Académique Documents

Professionnel Documents

Culture Documents

Plasma Manuel

Transféré par

poopDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Plasma Manuel

Transféré par

poopDroits d'auteur :

Formats disponibles

AJAN ELEKTRONIK SERVIS SANAYI TICARET LTD. STI.

MAINTENANCE MANUAL FOR AJAN PRECISION

PLASMA 260 AMPER PLASMA CUTTING MACHINES

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

INDEX

ii

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

INDEX

SECTION 1. INDEX

Section name .................................................................................................................. Page number

SECTION 1. INDEX .......................................................................................................................... i

SECTION 2. TABLE OF FIGURES .............................................................................................. iv

SECTION 3. TABLES .................................................................................................................... vii

SECTION 4. COMPANY PROFILE ...............................................................................................1

SECTION 5. INSTALLATION AND ELECTROMAGNETIC COMPATIBILITY .................2

5.1. EMC INTRODUCTION .......................................................................................................... 2

5.2. INSTALLATION AND USAGE ............................................................................................. 2

5.3. ESTIMATION OF AREA ........................................................................................................ 2

5.4. MAIN POWER......................................................................................................................... 3

5.5. EQUIPOTENTIAL BONDINGS ............................................................................................. 3

SECTION 6. SAFETY .......................................................................................................................4

6.1. RECOGNIZE SAFETY INFORMATION .............................................................................. 4

6.2. FOLLOWING SAFETY INSTRUCTIONS ............................................................................ 4

6.3. DANGER, WARNING, CAUTION ........................................................................................ 4

6.4. FIRE AND EXPLOSION RISKS WHILE CUTTING ............................................................ 5

6.4.1. Prevention from Explosion ................................................................................................ 5

6.5. ELECTRIC SHOCK................................................................................................................. 6

6.5.1. Prevention from Electric Shock......................................................................................... 6

6.6. TOXIC FUMES OCCUR WHILE CUTTING ........................................................................ 7

6.7. PLASMA ARC RAY INJURES EYES AND SKIN ............................................................... 7

6.7.1. GROUNDING SAFETY ................................................................................................... 8

6.7.2. SAFETY FOR COMPRESSED CYLINDERS................................................................. 8

6.7.3. GAS CYLINDERS CAN EXPLODE ............................................................................... 8

6.8. NOISE DAMAGE .................................................................................................................... 9

6.9. SAFETY SIGNS AND DESCRIPTIONS .............................................................................. 10

6.10. WELDING FUMES AND GASES ...................................................................................... 12

6.10.1. FUMES AND GASES .................................................................................................. 12

6.10.2. TOXIC FUMES AND GASES ..................................................................................... 13

6.10.3. LOW-TEMPERATURE PLASMA FUMES, EXHAUST GAS PURIFICATION FOR

ORGANIC ..................................................................................................................... 13

SECTION 7. WARRANTY .............................................................................................................14

7.1. AJAN BRAND PLASMA AND OXY-FUEL CUTTING MACHINE WARRANTY

CONDITIONS ..................................................................................................................... 14

7.2. CASES CAUSING OUT OF WARRANTY.......................................................................... 15

SECTION 8. PREUSAGE ...............................................................................................................16

8.1. ATTENTIONS BEFORE STARTING CUTTING WITH PRECISION PLASMA

MACHINES ......................................................................................................................... 16

8.1.1. CONTROL OF THE CYLINDERS AND THEIR PRESSURE ..................................... 16

8.1.2. STARTING GENERATOR ............................................................................................ 16

8.1.3. STARTING CNC UNIT.................................................................................................. 16

8.1.4. CHASSIS CABLE AND CONTROL ............................................................................. 16

i

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

INDEX

8.1.5. USAGE OF CUTTING TIPS .......................................................................................... 16

8.1.6. OPERATING JET FILTER ............................................................................................ 17

8.2. ATTENTIONS BEFORE STARTING CUTTING WITH P MACHINES ........................... 18

8.2.1. CONTROL OF THE CYLINDERS AND THEIR PRESSURE ..................................... 18

8.2.2. STARTING ..................................................................................................................... 18

8.2.3. USAGE OF OXYGEN CUTTING TIPS ........................................................................ 18

SECTION 9. MAINTENANCE INSTRUCTIONS .......................................................................19

SECTION 10. REPLACEMENT PLANS ......................................................................................20

SECTION 11. MECHANICAL PARTS .........................................................................................25

11.1. VENTILATION UNIT ......................................................................................................... 25

11.2. CUTTING TABLE ............................................................................................................... 28

11.3. SUCTION FAN .................................................................................................................... 29

11.4. MUFFLER ............................................................................................................................ 31

11.5. JET FILTER ......................................................................................................................... 32

11.5.1. THE DESCRIPTION OF THE JET FILTER PANEL ................................................. 35

11.5.2. DUST BAG SHAKER VALVE .................................................................................... 37

11.6. PLASMA HEAD UNIT ....................................................................................................... 38

11.7. PLASMA BRIDGE UNIT ................................................................................................... 39

11.8. X AXIS GEARBOX............................................................................................................. 41

11.9. Y AXIS GEARBOX............................................................................................................. 42

11.10. AJAN X-Y AXIS AC SERVO MOTOR ........................................................................... 43

11.11. AJAN Z AXIS AC SERVO MOTOR ................................................................................ 44

11.12. AJAN PLASMA TORCH .................................................................................................. 45

11.12.1. AJAN PLASMA TORCH CONNECTION DIAGRAM ............................................ 47

11.13. GENERATOR .................................................................................................................... 48

11.13.1. TORCH COOLING SYSTEM .................................................................................... 49

11.14. CNC UNIT ......................................................................................................................... 50

11.15. GENERATOR CONNECTION ......................................................................................... 51

SECTION 12. CABLES ...................................................................................................................52

12.1. INTERFACE SHEET CONNECTION CABLES ............................................................... 52

12.1.1. IHS LIMIT CABLE ...................................................................................................... 53

12.1.2. X, Y, TR, TL AXIS DRIVE CABLES ......................................................................... 54

12.1.3. GAS CONTROL CABLE ............................................................................................. 55

12.1.4. RELAY CONTROL KABLOSU .................................................................................. 56

12.1.5. GAS CONTROL AND RELAY CONTROL CABLES FUNCTIONS ....................... 57

12.1.6. HAND CONTROL CABLE ......................................................................................... 58

12.1.7. LIMIT CABLE .............................................................................................................. 59

12.1.8. RESUME CABLE ......................................................................................................... 60

12.2. DRIVE CONNECTION CABLES....................................................................................... 61

12.2.1. MOTOR CABLE .......................................................................................................... 62

12.2.2. DRIVE POWER CABLE .............................................................................................. 64

