Académique Documents

Professionnel Documents

Culture Documents

Pds Hempel's Coal Tar Epoxy Mastic 35670 En-Gb

Transféré par

Shanoor ASDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Pds Hempel's Coal Tar Epoxy Mastic 35670 En-Gb

Transféré par

Shanoor ASDroits d'auteur :

Formats disponibles

Product Data

HEMPEL'S COAL TAR EPOXY MASTIC 35670

35670: BASE 35679: CURING AGENT 98670

Description:

HEMPEL'S COAL TAR EPOXY MASTIC 35670 is a high solids, high-build polyamide cured coal tar

epoxy coating with excellent resistance to sea water, crude oil, various soil chemicals and soil stress.

Recommended use:

As a long-life protective coating on steel and concrete in severe corrosive environment, e.g., on

submerged surfaces, crude oil and slop tanks, ballast tanks, splash zones, sewage systems, etc.

Excellent resistance to chemical attack encountered on both steel and concrete including buried pipes.

Service temperature:

Maximum, dry exposure only: 90C/194F

In water (no temperature gradient): 40C/105F

Other liquids: Contact HEMPEL

Certificates/Approvals:

The product complies with ARAMCO Engineering Standard APCS-3. see REMARKS overleaf

Availability:

Not included in Group Assortment. Availability subject to special agreement.

PHYSICAL CONSTANTS:

Shade nos/Colours:

Finish:

Volume solids, %:

Theoretical spreading rate:

Flash point:

Specific gravity:

Dry to touch:

Fully cured:

VOC content:

19990*/ Black.

Semi-gloss

92 1

4.6 m2/l [184.5 sq.ft./US gallon] - 200 micron/8 mils

23 C [73.4 F]

1.5 kg/litre [12.2 lbs/US gallon]

8 - 10 approx. hour(s) 20C/68F

7 day(s) , 20C/68F

127 g/l [1.1 lbs/US gallon]

*other shades according to assortment list.

The physical constants stated are nominal data according to the HEMPEL Group's approved formulas.

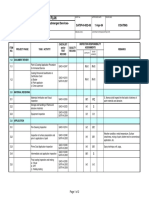

APPLICATION DETAILS:

Version, mixed product:

Mixing ratio:

Application method:

Thinner (max.vol.):

Pot life:

Nozzle orifice:

Nozzle pressure:

Cleaning of tools:

Indicated film thickness, dry:

Indicated film thickness, wet:

Overcoat interval, min:

Overcoat interval, max:

Safety:

35670

BASE 35679: CURING AGENT 98670

4:1 by volume

Airless spray / Brush/Roller

08450 (5%) / 08450 (15%)

8 approx. hour(s) 20C/68F

0.021 - 0.023 "

250 bar [3625 psi]

(Airless spray data are indicative and subject to adjustment)

HEMPEL'S TOOL CLEANER 99610

200 - 300 micron [8 - 12 mils]

225 - 325 micron [9 - 13 mils]

see REMARKS overleaf

see REMARKS overleaf

Handle with care. Before and during use, observe all safety labels on packaging and paint containers,

consult HEMPEL Safety Data Sheets and follow all local or national safety regulations.

Date of issue: October 2013

-

Page: 1/2

Product Data Sheet

HEMPEL'S COAL TAR EPOXY MASTIC 35670

SURFACE PREPARATION:

New steel: Remove oil and grease etc. thoroughly with suitable detergent. Remove salts and other

contaminants by high pressure fresh water cleaning. Abrasive blasting to near white metal Sa 2 (ISO

8501-1:2007) with a surface profile corresponding to Rugotest No. 3, BN10a, Keane-Tator Comparator

3.0 G/S, or ISO Comparator Rough Medium (G). Apply immediately after cleaning. All damage of

shopprimer and contamination from storage and fabrication should be thoroughly cleaned prior to

overcoating.

Repair and maintenance: Remove oil and grease etc. thoroughly with suitable detergent. Remove

salts and other contaminants by high pressure fresh water cleaning. Clean damaged areas thoroughly

by power tool cleaning (minor areas) or by abrasive blasting. Feather edges to sound and intact areas.

Dust off residues. Touch up to full film thickness.

