Académique Documents

Professionnel Documents

Culture Documents

Ammonia Plant Design

Transféré par

lockas222Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ammonia Plant Design

Transféré par

lockas222Droits d'auteur :

Formats disponibles

() www.final-yearproject.com | www.finalyearthesis.

com

PLANT DESIGN

FOR

AMMONIA PRODUCTION

(CAPACITY: 200 TPD)

A PROJECT REPORT

SUBMITTED TOWARDS PARTIAL FULFILMENT OF THE

REQUIREMENTS FOR THE AWARD OF DEGREE OF

BACHELOR OF TECHNOLOGY

IN

CHEMICAL ENGINEERING

Project Guide

Asst. Prof. Ashutosh

(H.O.D of Chemical Engg.

Neeraj Kumar

Sandeep Kumar

Yash Batra

(Final B.Tech. Chemical Engg.)

Submitted By

Mishra

Deptt.)

() www.final-yearproject.com | www.finalyearthesis.com

ACKNOWLEDGEMENT

We would like to convey our deepest gratitude to Asst. Prof. Ashutosh Mishra, who guided us

through this project. His keen interest, motivation and advice helped us immensely in

successfully completing this project. We would also like to thank him for allowing us to avail

all the facilities of the Department necessary for this project.

We also wish to express our gratefulness towards all the faculty members for their guidance

throughout the project.

Lastly, we cant forget the contribution of the Lab Attendants in giving wings to our efforts.

Neeraj Kumar

Sandeep Kumar

Yash Batra

(Final B.Tech. Chemical Engg.)

() www.final-yearproject.com | www.finalyearthesis.com

CERTIFICATE

This is to certify that the project entitled PLANT DESIGN FOR MANUFACTURE OF

AMMONIA (GAS BASED) submitted by Neeraj Kumar, Sandeep Kumar and Yash Batra to

the Department of Chemical Engineering, Dr. Ambedkar Institute of Technology for

Handicapped, Kanpur, as the final year undergraduate project is a bonafide piece of work

carried out by them under my guidance and supervision.

This work has not been submitted either in part or full in any other university for any purpose

whatsoever.

Asst. Prof. Ashutosh Mishra

(H.O.D . Of Chemical Engg. Deptt.)

() www.final-yearproject.com | www.finalyearthesis.com

ABSTRACT

Sincere efforts have been made to cover as comprehensively as possible the various aspects

of the stated problem. The report begins with an introduction of ammonia and its importance

as regards an Indian viewpoint. It gives a list of various properties and uses of ammonia,

which have been prepared after an extensive literature survey.

The report then describes the various processes that are available for its manufacture and

then deals with the basic raw materials required for the ammonia manufacture i.e natural gas.

It then covers the important aspects of process selection and the selected process is described

in detail along with the relevant equations and flow diagrams.

After this, report incorporates a detailed material and energy balance of the process selected

and also gives a list of the sizing of the equipment in the flow diagram according to the

capacity. This is followed by a detailed chemical and mechanical design of some important

equipment.

The report then gives some information on aspects such as PI & Control, safety, storage &

handling, utilities, plant location & layout, pollution control, etc.

Finally, the report deals with the most important aspect of the economic viability and techno

economic feasibility of the plant in the Indian environment.

() www.final-yearproject.com | www.finalyearthesis.com

INDEX

Introduction

Physical Properties

Chemical Properties

Flow Sheet

Material Balance

Energy Balance

Process Design

CO2 Absorber

Ammonia Converter

CO2 Stripping Column

Process Utility

Catalyst Used

Plant Safety

Hazard Identification

Effluent treatment

Storage handling and Transportation

Site Selection and Plant Layout

Cost Estimation

Conclusion

Bibliography

() www.final-yearproject.com | www.finalyearthesis.com

Introduction

Ammonia is a chemical consisting of one atom of nitrogen and three atoms of hydrogen. It is

designated in chemical notation as NH3.

Ammonia is extremely soluble in water and is frequently used as a water solution called aqua

ammonia. Ammonia chemically combines with water to form ammonium hydroxide.

Household ammonia is a diluted water solution containing 5 to 10 percent ammonia. On the

other hand, anhydrous ammonia is essentially pure (over 99 percent) ammonia. "Anhydrous"

is a Greek word meaning "without water;" therefore, anhydrous ammonia is the ammonia

without water.

Refrigerant grade anhydrous ammonia is a clear, colourless liquid or gas, free from visible

impurities. It is at least 99.95 percent pure ammonia. Water cannot have a content above 33

parts per million (ppm) and oil cannot have a content above 2 ppm. Preserving the purity of

the ammonia is essential to ensure proper function of the refrigeration system.

