, the position of the center of the stack from the closed end Xs and the spacing in the stack

2k. (b) Illustration of the standing wave pressure and velocity in the resonator.

Fig. 6 Amount of heat is shuttled along the stack plate

RS Publication

Page 61

International Journal of Emerging trends in Engineering and Development

ISSN 2249-6149

Issue1, Vol. 2

Due to the heat transfer of the parcel of gas to the next, as a result heat Q is

transported from the left end of the plate to the right end, using work W. The heat increases in

the stack from Qc to Qh.

Since the sinusoidal displacement x1 of gas parcels is smaller than the length of the

plate LS, there are many adjacent gas parcels, each confined in its cyclic motion to a short

region of length 2x1, and each reaching the extreme position as that occupied by an adjacent

parcel half an acoustic cycle earlier Figure 6. During the first half of the acoustic cycle, the

individual parcels move a distance x1 toward the pressure antinode and deposit an amount of

heat Q at that position on the plate. During the second half of the cycle, each parcel moves

back to its initial position, and picks up the same amount of heat, that was deposited a half

cycle earlier by an adjacent parcel of gas. The net result is that an amount of heat is passed

along the plate from one parcel of gas to the next in the direction of the pressure antinode as

shown in Figure 6. Finally, it can be noted that, although the adiabatic temperature T1 of a

given parcel may be small, the temperature difference T m over the stack can be large, as the

number of parcels LS/x1, can be large Figure 6. Due to the heat transfer of the parcel of gas to

the next, as a result heat Q is transported from the left end of the plate to the right end, using

work W. The heat increases in the stack from Q c to Qh.

From the above acoustic concept it is clear that the maximum cooling power is

roughly between the pressure antinode and pressure node( /8). From the Figure 4 it is clear

that for a normalized stack length above 0.35 the COP is lower than one. Considering the

above remarks and for practical reasons, a normalized stack center position of X n =0.15 was

chosen. To achieve optimum performance this requires a stack length of Lsn = 0.1. Expressed

in terms of the normal stack center position and length, X s= 6.0823331970753 cm and Ls =

4.0548887980502 cm. This is equivalent to place the hot end of the stack at a distance of

4.0548887980502 cm from the driver. Under these conditions the dimensionless cooling

power is Qcn =2.599747597328005e-006.

Since the required cooling power is 10 watt this leads to a cross sectional area A

=37.25061041907 cm2. This means a radius of r = 3.4434339782798 cm for a cylindrical

resonator. To pump 10 watt of heat the stack uses 4.008313650454014 watts of acoustic

power (COP = 2.494814745564465).

4 Conclusions

RS Publication

Page 62

International Journal of Emerging trends in Engineering and Development

ISSN 2249-6149

Issue1, Vol. 2

The design and optimisation of thermo acoustic refrigerator for a cooling power of 10 watt

was designed and analysed. From the available literatures initially it was assumed that the

optimised value of COP was found at normalised stack centre position, xsn=0.22 and

normalised stack length, Lsn=0.23 for a cooling power of 4 watt. The optimisation graphs

for 4 watt and 10 watt cooling power was compared. It was found that the optimised value

of stack COP for 10 watt cooling power was found to be 2.4948 at xsn=0.15 and Lsn=0.1

which is greater than the stack COP of 1.3 [2] .

From the optimization graph shown in Figure 5, it was clear that the maximum cooling

effect of the thermo acoustic refrigerator was found at the position of maximum pressure

amplitude (Pressure-antinode). Hence; the stack centre position should be placed at the

maximum pressure amplitude.

The acoustic power loss in the resonator tube was minimised by optimizing the geometry

of the resonator tube. It was found that the losses in small diameter tube were minimum at

the diameter ratio of 0.43.

The design has a lot of scope for further improvement by experimenting and investigating

the design and optimisation of the heat exchangers for various geometries for copper

material as it has a high thermal conductivity. The design of the heat exchangers can be

carried for different geometries and the particular geometry can be chosen which

dissipates minimum acoustic power loss. The design of the resonator can be further

improvised by incorporating various different configurations of resonator tube (square

tube, rectangular tube, hollow tube, etc) and the energy losses at the transition between the

large diameter and small diameter tube can be found. A method can be devised to reduce

the energy losses at the transition point (A point between large and small diameter

tube).The main aim of improvising the design of resonator tube geometry is to ensure that

the acoustic pressure waves do not create any turbulence problems.