Concrete: Remove slip agent and other possible contaminants by emulsion washing followed by high

pressure hosing with fresh water. Remove scum layer and loose matter to a hard, rough and uniform

surface, preferably by abrasive blasting, possibly by other mechanical treatment or acid etching. Seal

surface with suitable sealer, as per relevant painting specification.

APPLICATION CONDITIONS:

Apply only on a dry and clean surface with a temperature above the dew point to avoid condensation.

Use only where application and curing can proceed at temperatures above: 10C/50F. The

temperature of the surface and that of the paint itself must also be above this limit. Optimal spraying

properties for proper mixing and pumping are obtained at paint temperature: 20-25C/68-77F. In

confined spaces provide adequate ventilation during application and drying.

PRECEDING COAT:

Concrete: HEMPADUR SEALER 05990.

Steel: None, or as per specification.

SUBSEQUENT COAT:

REMARKS:

None, or as per specification. see REMARKS overleaf

Film thicknesses/thinning:

May be specified in another film thickness than indicated depending on purpose and area of use. This

will alter spreading rate and may influence drying time and recoating interval. Normal range dry is:

200-350 micron/8-14 mils.

Overcoating intervals related to later conditions of exposure: If the maximum overcoating interval is

exceeded, roughening of the surface is necessary to ensure intercoat adhesion.

Before overcoating after exposure in contaminated environment, clean the surface thoroughly with

high pressure fresh water hosing and allow drying.

Overcoating:

A specification supersedes any guideline overcoat intervals indicated in the table.

Environment

Atmospheric, medium

Surface temperature:

HEMPADUR

10C (50F)

30C (86F)

Max

Min

Max

Min

Max

60 h

17 d

24 h

7d

12 h

3 d

12 h

3 d

Environment

HEMPADUR

20C (68F)

Min

Immersion

60 h

17 d

24 h

7d

NR = Not Recomended, Ext. = Extended, m = minute(s), h = hour(s), d = day(s)

Overcoating intervals:

For overcoating, HEMPATEX HI-BUILD 46330 can be used. It is to be applied within maximum 16

hours at a surface temperature of 20C/68F.

Note:

HEMPEL'S COAL TAR EPOXY MASTIC 35670 Bleeding may occur into subsequent coat. This

effect is cosmetic only and has no influence on the protective properties.

For professional use only.

ISSUED BY:

HEMPEL A/S

3567019990

X Move PDS Disclaimer to Second page

This Product Data Sheet supersedes those previously issued.

For explanations, definitions and scope, see Explanatory Notes available on www.hempel.com. Data, specifications, directions and recommendations

given in this data sheet represent only test results or experience obtained under controlled or specially defined circumstances. Their accuracy,

completeness or appropriateness under the actual conditions of any intended use of the Products herein must be determined exclusively by the Buyer

and/or User.

The Products are supplied and all technical assistance is given subject to HEMPEL's GENERAL CONDITIONS OF SALES, DELIVERY AND SERVICE, unless

otherwise expressly agreed in writing. The Manufacturer and Seller disclaim, and Buyer and/or User waive all claims involving, any liability, including but

not limited to negligence, except as expressed in said GENERAL CONDITIONS for all results, injury or direct or consequential losses or damages arising

from the use of the Products as recommended above, on the overleaf or otherwise. Product data are subject to change without notice and become void

five years from the date of issue.

Date of issue: October 2013

-

Page: 2/2

Product Data Sheet

Vous aimerez peut-être aussi

- 24.2 The Core Assumptions of MindfulnessDocument9 pages24.2 The Core Assumptions of Mindfulnessale alvarezPas encore d'évaluation

- Challenger 350 Recommended Operating Procedures and TechniquesDocument104 pagesChallenger 350 Recommended Operating Procedures and Techniquessebatsea100% (1)

- Capacity of Bolts in Bearing Connection Based On AISC-ASD 9th EditionDocument3 pagesCapacity of Bolts in Bearing Connection Based On AISC-ASD 9th EditionShanoor ASPas encore d'évaluation

- SATIP-H-002-06 Coating For Submerged Services-APCS 113 ABCDocument2 pagesSATIP-H-002-06 Coating For Submerged Services-APCS 113 ABChossamalsherbinyPas encore d'évaluation

- Hempel'S Galvosil 15780: DescriptionDocument2 pagesHempel'S Galvosil 15780: DescriptionEngTamer100% (1)