12.3. CNC-GENERATOR CABLE CONNECTIONS ................................................................. 65

12.3.1. CURRENT-PLST/OKMO/ARC CABLE ..................................................................... 65

12.3.2. REMOTE CONTROL CABLE ..................................................................................... 66

12.3.3. ELECTRODE-NOZZLE CABLE ................................................................................. 67

12.4. Y AXIS CABLE CONNECTIONS ...................................................................................... 68

12.4.1. PLASMA TRANSMITTER CABLE ............................................................................ 68

ii

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

INDEX

12.4.2. OHMIC-OHMIC IHS-F5 CABLE ................................................................................ 69

12.4.3. PLASMA VALVE CABLE .......................................................................................... 70

12.4.4. OXYGEN(R) VALVE CABLE .................................................................................... 71

12.4.5. HEAD LIMIT(R)-THC(R)-PREHEAT SENSOR(R) CABLE ..................................... 72

12.4.6. OXYGEN TRANSMITTER CABLE ........................................................................... 74

12.4.7. OXYGEN(L) VALVE CABLE .................................................................................... 75

12.4.8. HEAD LIMIT(L)-THC(L)-PREHEAT SENSOR(L) CABLE ..................................... 76

SECTION 13. AJAN PRECISION PLASMA 260AMPER SPECIFICATIONS .......................78

13.1. AJAN PLASMA TORCH SCHEMA AND CONSUMABLES .......................................... 78

13.2. AJAN PRECISION PLASMA SYSTEM CONSUMABLES LIFETIMES AND GAS

CONSUMPTIONS ............................................................................................................... 80

13.3 PRECISION PLASMA 260AMPER PLASMA AUTOMATIC GAS CONSOLE .............. 81

13.4. ALL INCLUSIVE CONTROL PANEL............................................................................... 82

13.5. REMOTE CONTROL HARDWARE .................................................................................. 83

13.6. HEIGHT MEASUREMENT SOFTWARE AND HARDWARE WITH 1-ARC 2-SLIDING

SLEDGE 3-OHMIC CONTACT ......................................................................................... 84

13.7. AUTOMATIC CUTTING HEIGHT CORRECTION SOFTWARE RELATED TO

ELECTRODE AND NOZZLE WEAR ............................................................................... 85

13.8 PRECISION PLASMA 260AMPER GENERATOR ........................................................... 86

13.9. SYSTEM GAS REQUIREMENT ........................................................................................ 87

SECTION 14. CUTTING CHARTS ...............................................................................................88

SECTION 15. CNC UNIT AND GENERATOR CARDS ..........................................................108

SECTION 16. CONNECTION SCHEMAS .................................................................................124

16.1. PLASMA GENERATOR CIRCULATION SCHEMA ..................................................... 137

16.2. CARDS USED IN AJAN PRECISION PLASMA PLASMA CUTTING SYSTEM........ 167

SECTION 17. PRECISION PLASMA 260AMPER SPARE PARTS CHART ........................168

SECTION 18. AJAN OXYGEN- PRECISION PLASMA 260AMPER PLASMA

DESCRIPTION OF THE CNC UNIT .....................................................................................170

18.1. GUIDE FOR THE OPERATION OF THE UNIT ............................................................. 170

18.2. MENU: 0 (MAIN MENU) ................................................................................................. 173

18.3. MENU:1 ............................................................................................................................. 178

18.4. MENU:2 ............................................................................................................................. 186

18.5. OPERATION OF HAND CONTROL UNIT .................................................................... 192

18.6. G PREPARATORY AND AUXILIARY FUNCTIONS USED IN CNC ......................... 194

18.7. AUXILIARY CODES: ....................................................................................................... 195

18.8. SAMPLE PROGRAMS ..................................................................................................... 195

iii

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

TABLE OF FIGURES

SECTION 2. TABLE OF FIGURES

Drawing name ................................................................................................................ Page number

Figure 1. Protectors used during cutting.............................................................................................. 7

Figure 2. General replacement plan................................................................................................... 20

Figure 3. 3000x12000 mm plasma machine with jet filter replacement plan ................................... 21

Figure 4. 3000x6000 mm plasma machine with jet filter replacement plan ..................................... 22

Figure 5. 3000x12000 mm plasma machine without jet filter replacement plan .............................. 22

Figure 6. 2000x6000 mm plasma machine without jet filter replacement plan ................................ 23

Figure 7. 2000x6000 mm plasma machine with jet filter replacement plan ..................................... 23

Figure 8. 3000x6000 mm plasma machine without jet filter replacement plan ................................ 24

Figure 9. 3000 mm first block ventilation system ............................................................................. 25

Figure 10. 3000 mm first block ventilation unit installation drawing ............................................... 26

Figure 11. 3000 mm first block cover opening/closing handle system installation drawing ............ 27

Figure 12. 1500 mm cutting table installation drawing ..................................................................... 28

Figure 13. Suction fan ....................................................................................................................... 29

Figure 14. Suction fan installation drawing ...................................................................................... 30

Figure 15. Muffler ............................................................................................................................. 31

Figure 16. Jet filter ............................................................................................................................ 32

Figure 17. Total area of the cartridges used in the jet filter .............................................................. 34

Figure 18. Jet filter panel ................................................................................................................... 35

Figure 19. Dust bag shaker valve spare part list ................................................................................ 37

Figure 20. Plasma head installation drawing ..................................................................................... 38

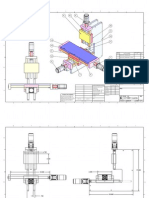

Figure 21. Plasma bridge installation drawing .................................................................................. 39

Figure 22. Plasma bridge unit installation drawing ........................................................................... 40

Figure 23. X axis gearbox installation drawing................................................................................. 41

Figure 24. Y axis gearbox installation drawing................................................................................. 42

Figure 25. Ajan X-Y axis AC servo motor installation drawing ....................................................... 43

Figure 26. Ajan Z axis AC servo motor installation drawing ........................................................... 44

Figure 27. Ajan plasma torch installation drawing ........................................................................... 45

Figure 28. Ajan plasma torch connection diagram ............................................................................ 47

Figure 29. Generator .......................................................................................................................... 48

Figure 30. Torch cooling liquid drum warning label ........................................................................ 49

Figure 31. CNC unit .......................................................................................................................... 50

Figure 32. Generator connection diagram ......................................................................................... 51

Figure 33. Interface sheet connection cables ..................................................................................... 52

Figure 34. Drive................................................................................................................................. 61

Figure 35. Ajan torch schema ............................................................................................................ 78

Figure 36. Ajan precson plasma 260 amper Electrode and Nozzle required life time chart ........... 80

Figure 37. Ajan precson plasma 130 amper Electrode and Nozzle required life time chart ........... 80

Figure 38. Other conventional automatic gas consoles ..................................................................... 81

Figure 39. Ajan automatic gas console.............................................................................................. 81

Figure 40. New conception Ajan all inclusive plasma cutting system .............................................. 82