Physical Properties

Anhydrous ammonia is a clear liquid that boils at a temperature of -28F. In refrigeration

systems, the liquid is stored in closed containers under pressure. When the pressure is

released, the liquid evaporates rapidly, generally forming an invisible vapour or gas. The

rapid evaporation causes the temperature of the liquid to drop until it reaches the normal

boiling point of -28F, a similar effect occurs when water evaporates off the skin, thus

cooling it. This is why ammonia is used in refrigeration systems.

Liquid anhydrous ammonia weighs less than water. About eight gallons of ammonia weighs

the same as five gallon of water

Liquid and gas ammonia expand and contract with changes in pressure and temperature. For

example, if liquid anhydrous ammonia is in a partially filled, closed container it is heated

from 0F to 68F, the volume of the liquid will increase by about 10 percent. If the tank is 90

percent full at 0F, it will become 99 percent full at 68F. At the same time, the pressure in

the container will increase from 16 pounds per square inch (psi) to 110 psi.

Liquid ammonia will expand by 850 times when evaporating:

Anhydrous ammonia gas is considerably lighter than air and will rise in dry air. However,

because of ammonias tremendous affinity for water, it reacts immediately with the humidity

in the air and may remain close to the ground.

The odour threshold for ammonia is between 5 - 50 parts per million (ppm) of air. The

permissible exposure limit (PEL) is 50 ppm averaged over an 8 hour shift. It is recommended

that if an employee can smell it they ought to back off and determine if they need to be using

respiratory protection.

() www.final-yearproject.com | www.finalyearthesis.com

Chemical Properties

Ammonia, especially in the presence of moisture, reacts with and corrodes copper, zinc, and

many alloys. Only iron, steel, certain rubbers and plastics, and specific nonferrous alloys

resistant to ammonia should be used for fabrications of anhydrous ammonia containers,

fittings, and piping.

Ammonia will combine with mercury to form a fulminate which is an unstable explosive

compound.

Anhydrous ammonia is classified by the Department of Transportation as non-flammable.

However, ammonia vapour in high concentrations (16 to 25 percent by weight in air) will

burn. It is unlikely that such concentrations will occur except in confined spaces or in the

proximity of large spills. The fire hazard from ammonia is increased by the presence of oil or

other combustible substances.

Anhydrous ammonia is an alkali.

Summary of properties:

Boiling Point

-28F

Weight per gallon of liquid at -28F

5.69 pounds

Weight per gallon of liquid at 60F

5.15 pounds

Specific gravity of the liquid (water=1)

0.619

Specific gravity of the gas (air=1)

0.588

Flammable limits in air

16-25%

Ignition temperature

1204F

Vapour pressure at 0F

16 psi

Vapour pressure at 68F

110 psi

Vapour pressure at 100F

198 psi

One cubic foot of liquid at 60F expands to

850 cubic foot of gas

Ammonia Molecular weight : 17.03 g/mol

() www.final-yearproject.com | www.finalyearthesis.com

Ammonia Melting point : -78oC

Ammonia Latent heat of fusion (1,013 bar, at triple point) : 331.37 kJ/kg

Ammonia Liquid Density (1.013 bar at boiling point) : 682 kg/m3 (250 K : 669 kg/m3)

(300 K : 600 kg/m3) (400 K : 346 kg/m3)

Ammonia Liquid Specific Heat Capacity (cp) (250 K : 4.52 kJ/kg.K) (300 K : 4.75

kJ/kg.K) (400 K : 6.91 kJ/kg.K)

Ammonia Liquid/gas equivalent (1.013 bar and 15oC (59oF)) : 947 vol/vol

Ammonia Liquid Dynamic Viscosity (250K : 245 106 Ns/m2) (300K : 141 106 Ns/m2)

(400K : 38 106 Ns/m2)

Ammonia Liquid Thermal Conductivity (250 K : 592 106 kW/m.K) (300 K : 477 106

kW/m.K) (400 K : 207 106 kW/m.K)

Ammonia Boiling point (1.013 bar) : -33.5oC

Ammonia Latent heat of vaporization (1.013 bar at boiling point) : 1371.2 kJ/kg

Ammonia Vapour pressure (at 21oC or 70oF) : 8.88 bar

Ammonia Critical point - Critical temperature : 132.4oC - Critical pressure : 112.8 bar