- Payroll Solution in Single SheetDocument818 pagesPayroll Solution in Single SheetTarique KhanPas encore d'évaluation

- SAIC-H-2032 Rev 7Document4 pagesSAIC-H-2032 Rev 7Satheesh Rama SamyPas encore d'évaluation

- Saep 1200Document9 pagesSaep 1200Anonymous 4IpmN7On100% (1)

- Saes H 101V PDFDocument389 pagesSaes H 101V PDFQA QCPas encore d'évaluation

- 09 Samss 060Document4 pages09 Samss 060asimazami69Pas encore d'évaluation

- Saes H 102Document10 pagesSaes H 102HaleemUrRashidBangash100% (1)

- 16 JRTP 02 ITP - Rev01Document13 pages16 JRTP 02 ITP - Rev01khsaeed100% (1)

- WF Base Plate Design Based On AISC-ASD 9th Edition: Input Data & Design SummaryDocument2 pagesWF Base Plate Design Based On AISC-ASD 9th Edition: Input Data & Design SummaryShanoor ASPas encore d'évaluation

- Painting ReportDocument1 pagePainting Reportbaidu1980Pas encore d'évaluation

- Tech SpecDocument34 pagesTech SpecAnonymous jLVLP4w3m100% (2)

- Fiberglass Coating SpecDocument3 pagesFiberglass Coating Specponnivalavans_994423100% (1)

- Apcs & Ses - PCS - NewDocument44 pagesApcs & Ses - PCS - Newnasir100% (1)

- Process Industry Practices Insulation: PIP INTG1000 Insulation Inspection ChecklistDocument7 pagesProcess Industry Practices Insulation: PIP INTG1000 Insulation Inspection ChecklistCristian Jhair PerezPas encore d'évaluation

- Aramco Abrasive and Samss#Document2 pagesAramco Abrasive and Samss#Sivaratnam Navatharan100% (1)

- Process Industry Practices Insulation: PIP INIH1000 Hot Insulation Installation DetailsDocument25 pagesProcess Industry Practices Insulation: PIP INIH1000 Hot Insulation Installation DetailsSarwar KhanPas encore d'évaluation

- Approved Sigma Paint System Apcs 1 BDocument1 pageApproved Sigma Paint System Apcs 1 BChiller jnglPas encore d'évaluation

- Apcs 17a 85710Document2 pagesApcs 17a 85710jojo_323Pas encore d'évaluation

- 09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)Document9 pages09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)middlepermian100% (1)

- APCS DeatailsDocument3 pagesAPCS DeatailsDandaman100% (3)

- Materials System SpecificationDocument6 pagesMaterials System SpecificationAjeetKumarPas encore d'évaluation

- 09 Samss 068Document7 pages09 Samss 068AjeetKumarPas encore d'évaluation

- Aramco Painting SpecificationDocument6 pagesAramco Painting Specificationvicky100% (1)

- MineralWoolInsulation Data SheetDocument18 pagesMineralWoolInsulation Data SheetAnonymous MB5YbaLrBEPas encore d'évaluation

- Astm B633Document5 pagesAstm B633nisha_khan100% (1)

- Abu Ali project-APCS 1D Using Hempel Paint REV.01 PDFDocument10 pagesAbu Ali project-APCS 1D Using Hempel Paint REV.01 PDFravi ajith100% (1)

- Biodegradable Plastic Bag Manufacturing Industry-800655 PDFDocument68 pagesBiodegradable Plastic Bag Manufacturing Industry-800655 PDFAryanPas encore d'évaluation

- Data Sheet For Hoses (2473)Document5 pagesData Sheet For Hoses (2473)Romawi StevyandiPas encore d'évaluation

- Blastline - Owner's ManualDocument24 pagesBlastline - Owner's ManualFariz AbdullaPas encore d'évaluation

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportMoghal AliPas encore d'évaluation

- Materials System SpecificationDocument7 pagesMaterials System SpecificationAjeetKumarPas encore d'évaluation

- Test: Ambient Temperature (Wet/Dry), Dew Point, Peralatan: Sling Hygrometer, Dew Point Calculator, SurfaceDocument6 pagesTest: Ambient Temperature (Wet/Dry), Dew Point, Peralatan: Sling Hygrometer, Dew Point Calculator, SurfaceNurmalinda SihombingPas encore d'évaluation