The variation of the COP with respect to the cooling power can be studied and analysed.

The PLL controller (Phase Loop Locked) can be designed and its performance can be

studied and suitable steps can be incorporating to improve its design. Suitable mechanism

to detect the gas leakage can be found such as pressure relieving valve or safety valve as

the leakage of the inert gases can lead to asphyxiation problems.

RS Publication

Page 63

International Journal of Emerging trends in Engineering and Development

ISSN 2249-6149

Issue1, Vol. 2

Finally, it can conclude that there is nothing like the universal best design since the

thermo acoustics is an ongoing research area. In future an improvised design can be

expected so that its working can be made feasible and applicable in various fields such as

Automobiles, Aeronautics and electronic cooling equipments (Feasibility study of thermo

acoustic heat engines on the performance of automobiles and aircrafts can be studied).The

support of industries and governmental agencies is must for this technology to be made a

viable option. Thermo acoustic Technology is still relatively young, but it holds much

promise for a more sustainable future. The reason for making thermo acoustic a viable

option is to solve the environmental problems such as global warming and green house

gas effects.

References

[1] Swift G W, Thermoacoustic engines, Journal of Acoustic Society of America, 84, 1988

pp. 1146-80

[2] Tijani M E H, Loud speaker driven Thermoacoustic Refrigerators, Ph. D Thesis

[3] Swift G W. Thermoacoustic A unifying perspective for some engines and refrigerators,

Acoust Society of America, American institute of physics, 2002

[4] Tijani MEH, Zeegers JCH, de Waele ATAM, A gas-spring system for optimizing

loudspeakers in thermoacoustic refrigerators, Journal of Applied Physics

[5] Tijani MEH, Zeegers JCH, de Waele ATAM, Design of thermoacoustic refrigerators,

Journal of Cryogenics, 42 (2002), pp 49-57

[6] Tijani MEH, Zeegers JCH, de Waele ATAM, Construction and performance of

thermoacoustic refrigerators, Journal of Cryogenics, 42 (2002), pp 59-66

[7] Feng Wu, Lingen chen, anqing Shu, Xuxian Kan, Kun Wu, Zhichun Yang, Constructal

design of stack filled with parallel plates in standing-wave thermo-acoustic

cooler,Journal of Cryogenics, 49 (2009), pp 107-111

RS Publication

Page 64

International Journal of Emerging trends in Engineering and Development

ISSN 2249-6149

Issue1, Vol. 2

NOMENCLATURE

Lower case

Lower case Greek

Thermal expansion co-efficient

Sound velocity

[m/s]

Cp

Isobaric specific heat

[J/KgK]

Cv

Isochoric specific heat

[J/KgK]

Cs

Specific heat of the stack material [J/KgK]

pressure

Resonator Radius

Position along Sound Propagation [m]

Xs

Position of the Stack

Position perpendicular to sound propagation [m]

yo

Plate half-gap

Prandtl number

[Pa]

Molecular weight

Mach number

[Kg/mol]

Temperature

Volume

Acoustic power

Tm Mean temperature

RS Publication

Dynamic viscosity

[Pa/s]

Angular frequency

[rad/s]

[m]

Stack heat capacity ratio

Wave length

[m]

Upper case Greek

ormalized temperature gradient

Perimeter

[m]

Sub and Superscripts

k

[kg/m3]

Ratio of isobaric to isochoric specific heats

[m]

[m]

Density

Penetration depth

[m]

Upper case

m

[K-1]

[K]

[

Thermal

res Resonator

Viscous

[watt]

[K]

Page 65

Vous aimerez peut-être aussi

- Aarush S AjithDocument1 pageAarush S AjithMichael DouglasPas encore d'évaluation

