Académique Documents

Professionnel Documents

Culture Documents

Safety Alert - Accident Mansarovar A2 - Eng

Transféré par

prabhuarunkumarTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Safety Alert - Accident Mansarovar A2 - Eng

Transféré par

prabhuarunkumarDroits d'auteur :

Formats disponibles

SHEQ Alert!

No.20081219

February2009

ExplosionatMansarovar:HotWorkonHeaterTreater

Summary

Tanksanddrumsthatseemtobeemptyusuallystillhave

residuesinthebottom,inseamsandothercrevices.Justa

teaspoonofpetrolinadrumcanbeenoughtocausean

explosion,whenheatedandturnedintovapor.Thisiswhat

occurredonDecember19th,2008atMansarovarEnergy

ColombiaLtd.(MECL)inPuertoBoyac.

TwodaysbeforeHeatertreaterEHT106(seefigureno.1and

no.2)wasdrainedandvented(bysamplevalvesand3/4

valveontop)inordertoreplacethestudboltsandgasketsof

thefiretubeflange.Onthedayoftheeventworkactivities

changedfromcoldtohotworkwhenthedecisionwas

madetoremoveseveralstudboltswithacuttingtorch.An

explosionoccurredwhichkilledaMecnicosAsociadosS.A.

(MASA)employeeandsix(6)otheremployees,four(4)from

MASAandtwo(2)fromtheclientMansarovar,hadtobe

transportedbytraumahelicoptertothehospital.Theyall

suffered2ndand3rddegreeburnsfromtheexplosion.

MecnicosAsociadosS.A.issuesthisSafetyBulletintofocus

attentiononhotworkhazardsthatcontributedtothe

explosionatMansarovarEnergyColombiaLtd.(MECL)in

PuertoBoyacandspecificactionscontractorcantaketo

preventsimilaraccidents,whichinclude:

Preparingtanksanddrumsforhotwork;

ProperexecutionofPermitToWorksystem;

Managethechangeofscope.

Figure1.HeatertreateratMansarovarEnergyColombiaLtd.

Figure2.RupturedpartitionofHeatertreaterEHT106

HeatertreaterEHT106

Justateaspoonofpetrolinadrum

canbeenoughtocauseanexplosion,

whenheatedandturnedintovapor.

TheelectrostaticHeatertreaterisahorizontalunit

andthefunctionofthistreateristo:

InletDegassing

FreeWaterremoval

Heating

Electrostaticcoalescingofwaterdroplets

ControlleddischargeofGas/Oil/andWater

Theheatingsectionofthetreatercomprisesofa

UTypefiretubewhichisavailablewithagasor

oilfiredburnersystemandassociatedlocalcontrol

panel.

Page1of5

SafetyAlertNo.20081219|February2009

IncidentDescription

The15thofDecember,2008MASA

triedtostoptheflangefromleakingby

tighteningthestudboltsbyhandagain

andtheuseofsilicon.Despitethe

effortsmadebyMASApersonnel,the

leakingdidntstop.

th

The16 ofDecember,2008MASA

reportedverballytoMECLfield

managerthattheHeatertreaterwas

stillleakingandtherearenotableto

handtightenthestudbolts.

ThesamedayMECLcontracted

companyLAPSwhichisspecializedin

jointorqueconnections.

The17thofDecember,2008LAPS

diagnosedandadvisedtochangethe

studboltsandgasket.Thesameday

MECLpersonneldrainedtheHeater

treaterandopenedtheventilation

hatch(samplevalvesandthe3/4

valveontop).LAPSverifiedthestud

boltsfromthefiretubeflangewith

1.400poundoftorque.Noneofthe

boltscameloose.

Between11:30AMand01:00PMGMT

05:00aMASArepresentative

requestsworkpermitsbyfollowing

theproceduresofMECLandMECL

productionsupervisoraskedwelder

andhelpertoreturntotheworksite.

DuethechangeofworkMASA

workershadtopostponetheirlunch.

Between11:30AMand01:00PMGMT

05:00concernedwelderandhelper

arriveattheworksite.TheMECL

MajorMaintenanceEngineercalls

MECLProductionSupervisor.

Between11:30AMand01:00PMGMT

05:00MECLProductionSupervisor

andMECLProductionLeaderarrived

atthejobsiteforgastesting.

TheMECLProductionSupervisor

makesthemeasurementofthe

atmospheretodetectpresenceof

flammablegasses.