- Insulation Method StatementDocument4 pagesInsulation Method StatementShanoor AS100% (1)

- APCS-22A HempelDocument3 pagesAPCS-22A Hempelarjunmohanan50% (2)

- Procedure of Apcs-113cDocument8 pagesProcedure of Apcs-113cNoman AhmedPas encore d'évaluation

- APCS DeatailsDocument3 pagesAPCS DeatailsnasirPas encore d'évaluation

- Saes H 204Document34 pagesSaes H 204heartbreakkid132Pas encore d'évaluation

- WPS - Welding Instruction - FUCHSDocument23 pagesWPS - Welding Instruction - FUCHSShanoor AS100% (1)

- Apcs 113a Rev 3 Pid ApprovalDocument19 pagesApcs 113a Rev 3 Pid ApprovalMedel Cay De Castro50% (2)

- Fendolite MII Application Manual FireproofingDocument22 pagesFendolite MII Application Manual Fireproofingfloreda80% (5)

- Cold Thermal Insulation SpecificationDocument13 pagesCold Thermal Insulation SpecificationCameliaPas encore d'évaluation

- CP Painting Revised SpecsDocument57 pagesCP Painting Revised SpecsanilnwaychalPas encore d'évaluation

- Resume For Painting InspectorDocument3 pagesResume For Painting InspectorMITHUNPas encore d'évaluation

- Saes H 004Document8 pagesSaes H 004kaleeswaran s100% (1)

- Paint System Recommendations PDFDocument6 pagesPaint System Recommendations PDFKumarPas encore d'évaluation

- 18B. Protegol UR 32.55R Data SheetDocument3 pages18B. Protegol UR 32.55R Data SheetClarkFedele27Pas encore d'évaluation

- Coating Personnel Id FormatDocument1 pageCoating Personnel Id FormatShabbar Abbas MalikPas encore d'évaluation

- Hempel's ZP Alkyd Primer 12090Document2 pagesHempel's ZP Alkyd Primer 12090EngTamerPas encore d'évaluation

- G16S-0205-01 - Repair Hot Drip Galv SurfaceDocument5 pagesG16S-0205-01 - Repair Hot Drip Galv Surfacepuwarin naja100% (1)

- Hempaprime Multi 500 Summer 45950Document3 pagesHempaprime Multi 500 Summer 45950omar alkarabliehPas encore d'évaluation

- SCM 400 Salt Contamination MeterDocument2 pagesSCM 400 Salt Contamination MeterJohn WatsonPas encore d'évaluation

- Interzone 485 - Application GuidelinesDocument7 pagesInterzone 485 - Application GuidelinesBon Panganiban100% (1)

- Manufacturer - Approved Saudi Aramco Data Sheet APCS-1A/1D/11A/17ADocument3 pagesManufacturer - Approved Saudi Aramco Data Sheet APCS-1A/1D/11A/17AjinujosePas encore d'évaluation

- Saes H 204Document33 pagesSaes H 204Rei Lizardo100% (1)

- Dfy - Coating Quality Key PointsDocument1 pageDfy - Coating Quality Key PointsMohammed SadiqPas encore d'évaluation

- Marathon XHBDocument4 pagesMarathon XHBeskim00Pas encore d'évaluation

- 05500Document6 pages05500khalid764Pas encore d'évaluation

- Product DataDocument2 pagesProduct DataYaser Al NasrPas encore d'évaluation

- Pds Hempadur 85671 En-GbDocument3 pagesPds Hempadur 85671 En-GbMario KoričanPas encore d'évaluation

- Pds Hempadur Pro Zinc 17380 En-GbDocument2 pagesPds Hempadur Pro Zinc 17380 En-GbThines Kumar0% (1)

- 353 SaDocument2 pages353 Sakhalid764Pas encore d'évaluation

- Hempadur Zinc 17360Document2 pagesHempadur Zinc 17360Krishna Vacha100% (1)

- Pds Hempadur 85671 En-GbDocument2 pagesPds Hempadur 85671 En-GbbpajicPas encore d'évaluation