Figure 41. Schema for required connection between units on Ajan all inclusive plasma system ..... 83

Figure 42. Ajan initial height control systems................................................................................... 84

Figure 43. Ohmic system comparison ............................................................................................... 84

Figure 44. Torch height control systems comparison ....................................................................... 85

Figure 45. precson plasma 260 Amper generator ........................................................................... 86

Figure 46. Arc transfer card............................................................................................................. 108

Figure 47. Firing box card ............................................................................................................... 109

iv

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

TABLE OF FIGURES

Figure 48. Flow card ........................................................................................................................ 110

Figure 49. IGBT driver card ............................................................................................................ 111

Figure 50. IHS limit card ................................................................................................................. 112

Figure 51. Interface sheet ................................................................................................................ 113

Figure 52. precson plasma generator control card ........................................................................ 114

Figure 53. precson plasma Generator control card........................................................................ 115

Figure 54. Condenser card ............................................................................................................... 116

Figure 55. Logic control card .......................................................................................................... 117

Figure 56. Logic control card .......................................................................................................... 118

Figure 57. Front panel card.............................................................................................................. 119

Figure 58. Power card ...................................................................................................................... 120

Figure 59. Resistance card ............................................................................................................... 121

Figure 60. Start circuit ..................................................................................................................... 122

Figure 61. Varistor card ................................................................................................................... 123

Figure 62. Plasma plate ................................................................................................................... 124

Figure 63. Plasma plate hose gas connection schema ..................................................................... 125

Figure 64. Oxygen plate .................................................................................................................. 126

Figure 65. Oxy-Plasma hose gas connection schema ...................................................................... 127

Figure 66. Plasma plate card connection schema ............................................................................ 128

Figure 67. precson plasma automatic gas console plasma plate connection schema .................... 129

Figure 68. precson plasma single head oxygen plate connection schema..................................... 130

Figure 69. precson plasma automatic gas console double head plate connection schema ............ 131

Figure 70. precson plasma double head oxygen plate connection schema ................................... 132

Figure 71. precson plasma automatic gas console double oxygen plate connection schema ....... 133

Figure 72. precson plasma four head oxygen plate connection schema ....................................... 134

Figure 73. precson plasma triple head plate connection schema ................................................. 135

Figure 74. Interface connection schema .......................................................................................... 136

Figure 75. Plasma generator circulation schema ............................................................................. 137

Figure 76. precson plasma 260A generator connection schema .................................................. 138

Figure 77. precson plasma 260A+oxygen cutting CNC connection schema ................................ 139

Figure 78. precson plasma 260A+double head oxygen cutting CNC connection schema ........... 140

Figure 79. Arc voltage divider connection schema ........................................................................ 141

Figure 80. Arc voltage control system connection schema ............................................................. 142

Figure 81. Axis control system connection schema ........................................................................ 143

Figure 82. precson plasma generator control card connection schema ......................................... 144

Figure 83. Flow LED control system connection schema ............................................................... 145

Figure 84. Plasma start control card connection schema ................................................................ 146

Figure 85. Jet filter system connection schema ............................................................................... 147

Figure 86. precson plasma 260A main power connection schema ............................................... 148

Figure 87. precson plasma oxygen+marking control card connection schema............................. 149

Figure 88. IGBT drive system connection schema ......................................................................... 150

Figure 89. precson plasma double head control card connection schema..................................... 151

Figure 90. precson plasma double head plate connection schema ................................................ 152

Figure 91. Logic card input-output control connection schema ...................................................... 153

Figure 92. Plasma control connection schema ................................................................................ 154

Figure 93. precson plasma power control connection schema ...................................................... 155

Figure 94. CNC power system connection schema ......................................................................... 156

Figure 95. Remote control start-stop system connection schema ................................................... 157

Figure 96. Servo motor drive system connection schema ............................................................... 158

Figure 97. THC unit system connection schema ............................................................................. 159

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

TABLE OF FIGURES

Figure 98. Logic card input-output controls schema ....................................................................... 160

Figure 99. Generator fan, CNC connection schema ........................................................................ 161

Figure 100. Generator fan, CNC connection schema ...................................................................... 162

Figure 101. Interface DSUB output sockets connection schema .................................................... 163

Figure 102. precson plasma block connection output connection schema ................................... 164

Figure 103. precson plasma 260A connection schema ................................................................. 165

Figure 104. precson plasma CNC plasma main transformer ........................................................ 166

Figure 105. Hand control unit label ................................................................................................. 192

vi

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

TABLES

SECTION 3. TABLES

Table name ..................................................................................................................... Page number

Table 1. Table of safety signs and descriptions ................................................................................. 10

Table 2. IHS limit cable color and functions table ............................................................................ 53

Table 3. X, Y, TR, TL axis drive cables color and functions table ................................................... 54

Table 4. Gas control cable color and functions table ........................................................................ 55

Table 5. Relay control cable color and functions table ..................................................................... 56

Table 6. Gas control and relay control cables color and functions table ........................................... 57

Table 7. Hand control cable color and functions table ...................................................................... 58

Table 8. Limit cable color and functions table .................................................................................. 59

Table 9. Resume cable color and functions table .............................................................................. 60

Table 10. Motor cable color and functions table ............................................................................... 62

Table 11. Motor cable color and functions table ............................................................................... 62

Table 12. Motor cable lengths with respect to Y axis lengths ........................................................... 63

Table 13. Drive power cable color and functions table ..................................................................... 64

Table 14. Current-PLST/OKMO/Arc cable color and functions table .............................................. 65

Table 15. Remote control cable color and functions table ................................................................ 66

Table 16. Plasma transmitter cable color and functions table ........................................................... 68

Table 17. Ohmic-Ohmic IHS-F5 cable color and functions table ..................................................... 69

Table 18. Plasma valve cable color and functions table .................................................................... 70

Table 19. Oxygen(R) valve cable color and functions table ............................................................. 71

Table 20. Head limit(R) cable color and functions table ................................................................... 72

Table 21. Torch height control(R) cable color and functions table ................................................... 73

Table 22. Preheat sensor(R) cable color and functions table ............................................................ 73

Table 23. Oxygen transmitter cable color and functions table .......................................................... 74

Table 24. Oxygen(L) valve cable color and functions table.............................................................. 75

Table 25. Head limit(L) cable color and functions table ................................................................... 76

Table 26. Torch height control(L) cable color and functions table ................................................... 77

Table 27. Preheat sensor(L) cable color and functions table ............................................................. 77

Table 28. Ajan precson plasma 260 plasma generator gas flow rates ............................................. 80

Table 29. precson plasma 260A generator technical specifications ................................................ 86

Table 30. System gas requirement ..................................................................................................... 87

Table 31. System gas requirement ..................................................................................................... 87

Table 32. Mild steel, O2 Plasma/O2 Shield, 30A cutting chart ........................................................ 88