TheMECLProductionSupervisor

showsthereadingofthegastesterto

MECLProductionLeaderand

authorizedtheworkpermitfollowing

theproceduresofMECL.

MECLProductionSupervisorleftthe

jobsitetogiveinstructionstoanother

contractorandMECLProduction

Leaderwentbacktotheoffice

container.

The19thofDecember,2008;01:00PM

GMT05:00concernedwelderentered

thescaffoldandstartedtocutthestud

bolts.Finishedcuttingthefirststud

boltanexplosionfollowedand

expelledthe13TONfiretube.

Thewelderwaskilledduringtheact

whencrushedbetweenthefiretube

andthecrane30feetaway(seefigure

no.3).

Hishelper,standingunderneaththe

scaffoldsufferedburnsinhisfaceand

onhishands.

Three(3)otheremployeesfromMASA

andtwo(2)employeesfromMECL

suffered2ndand3rddegreeburns.All

ofthemweretransportedtotheburn

centerinBogotabytraumahelicopter.

AnemployeefromMASApassedaway

fivedayslaterinthehospitaldueto

hisinjuries.

The18thofDecember,2008LAPS

verifiedthestudboltsagainwitha

maximumof3.200poundoftorque.

Theyremovedseveralstudbolts

wherebyeight(8)studboltsdidnt

camelooseoffiretubeno.1andten

(10)didntcamelooseoffiretubeno.

2.

The19thofDecember,2008;10:30AM

GMT05:00MASAusedhandtools

(impactwrench,extensionbarand20

hammer)toremovethestudbolts

withthefollowingresult:

Firetubeno.1:Three(3)studbolts

couldntbeloosedbyhand.

Firetubeno.2:Six(6)studbolts

couldntbeloosedbyhand.MASA

welderandhelperlefttheworksite

forlunch.

Between11:30AMand01:00PMGMT

05:00MECLsupervisordecidesthat

thestudboltswillbecutwithatorch

andcallstheconcernedwelderand

helper.

Figure3.HeatertreaterEHT106withexpelledfiretubeafterexplosion.

Page2of5

SafetyAlertNo.20081219|February2009

IncidentAnalysis

MecnicosAsociadosS.A.(MASA)

usedphysicalevidence,interviewsand

informationfromMansarovarEnergy

ColombiaLtd.(MECL)toestablishthe

likelyfailuresequence:

Noformalhandoverbetween

production(MECL)and

maintenance(MASA);

ScopechangemadebyMECLnot

communicatedtoconcerned

responsible(s)inMASA;

Noworkpermitsforhotwork(only

coldwork).Lastminutedecisionin

thefield;

Noworkpermittrainingexecuted;

Gastestinginsufficient.Only

externaltestandMECLemployee

nottrained;

Hotworkisanyprocessthatgenerates

flames,sparksorheat.Itincludes

welding,cutting,grindingandsawing.

Thepreparationofthetankordrum

shouldbeconsideredaspartofthe

riskassessmentandcontrolmeasures

shouldbeidentified.

Isolation

Tanksshouldbeisolatedfromother

equipment,preferablybyremoving

pipesections.Ifpossible,disconnect

smalltanksandremovethemtoasafe

place.Donotrelyonisolationvalves;

evensmallleakscanhaveserious

consequences.

Emptying

Heatertreaterwasonlydrained;

Procedures(e.g.PermitToWork

system)availableandutilized,but

notexecuted.

Thetankordrumshouldbeemptied

bypumpingordrainingtheliquidinto

asuitablecontainer.Theresidues

shouldbedisposedofinlinewith

environmentalrequirementsandnot

tippedintodrains,sewersorwater

courses.

TimepressuretogetHeatertreater

inoperationagain;

Noproperhazardassessment,

includingintheassessment,people

trainedinthehazardassessment

processandtechnicalcompetentin

theworktobedoneandits

associatedrisks.

Inthisdocumentthree(3)important

activitieswillbehighlightedwhich

contributedtotheaccidentat

Mansarovar:

Preparingtanksanddrumsforhot

work;

PermitToWorksystem;

ManageofChange.

Hotworkisanyprocess

thatgeneratesflames,

sparksorheat.Itincludes

welding,cutting,grinding

andsawing.

PreparingTanksand

DrumsforHotWork

Cleaning

Inmostcases,cleaningwillbe

necessaryandincludethemethods:

Washingorjettingusingwateror

detergentsolutions;

Steamcleaning;and

Solventwashing/jetting.