Ammonia Gas Density (1.013 bar at boiling point) : 0.86 kg/m3

Ammonia Gas Density (1.013 bar and 15oC (59oF)) : 0.73 kg/m3

Ammonia Gas Compressibility Factor (Z) (the ratio of the actual volume of the gas to

the volume determined according to the perfect gas law) (1.013 bar and 15oC (59oF)) :

0.9929

Ammonia Gas Specific Gravity (air = 1) (1.013 bar and 21oC (70oF)) : 0.597

Ammonia Gas Specific volume (1.013 bar and 21oC (70oF)) : 1.411 m3/kg

Ammonia Gas Specific Heat Capacity at constant pressure (cp) (1.013 bar and 15oC

(59oF)) : 0.037 kJ/(mol.K)

Ammonia Gas Specific Heat Capacity at constant volume (cv) (1.013 bar and 15oC

(59oF)) : 0.028 kJ/(mol.K)

() www.final-yearproject.com | www.finalyearthesis.com

Ammonia Gas Ratio of Specific Heats (Gamma: cp/cv) (1.013 bar and 15oC (59oF)) :

1.309623

Ammonia Gas Dynamic Viscosity (1.013 bar and 0oC (32oF)) : 0.000098 Poise

Ammonia Gas Thermal conductivity (1.013 bar and 0oC (32oF)) : 22.19 mW/(m.K)

Ammonia Gas Solubility in water (1.013 bar and 0oC (32oF)) : 862 vol/vol

Ammonia Gas Auto ignition temperature : 630oC

() www.final-yearproject.com | www.finalyearthesis.com

Desulphuriser

Steam

Natural gas

Primary Reformer

Secondary Reformer

Shift convertor

CO2

Air

CO2 removal system

Absorber & Stripper

Ammonia convertor

Compressor

Ammonia product

Methanator

Separator

PGR

Purge gas

() www.final-yearproject.com | www.finalyearthesis.com

MATERIAL BALANCE

Natural gas composition (as supplied by ONGC):

Component

Vol %

CH4

89.96

C2H6

4.09

C3H8

2.3

i-C4H10

0.46

n-C4H10

0.6

i-C5H12

0.2

n-C5H12

0.2

CO2

0.35

N2

1.84

Sulphur content : 5 ppm

(Data taken from IFFCO Kalol plant manual)

Calculating from above data

Mole fraction of carbon , xC : 0.219

Mole fraction of hydrogen , xH : 0.781

PRIMARY REFORMER:

() www.final-yearproject.com | www.finalyearthesis.com

Main reaction of primary reformer is

CH4 + H2O

CO + 3H2

H = +ve

CO + H2O

CO2 + H2

H = -ve

Inlet temperature of primary reformer: 500C

Outlet temperature of primary reformer: 800C

Let flow rate of inlet stream: F1 (mol/s)

Composition of primary reformer outlet:

xH2

0.337

xCO2

0.051

xH2O

0.489

xCO

0.087

xCH4

0.0357

Steam added = 3 xC F1 = 0.657F0

Let outlet flow rate = F2 mol/s

Balancing carbon at inlet and outlet of primary reformer

0.219F1 = (0.087+0.051+0.0357) F2

0.219F1 = 0.1737F2

F2 = 1.261F1

SECONDARY REFORMER:

. (1)

() www.final-yearproject.com | www.finalyearthesis.com

Inlet temperature: 800C

Reactions taking place here are:

CH4 + H2O

CO + 3H2

H = +ve

CH4 + O2

CO + 2H2

H = -ve

H2 + O2

H2O

H = -ve

CO+ O2

CO2

H = -ve

Air is added here so that complete conversion of CH4 takes place

Let air added = A mol/s

So,

0.21 A = 2 xCH4 F2

A = 0.34 F2 = 0.429F1

(2)

Composition at secondary reformer outlet

xH2

0.365

xCO2

0.055

xN2

0.1446

xCO

0.0735

xCH4

0.0012

xinert

0.0007

xsteam

0.36

Balancing carbon at inlet and outlet of secondary reformer:

(0.087+0.051+0.0357)F2

(0.0735+0.055+0.0012) F3

F3 = 1.339 F2 = 1.689F1

HIGH TEMPERATURE SHIFT CONVERTOR:

(3)

() www.final-yearproject.com | www.finalyearthesis.com

Inlet temperature: 400C

CO + H2O

CO2 + H2

Outlet composition of HTSC:

xH2

0.418

xCO2

0.108

xN2

0.145

xCO

0.02

xCH4

0.0012

xinert

0.0007

xsteam

0.3

Balancing carbon:

0.1297 F3 = (0.02+.108+.0012) F4

F4 = 1.004F3 = 1.689F1

. (4)

LOW TEMPERTURE SHIFT CONVERTOR:

Inlet temperature: 200C

CO + H2O

CO2 + H2

Outlet composition of LTSC:

xH2

0.436

xCO2

0.126

xN2

0.145

xCO

0.002

xCH4

0.0012

xinert

0.0012

xsteam

0.289

Balancing carbon,

We get .