Table 33. Mild steel, O2 Plasma/Air Shield, 40A cutting chart ........................................................ 89

Table 34. Mild steel, O2 Plasma/O2 Shield, 80A cutting chart ........................................................ 90

Table 35. Mild steel, O2 Plasma/O2 Shield, 130A cutting chart ...................................................... 91

Table 36. Mild steel, O2 Plasma/O2 Shield, 260A cutting chart ...................................................... 92

Table 37. Stainless steel, F5 Plasma/N2 Shield, 45A cutting chart .................................................. 93

Table 38. Stainless steel, N2 Plasma/N2 Shield, 45A cutting chart .................................................. 94

Table 39. Stainless steel, Air Plasma/Air Shield, 80A cutting chart ................................................. 95

Table 40. Stainless steel, F5 Plasma/N2 Shield, 80A cutting chart .................................................. 96

Table 41. Stainless steel, Air Plasma/Air Shield, 130A cutting chart ............................................... 97

Table 42. Stainless steel, H35 Plasma/N2 Shield, 130A cutting chart .............................................. 98

Table 43. Stainless steel, N2 Plasma/N2 Shield, 130A cutting chart ................................................ 99

Table 44. Stainless steel, Air Plasma/Air Shield, 260A cutting chart ............................................. 100

Table 45. Stainless steel, H35 Plasma/N2 Shield, 260A cutting chart ............................................ 101

Table 46. Stainless steel, H35 Plasma/N2 Shield, 260A cutting chart ............................................ 102

Table 47. Aluminum, N2 Plasma/N2 Shield, 45A cutting chart ..................................................... 103

vii

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

TABLES

Table 48. Aluminum, Air Plasma/Air Shield, 130A cutting chart .................................................. 104

Table 49. Aluminum, H35 Plasma/N2 Shield, 130A cutting chart ................................................. 105

Table 50. Aluminum, H35 Plasma/N2 Shield, 260A cutting chart ................................................. 106

Table 51. Aluminum, Air Plasma/Air Shield, 260A cutting chart .................................................. 107

Table 52. Cards used in precson plasma plasma cutting system ................................................... 167

Table 53. precson plasma 260A spare parts chart ......................................................................... 168

Table 54. G and preparatory M codes used in CNC........................................................................ 194

Table 55. Auxiliary codes used in CNC .......................................................................................... 195

viii

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

COMPANY PROFILE

SECTION 4. COMPANY PROFILE

Manufacturer since 1973

Ajan Elektronik, established in 1973, started its life by manufacturing uninterruptable power supply

systems. The firm decided to manufacture Electrical Discharge Machines and released the first

machine in 1975 to the market.

In early years due to the conditions of the day, the company manufactured hydraulic machines, but

today the company switched to AC servo controlled machines.

Ajan Elektronik started to work on CNC projects in 198889, and manufactured the first CNC

Erosion Machine in 2000. Continuing working on this subject in R&D department, the company

developed and manufactured CNC Milling Machines, CNC Lathes, CNC Plasma and Oxy-Fuel

Cutting Machines, CNC Drilling Machines and CNC Laser Cutting Machines.

All the CNC control units and software, servo drives and AC servo motors of the manufactured

machines are completely own production of the company.

Ajan Elektronik provides AjanCAD Ajan Drawing software free of charge with the manufactured

machines to the customers.

The company supplies 85% of the raw and intermediary materials used in manufacturing of the

machines, whose design is completely done by itself, from the domestic market. Hence, the

company supports the economy of the country.

In addition, Ajan Elektronik began many new projects according to the customer demands.

As a result of giving importance to quality, the company has won ISO 9001:2000 Quality

Certificate on June 24th 2003.

AJAN ELEKTRONIK SERVIS SAN. VE TIC. LTD. STI.

Address

: Merkez Mah. 67. Sk. No:3 Sasali-Cigli / Izmir / TURKEY

Web

: www.ajancnc.com

: info@ajancnc.com

Tel

: +902323273480

Fax

: +902323273430

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

INSTALLATION AND ELECTROMAGNETIC COMPATIBILITY

SECTION 5. INSTALLATION AND ELECTROMAGNETIC

COMPATIBILITY

5.1. EMC INTRODUCTION

Ajan Plasma Machine with CE mark is built compliance with machinery directive 98/37/EC, low

voltage directive 73/23/EEC and EMC directive 89/336/EEC.

TS EN 2921/2922

TS 10316 EN 602041

TS EN 503702

TS EN 6100062

CNC PLASMA AND TS EN 1050

OXY-FUEL CUTTING TS EN 613101/2

MACHINES

TS EN 614961

TS EN 1037

TS EN 953

TS EN 563

TS EN ISO 9001:2000

5.2. INSTALLATION AND USAGE

The user is responsible for the specified directives while using Ajan brand plasma, oxygen

machines and equipments. During solving any electromagnetic problem, at first the technical

documents supplied by the manufacturer firm then technical assistance of the firm must be applied.

In some cases, although the defects can be simply solved, because of unauthorized actions may

cause the solution hard.

5.3. ESTIMATION OF AREA

The user should specify the areas situation by taking into account the following electromagnetic

influence risks before the installation.

Supply cables, control cables, telephone cables near the machines control units

Radio and television transmitters and receivers

Computer and other control units

Safety critical equipments

The health devices like pacemaker and hearing equipments and the people using these

Calibration and measurement devices

The indicated influences differ depending on the building structure and other activities in the

surrounding area. These may extend beyond the surrounding area.

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

INSTALLATION AND ELECTROMAGNETIC COMPATIBILITY

5.4. MAIN POWER

The grounding must take place at the main power.

The main power of the machine must be connected in accordance to the manufacturers directives.

If any interference or undulation at the current occurs, a filter (regulator) can be added to the main

power or the supply cable can be shielded. In addition, it is advised that the electrical supply cable

must be in length of maximum 5 meters and the temperature of the ambiance must not extend 40C.

Under the case of that the allowed temperature is extended, the cutting current should be reduced. It

is suitable for the cables to be put into a metal conduit in order to prevent having hazards.

5.5. EQUIPOTENTIAL BONDINGS

The machine produces high voltage during firing. The operator must not touch the cutting

equipments (torch, electrodes, etc.) during firing in order to prevent an electric shock. In addition to

this, unearthed work piece and all equipments connected to the machine includes high voltage

during cutting and this causes critical risk. So grounding of the work piece and all equipments must

be supplied.

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

SAFETY

SECTION 6. SAFETY

6.1. RECOGNIZE SAFETY INFORMATION

The symbols shown in this section are used at areas where potential risks may

occur. Understand the potential personal injury and follow the instructions to prevent the hazard

when you see a safety symbol in this manual or on your machine.

6.2. FOLLOWING SAFETY INSTRUCTIONS

Read all safety messages and warnings in this manual and safety labels on your machine.

