Académique Documents

Professionnel Documents

Culture Documents

Materials System Specification

Transféré par

AjeetKumarDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Materials System Specification

Transféré par

AjeetKumarDroits d'auteur :

Formats disponibles

Materials System Specification

09-SAMSS-071

16 July 2011

Qualification Requirements for Inorganic

Zinc Primer (APCS-17A) and (APCS-17B)

Document Responsibility: Paints and Coatings Standards Committee

Saudi Aramco DeskTop Standards

Table of Contents

1

Scope............................................................. 2

Conflicts and Deviations................................. 2

References..................................................... 3

General Requirements................................... 4

Qualification Tests and Requirements........... 4

Method of Packaging..................................... 6

Previous Issue: 8 August 2007 Next Planned Update: 16 July 2016

Revised paragraphs are indicated in the right margin

Primary contact: Nujaim, Salah Ahmed on 966-3-8760258

CopyrightSaudi Aramco 2006. All rights reserved.

Page 1 of 6

Document Responsibility: Paints and Coatings Standards Committee

09-SAMSS-071

Issue Date: 16 July 2011

Qualification Requirements for Inorganic

Next Planned Update: 16 July 2016

Zinc Primer (APCS-17A) and (APCS-17B)

Scope

This Specification defines the minimum mandatory requirements for qualifying

individual coating products for use in Saudi Aramco's approved protective coating

systems APCS-17A and APCS-17B for inorganic zinc coatings. It shall be used when

any of the following situations occur:

1.1

Initial Product Approval

This specification shall be given to coating manufacturers, or other vendors of

coating products, who wish to obtain initial approval for products that have not

previously been qualified in accordance with this specification.

1.2

Purchase Requisitions/Purchase Orders

This specification shall be attached to Purchase Requisitions or Purchase Orders

when those documents address the procurement of coating products that have

not been previously qualified in accordance with this specification.

This specification does not apply to, and should not be included with, Purchase

orders or requisitions for coating products that have been previously qualified

per this specification. This specification should also not be included with

purchase orders or requisitions for coated items or equipment when a Saudi

Aramco approved protective coating system has been specified.

1.3

Periodic Product Compliance Checks

This specification shall be used for periodic product compliance checks on

previously approved coatings. It shall be given to the organization conducting

the compliance tests.

Conflicts and Deviations

2.1

Any conflicts between this specification and other applicable Saudi Aramco

Materials System Specifications (SAMSSs), Engineering Standards (SAESs),

Standard Drawings (SASDs), or industry standards, codes, and forms shall be

resolved in writing by the Company or Buyer Representative through the

Manager, Consulting Services Department of Saudi Aramco, Dhahran.

2.2

Direct all requests to deviate from this specification in writing to the Company or

Buyer Representative, who shall follow internal company procedure SAEP-302

and forward such requests to the Manager, Consulting Services Department of

Saudi Aramco, Dhahran.

Page 2 of 6

Document Responsibility: Paints and Coatings Standards Committee

09-SAMSS-071

Issue Date: 16 July 2011

Qualification Requirements for Inorganic

Next Planned Update: 16 July 2016

Zinc Primer (APCS-17A) and (APCS-17B)

References

References noted below shall be of the latest edition, addenda, or revision in effect:

a)

On the date of the Purchase Order.

b)

On the date testing is begun if there is no Purchase Order involved.

3.1

Saudi Aramco References

Saudi Aramco Engineering Procedure

SAEP-302

Instructions for Obtaining a Waiver of a

Mandatory Saudi Aramco engineering

Requirement

Saudi Aramco Materials System Specification

09-SAMSS-060

Packaging Requirements for Coatings

Saudi Aramco Engineering Standards

SAES-H-101 APCS-17A Inorganic Zinc Primer (Solvent Based)

SAES-H-101 APCS-17B Inorganic Zinc Primer (Water Based)

3.2

Industry Codes and Standards

American Society for Testing and Materials

ASTM A36

Structural Steel

ASTM B117

Salt Spray (Fog) Testing

ASTM-D520

Zinc Dust Pigments

ASTM D-521

Methods for Chemical Analysis of Zinc Dust

ASTM D-562

Consistency of Paints Measuring Krebs Unit (KU)

