Académique Documents

Professionnel Documents

Culture Documents

Oerlikon Citotig 240 Ac DC

Transféré par

jan_villalisTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Oerlikon Citotig 240 Ac DC

Transféré par

jan_villalisDroits d'auteur :

Formats disponibles

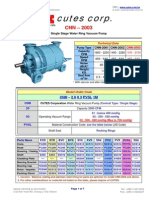

CITOTIG 240 & 310 AC/DC

TIG AC/DC machine for highly

demanding welding specialists

www.oerlikon-welding.com

CITOTIG AC/DC

2009-562

2010-639

2011-006

CITOTIG AC/DC machines are designed to meet the expectations

of the most demanding welders. Optimum performance

is associated with the ruggedness necessary for daily work

both in the workshop and on site.

CITOTIG AC/DC

For high demanding

sectors of activity.

High quality

welding results

on carbon and

stainless steels

and light alloys.

Petrochemicals

2001-317

2001-316

Boiler making

2010-835

Shipbuilding

2008-760

2004-298

Piping

2010-810

Offshore

CITOTIG AC/DC

0255-27

Improving your quality and productivity is our target.

CITOTIG AC/DC machines are the most advanced equipment

available on the market for the applications.

2000-499

The technical characteristics that make the difference.

CITOTIG AC/DC are designed for manual TIG welding of all metals, including

aluminium and stainless steel.

They can also be easily used for MMA welding.

You can choose single- or 3-phase primary alimentation in 2 intensity range

- CITOTIG 240 AC/DC is a 230 A @ 40% in a single phase power source,

for joining aluminium up to 5 mm thick,

- CITOTIG 310 AC/DC is a 300 A @ 40% in a three phase power source.

All the characteristics that TIG welding need. CITOTIG AC/DC permits TIG

welding with any type of current: AC, DC+, and DC-.

Additional features for improved results:

COMPOTIG

Is a dedicated process for welding thin

sheet. Developed with a strict focus on

assembly and welding thin sheet.

Sturdy and robust process that uses

simultaneously AC and DC. The composition

of the two different processes can be

regulated to obtain complete penetration

and effective cleaning. More AC for better

cleaning and more DC for better penetration.

Without TACK FOR THIN

2004-294

With TACK FOR THIN

The difference in the tack welds is clearly visible. TACK

FOR THIN was used to weld the piece on the bottom,

and regular TIG was used on the piece on the top.

An easy to use front panel

The COMPOTIG

function combines

the beneficial

qualities of both

direct and alterning

current. It simplifies

joining aluminium

alloys and

decreases the

number of defects.

1

3

4

2

5

11

6

7

8

Pulsed TIG and

synergic pulsed TIG

The pulsed TIG process, due to the

possibility of regulation of all parameters,

allows improved control of the weld pool.

In order to simplify the regulation, there is

an additional process, synergic pulsed TIG.

With the synergic pulsed system, there

is no need to adjust the

welding current or other

pulse parameters that are

pre-programmed.

The pulse frequency gives

a highly concentrated arc

and increases welding

speed.

CITOSTEP

With the CITOSTEP function, two current

levels can be chosen, the welding current

and the base current. This facilitates the

change from one to the other by rapidly

pressing the torch trigger.

The CITOSTEP function can be used to

adjust heat input momentarily, to change

welding positions or to replenish the filler

metal supply without having to stop

welding.