Controlmeasureswillbeneededto

ensurethatthecleaningoperations

arecarriedoutsafely.

Gasfreeing

Vaporsandothervolatilematerialcan

sometimesberemovedbyblowingair

orsteamthroughthetank.Thisis

termedgasfreeing.Thevapor

concentrationshouldbemonitored

usingagasdetector.Gasfreeing,on

itsown,israrelyadequate,asmost

tanksanddrumswillstillcontainliquid

orsolidresiduestrappedinseamsand

Page3of5

Figure4.HeatertreaterEHT106

crevices.Agasdetectormaynot

detecttheseresiduesbuttheymay

stillbecapableofproducing

flammablevaporswhenheatedby

hotworkoperations.

Inspection

Inspectingtheinsideofatankordrum

thathaslimitedopeningsisdifficult.

Mirrorsandtorchescanbeused,but

anylightusedinsidethetankmustbe

flameproof,e.g.designedforusein

flammableatmospheres.Never

assumethatatankisfreeof

flammablevaporsorliquid;always

inspectitcarefully.

Agasdetectororexplosionmetercan

beusedtocheckforvapor,butit

needscareandtrainingtobeused

safely.Itwillnotdetectsolidmaterial

ornonvolatileliquids.

Inerting

Anotherwaytoreducetheriskofan

explosionistoreplacetheairinthe

tankordrumbyfillingitwithwateror

aninertgas,suchasnitrogen.Thiscan

beusefulwherecleaningisdifficult,

althoughthetankshouldalwaysbe

cleanedasmuchaspossible

beforehand.

Ifwaterisused,aventforthesteam

willbenecessary.Contaminatedwater

mayrequirespecialistwastedisposal.

Ifaninertgasisused,itcanbedifficult

topreventthegasescapingandair

gettingbackin.Therefore,anoxygen

meterwillbeneededtomonitorthe

oxygenlevels.Thismethodshouldbe

lefttospecialists.

SafetyAlertNo.20081219|February2009

Apermittoworksystem:

PermitToWork

System

a. Ensuresappropriatepeopleare

authorisedtocarryout

designatedwork.Thisdesignated

workmaybeaspecifictypeof

work,oranytypeofworkina

specificarea;

APermitToWorksystemisaformal

writtensystemusedtocontrolcertain

typesofworkwhichareidentifiedas

potentiallyhazardous.Itisalsoa

meansofcommunicationbetween

site/installationmanagement,plant

supervisorsandoperatorsandthose

whocarryoutthework.

Apermittoworkisadocumentwhich

specifiestheworktobedoneandthe

precautionstobetaken.Permitsto

workformanessentialpartofsafe

systemsofworkformany

maintenanceactivities.Theyallow

worktostartonlyaftersafe

procedureshavebeendefinedand

theyprovideaclearrecordthatall

foreseeablehazardshavebeen

considered.

Apermitisneededwhenmaintenance

workcanonlybecarriedoutifnormal

safeguardsaredroppedorwhennew

hazardsareintroducedbythework.

Examplesareentryintovessels,hot

workandpipelinebreaking.

Thepermittoworkformmusthelp

communicationbetweeneveryone

involved.Itshouldbedesignedbythe

companyissuingthepermit,taking

intoaccountindividualsiteconditions

andrequirements.

Separatepermitformsmaybe

requiredfordifferenttasks,suchas

hotworkandentryintoconfined

spaces,sothatsufficientemphasiscan

begiventotheparticularhazards

presentandprecautionsrequired.

b. Makesitcleartopeoplecarrying

outtheworktheexactidentity,

natureandextentofthejoband

thehazardsinvolved.Italso

outlinesanylimitationsonthe

extentoftheworkandthetime

duringwhichthejobmaybe

carriedout;

c. Specifiestheprecautionswhich

needtobetaken,includingsafe

isolationfrompotentialriskssuch

aselectricityandhazardous

substances;

d. Ensuresthepersonindirect

chargeoftheplantorinchargeof

theareawheretheplantis

located,isawareofallthework

beingdoneunderthepermitto

worksystem;

e. Providesasystemofcontinuous

control;

f. Providesarecordshowingthe

natureoftheworkandthe

precautionsneededwhichis

checkedbyacompetentperson

orpeople;

g. Providesforthesuitabledisplay

ofpermits;

h. Providesaprocedurefortimes

whenworkhastobesuspended;

i. Providesforcrossreferencingof

permitsforworkactivitiesthat

mayinteractoraffectone

another;

j. Providesaformalhandover

procedureforusewhenthe

permitisissuedforaperiod

longerthanoneshift;and

Figure5.StudboltsflangeofHeatertreater

k. Providesaformalhandback

proceduretoensurethatpartof

theplantaffectedbytheworkis

inasafeconditionandreadyfor

reinstatement.