Keep the safety labels on your machine seen. For that, use cleaning materials that does not

damage the labels while cleaning. Replace the damaged and missing labels with a new one.

Learn how to operate the machine and its controls. Do not allow unauthorized or ignorant

person to operate the machine.

Keep the machine in suitable working conditions. Unauthorized modifications on the machine

may affect wrongly the safety and operation of the machine.

6.3. DANGER, WARNING, CAUTION

DANGER word identifies the most serious hazards like ELECTRIC SHOCK CAN KILL.

WARNING symbol follows the instructions that may cause injury or death when they are not

correctly obeyed. OXYGEN CUTTING CAN CAUSE EXPLOSION

A CAUTION safety message identifies the instructions that may cause damage to the machine

or equipment if it is not correctly followed. COOLING PUMP WILL BE DAMAGED IF IT IS

RUN WITH WATER ONLY

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

SAFETY

6.4. FIRE AND EXPLOSION RISKS WHILE

CUTTING

Prevention from Fire

Keep safety of the cutting area before starting to cut and place a fire extinguisher near you.

Do not place any flammable or explosive materials within 2 meters of the cutting area.

Do not handle the hot cut material or wait until it cools.

Do not cut containers including flammable or explosive material, pressurized gases or toxic

materials.

Flammable atmosphere should be removed from the area before cutting.

WARNING

Explosion Hazard

Argon-Hydrogen

Hydrogen is a flammable gas that may cause an explosion hazard. Keep cylinders and hoses

containing Hydrogen away from the flame. Keep torch hoses away from flame and spark during

Hydrogen-Argon plasma cutting.

6.4.1. Prevention from Explosion

If there is possibility of that explosive smokes or vapors exist in the area, do not use plasma

system.

Do not cut containers including pressurized cylinders, hoses or any closed containers.

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

SAFETY

6.5. ELECTRIC SHOCK

It can cause fatal shocks or severe burns to touch parts containing electricity.

The plasma systems work in principle of completing electric current between the cutting

torch and the work piece. So since work piece and anything touching the work piece area

part of this electrical circuit, do not touch the torch body while plasma system is

operated.

6.5.1. Prevention from Electric Shock

All Ajan plasma systems work with open circuit 300 V direct current high voltage principle.

Follow the instructions indicated below for safety:

Wear insulated gloves, boots, and dry clothes.

Do not contact to wet any surface while operating the plasma system.

Prevent physical contact from the ground or any material in connection with the ground.

For that, you can use dry insulating mat or cover. If the working area is damp, be

careful.

Inspect frequently the durability of main supply cables. Replace the damaged cables

with a new one. Bare wiring can cause kill.

Disconnect the main power before cleaning or changing the parts of torch unit.

Do not pick up the work piece or cut materials during cutting.

Before acting on the electric unit, disconnect electrical connections and wait for

minimum 5 minutes to let the capacitors discharge.

Connect grounding conductor when making input connections.

Ajan plasma systems are designed for only specific Ajan torches. It causes danger to use

other torches.

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

SAFETY

6.6. TOXIC FUMES OCCUR WHILE CUTTING

Plasma and oxygen cutting can cause gases that can reduce oxygen and cause injury or death.

Ventilate the cutting area well and remove the occurring gases from the atmosphere.

Do not make cutting near places where cleaning processes are done.

Use a ventilation system while cutting materials containing Lead, Cadmium, or Beryllium.

Otherwise, since poisonous gases and fumes occur while cutting, it can cause injury or

death.

Do not cut the containers containing toxic materials. Empty and clean properly.

6.7. PLASMA ARC RAY INJURES EYES AND SKIN

Plasma arc rays produce visible or invisible rays that may burn eyes and skin.

Use eye protectors suitable to the cutting parameters.

While cutting, use protectors specified by ISO 4850 and TS.

Helmet type with lift-up glass

Helmet type with fixed glass

Headgear with fixed glass

Helmet with handle

Figure 1. Protectors used during cutting

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

SAFETY

Use clothes protecting against burns caused by ultraviolet rays, sparks and hot metal.

Wear gauntlet gloves, safety shoes and helmet.

Flame resistant clothes for persons working in the cutting area.

Use protective screen or barrier against violent light.

Warn others not to watch the occurred arc. Use placards or signs.

If the wall coatings around the cutting area are dark, this helps to lower the ultraviolet ray

reflection.

6.7.1. GROUNDING SAFETY

Be sure to connect the work piece and cutting table properly during cutting, not to allow the

work piece displace or fall down.

The grounding should well contact to the work piece. Do not connect it to the piece that will

fall away when cutting is done.

Ground the work piece and work table with appropriate directives.

6.7.2. SAFETY FOR COMPRESSED CYLINDERS

Do not lubricate cylinder valves or regulators.

Use only cylinders, regulators, hoses and fittings advised by the manufacturer.

Connect all fitting hoses in appropriate to color grouping.

6.7.3. GAS CYLINDERS CAN EXPLODE

Do not use cylinders if they are not stood up or well arranged.

Do not force to open stuck valves and never apply stroke.

Do not work making flame or spark near explosive gas cylinders.

Do not cut near cylinders that may flame or explode.

Control frequently the gas cylinder fittings against leakage.

Make sure the fittings should be carefully done by an authorized person.

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

SAFETY

6.8. NOISE DAMAGE

There is a hearing loss hazard during prolonged cutting and piece removal processes applying

stroke.

Use ear bung during plasma cutting.

Identify the noise hazard in the working area of plasma machine with warning signs.

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

SAFETY

6.9. SAFETY SIGNS AND DESCRIPTIONS

Table 1. Table of safety signs and descriptions

10

10

11

12

13

14

15

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

SAFETY

1.

2.

3.

4.

5.

6.

7.

Use gauntlet and dry gloves for protection from hot metals, spark, dross and electric shocks.

Use protective helmets against dross and ultraviolet rays.

Do not touch bare cables against electric arcs.

There is ultraviolet ray hazard, follow the directives.

Wear dry, well-built, safety shoes.

Do not cut closed containers that contain flammable, explosive, or unknown materials.

Keep pressurized gas cylinders upright and protective caps in place over valve when the

cylinders are not in use.

8. Magnetic fields caused by the high current may injure the operands using pacemaker or

having heart diseases.

9. Keep a fire extinguisher nearby.

10. There may be flammable and explosive gases while machine is operating. To avoid this, do

not smoke near the machine and gas cylinders.

11. There may be flammable and explosive gases while machine is operating. To avoid this, do

not keep flame available near the machine and gas cylinders.

12. Plasma cutting produces noise that may cause hearing hazards. Use approved ear protection

during cutting.

13. Do not insert any material or your organs into the moving mechanisms that may obstruct the

movement.