1

2

3

4

5

6

7

8

9

10

11

12

13

10

12

13

Safety and operation indicators

Welding cycle layout

TIG operation selection

MMA operation selection

Parameter value display

Torch cycle selection

Parameter selection

Striking selection HF/ Lift

Pulse / Spot selection

Program management

Main regulation knob

Gas test

Remote control operations

2009-564_r

TACK FOR THIN device

2003-201

Comply with the EN 61000-3-2/12

standard effective since december

2010, that limits the harmonic

currents produced by equipment

connected to public low-voltage

systems

3.9 kVA

7.9 kVA

58 V

3 A - 230 A / 19.2 V

10 A - 180 A / 27.2 V

230 A

200 A

180 A

63 V

3 A - 300 A / 22 V

10 A - 250 A / 30 V

300 A

230 A

190 A

DC - AC - Mix AC/DC - Pulsed

AC - DC- - DC+

BI LEVEL CURRENT - TACK FOR THIN - COMPOTIG

10

Trolley

Remote control

Foot pedal

Foot-operated

control pedal

RC1

5 m or 10 m long

FP1

5 m long

COOLERTIG III

230 V (+/- 15%)

24 V DC

Cooler

Trolley

1.0 kW

4 bar

T3

475 x 200 x 405 mm

9 kg

525 x 198 x 295 mm

8 kg

To order

CITOTIG 240 AC/DC

W000275842

COOLERTIG II

W000275844

TROLLEY T3

W000277087

RC1 - 5 m long

W000263311

RC1 - 10 m long

W000270324

FP1

W000263313

CITOTIG 310 AC/DC

W000278470

COOLERTIG III

W000278471

TROLLEY T3

W000277087

RC1 - 5 m long

W000263311

RC1 - 10 m long

W000270324

FP1

W000263313

2010-631

Cooler

Remote control

2006-651

IP 23C

475 x 200 x 405 mm

505 x 195 x 440 mm

17 kg

25 kg

COOLERTIG II

Power source

Options and accessories

These equipment are designed for industrial and professional use only.

The CITOTIG 310 AC/DC does not comply with EN 61000-3-2/12. If it is connected

to a public low voltage system, it is the responsibility of the installer or user of the

equipment to ensure, by consultation with the distribution network operator if

necessary, that the equipment may be connected. (See also the instruction manual)

PRIMARY

Power supply

Cooling unit power

Maximum pressure

GENERAL

Dimensions (l x w x h)

Weight

2010-636

16 A

2006-649

Maximum primary

consumption (100%)

Fuses

SECONDARY

Open circuit voltage

Welding range TIG

Welding range MMA

40%

Duty

60%

cycle

100%

APPLICATION

Processes TIG

Processes MMA

Additional Feature

Programs

GENERAL

EN 60974-1

StanEN 60974-10

dard

EN 61000-3-2/12

Protection index

Dimensions (l x w x h)

Weight

3 Ph - 50/60 Hz

400 V (+/-10%)

1 Ph - 50/60 Hz

230 V ( +/-15%)

2006-731

Power supply

2009-562

CITOTIG 240 AC/DC CITOTIG 310 AC/DC

PRIMARY

TIG torches

2003-202

The new range of CITORCH T TIG torches perfectly fit with

the high level of quality provided by the CITOTIG AC/DC machine.

The adapted models are CITORCH T 30 for the air cooled

torches and the CITORCH T 10 W for the water cooled models.

They come either with trigger as a blade:

RL models or as a button: EB types.

See complete range

in the CITORCH T NG

brochure.

The EB types are modular as they can be modified with the

different type of buttons.

2010-643

2010-668

RL: Blade

CITORCH T NG 30 RL C5B

CITORCH T NG 10 W RL C5B

CITORCH T NG 30 EB C5B

Air

Water

Air

Water

200 A @ 35%

250 A @ 100%

200 A @ 35%

250 A @ 100%

Cooling

Duty Cycle

To order

8m

5m

8m

5m

8m

5m

8m

W000278988

W000278989

W000278992

W000278993

W000278384

W000278385

W000278388

W000278389

W000306443

W000306441

Modular system:

W000306441

As an option, adjustable torch bodies are available. Welding in

inaccessible locations becomes easier. You have the choice of 2 heads,

small and large to be mounted on air cooled or water cooled bodies.

Air cooled body - W000279381

Water cooled body - W000279382

Head CITORCH T NG 10 - W000279383

Head CITORCH T NG 20-30 - W000279384

2010-949

Horizontal potmeter - W000279370

2 Vertical potmeter - W000279246

3 Doublon button - W000279242

4 Blade - W000279245

For potmeter adapt the wiring to the welding

machine using the 7 pins plug - W000271826

1

2010-948

2011-005

W000306443

In option: Adjustable heads

All torches are delivered with a single

button module. If you want another

control module, order it separatly.