Viscosity Using a Stormer-Type Viscometer

(Metallic Zinc Powder)

ASTM D610

Evaluating Degree of Rusting on Painted Steel

Surfaces

ASTM D660

Evaluating Degree of Checking of Exterior Paints

ASTM D661

Evaluating Degree of Cracking of Exterior Paints

ASTM D822

Operating Light-and-water Exposure Apparatus

(Carbon-arc Type) for Testing Paint, Varnish,

Lacquer, and Related Products

ASTM D714

Evaluating Degree of Blistering of Paints

Page 3 of 6

Document Responsibility: Paints and Coatings Standards Committee

09-SAMSS-071

Issue Date: 16 July 2011

Qualification Requirements for Inorganic

Next Planned Update: 16 July 2016

Zinc Primer (APCS-17A) and (APCS-17B)

ASTM D1654

Method for Evaluation of Painted or Coated

Specimens Subjected to Corrosive

Environments

ASTM D3363

Film Hardness by Pencil Test

ASTM G26

Operating Light-Exposure Apparatus (Xenon-Arc

Type) With and Without Water for Exposure of

Nonmetallic Materials

The Society for Protective Coatings

SSPC-PA2

Measurement of Dry Coating Thickness with

Magnetic Gages

SSPC-Paint 20

Zinc-Rich Primers (Type I, Inorganic) dated

November 1, 1982

SSPC-Vis 1

Visual Standard for Abrasive Blast Cleaned Steel

International Standard Organization (ISO)

ISO 12944

Paints & Varinches, Corrosion Protection of Steel

Structure by Protective Paint System

General Requirements

4.1

For purposes of this specification, the Buyer's Representative shall be the

Responsible Standardization Agency Representative (RSA).

4.2

In order to qualify a coating system as acceptable under this specification, the

coating supplier shall submit a certified test report documenting that the

proposed coating system meets the qualification tests and requirements of this

SAMSS. Preparation and testing shall be performed and/or witnessed by an

independent laboratory or inspection agency. The coating quality assurance of

zinc-rich coatings Type I shall follow the requirement in SSPC-20. This test

report shall be submitted to the Saudi Aramco RSA for review and approval if

the data presented by the Supplier satisfies all the requirements.

4.3

All initial product qualification tests shall be carried out at no cost to Saudi

Aramco.

Qualification Tests and Requirements

5.1

Modification to SSPC-Paint 20

All paint supplied under this Specification shall meet the requirements of

SSPC-Paint 20 except as modified below:

Page 4 of 6

Document Responsibility: Paints and Coatings Standards Committee

09-SAMSS-071

Issue Date: 16 July 2011

Qualification Requirements for Inorganic

Next Planned Update: 16 July 2016

Zinc Primer (APCS-17A) and (APCS-17B)

Paragraph 5.6: Shall be replaced by paragraph 5.2.2.1 of this Specification.

Paragraph 5.9: Shall be replaced by paragraph 5.2.3 of this Specification.

Paragraphs 7, 9 and 10.8: Delete requirements.

5.2

Requirements in Addition to SSPC - Paint 20

5.2.1

Physical Property Tests

Hardness: When cured for 24 hours at 20C and 50-60% relative

humidity, the cured film shall have a hardness equivalent of not less than

2H when tested in accordance with ASTM D3363.

5.2.2

5.2.3

Steel Panel Preparation

5.2.2.1

Test panels shall be ASTM A36 hot rolled steel approximately

100 mm X 150 mm. Prior to preparing the surface, the

condition of the test panel shall be equivalent to SSPC-Guide

to Vis 1 Rust Grade A, Adherent Mill Scale. The minimum

thickness of the test panel shall be 5 mm.

5.2.2.2

The surface cleanliness of the test panels shall meet (but not

exceed) the requirements of SSPC SP10, Near White Blast

Cleaning (SIS Sa2-, Very Thorough Blast Cleaning).

5.2.2.3

The profile of blasted surface shall be 40-65 micrometers

(1.5 - 2.5 mils) and shall be determined with replica tape.

5.2.2.4

Mix, apply, and cure, the in accordance with the Vendor's

recommendations. Measure and report the dry film thickness

in accordance with SSPC-PA2. The dry film thickness shall be

in the range of 65-100 micrometers (2.5 - 4 mils).