14. Do not step onto or do not load onto places where may obstruct machines operation.

15. Do not make contact to hot metals.

11

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

SAFETY

6.10. WELDING FUMES AND GASES

Welding fumes are an unavoidable by-product of the welding and cutting process. All these

processes generate fumes, only the type and amount vary from process to process. It consists of

particulate fume, the part you can see, and gaseous fume, the part you cannot see, but can

sometimes smell.

Exposure of welders to welding fumes depends on many factors: the most important of which is

actual type of welding is being done.

For example, FCAW, MMA, MIG, thermic lancing and plasma cutting tend to produce the highest

amounts of most particulate fumes, while TIG, plasma welding, oxy-fuel welding, laser welding,

laser cutting and submerged arc normally give very little.

TIG, plasma welding, MIG, laser cutting and welding tend to produce the most gaseous fumes

while MMA, plasma cutting and FCAW normally produce very little.

The potential effect of exposure to welding or cutting fumes depends on the composition of the

fumes.

The health effects of exposure to fumes include irritation of the upper respiratory tract (nose and

throat), tightness in the chest, wheezing, metal fume fever, lung damage, bronchitis or pneumonia,

possibly even cancer or emphysema.

Possible control measures include doing things such as changing or modifying the process, or the

way the job is done.

6.10.1. FUMES AND GASES

The nature of fume depends upon the metal being cut and upon any coating. Cutting of stainless

steel is potentially the most hazardous as the fumes will contain chromium and nickel. Copper and

its alloys are also commonly cut and can also produce a significant fume hazard. The risks from

fumes should be assessed in accordance with HSE Guidance Note EH54 Assessments of exposure to

fume from welding and allied processes.

Oxides of nitrogen are formed during plasma cutting and could accumulate in areas of poor

ventilation. These are likely to be most significant during plasma cutting where air or nitrogen is

used as the plasma gas. Ozone is most likely to be formed during cutting of aluminum or stainless

steel.

Where inert gases are used they may accumulate in contained spaces causing an asphyxiation risk.

This is most likely to occur when the gas is significantly heavier than air e.g. argon/nitrogen

mixtures.

In poorly ventilated areas, flammable gases may also produce a risk.

Gases, particularly oxides of nitrogen, are a more significant hazard at hand-held cutting than at

mechanized cutting as the operator is in close proximity to the torch.

12

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

SAFETY

6.10.2. TOXIC FUMES AND GASES

Plasma arc cutting can produce toxic fumes and gases that deplete oxygen and cause serious injury.

Keep the cutting area well ventilated or use an approved air-supplied respirator.

Do not cut in locations near degreasing, cleaning or spraying operations. The vapors from

certain chlorinated solvents decompose to form phosgene gas when exposed to ultraviolet

radiation.

6.10.3. LOW-TEMPERATURE PLASMA FUMES, EXHAUST GAS PURIFICATION

FOR ORGANIC

On principle, the purification device uses corona current and high power pulse discharge principle,

so that the air around the plate becomes a low-temperature plasma.

Plasma with many high-energy (OH-, O2-, H+, O3) ions are surrounding the plate, with energy of

the plasma can interrupt a variety of organic molecules of gas between the key elements so that the

decomposition of harmful gases to the fumes, formaldehyde, xylene, sulfur dioxide, ammonia

nitrogen oxides and other harmful gases and odor generated degradation and oxidation, deal with

organic material and degradation of smell effectively. In addition the purification equipment

compared with electrostatic precipitator, low power consumption, more efficient purification, and

so on.

13

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

WARRANTY

SECTION 7. WARRANTY

Ajan Kesme Makinalari San. ve Tic. Ltd. Sti. supplies mechanical and electronic units and all

equipments of your machine completely depending on the made agreements. The installation, first

operation of the machine and the education will be supplied by the manufacturer firm. Ajan Plasma

and Oxygen Cutting Machine mechanical units, electronic units, software and torch are

manufactured under Ajan brand. Ajan Ltd. warrants the machines under all these conditions.

7.1. AJAN BRAND PLASMA AND OXY-FUEL CUTTING MACHINE

WARRANTY CONDITIONS

1- The warranty period is 2 (two) years after the machine delivery.

2- All the parts of the machine are under our companys guarantee.

3- Under the case when the machine has been broken down in the guarantee period, the

maintenance period is added to the warranty period. The maintenance period is 15 days

excluding the transportation under the case when the machine fault is overcome by the

manufacturer factory.

4- The approved technical staff can interfere to the fault on the machine in 48 hours after the

customer informs the manufacturer.

5- The faults, determined by the technical staff, caused by the design and production are

overcome free of charge.

6- In cases when the machine fault is out of warranty, the applied service fare is 80.00+VAT

for the year 2009. The prices of the spare part to be replaced will be sent by ourselves. The

spare part prices are valid for the year 2009 and the applicable unit price change is under the

manufacturers right.

7- Under the case when the machine is broken down because of either material, or

workmanship, or installation faults; the maintenance will be done without any name under

either workmanship charge, or replaced part charge, or anything else.

8- The problems; caused by the usage against to the subjects noted on the manual and the extra

apparatus or spare parts without any approval or information of the manufacturer; are out of

warranty.

14

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

WARRANTY

7.2. CASES CAUSING OUT OF WARRANTY

In case the machine isnt operated by firms authorized technical service,

The machine faults which were overcome by unauthorized services,

In case of the faults caused by carriage, replacement and usage problems,

The faults caused by not cleaning the machine or not maintaining of the periodically

maintainable places,

5- Paint applied on the machine, cooling liquid, unsuitable cleaning chemical materials, the

problems caused by cutting with consumables and apparatus unapproved by manufacturer,

6- The faults and unqualified cuttings caused by false usage of operator,

7- The problems and faults because of wrong usage of consumables,

8- The faults and unqualified cuttings occurred by unqualified gas usage on machine,

9- The faults and unqualified cuttings occured because of unfiltered moistured air used during

cutting

10- The faults and problems occured because of not following warnings and signs on the

machine,

11- The problems caused by line voltage to the machine,

12- The faults and problems caused by the software installed on the machine by the network or

any external memory devices,

13- The problems caused by unapproved revision on the software on the machine,

14- The problems occured because of not following maintenance instructions of the machine,

15- The spare parts, software, equipments, torch consumables or apparatus installed on the

machine without any information, approval or control of the manufacturer,

16- The fault maintenance and modifications on the machine by the technical support or any

technical staff of the manufacturer,

17- The mechanical or electronical damages occurred by the replacement and transportation of

the machine,

18- The loss of life or property and faults caused by the installation or deinstallation and without

technical support of the manufacturer,

19- The loss of life or property and faults caused by any parasitic interference or fluctuation on

the power line,

20- The loss of life or property and faults caused by not obeying the safety warnings or wrong

usage,

1234-

The above mentioned mechanical, electronical, software faults or problems which may danger

property or life safety does not claim that our company is under liability.