- Handbook of Industrial EngineeringDocument24 pagesHandbook of Industrial EngineeringRanachetan SinghPas encore d'évaluation

- Keam Admitcard PDFDocument1 pageKeam Admitcard PDFMichael DouglasPas encore d'évaluation

- Gasdynamics PDFDocument465 pagesGasdynamics PDFPeri Pitriadi CaralozPas encore d'évaluation

- Construction Therm RefrigeratorDocument8 pagesConstruction Therm RefrigeratorKiran KumarPas encore d'évaluation

- Handout Module6Document69 pagesHandout Module6Oana MirceaPas encore d'évaluation

- Human Serum Albumin, Systemic in Ammation, and Cirrhosis: ReviewDocument12 pagesHuman Serum Albumin, Systemic in Ammation, and Cirrhosis: ReviewMichael DouglasPas encore d'évaluation

- Es Pod Mono Pod User ManualDocument3 pagesEs Pod Mono Pod User ManualMichael DouglasPas encore d'évaluation

- Codex General Standard For Food Additives Cxs - 192eDocument332 pagesCodex General Standard For Food Additives Cxs - 192eMichael DouglasPas encore d'évaluation

- AISI 316L Stainless Steel GuideDocument2 pagesAISI 316L Stainless Steel GuideMichael DouglasPas encore d'évaluation

- Human Serum Albumin, Systemic in Ammation, and Cirrhosis: ReviewDocument12 pagesHuman Serum Albumin, Systemic in Ammation, and Cirrhosis: ReviewMichael DouglasPas encore d'évaluation

- Instruction: Installation, Configuration, Troubleshooting, and MaintenanceDocument72 pagesInstruction: Installation, Configuration, Troubleshooting, and MaintenanceMichael DouglasPas encore d'évaluation

- DOP Test ProtocolDocument10 pagesDOP Test ProtocolIzi100% (2)

- AISI 316L Stainless Steel GuideDocument2 pagesAISI 316L Stainless Steel GuideMichael DouglasPas encore d'évaluation

- General Specifications: Daqstation DX1000Document23 pagesGeneral Specifications: Daqstation DX1000Michael DouglasPas encore d'évaluation

- Ficha Tecnica SIEMENS S7300Document124 pagesFicha Tecnica SIEMENS S7300Daniel SuarezPas encore d'évaluation

- General Specifications: Daqstation DX1000Document23 pagesGeneral Specifications: Daqstation DX1000Michael DouglasPas encore d'évaluation

- Luxmeter ManualDocument2 pagesLuxmeter ManualMichael DouglasPas encore d'évaluation

- Pencillium MorphologyDocument4 pagesPencillium MorphologyMichael DouglasPas encore d'évaluation

- Hold Up Volume CalculatorDocument3 pagesHold Up Volume CalculatorMichael DouglasPas encore d'évaluation

- IndiaTop60 Brochure LRDocument2 pagesIndiaTop60 Brochure LRMichael DouglasPas encore d'évaluation

- GBT 004 LabelingDocument12 pagesGBT 004 LabelingMichael DouglasPas encore d'évaluation

- 1794 Um061 - en PDocument132 pages1794 Um061 - en PHimanshu MauryaPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Uncertainty IR PDFDocument8 pagesUncertainty IR PDFluisPas encore d'évaluation

- Shot Peenning and Grit Blasting Effect On Surface Integrity PDFDocument6 pagesShot Peenning and Grit Blasting Effect On Surface Integrity PDFmanuPas encore d'évaluation

- Spectrophotometric Determination of The Equilibrium Constant of A Reaction DraftDocument3 pagesSpectrophotometric Determination of The Equilibrium Constant of A Reaction DraftFem T. BartolomePas encore d'évaluation

- Development of Ghat River in Jaunpur City: 1-Anil BhartiDocument9 pagesDevelopment of Ghat River in Jaunpur City: 1-Anil BhartiA8304008005Pas encore d'évaluation

- RC Corbel Design (ACI318-05)Document2 pagesRC Corbel Design (ACI318-05)Mohammed Z. AlSaqqa100% (1)