1

CITORCH T NG 10 W EB C5B

5m

Cat. number

maintenance

box

2011-007

EB: Button

Contacts for other countries:

ALW Export Department Italy

Via Torricelli15/A

37135 VERONA

Tel.: +39 045 82 91 511- Fax: +39 045 82 91 536

E-mail: export.alwitaly@airliquide.com

ALW Export Department France

13, rue dEpluches

BP 70024 Saint Ouen lAumne

95315 CERGY-PONTOISE Cedex

Tel.: +33 1 34 21 33 33 - Fax: +33 1 30 37 19 73

E-mail: export.alwfrance@airliquide.com

www.airliquide.com

Air Liquide is the world leader in gases for industry, health and the environment, and is present in over 75 countries with 43.000 employees Oxygen, nitrogen,

hydrogen and rare gases have been at the core of Air Liquides activities since its creation in 1902. Using these molecules, Air Liquide continuously reinvents

its business, anticipating the needs of current and future markets. The Group innovates to enable progress, to achieve dynamic growth and a consistent

performance. Air Liquide combines many products and technologies to develop valuable applications and services not only for its customers but also for society.

Air Liquide Welding France reserves the right to carry out modifications to its machinery without prior notice.

The manufacturer accepts no liability for illustrations, descriptions and characteristics, which are for information only.

PORTUGAL

AIR LIQUIDE SOLDADURA LDA

Rua Dr. Antnio Loureiro Borges, 4-2 Arquiparque

Miraflores - 1495-131 ALGS

Tel: +351 21 41 64 900 - Fax: +351 21 41 69 40

ROMANIA

DUCTIL

Aleea Industriilor Nr 1 - 120224 BUZAU

Tel.: +40 238 722 058 - Fax: +40 238 716 861

RUSSIA

AIR LIQUIDE WELDING

17 Vorontsovskaya Str. - 109147 MOSCOW

Tel.: +7 495 641 28 98 - Fax: +7 495 641 28 91

SCANDINAVIA

OERLIKON SKANDINAVIEN AB

Krossverksgatan 7 - 216 16 LIMHAMN

Tel.: +46 (0)40 670 15 00 - Fax: +46 (0)40 670 15 01

SLOVAKIA

AIR LIQUIDE WELDING CENTRAL EUROPE S.R.O.

Hlohoveck 6 - 951 41 NITRA - LUIANKY

Tel.: +421 37 692 4610 - Fax: +421 37 651 28 04

SPAIN

OERLIKON SOLDADURA SA

Poligono Industrial la Noria Carretera de Castellon

Km-15,500 - 50730 El Burgo de Ebro - ZARAGOZA

Tel.: +34 976 10 47 00 - Fax: +34 976 10 42 67

SWITZERLAND

OERLIKON SCHWEISSTECHNIK AG

Mandachstrasse 54 - CH 8155 NIEDERHASLI

Tel.:+41 44 3076 111 - Fax: +41 44 3076 112

THAILANDE

AIR LIQUIDE WELDING THAILAND Co. Ltd.

40 Moo 6 - Ramindra Road Km 9.5 - KHANNAYAO, BANGKOK 10230

Tel.: +66 29 43 2250 - Fax: +66 29 43 2256

UAE

AIR LIQUIDE WELDING MIDDLE EAST FZE

Jebel Ali free zone warehouse No. FZS1AH05

P.O. BOX 18734 - Jebel Ali - DUBAI

Tel.: +971(0)48861606 - Fax: +971(0)48861608

U. K.

AIR LIQUIDE WELDING Ltd

Low March / London Road - DAVENTRY - Northants NN11 4SD

Tel.: +44 1 327 70 55 11 - Fax: +44 1 327 70 13 10

UKRAINE

AIR LIQUIDE WELDING UKRAINE, Llc.