Page4of5

Thepermittoworkform

musthelpcommunication

betweeneveryone

involved.

Managementof

Change

TheU.S.ChemicalSafetyandHazard

InvestigationBoard(CSB)issueda

SafetyBulletinitofocusattentionon

theneedforsystematicallymanaging

thesafetyeffectsofprocesschanges

inthechemicalindustry.

Thebulletindiscussestwoincidents

thatoccurredintheUnitedStatesin

1998.Eachcasehistoryoffersvaluable

insightsintotheimportanceofhaving

asystematicmethodforthe

managementofchange(MOC).An

MOCmethodologyshouldbeapplied

tooperationaldeviationsand

variances,aswellastopreplanned

changessuchasthoseinvolving

technology,processes,and

equipment.

LessonsLearned

Safetyissues/warningsrecognized

bySISamanagementteam,butno

promptaction.

Collaborationbetweenexecution

andHSEtobeenforcedby

managementteam.

Neverchangefromcoldtohot

workwithoutproperriskanalysis

andpermit.

Dontrelyonexperience.Respect

safetyawarenessandbarriers.

Valueculturalimpactondecision

making.

ClientHazardAnalysispriorto

bid/nobiddecision.

Managesafetyinthefieldinstead

ofkeyperformanceindicators

(KPIs).

SafetyAlertNo.20081219|February2009

Recommendations

MansarovarEnergyColombiaLtd.

Assuresafeworkprogramsandbarriersare

inplaceandemployeesaretrained.For

example:PermitToWorktraining,Job

SafetyAnalysis,LockOutTagOut,etc.

OVLinaconsortiumwithSINOPEC(TheNationalOilCompanyofChina)

hasacquiredOmimexdeColombiaon20thSeptember,2006.The

acquiredcompanyhasbeensubsequentlymergedintoMansarovar

EnergyColombiaLimited(MECL),a50:50JointVenturebetweenOVL

andSINOPEC.Earlier,OmimexdeColombiawasasubsidiaryofOmimex

Resources,Inc.whichisaprivatelyheldcompanybasedinFortWorth,

Texas,U.S.A.

Establishgatekeeper(forthiscontract)

onsitetoassureallsafetybarriersarein

place.Makeroledescriptionclearby

positionandauthorizationstowardsclient

andmaintenanceorganization.

Establishformalhandoverofequipment

betweenoperations(MECL)and

maintenance(MASA).Reviewhandover

proceduresandactivitieslike:Preparing

TanksandDrumsforHotWorkprocedure.

Assureemploymentconditionsdontaffect

safeworkpractice.Discusscontractand

laboragreementsandfollowupwith

representativesofCOPASOorotherworkers

committees.

MansarovarEnergyColombiaLimitedholds100%interestinthe

VelsquezfeemineralpropertylocatedintheMiddleMagdalenaBasin

andalsoholds100%interestintheVelsquezGalnPipeline,whichruns

189kmfromtheVelsquezpropertytoEcopetrolsBarrancabermeja

refinery.Inaddition,Mansarovaralsoholdsa50%interestinthenearby

NareandCocornAssociationContracts,surfacerights,drillingand

otheroilfieldequipmentforaselfsustainedoperation.Theother50%

interestinNareandCocornAssociationContractsareheldby

Ecopetrol,theNationalOilCompanyofColombiaMansarovaristhe

operatorofthefieldsandthepipelinewithinitscontract.Mansarovar

currentlyproducesapproximately21,500bblperday.

Conductaudittoallcontractsexecutedby

MASA.ReviewSHEQatrisksituations

identifiedandrelatedtotheMansarovar

accidentandidentifiedinthissafetyalert.

IncludeSHEQinTenderprocedureas

decisionmakingitemtoassurerisksare

identified,reviewedanddiscussedbefore

BID/NOBIDdecision.

Assureswiftreportandresponseofsafety

issuestoMTandviceversa.Theproposalis

todiscussrecordableincidentswith

concernedManagementTeamofthe

OperatingCompanyandSISaMT

representativeswithin24hours.