Performance Tests

Scribe the fully cured coating in accordance with ASTM D1654 and

expose alternately in a Weather-O-Meter in accordance with either

(a) ASTM D822, Procedure B; (b) ASTM G26, Method B; or

(c) ASTM G-53 and a salt fog cabinet in accordance with ASTM B117.

Panels are to be initially placed in the Weather-O-Meter for 100 hours

and then tested in the salt fog cabinet for 200 hours. This procedure

shall be continued until the test panels are exposed for 500 hours in

Weather-O-Meter and 1000 hours in salt fog. At the conclusion of the

test, each coating shall be evaluated for and shall meet the criteria of

Table 1.

Page 5 of 6

Document Responsibility: Paints and Coatings Standards Committee

09-SAMSS-071

Issue Date: 16 July 2011

Qualification Requirements for Inorganic

Next Planned Update: 16 July 2016

Zinc Primer (APCS-17A) and (APCS-17B)

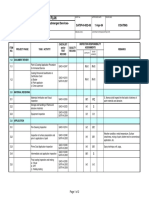

Table 1 Performance Test

Standard

5.2.4

Acceptable Rating

ASTM D714

Evaluating Degree of Blistering

of Paints

No blisters

ASTM D660

Evaluating Degree of Checking

of Exterior Paints

No checking

ASTM D661

Evaluating Degree of Cracking

of Exterior Paints

No cracking

ASTM D610

Evaluating Degree of Rusting

on Painted Steel Surfaces

10

ASTM D1654

Standard Evaluation of Painted

Rating of Failure at

or Coated Specimens Subjected

Scribe shall be: 10.

to Corrosive Environments

Recoat Time

Prepare two test panels in accordance with paragraph 5.2.2. Cure the

panels for 48 hours at 55 to 80% relative humidity and 25C 1C.

Topcoat one of the panels with 100-150 micrometers (4.0 - 6.0 mils) of

an epoxy paint (APCS-1A topcoat or equivalent). Topcoat the other

panel with 15 - 40 micrometers (0.5 - 1.5 mils) of a silicone aluminum

paint (APCS-11A topcoat or equivalent). Allow the topcoats to cure.

The panels shall show no signs of blistering or pinholing.

Method of Packaging

Coatings shall be packaged in accordance with 09-SAMSS-060.

16 July 2011

Revision Summary

Revised the "Next Planned Update". Reaffirmed the contents of the document, and reissued

with editorial revision to remove the committee members list.

Page 6 of 6

Vous aimerez peut-être aussi

- SATIP-H-002-06 Coating For Submerged Services-APCS 113 ABCDocument2 pagesSATIP-H-002-06 Coating For Submerged Services-APCS 113 ABChossamalsherbinyPas encore d'évaluation

- 09 Samss 088Document4 pages09 Samss 088Moustafa BayoumiPas encore d'évaluation

- Water Fill Up Testing Procedure-R3 07.07.2011sohar 2Document7 pagesWater Fill Up Testing Procedure-R3 07.07.2011sohar 2AjeetKumarPas encore d'évaluation

- Apcs 113a Rev 3 Pid ApprovalDocument19 pagesApcs 113a Rev 3 Pid ApprovalMedel Cay De Castro50% (2)

- Elevators: Interiors, Ceilings, Handrails, Doors, Lobby Walls & MaterialsDocument32 pagesElevators: Interiors, Ceilings, Handrails, Doors, Lobby Walls & MaterialsAbu NijamPas encore d'évaluation

- 09 Samss 091Document19 pages09 Samss 091Sohail Tisekar100% (1)

- Saep 1200Document9 pagesSaep 1200Anonymous 4IpmN7On100% (1)

- SAES-H-102-Safety Requirements For Coating Applications2Document12 pagesSAES-H-102-Safety Requirements For Coating Applications2محمد العيسوىPas encore d'évaluation

- Specifications of Painting WorksDocument7 pagesSpecifications of Painting WorksSiddharth Gamare100% (1)

- 09 Samss 060Document4 pages09 Samss 060asimazami69Pas encore d'évaluation

- 09 Samss 021Document8 pages09 Samss 021Kalanithi KasirajanPas encore d'évaluation