Moskovskij Prospect 199 - Office 339 - 61037 KHARKOV

Tel.: +38 057 728 08 52- Fax: +38 057 728 08 53

BELGIUM

AIR LIQUIDE WELDING BELGIUM SA

Z.I. West Grijpen - Grijpenlaan 5 - 3300 TIENEN

Tel.: +32 16 80 48 20 - Fax: +32 16 78 29 22

CHINA

SAF SHANGHAI REP.OFF.

Rm 722 Pine City Hotel

777 Zhao Jia Bang Lu - SHANGHAI 200032

Tel.: +86 21 64 43 89 69 - Fax: +86 21 64 43 58 97

CZECH REPUBLIC

AIR LIQUIDE CZ S.R.O. - Welding and Cutting

Podnikatelsk 565 - Arel SVUM - 190 11 PRAHA 9 - Bchovice

Tel.: +420 274 023 163 - Fax: +420 274 023 233

FRANCE

AIR LIQUIDE WELDING FRANCE

13, rue dpluches - BP 70024 Saint-Ouen lAumne

95315 CERGY PONTOISE Cedex

Tel.: +33 1 34 21 33 33 - Fax: +33 1 34 21 31 30

GERMANY

OERLIKON SCHWEISSTECHNIK GmbH

Industriestrasse 12 - D-67304 EISENBERG/PFALZ

Tel.: +49 6351 4760 - Fax: +49 6351 476 335

HUNGARY

AIR LIQUIDE HUNGARY - Welding & Cutting

Krisztina krt. 39/b - H-1013 BUDAPEST

Tel.: +36 1 339 8650 - Fax: +36 1 339 8649

ITALY

AIR LIQUIDE WELDING ITALY

Via Torricelli 15/A - 37135 VERONA

Tel.: +39 045 82 91 511 - Fax: +39 045 82 91 536

LUXEMBOURG

AIR LIQUIDE WELDING LUXEMBOURG S.A.

5 rue de la Dportation - BP 1385 - L-1415 LUXEMBOURG

Tel.: +352 48 54 56 - Fax: +352 48 54 57

MALAYSIA

SAF-OERLIKON MALAYSIA SDN BHD

No 10, Jalan TPP 5/1

Taman Perindustrian Puchong - 47100 PUCHONG, SELANGOR

Tel.: +603 8060 8638 - Fax: +603 8061 620

NETHERLANDS

AIR LIQUIDE WELDING NETHERLANDS

Rudonk 6 B - NL 4824 AJ BREDA

Tel.: +31 76 541 00 80 - Fax: +31 76 541 58 96

POLAND

AIR LIQUIDE WELDING POLSKA - SP. Z.o.o

UL. Porcelanowa 10 - 40-246 KATOWICE

Tel.: +48 32 609 04 50 - Fax: +48 32 609 04 60

ALW - W000277243 - 01 2011 - PLDB 6848

Contacts

Vous aimerez peut-être aussi

- Flex Buffalo - w000266150 - en - Noc36993Document8 pagesFlex Buffalo - w000266150 - en - Noc36993silvestre_25Pas encore d'évaluation

- SOCOLMATICDocument15 pagesSOCOLMATICtavi230Pas encore d'évaluation

- Self Priming Monoblock Pump: Hi-Flow SeriesDocument4 pagesSelf Priming Monoblock Pump: Hi-Flow Seriespkgoyal1983Pas encore d'évaluation

- MULTi-V NT ENG 60HzDocument44 pagesMULTi-V NT ENG 60HzMarco Antonio Zelada HurtadoPas encore d'évaluation

- WEG DC Motor 678 Brochure EnglishDocument8 pagesWEG DC Motor 678 Brochure EnglishS Sarath ChandraPas encore d'évaluation

- Moulded Case Circuit Breakers: New DU Series 20 A To 250 ADocument8 pagesMoulded Case Circuit Breakers: New DU Series 20 A To 250 AtanushagrPas encore d'évaluation

- ERKE Group, CompAİr Dizel Seyyar Kompresör Kataloğu (İng.)Document14 pagesERKE Group, CompAİr Dizel Seyyar Kompresör Kataloğu (İng.)erkegroupPas encore d'évaluation