15

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

PREUSAGE

SECTION 8. PREUSAGE

8.1. ATTENTIONS BEFORE STARTING CUTTING WITH PRECISION

PLASMA MACHINES

8.1.1. CONTROL OF THE CYLINDERS AND THEIR PRESSURE

In addition, propane gas is used in oxygen cutting machine.

O2 Oxygen(8.5 bars)

N2 Nitrogen (8.5 bars)

Air (between 7 10 bars)

Propane (2.5 bars)

For stainless steel sheet cutting with plasma cutting machine, H35 and F5 gases are added.

H35 (8.5 bars)

F5 (8.5 bars)

8.1.2. STARTING GENERATOR

Generator, which only takes place with plasma cutting machines, is got ready by starting before

cutting. This operation is done by circuit breaker on the front panel of the generator is turned on,

then the stop button is unlocked by turning left, and then start button is pressed.

Pressing is continued until the phase lack and circulation error lights turn off.

Just after phase lack light turns off, circulation error warning light turns off.

8.1.3. STARTING CNC UNIT

The switch on the right side cover of the CNC unit is turned to (1) position, and then computer start

is waited for.

If after this operation, the computer cannot be started, ON switch on the front panel is pressed and

then the computer starts.

The driver fail warnings on the computer screen show that the machine is stopped.

Starting:

Stop button is turned on by turning left.

Start button is pressed until the driver fail warnings disappear.

8.1.4. CHASSIS CABLE AND CONTROL

The cable, between the table on which the cutting is done and the rolling rails which provides the

bridge movement, functions as chassis between the ventilation system and the rolling rails. There is

another chassis cable between the rolling rails and the generator.

Its impossible for the plasma cutting to be done when the chassis cables loose, break, etc.

8.1.5. USAGE OF CUTTING TIPS

During replacement of the consumable parts, some instructions take place that should be obeyed.

Otherwise, the mistakes you did affect the cutting quality, causes consumable life-time and even

causes that the machine gets out of order until the service personnel intervenes.

The parameters that should be obeyed:

During consumable replacement, an ambient purified from dust should be obtained.

The consumables which drops on the floor or exposed to stroke shouldnt be used.

16

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

PREUSAGE

The nozzle and electrode is mounted with a torch wrench. During this operation, you

shouldnt use over force.

After replacing cutting tips, purge operation is done from the parameters. This operation

throws out the dust taking place on the tips and checks gas flows.

8.1.6. OPERATING JET FILTER

The iron dust, occurring during the work piece cut, is conveyed to the jet filter with the aid of fan.

Its checked with panel on the front side. The working system of the shaker valves cleaning the

filters is adjusted from this panel.

The iron dusts shaken off the filters are detained in the buckets at the bottom.

The buckets should be cleaned with dust mask.

The jet filter should be operated with the remote control on the fan and the generator CNC

unit.

17

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

PREUSAGE

8.2. ATTENTIONS BEFORE STARTING CUTTING WITH P MACHINES

8.2.1. CONTROL OF THE CYLINDERS AND THEIR PRESSURE

The gases used with P model plasma cutting machines:

Air (between 7 10 bars)

The gases used with P model oxygen cutting machines:

Oxygen (8.5 bars)

Propane (3 bars)

The air, used for cooling antenna and antenna bowl obtaining the torch cutting height during oxygen

cutting, should be connected to the system.

Aim for using air in oxygen cutting machine:

Because of overheat, the antenna cannot sense the correct height of the torch.

After adjusting the output pressures of the cylinder and the compressor, they are set suitable with

respect the regulators in front of the generator from the parameters.

Note: After adjusting the cutting current from the parameters, the same ampere is set on the

generator.

8.2.2. STARTING

The main power switch on the front panel of the generator is turned up, then stop button lock is

turned to left and on, and then start button is pressed.

Pressing is continued until the phase lack and circulation error lights turn off.

Just after phase lack light turns off, circulation error warning light turns off.

Note: It is not needed to open the generator during cutting with precson plasma and P model

machines.

8.2.3. USAGE OF OXYGEN CUTTING TIPS

The set of heating nozzle and nozzle is mounted on the tip of the torch. The cutting capability of the

nozzle is marked on it.

The tip marked as (10-25) is used during 10 to 25 mm thick sheet cutting.

NO TORCH: The No Torch error is turned on when the magnets holding the torch are taken

apart. The touching magnet surfaces are purified from the dust to overcome this error. If the error

goes on, the cable connected to the magnets should be checked.

IHSTR: This error takes place on left top of the screen during each torch elevation. It appears

during cutting, and if cutting is stopped, it turns to IHSTR error.

You can get rid of the error using the remote control.

18

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MAINTENANCE INSTRUCTIONS

SECTION 9. MAINTENANCE INSTRUCTIONS

The racks and chrome plated rods on machines head group and rolling rails should be kept

clean.

Since the plasma cutting is a dusty process, the moving parts should be kept away from the

dust. In addition, for every work piece loading, the moving parts should be checked visually,

that should be checked whether there exist any materials preventing movement on the racks.

The crane, forklift, etc devices should be controlled; the machine should be kept away from

beat.

The wipers on X and Y axes should be checked every day and be replaced if eroded or

broken down.

The bellows on the machines head group should be checked for stability and be replaced if

eroded or broken down.

The cutting buckets of the ventilation unit should be necessarily checked for fullness,

because this is very important for the suction quality.

The suction system of the machine works with the help of the press handles. These handles

should be checked whether it works well.

The warning labels on the machine should never be taken out, and be replaced if eroded, and

they should be obeyed to.

No combustible materials such as paper, cigarette butt, nylon, etc should be thrown into the

ventilation unit; no water should be used during intervening.

Twice a week, CNC unit and generator unit must be cleaned using dry air or nitrogen gas,

the machine shouldnt be used in one hour after this application.

The jet filter buckets should be cleaned until it is filled in half.

The jet filter cartridges should be neither opened nor cleaned without manufacturer company

control.

19

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

REPLACEMENT PLANS

SECTION 10. REPLACEMENT PLANS

Figure 2. General replacement plan

20

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

REPLACEMENT PLANS

Figure 3. 3000x12000 mm plasma machine with jet filter replacement plan

21

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

REPLACEMENT PLANS

Figure 4. 3000x6000 mm plasma machine with jet filter replacement plan

Figure 5. 3000x12000 mm plasma machine without jet filter replacement plan

22

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

REPLACEMENT PLANS

Figure 6. 2000x6000 mm plasma machine without jet filter replacement plan

Figure 7. 2000x6000 mm plasma machine with jet filter replacement plan

23

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

REPLACEMENT PLANS

Figure 8. 3000x6000 mm plasma machine without jet filter replacement plan

24

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

SECTION 11. MECHANICAL PARTS

11.1. VENTILATION UNIT

They are the systems sucking and removing the dangerous gases and dust occurring during the

plasma cutting application away from the medium. As the working principle, the air suction occurs

when the pressure handles on the working area are opened by pressure sheet on the machines

bridge unit, and it sucks the dust and gas in the cutting area. The sheet to be cut is placed on the grid

blocks. After the cutting process, the dross and some cutting wastes are collected in the cutting

buckets. For a long life and proper operation of the ventilation unit, it should be frequently cleaned

depending on the fullness ratio.