- Materials System SpecificationDocument10 pagesMaterials System SpecificationAjeetKumar100% (1)

- Abrasives and SAMSS Numbers GuideDocument2 pagesAbrasives and SAMSS Numbers GuideSivaratnam Navatharan100% (1)

- Alodine Application GuideDocument110 pagesAlodine Application GuidewashgusberPas encore d'évaluation

- SAUDI ARAMCO ID/PIEU-30-Nov-2018Document2 pagesSAUDI ARAMCO ID/PIEU-30-Nov-2018Moghal AliPas encore d'évaluation

- Epoxy Coating Systems Guide for Atmospheric & Immersion ApplicationsDocument3 pagesEpoxy Coating Systems Guide for Atmospheric & Immersion ApplicationsnasirPas encore d'évaluation

- 09 Samss 068Document7 pages09 Samss 068AjeetKumarPas encore d'évaluation

- Saes H 200 PDFDocument9 pagesSaes H 200 PDFSohail Aziz Ahmad Malik100% (1)

- Saes H 101V PDFDocument389 pagesSaes H 101V PDFQA QCPas encore d'évaluation

- Saudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatDocument3 pagesSaudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatMoghal AliPas encore d'évaluation

- SAEP-303: 2 Conflicts and DeviationsDocument19 pagesSAEP-303: 2 Conflicts and DeviationsnasirPas encore d'évaluation

- CBT Questions 26022020Document43 pagesCBT Questions 26022020Shawn LeoPas encore d'évaluation

- 09 Samss 030Document8 pages09 Samss 030Kalanithi KasirajanPas encore d'évaluation

- SAIC-H-2032 Rev 7Document4 pagesSAIC-H-2032 Rev 7Satheesh Rama SamyPas encore d'évaluation

- Astm c478mDocument8 pagesAstm c478mNelson HernandezPas encore d'évaluation

- Hetron Fabrication Process PDFDocument57 pagesHetron Fabrication Process PDFDyah AyuPas encore d'évaluation

- 09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)Document9 pages09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)middlepermian100% (1)

- Saes H 204Document34 pagesSaes H 204heartbreakkid132Pas encore d'évaluation

- Materials System SpecificationDocument8 pagesMaterials System SpecificationAjeetKumarPas encore d'évaluation

- 09 Samss 069Document10 pages09 Samss 069Selvakpm06Pas encore d'évaluation

- Saudi Aramco Concrete Coating ProcedureDocument10 pagesSaudi Aramco Concrete Coating Proceduremoytabura96100% (1)

- Materials System SpecificationDocument10 pagesMaterials System SpecificationAjeetKumar100% (1)

- Materials System SpecificationDocument10 pagesMaterials System SpecificationAjeetKumar100% (1)

- BGas Painting Inspection Grade 2 Multiple ChoiceDocument12 pagesBGas Painting Inspection Grade 2 Multiple Choicetcagokl93% (43)

- SAES-H-201 General Specification For Over-The-Ditch External & Internal ... 2017 VersionDocument13 pagesSAES-H-201 General Specification For Over-The-Ditch External & Internal ... 2017 VersiondanishPas encore d'évaluation

- Nbs Plus k10 Specification DetailsDocument0 pageNbs Plus k10 Specification Detailsmajkil1988100% (1)

- Inspection Check List 2Document34 pagesInspection Check List 2r.devendranPas encore d'évaluation

- SP0490-2007 Holiday Detection of Fusion-Bonded Epoxy CoatingsDocument1 pageSP0490-2007 Holiday Detection of Fusion-Bonded Epoxy CoatingsJhon Fredy De La Hoz Martinez67% (3)

- External Floating RoofDocument14 pagesExternal Floating RoofAjeetKumarPas encore d'évaluation

- Aramco Apcs 1bDocument55 pagesAramco Apcs 1bSadek Sad100% (2)

- 09-SAMSS-069 - Epoxy Coating For Atmospheric Service PDFDocument10 pages09-SAMSS-069 - Epoxy Coating For Atmospheric Service PDFsuresh_viki100% (1)

- Painting Inspection Grade 2/3 Exam: Unit Test - 4Document1 pagePainting Inspection Grade 2/3 Exam: Unit Test - 4AjeetKumar0% (1)