- Robotmount: Specified Internationally For The New Arc Welding Robot ARC Mate 100icDocument8 pagesRobotmount: Specified Internationally For The New Arc Welding Robot ARC Mate 100icAsrul Arashi IrdianaPas encore d'évaluation

- Multi-H Eng 50hzDocument8 pagesMulti-H Eng 50hzIzquierdo AlfedPas encore d'évaluation

- VFD DocumentsDocument592 pagesVFD DocumentsLe Anh Dang50% (2)

- Wet and Dry Vacuum Cleaners GuideDocument2 pagesWet and Dry Vacuum Cleaners GuideAPas encore d'évaluation

- Att 472008172710Document2 pagesAtt 472008172710APas encore d'évaluation

- Tapflo CT BrochureDocument8 pagesTapflo CT BrochureСања БанковићPas encore d'évaluation

- General Catalog 2011: SELCO S.R.LDocument194 pagesGeneral Catalog 2011: SELCO S.R.LPapp ZsoltPas encore d'évaluation

- Tongil Gu SeriesDocument3 pagesTongil Gu Seriesmatthew_k_kohPas encore d'évaluation

- Efficient Modular Cooling Towers for Air Conditioning and Industrial ApplicationsDocument12 pagesEfficient Modular Cooling Towers for Air Conditioning and Industrial ApplicationsnkhhhPas encore d'évaluation

- On Load Changeover Switches Manual/Motorised OperationDocument12 pagesOn Load Changeover Switches Manual/Motorised Operationrajpre1213Pas encore d'évaluation

- JAVAC - Your experts in welding technology 2010Document33 pagesJAVAC - Your experts in welding technology 2010aisman8Pas encore d'évaluation

- Welding Products (Pg164-180)Document17 pagesWelding Products (Pg164-180)EswaranPas encore d'évaluation

- York Furnace ManualDocument8 pagesYork Furnace ManualToky100Pas encore d'évaluation

- Steam SterilizationDocument27 pagesSteam SterilizationJm Larrea CasanovaPas encore d'évaluation

- 30HXC CNDocument12 pages30HXC CNtechnokakiPas encore d'évaluation

- Exploded Office Espresso Machine DiagramDocument24 pagesExploded Office Espresso Machine DiagramFrank DonovanPas encore d'évaluation

- CL-kompl EDocument6 pagesCL-kompl EpecqroPas encore d'évaluation

- JJ.J3C v2Document2 pagesJJ.J3C v2GOLIANDROPas encore d'évaluation

- V270SDocument2 pagesV270SlainstanPas encore d'évaluation

- Dunkin Brands Global Parts CML Catalog PDFDocument68 pagesDunkin Brands Global Parts CML Catalog PDFAmin Santana100% (1)

- REXA Fit - Submersible Waste Water PumpsDocument22 pagesREXA Fit - Submersible Waste Water PumpsAdrian DragusinPas encore d'évaluation

- Bomba CNN 2003 PVSLDocument7 pagesBomba CNN 2003 PVSLvictorPas encore d'évaluation

- Trunnion Mounted Ball Valves API 6D & 6ADocument2 pagesTrunnion Mounted Ball Valves API 6D & 6A2009tamerPas encore d'évaluation

- Sewage Pumps Catalogue Drainage and Sewage SystemsDocument618 pagesSewage Pumps Catalogue Drainage and Sewage SystemsOzren Djuric100% (1)

- Ghidini p87 88 Navod ND enDocument31 pagesGhidini p87 88 Navod ND enjunkyjunk7116Pas encore d'évaluation

- SENTRON - LV10-PH01 - Complete English 2014Document62 pagesSENTRON - LV10-PH01 - Complete English 2014Patrick MacielPas encore d'évaluation

- Optimex Prei RangeDocument12 pagesOptimex Prei RangeThomas DamonPas encore d'évaluation

- In-Line duct fans TD-MIXVENTDocument26 pagesIn-Line duct fans TD-MIXVENTWilder Phill Arzapalo GinesPas encore d'évaluation