- 81970Document2 pages81970khalid764Pas encore d'évaluation

- Hempel Paint TDSDocument3 pagesHempel Paint TDSKelly BatesPas encore d'évaluation

- Hempel: Product Data ManualDocument1 pageHempel: Product Data ManualShanoor ASPas encore d'évaluation

- Single Expansion Bolts (FBN Ii) : Nstallation UideDocument2 pagesSingle Expansion Bolts (FBN Ii) : Nstallation UideShanoor ASPas encore d'évaluation

- Hempedur 85671Document2 pagesHempedur 85671Shanoor ASPas encore d'évaluation

- Tankwelder AGW1-AGW2: Single-Side & Double-SideDocument2 pagesTankwelder AGW1-AGW2: Single-Side & Double-SideShanoor ASPas encore d'évaluation

- E10b MERCHANT NAVY CODE OF CONDUCTDocument1 pageE10b MERCHANT NAVY CODE OF CONDUCTssabih75Pas encore d'évaluation

- Lecture 8 - ThermodynamicsDocument65 pagesLecture 8 - ThermodynamicsHasmaye PintoPas encore d'évaluation

- Course Guide Pe1 PDFDocument4 pagesCourse Guide Pe1 PDFrahskkPas encore d'évaluation

- Constantino V MendezDocument3 pagesConstantino V MendezNīc CādīgālPas encore d'évaluation

- Unknown Facts About Physicians Email List - AverickMediaDocument13 pagesUnknown Facts About Physicians Email List - AverickMediaJames AndersonPas encore d'évaluation

- B1 Pendent SprinklerDocument2 pagesB1 Pendent SprinklerDave BrownPas encore d'évaluation

- Classification of Nanostructured Materials: June 2019Document44 pagesClassification of Nanostructured Materials: June 2019krishnaPas encore d'évaluation

- Social Style InventoryDocument12 pagesSocial Style InventoryMaheshwari JaniPas encore d'évaluation

- Amul Amul AmulDocument7 pagesAmul Amul Amulravikumarverma28Pas encore d'évaluation

- Aplikasi Metode Geomagnet Dalam Eksplorasi Panas BumiDocument10 pagesAplikasi Metode Geomagnet Dalam Eksplorasi Panas Bumijalu sri nugrahaPas encore d'évaluation

- Borelog CP.101Document1 pageBorelog CP.101radixkusumaPas encore d'évaluation

- Lesson Plan PPEDocument3 pagesLesson Plan PPEErika Jean Moyo ManzanillaPas encore d'évaluation

- Grand Hyatt Manila In-Room Dining MenuDocument14 pagesGrand Hyatt Manila In-Room Dining MenuMetroStaycation100% (1)

- AERO241 Example 10Document4 pagesAERO241 Example 10Eunice CameroPas encore d'évaluation

- Beckhoff Service Tool - USB StickDocument7 pagesBeckhoff Service Tool - USB StickGustavo VélizPas encore d'évaluation

- Thai Guava Production PDF by VNRDocument29 pagesThai Guava Production PDF by VNRDatta100% (2)

- MPERSDocument1 pageMPERSKen ChiaPas encore d'évaluation

- Improving The Livelihoods of Smallholder Fruit Farmers in Soroti District, Teso Sub Region, Eastern Uganda RegionDocument2 pagesImproving The Livelihoods of Smallholder Fruit Farmers in Soroti District, Teso Sub Region, Eastern Uganda RegionPatricia AngatoPas encore d'évaluation

- Form - Pelaporan B3Document16 pagesForm - Pelaporan B3sukma nugraPas encore d'évaluation

- Schedule NDocument3 pagesSchedule Nmittal kelaPas encore d'évaluation

- Scoop of Practice aOTADocument9 pagesScoop of Practice aOTAfercespedPas encore d'évaluation

- Campus Sexual Violence - Statistics - RAINNDocument6 pagesCampus Sexual Violence - Statistics - RAINNJulisa FernandezPas encore d'évaluation

- BUERGER's Inavasc IV Bandung 8 Nov 2013Document37 pagesBUERGER's Inavasc IV Bandung 8 Nov 2013Deviruchi GamingPas encore d'évaluation

- Cyber Safety PP Presentation For Class 11Document16 pagesCyber Safety PP Presentation For Class 11WAZ CHANNEL100% (1)