- Sigmacover 410Document4 pagesSigmacover 410gstketutPas encore d'évaluation

- Coating CardDocument15 pagesCoating CardAnton Thomas PunzalanPas encore d'évaluation

- Materials System SpecificationDocument7 pagesMaterials System SpecificationAjeetKumarPas encore d'évaluation

- Materials System SpecificationDocument7 pagesMaterials System SpecificationAjeetKumarPas encore d'évaluation

- Saes H 102Document10 pagesSaes H 102HaleemUrRashidBangash100% (1)

- 09 SAMSS 089 (Final Draft - 2018)Document28 pages09 SAMSS 089 (Final Draft - 2018)lhanx2Pas encore d'évaluation

- SATIP H 002 08 Pipe Internal CoatingDocument3 pagesSATIP H 002 08 Pipe Internal CoatinghossamalsherbinyPas encore d'évaluation

- Paint System Recommendations PDFDocument6 pagesPaint System Recommendations PDFKumarPas encore d'évaluation

- Renovation Coating Inspection PlanDocument10 pagesRenovation Coating Inspection PlanMoghal AliPas encore d'évaluation

- Saes H 201Document9 pagesSaes H 201heartbreakkid132Pas encore d'évaluation

- Saes H 004Document8 pagesSaes H 004kaleeswaran s100% (1)

- Saes H 102Document10 pagesSaes H 102Kaleelur RahmanPas encore d'évaluation

- Ipcoat Exam Test Paper 123Document1 pageIpcoat Exam Test Paper 123Senthil Kumar100% (1)

- Saudi Aramco Field Coating Inspection ReportDocument3 pagesSaudi Aramco Field Coating Inspection Reportravi ajith100% (1)

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGDocument5 pagesTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGvajidqcPas encore d'évaluation

- SATIP-H-002-05 Epoxy For Atmospheric Up To 150CDocument2 pagesSATIP-H-002-05 Epoxy For Atmospheric Up To 150ChossamalsherbinyPas encore d'évaluation

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanMoghal AliPas encore d'évaluation

- 18B. Protegol UR 32.55R Data SheetDocument3 pages18B. Protegol UR 32.55R Data SheetClarkFedele27Pas encore d'évaluation

- SATR-H-2004 Rev 7Document3 pagesSATR-H-2004 Rev 7josephPas encore d'évaluation

- Removing Coatings and Cleaning Masonry Substrates: Kenneth A. Trimber KTA-Tator, IncDocument46 pagesRemoving Coatings and Cleaning Masonry Substrates: Kenneth A. Trimber KTA-Tator, IncMilagros MorantesPas encore d'évaluation

- Saes H 200Document9 pagesSaes H 200راجہ شہزاد انورPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistAnantha PadmanabhanPas encore d'évaluation

- Coating Personnel Id FormatDocument1 pageCoating Personnel Id FormatShabbar Abbas MalikPas encore d'évaluation

- Apcs 117Document12 pagesApcs 117Ilyas AhmedPas encore d'évaluation

- Saes H 204Document33 pagesSaes H 204Rei Lizardo100% (1)

- Saep 119Document11 pagesSaep 119Demac SaudPas encore d'évaluation

- 09 Samss 071Document6 pages09 Samss 071inatt101100% (1)

- Qualification Requirements for Inorganic Zinc PrimerDocument6 pagesQualification Requirements for Inorganic Zinc PrimeraliabdulhamidPas encore d'évaluation

- 09 Samss 070Document11 pages09 Samss 070NASIR SYEDPas encore d'évaluation

- 09 Samss 087 PDFDocument8 pages09 Samss 087 PDFMohamed SolimanPas encore d'évaluation

- 09-SAMSS-101 - Qualification Requirements For Stand Alone Self-Priming EpoxyDocument9 pages09-SAMSS-101 - Qualification Requirements For Stand Alone Self-Priming EpoxyAhmed HassaninPas encore d'évaluation

- Materials System SpecificationDocument22 pagesMaterials System SpecificationAjeetKumarPas encore d'évaluation

- Materials System SpecificationDocument17 pagesMaterials System SpecificationAjeetKumarPas encore d'évaluation

- 09 Samss 087Document7 pages09 Samss 087AjeetKumarPas encore d'évaluation

- 09 Samss 075Document4 pages09 Samss 075Moustafa Bayoumi50% (2)