- v270t ENGDocument2 pagesv270t ENGStojanovic MiodragPas encore d'évaluation

- Sentron 3WT BrochureDocument6 pagesSentron 3WT BrochureAchint KumarPas encore d'évaluation

- Autopress 62Document4 pagesAutopress 62Ken VikstromPas encore d'évaluation

- Current Transformer Iosk 1Document8 pagesCurrent Transformer Iosk 1Dumitru Tănase0% (1)

- CAT 003 1 - 06 U TronicDocument20 pagesCAT 003 1 - 06 U Tronic4nagPas encore d'évaluation

- SCOH-K Tech Guide 0705Document48 pagesSCOH-K Tech Guide 0705Emir OmerdicPas encore d'évaluation

- B3887BHF1Document4 pagesB3887BHF1xianmingPas encore d'évaluation

- Compressed Air Filtration-Product Catalogue 2009Document52 pagesCompressed Air Filtration-Product Catalogue 2009Jose SantosPas encore d'évaluation

- TP SeriesDocument3 pagesTP SeriesPrasad KadamPas encore d'évaluation

- Vanzetti Cryogenic Pumps & Technology GuideDocument0 pageVanzetti Cryogenic Pumps & Technology GuidekanchanabalajiPas encore d'évaluation

- Maa Pitambra - BANK Project ReportDocument76 pagesMaa Pitambra - BANK Project ReportSanu KS100% (1)

- The European Products Catalogue 2013Document237 pagesThe European Products Catalogue 2013anon_558925735Pas encore d'évaluation

- SGQ ATS V2.4 en PDFDocument11 pagesSGQ ATS V2.4 en PDFnhocti007Pas encore d'évaluation

- VTL 30 DetailsDocument4 pagesVTL 30 DetailspranaybinaykePas encore d'évaluation

- Gardner Denver Industrial Blowers TF 140L K202Document8 pagesGardner Denver Industrial Blowers TF 140L K202Aleksandar JočićPas encore d'évaluation

- IE Catalogue 2007Document38 pagesIE Catalogue 2007Вадим НикитенкоPas encore d'évaluation

- Bry-Air Dehumidifier FFB SeriesDocument6 pagesBry-Air Dehumidifier FFB Seriesmfisol2000Pas encore d'évaluation

- Problem Encounterd and Their SolutionDocument6 pagesProblem Encounterd and Their SolutionTophe DimaapiPas encore d'évaluation

- MAXROY Series A, B & D DatasheetDocument4 pagesMAXROY Series A, B & D Datasheetnguyenquoc1988Pas encore d'évaluation

- Iron50 Ex 230 Vac 12 24 VDC g237Document1 pageIron50 Ex 230 Vac 12 24 VDC g237Najam KhanPas encore d'évaluation

- TITANIA 1138enDocument4 pagesTITANIA 1138enalexprgPas encore d'évaluation

- Ventilator - Mixvent-Td (En)Document23 pagesVentilator - Mixvent-Td (En)Muhidin KozicaPas encore d'évaluation

- Katalogos Genikos Ot-Oetl FortioyDocument82 pagesKatalogos Genikos Ot-Oetl FortioyMarco OlazabalPas encore d'évaluation

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- Real Time Braille To Speech Using PythonDocument10 pagesReal Time Braille To Speech Using PythonKali LinuxPas encore d'évaluation

- Myers Et Al - Clear and Present ThinkingDocument214 pagesMyers Et Al - Clear and Present ThinkingAEPas encore d'évaluation

- Unit 30 WorkDocument2 pagesUnit 30 WorkThanh HàPas encore d'évaluation

- Hydro Cyclone: Centripetal Force Fluid ResistanceDocument10 pagesHydro Cyclone: Centripetal Force Fluid ResistanceMaxwell ToffahPas encore d'évaluation

- Artificial MusclesDocument8 pagesArtificial MusclespinnakapentiumPas encore d'évaluation