ExecuteManagementsafetywalkstoassure

executivepersonalcanfeedbacksafety

issuesand/orconcernsdirectlytotop

management.Makesuremanagement

supportsrefusetoworkdecisionsmadeby

executivepersonalinthefield.

Reference

i

U.S.ChemicalSafetyandHazardInvestigationBoardManagementofChange;No.200104SB|August2001

http://www.csb.gov/safety_publications/docs/moc082801.pdf

Page5of5

SafetyAlertNo.20081219|February2009

Vous aimerez peut-être aussi

- 11 8166 WP Streaming Projects FINALDocument8 pages11 8166 WP Streaming Projects FINALprabhuarunkumarPas encore d'évaluation

- Design Challenges For Recip Compressors in Specialty Gas ServicesDocument17 pagesDesign Challenges For Recip Compressors in Specialty Gas Servicessammar_10Pas encore d'évaluation

- Contaminants and EffectsDocument24 pagesContaminants and EffectsdediodedPas encore d'évaluation

- 05 PumpsDocument80 pages05 PumpsRoberto O'ConnorPas encore d'évaluation

- 92-Understanding The Pulsation and Vibration Control Concepts - Api 618 Paper JDT Kea Asp PDFDocument24 pages92-Understanding The Pulsation and Vibration Control Concepts - Api 618 Paper JDT Kea Asp PDFAlfred LamPas encore d'évaluation

- Pulsation Course BruemmerDocument43 pagesPulsation Course BruemmerAyman ElsebaiiPas encore d'évaluation

- Biodiesel Workshop Presentation 2012-10-05Document40 pagesBiodiesel Workshop Presentation 2012-10-05ali razaPas encore d'évaluation

- StartupIndia ActionPlan 16january2016Document40 pagesStartupIndia ActionPlan 16january2016Kaushik RudraPas encore d'évaluation

- TP 157 HSS RemovalDocument7 pagesTP 157 HSS RemovalSufyan_KhanPas encore d'évaluation

- Norsok ST 2001Document131 pagesNorsok ST 2001mamounsdPas encore d'évaluation

- SME2011 Rawlins MechanismsFlotationOilDocument11 pagesSME2011 Rawlins MechanismsFlotationOilprabhuarunkumarPas encore d'évaluation

- A Review of Compressor Lines Pulsation Analysis and Muffler DesigDocument11 pagesA Review of Compressor Lines Pulsation Analysis and Muffler DesigprabhuarunkumarPas encore d'évaluation

- Watercut MeterDocument3 pagesWatercut MeterprabhuarunkumarPas encore d'évaluation

- TP 157 HSS RemovalDocument7 pagesTP 157 HSS RemovalSufyan_KhanPas encore d'évaluation

- Carry OverDocument2 pagesCarry OverprabhuarunkumarPas encore d'évaluation

- 02 PropaneRefrigerationLoopDocument26 pages02 PropaneRefrigerationLoopChristian ChineduPas encore d'évaluation

- CV To DiameterDocument2 pagesCV To DiameterprabhuarunkumarPas encore d'évaluation

- Indirect Fired HeaterDocument3 pagesIndirect Fired Heatermatteo2009Pas encore d'évaluation

- Indirect Fired HeaterDocument3 pagesIndirect Fired Heatermatteo2009Pas encore d'évaluation

- Bonny Assay ClasificationDocument2 pagesBonny Assay ClasificationprabhuarunkumarPas encore d'évaluation

- Section 20Document78 pagesSection 20prabhuarunkumarPas encore d'évaluation

- Indian Chemical Industry 2012-17 PDFDocument107 pagesIndian Chemical Industry 2012-17 PDFaagrawal3Pas encore d'évaluation

- Indian Chemical Industry 2012-17 PDFDocument107 pagesIndian Chemical Industry 2012-17 PDFaagrawal3Pas encore d'évaluation

- STD Vertical Tank Dmns Vs VolumeDocument2 pagesSTD Vertical Tank Dmns Vs VolumeprabhuarunkumarPas encore d'évaluation

- Chapter 2: Heat Exchangers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocument85 pagesChapter 2: Heat Exchangers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallNadirah RahmanPas encore d'évaluation

- Polyox PDFDocument24 pagesPolyox PDFea100% (1)

- 326 - Cone Layout Tool Ver E4.02Document1 page326 - Cone Layout Tool Ver E4.02Honey TiwariPas encore d'évaluation