- Maximizing Volumetric Efficiency of IC Engine Through Intake Manifold TuningDocument8 pagesMaximizing Volumetric Efficiency of IC Engine Through Intake Manifold TuningMahtab GhummanPas encore d'évaluation

- Sta. Lucia High School Science TestDocument3 pagesSta. Lucia High School Science TestEileen Joy Noceda86% (69)

- Chemical StabilizationDocument63 pagesChemical Stabilizationanahita_63100% (1)

- Microdroplet Technology - Principles and Emerging Applications in Biology and Chemistry - Philip Day Et Al. (Springer, 2012)Document249 pagesMicrodroplet Technology - Principles and Emerging Applications in Biology and Chemistry - Philip Day Et Al. (Springer, 2012)CA Uttam Prakash Agarwal100% (1)

- Activity 2.2 Atomic Orbitals - S2-2015Document10 pagesActivity 2.2 Atomic Orbitals - S2-2015Devandra Eko RadityoPas encore d'évaluation

- The WATERMARK CODEX MentalismDocument10 pagesThe WATERMARK CODEX Mentalismtrixter11793100% (1)

- Float ValveDocument1 pageFloat Valveabdulkidwai2009Pas encore d'évaluation

- What Is The Major Function of The Coating On An Arc Welding ElectrodeDocument7 pagesWhat Is The Major Function of The Coating On An Arc Welding ElectrodeElham Jaraine Garcia Lpt100% (4)

- Experiment 4Document5 pagesExperiment 4chsullivan17Pas encore d'évaluation

- Pen Type Visual Fault Locator: SpecificationsDocument1 pagePen Type Visual Fault Locator: SpecificationsHuy DuPas encore d'évaluation

- Chapter 6 Final A5 EditDocument16 pagesChapter 6 Final A5 EditkINGPas encore d'évaluation

- Current Events: Internet 1: An Optical Switch Based On A Single Nano-DiamondDocument3 pagesCurrent Events: Internet 1: An Optical Switch Based On A Single Nano-Diamondjennylee00182Pas encore d'évaluation

- THE HIGH PRESSURE ROLLER PRESSDocument27 pagesTHE HIGH PRESSURE ROLLER PRESSThaigroup Cement100% (10)

- Strength Materials Lab ManualDocument32 pagesStrength Materials Lab ManualMuhammad Junaid100% (1)

- What Are HerbicidesDocument14 pagesWhat Are HerbicidesBabatunde Alim OluwafẹmiPas encore d'évaluation

- ManualDocument68 pagesManualMohammadIsmailPas encore d'évaluation

- As Physics 2016Document21 pagesAs Physics 2016WongXinXinPas encore d'évaluation

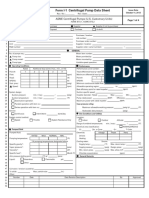

- Form I-1 Centrifugal Pump Data SheetDocument4 pagesForm I-1 Centrifugal Pump Data SheetJohnPas encore d'évaluation

- DAO 2016-08 Features and CAPDocument64 pagesDAO 2016-08 Features and CAPDianne Kristine Avila100% (4)

- BMW Fault Codes OBDDocument15 pagesBMW Fault Codes OBDtitibacsiPas encore d'évaluation

- Specification For Pressure Vessel Plates, Alloy Steel, Manganese-Molybdenum and Manganese-Molybdenum-NickelDocument4 pagesSpecification For Pressure Vessel Plates, Alloy Steel, Manganese-Molybdenum and Manganese-Molybdenum-NickelmalsttarPas encore d'évaluation

- MEC102 Engineering Mechanics Course OverviewDocument1 pageMEC102 Engineering Mechanics Course OverviewVkrthirumalai RamanathanPas encore d'évaluation

- Welding Procedure Datasheet: ScopeDocument5 pagesWelding Procedure Datasheet: ScopePerminder SinghPas encore d'évaluation

- Motion Canada - Bearing CatalogDocument212 pagesMotion Canada - Bearing CatalogEric Lafrance100% (1)

- How To Process and Print Black-and-White FilmDocument6 pagesHow To Process and Print Black-and-White FilmPepParamosPas encore d'évaluation