- 268US03 Oiltech Technical & Product Catalogue Letter WDocument48 pages268US03 Oiltech Technical & Product Catalogue Letter WMauricio CarestiaPas encore d'évaluation

- Field Behaviour of Stiffened Deep Cement Mixing PilesDocument17 pagesField Behaviour of Stiffened Deep Cement Mixing PilesNguyen Quoc KhanhPas encore d'évaluation

- COE 107.04 Cathodic Protection Monitoring Instruments and ProceduresDocument42 pagesCOE 107.04 Cathodic Protection Monitoring Instruments and ProceduresMo'tasem Serdaneh100% (1)

- EPABX User's Guide for Making Calls and Using FeaturesDocument4 pagesEPABX User's Guide for Making Calls and Using FeaturesPraveen KumarPas encore d'évaluation

- Single Point Loading Working Model Specifications and Parts OverviewDocument4 pagesSingle Point Loading Working Model Specifications and Parts OverviewAnonymous CYdagI100% (1)

- Zelenbabini Darovi Ivana N Esic - CompressDocument167 pagesZelenbabini Darovi Ivana N Esic - CompressСања Р.0% (1)

- Organizational Structure and ProfilesDocument178 pagesOrganizational Structure and ProfilesImran Khan NiaziPas encore d'évaluation

- Industrial Wire Cutting Machine: A Senior Capstone Design ProjectDocument17 pagesIndustrial Wire Cutting Machine: A Senior Capstone Design ProjectTruta IonutPas encore d'évaluation

- CH 07Document40 pagesCH 07Ambreen31Pas encore d'évaluation

- ResumeDocument4 pagesResumeBazlaa HasmanPas encore d'évaluation

- Ref ModulesDocument148 pagesRef ModuleshoneyPas encore d'évaluation

- ACP160DDocument14 pagesACP160Dinbox934Pas encore d'évaluation

- High Current Transistor SpecsDocument5 pagesHigh Current Transistor SpecsamernasserPas encore d'évaluation

- Final Koni FinalDocument124 pagesFinal Koni FinalBinod BoharaPas encore d'évaluation

- Aadhaar is proof of identity, not citizenshipDocument1 pageAadhaar is proof of identity, not citizenshipPARTAPPas encore d'évaluation

- Specification of PCB800099 Controller Board V1.0Document10 pagesSpecification of PCB800099 Controller Board V1.0benabdullahPas encore d'évaluation

- Generate power from solar roof tilesDocument4 pagesGenerate power from solar roof tilesshalinthPas encore d'évaluation

- IRCTC Next Generation Eticketing SystemDocument4 pagesIRCTC Next Generation Eticketing Systemsivagokul526Pas encore d'évaluation

- LG - Week 1 - Operations - ManagementDocument4 pagesLG - Week 1 - Operations - ManagementMechaella Shella Ningal ApolinarioPas encore d'évaluation

- TFT-LCD TV/MONITOR SERVICE MANUALDocument54 pagesTFT-LCD TV/MONITOR SERVICE MANUALhimkoPas encore d'évaluation

- Assignment 5: Building More Complex Tasks: 1 BackgroundDocument3 pagesAssignment 5: Building More Complex Tasks: 1 Backgroundt_hoffmannPas encore d'évaluation

- Management Science BUMA 20103 Module New PDFDocument290 pagesManagement Science BUMA 20103 Module New PDFLee TeukPas encore d'évaluation

- Energies: Review of Flow-Control Devices For Wind-Turbine Performance EnhancementDocument35 pagesEnergies: Review of Flow-Control Devices For Wind-Turbine Performance Enhancementkarthikeyankv.mech DscetPas encore d'évaluation

- PandoraFMS Alerts WhatsappDocument6 pagesPandoraFMS Alerts Whatsapppacolo89Pas encore d'évaluation

- "Roughness": Filtering and Filtering and Filtering and Filtering and Surface Surface Texture TextureDocument29 pages"Roughness": Filtering and Filtering and Filtering and Filtering and Surface Surface Texture TextureZouhair BenmabroukPas encore d'évaluation