- Tank & DikeDocument6 pagesTank & Dikeacastillo1339Pas encore d'évaluation

- Liquid 20distributorsDocument8 pagesLiquid 20distributorsprabhuarunkumarPas encore d'évaluation

- Property 20package 20descriptionsDocument23 pagesProperty 20package 20descriptionsGonnartPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Recovery From Black LiquorDocument7 pagesRecovery From Black LiquorNav KumarPas encore d'évaluation

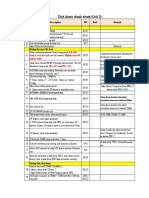

- Shutdown Check Sheet-Rev PDFDocument3 pagesShutdown Check Sheet-Rev PDFTino FerinandaPas encore d'évaluation

- Sealing Hot Water 3-3Document3 pagesSealing Hot Water 3-3Aiman ArifPas encore d'évaluation

- D9x13SeriesII 10091Document6 pagesD9x13SeriesII 10091madal25Pas encore d'évaluation

- ASTM D-3177 Azufre Total en CarbonDocument4 pagesASTM D-3177 Azufre Total en CarbonGilda Elizabeth Caballero LumbaPas encore d'évaluation

- TelusDocument3 pagesTelusGembonz Crew Gon'z SpeedPas encore d'évaluation

- Commercial Gas Boilers Efficient - Aae Series: For Hydronic Heating SystemsDocument4 pagesCommercial Gas Boilers Efficient - Aae Series: For Hydronic Heating SystemsEd BeneschPas encore d'évaluation

- Overview of Drilling Operations MAY 2011 SEMDocument48 pagesOverview of Drilling Operations MAY 2011 SEMdatug100% (1)

- PSV Sizing and Reaction Force Modelling Rev 1.1Document11 pagesPSV Sizing and Reaction Force Modelling Rev 1.1Hoang-Vu BuiPas encore d'évaluation

- GR00001000 00Document56 pagesGR00001000 00Art Del R SalongaPas encore d'évaluation

- Density - StudenT QuestionDocument6 pagesDensity - StudenT Questionmirete86Pas encore d'évaluation

- 02b Hydrocarbon Source RocksDocument28 pages02b Hydrocarbon Source Rocksirvan saktiPas encore d'évaluation

- List of Oil ZFDocument16 pagesList of Oil ZFkujkoja100% (1)

- 300+ TOP I.C. ENGINES Objective Questions and Answers PDF MCQsDocument39 pages300+ TOP I.C. ENGINES Objective Questions and Answers PDF MCQsMayank PachauriPas encore d'évaluation

- T4W Filter ListDocument7 pagesT4W Filter List10% (1)

- Chapter 4 Study Guide PDFDocument57 pagesChapter 4 Study Guide PDFkPas encore d'évaluation

- Dual Fuel - Ms9001Document6 pagesDual Fuel - Ms9001shravani mangalpalliPas encore d'évaluation

- Be20 Memory Items PDFDocument486 pagesBe20 Memory Items PDFJose100% (2)

- BW Gas Alert Micro5 QSG D6258 1 2009Document29 pagesBW Gas Alert Micro5 QSG D6258 1 2009Khabtane AbdelhamidPas encore d'évaluation

- Section 3 Itt Technical PackageDocument157 pagesSection 3 Itt Technical PackageAli HosseiniPas encore d'évaluation

- Datasheet SP 2000wDocument2 pagesDatasheet SP 2000wWilliam Boyle Jr.Pas encore d'évaluation

- Alternative FuelDocument358 pagesAlternative FuelEduardo Vasconcelos100% (1)

- PDI ChecklistDocument2 pagesPDI ChecklistAmmar Baig80% (5)

- Terminology Related To I.C. EngineDocument14 pagesTerminology Related To I.C. EngineIbrahim KhaleelPas encore d'évaluation

- Forest Oil Project Well Control Bridging Document2Document13 pagesForest Oil Project Well Control Bridging Document2Sean Kalu Onuoha100% (1)

- Function 1 MAREDocument100 pagesFunction 1 MARERj DeciertoPas encore d'évaluation

- Fuel, Ignition, Lubrication, Cooling SystemsDocument24 pagesFuel, Ignition, Lubrication, Cooling SystemsIbrahim KhaleelPas encore d'évaluation

- Pages From Cvh99Document16 pagesPages From Cvh99Paraschiv AlexandruPas encore d'évaluation

- MTL Intern ReportDocument25 pagesMTL Intern ReportnumanPas encore d'évaluation