Figure 9. 3000 mm first block ventilation system

25

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

Figure 10. 3000 mm first block ventilation unit installation drawing

26

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

Figure 11. 3000 mm first block cover opening/closing handle system installation drawing

27

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

11.2. CUTTING TABLE

It is used in the oxygen cutting machines. The sheet to be cut is placed on the cast parts. The cast

parts help in decreasing the harms of strong flame and dross occurring during cutting to the cutting

grids.

Figure 12. 1500 mm cutting table installation drawing

28

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

11.3. SUCTION FAN

The fan system obtaining suction on the ventilation unit. It has the suction capacities 5,000 m3/h,

10,000 m3/h and 15,000 m3/h depending on the width and length ratio of the ventilation unit.

Figure 13. Suction fan

29

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

Figure 14. Suction fan installation drawing

30

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

11.4. MUFFLER

The system used to decrease the high decibel level occurred in the suction fan.

Figure 15. Muffler

31

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

11.5. JET FILTER

Figure 16. Jet filter

32

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

33

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

Figure 17. Total area of the cartridges used in the jet filter

The jet filter is manufactured in 4 different models, such as 6-, 8-, 12- and 16-cardridge, depending

on the ventilation capacity required for the machine. Every cartridge is made up from 24 meter

square burn-delayed plied filter paper.

System dirt level is controlled by electronic filter cleaning unit. With the help of blow level control,

the blow frequency is decreased, cycle is increased. So unnecessary air consumption is prevented.

30% more efficient reverse jet filter cleaning air flows are obtained by dust bag shaker valves

integrated on the filter body. Because of that the cartridges are horizontally mounted, the

maintenance and replacement are easily done. Jet filter unit is additionally preserved with flame

trap that should take place in every plasma cutting table ventilation.

Flame trap holds cigarette butt, burning paper sheets and cloth parts and moves them to the buck it

has.

Ajan jet filter system is a genuine design completely suitable to the world standards. The air suction

fan is mounted outside of the filter and it is suitable for cleansing after long-time usage. The motor

and propeller are equipped with an easily opened and closed cover system.

The complete filter system is transported by demounted during the transportation. The air suction

system has been designed to be fit in any smallest area behind the plasma ventilation table. During

the filter design, space occupation is kept in mind in height in spite of width or length. A muffler

with two walls is mounted on the fan output. The muffler output can be mounted outside of the

building by the customer.

34

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

11.5.1. THE DESCRIPTION OF THE JET FILTER PANEL

1

2

3

4

5

6

7

Filter pressure gauge

Cartridge indicator

Blow period

Dirt level

Filter clean

Filter dirty

Filter dirt warning lamp

Figure 18. Jet filter panel

35

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

1. FILTER PRESSURE GAUGE:

The permeability of the jet filter cartridge is decreased by fullness, and so pressure on the

cartridges gets high. The fullness of the cartridge is observed by the pressure gauge. 7002,000 Pascal value means workable level; however 2,000-3,000 Pascal value means a

critical operation level in Ajan brand jet filters. The cartridges should be replaced when

critical values are reached. The cartridges used in Ajan jet filter systems are made from

flame-retardant paper and the m2 values are shown in Figure 17.

WARNING:

Do not use any cartridge not approved by the manufacturer in Ajan jet filter systems.

2. CARTRIDGE INDICATOR:

The filter unit blows in adjusted periods in order to clean the cartridges. This indicator

indicates the cartridge group to be blowen.

3. BLOW CYCLE:

Synchronized to other adjustments.

4. DIRT LEVEL:

It is used to determine the cartridge dirt level. The cartridge blow cycles are adjusted

depending on the determined dirt level (the ideal value is 1,000 Pascal).

5. FILTER CLEAN:

It is used to adjust the blow cycle when the filter is in clean mode (the ideal value is 15 sec.).

6. FILTER DIRTY:

It is used to adjust the blow cycle when the filter is in dirt mode (the ideal value is 6 sec.).

7. FILTER DIRT WARNING LAMP:

The LED that warns that the filters reached the determined dirt level.

36

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

11.5.2. DUST BAG SHAKER VALVE

Definition: Dust bag shaker valves are designed for the systems that discharges pressured air swift

and produce air strokes as shock. It operates in the same way with other 2-way solenoid valves. But

input and output connections are perpendicular (90) to each other. So it sends air as stroke (shock)

and it is also called Air Shock (Jet Filter) valve.

PART NO

PART NAME

Body

Large diaphragm

2a

Diaphragm

Large diaphragm spring

3a

Spring

Large body cover

Small diaphragm

Cover

6a

Cover

Plunger

Tube

Coil

10

Connector

Figure 19. Dust bag shaker valve spare part list

37

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

11.6. PLASMA HEAD UNIT

The system supplying plasma torch movement

Figure 20. Plasma head installation drawing

38

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

11.7. PLASMA BRIDGE UNIT

Figure 21. Plasma bridge installation drawing

39

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

Figure 22. Plasma bridge unit installation drawing

40

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

11.8. X AXIS GEARBOX

The system supplying machine

movement in X axis

Figure 23. X axis gearbox installation drawing

41

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

11.9. Y AXIS GEARBOX

The system supplying machine

movement in Y axis

Figure 24. Y axis gearbox installation drawing

42

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

11.10. AJAN X-Y AXIS AC SERVO MOTOR

Figure 25. Ajan X-Y axis AC servo motor installation drawing

43

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

11.11. AJAN Z AXIS AC SERVO MOTOR

Figure 26. Ajan Z axis AC servo motor installation drawing

44

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

11.12. AJAN PLASMA TORCH

Figure 27. Ajan plasma torch installation drawing

45

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

46

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

11.12.1. AJAN PLASMA TORCH CONNECTION DIAGRAM

Figure 28. Ajan plasma torch connection diagram

47

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

11.13. GENERATOR

Figure 29. Generator

48

MAINTENANCE MANUAL FOR AJAN PRECISION PLASMA CUTTING MACHINES

MECHANICAL PARTS

11.13.1. TORCH COOLING SYSTEM

The plasma generator torch cooling tank is emptied before transportation and 20 lt. cooling liquid is

transported in the generator with the machine. A mixture of 30% Propileneglicol (C3H8O2), 69.9%

deionized water and 0.1% Benzotriazole (C6H5N3) is suggested for Ajan cooling liquid. This

mixture prevents freezing up to 12C.

Warning: The operations in colder than the above indicated degree, the propileneglicol ratio should

be increased. For the required ratios and material supply, please contact the manufacturer company.

WARNING