- Materials System SpecificationDocument8 pagesMaterials System SpecificationAjeetKumar100% (1)

- 09 Samss 021Document8 pages09 Samss 021Moustafa BayoumiPas encore d'évaluation

- Materials System SpecificationDocument4 pagesMaterials System SpecificationAjeetKumarPas encore d'évaluation

- Uk Technical Institute, Kottakkal, Malappuram DT: Answer in Short (2 Marks Each)Document1 pageUk Technical Institute, Kottakkal, Malappuram DT: Answer in Short (2 Marks Each)AjeetKumar75% (4)

- Painting SpecificationDocument53 pagesPainting SpecificationAjeetKumar100% (2)

- 09 Samss 087Document7 pages09 Samss 087AjeetKumarPas encore d'évaluation

- CNC Wood Turning Lathe Cutters Bits Knife ToolsDocument5 pagesCNC Wood Turning Lathe Cutters Bits Knife ToolsSalce SmithPas encore d'évaluation

- Is 6745 1972Document20 pagesIs 6745 1972Sathish Kumar100% (2)

- Final ReportDocument35 pagesFinal ReportAsiri MihiranPas encore d'évaluation

- P00558 Coatings Presentation External - FINALDocument17 pagesP00558 Coatings Presentation External - FINALLowLacPas encore d'évaluation

- Ceramics, Glasses, and Superconductors Processing TechniquesDocument44 pagesCeramics, Glasses, and Superconductors Processing TechniquesSuleman Ayub100% (1)

- Cancord CatalogueDocument50 pagesCancord CataloguejsdoodnathPas encore d'évaluation

- NADCA Product Specification Standards For Die Castings-Chapter10-2012Document32 pagesNADCA Product Specification Standards For Die Castings-Chapter10-2012wholenumberPas encore d'évaluation

- Review Durability of Materials in Molten Aluminum AlloysDocument11 pagesReview Durability of Materials in Molten Aluminum AlloysJavier Alejandro Araujo MoreraPas encore d'évaluation

- Data Sheet Proguard CN 200 A.SDocument3 pagesData Sheet Proguard CN 200 A.SAlexir Thatayaone NdoviePas encore d'évaluation

- Transportation Lab PostersDocument8 pagesTransportation Lab PostersTushar WalePas encore d'évaluation

- Standard Primer Product Data PDFDocument2 pagesStandard Primer Product Data PDFgafarmerdan100% (1)

- Copper Tube Federal and Astm SpecificationsDocument4 pagesCopper Tube Federal and Astm SpecificationsSai PrasathPas encore d'évaluation

- Bison Power Adhesive BisoniteDocument1 pageBison Power Adhesive BisoniteRadu ConstantinPas encore d'évaluation

- Silane Coup-Ling AgentsDocument263 pagesSilane Coup-Ling Agentssasidharkantheti100% (1)

- Us Elastomeric CoatingsDocument122 pagesUs Elastomeric CoatingsTeresapilarPas encore d'évaluation

- Richard Nakka's Experimental Rocketry SiteDocument8 pagesRichard Nakka's Experimental Rocketry Siteazrim02Pas encore d'évaluation

- Factors Affecting Concrete WorkabilityDocument4 pagesFactors Affecting Concrete WorkabilityAli ArsalanPas encore d'évaluation

- Life Expectancy - Home ComponentsDocument19 pagesLife Expectancy - Home ComponentsLuke LauPas encore d'évaluation

- KH - Design CriteriaDocument8 pagesKH - Design Criteriamohamed_126193901Pas encore d'évaluation

- A Micromechanics-Based Model For Stiffness and Strength Estimation of Cocciopesto MortarsDocument9 pagesA Micromechanics-Based Model For Stiffness and Strength Estimation of Cocciopesto Mortarszebra00Pas encore d'évaluation

- Al-Jazeera Afrw Base Coat14Document1 pageAl-Jazeera Afrw Base Coat14bsranjha100% (1)

- Asphalt LectureDocument11 pagesAsphalt LectureKeesh Marlon Repatacodo TabalPas encore d'évaluation

- Bond strength between old and new concreteDocument14 pagesBond strength between old and new concreteMaurício FerreiraPas encore d'évaluation