F5 = F4 = 1.689F1

.. (5)

() www.final-yearproject.com | www.finalyearthesis.com

CONDENSER:

Outlet from LTSC goes to condenser, where steam gets condensed out and rest of the gases

go to CO2 absorber section.

At inlet of condenser:

xH2

0.436

0.736F1

xCO2

0.126

0.213 F1

xN2

0.145

0.245 F1

xCO

0.002

0.003 F1

xCH4

0.0012

0.0012 F1

xinert

0.0012

0.0012 F1

xsteam

0.289

0.488 F1

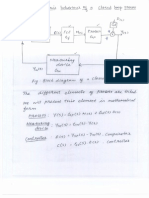

SYNTHESIS LOOP:

Fci

Make up gas, M

Recycle comp

Fco

Convertor

Separator

NH3

P.G.R

Recycle gas, R

Purge gas, Pg

Compositions: (mole fraction)

() www.final-yearproject.com | www.finalyearthesis.com

Component

Purge ( Pg)

Recycle (R)

At convertor inlet,

(Fci)

H2

0.721

0.618

0.645

N2

0.0898

0.205

0.215

NH3

0.0955

0.0257

0.019

Inerts

0.0932

0.151

0.1199

Applying mass balance for completer loop,

M (xinert)M =

Pg(xinert)Pg

M (xN2)M = Pg(xN2)Pg + (Pg(xNH3)Pg +136.2)

M (xH2)M = Pg(xH2)Pg + 3/2 (Pg(xNH3)Pg +136.2)

Adding all these,

M = 1.095Pg +272.4

.. (6)

Also at separator,

Fco = Pg + R + 136.2

.. (7)

At recycle point,

Fci = M+ R

.. (8)

Taking 14% conversion per pass for the reactor at 200 atm pressure and 500C,

Fco = Fci (xN2)Fci0.86 + Fci (xH2)Fci0.86 + Fci (xNH3)Fci + Fci (xN2)Fci0.28 + Fci (xinert)Fci

On solving,

Fco = 0.9387Fci

. (9)

Also at recycle,

R(xNH3)R = Fci(xNH3)Fci

Fci = 1.35R

Solving eqs. (6), (7), (8), (9) and (10)

.. (10)

() www.final-yearproject.com | www.finalyearthesis.com

Stream

Flow rate (Mol/s)

2136.12

747.64

Fci

2883.76

Pg

434.18

Fco

2706.98

Make up gas to synthesis loop comes from methanator.

METHANATOR

Outlet composition of this is same as that at inlet of synthesis loop.

Components

Mole

fraction

Flow rate

(Mol/s)

H2

0.737

552.88

N2

0.249

186.54

CH4

0.007

5.15

0.004

0.003

2.25

Inert

(CO, CO2, & Ar)

Steam

Inlet flow rate for methanator can be calculated using inlet composition for methanator and

balancing flow rate of nitrogen (as nitrogen remains unaffected in methanator).

Inlet flow rate and composition of methanator are:

() www.final-yearproject.com | www.finalyearthesis.com

Components

Mole

fraction

Flow rate

(Mol/s)

H2

0.745

562.54

N2

0.247

186.54

CH4

0.002

1.51

Inert

0.001

0.75

CO

0.004

3.02

CO2

0.001

0.75

CO2 ABSORBER:

In CO2 absorber, only Carbon dioxide is absorbed and rest of the gases remain unaffected.

Inlet and outlet compositions for CO2 absorber,

Components

Inlet mole

fraction

Outlet

mole

fraction

Outlet

flow rate

(Mol/s)

H2

0.687

0.745

562.54

N2

0.228

0.247

186.54

CH4

0.002

0.002

1.51

Inert

0.004

0.001

0.75

CO

0.078

0.004

3.02

CO2

0.001

0.001

0.75

Let inlet flow rate: Fa

Balancing hydrogen in CO2 absorber,

Fa 0.687 = 562.64

() www.final-yearproject.com | www.finalyearthesis.com

Fa =

818.98 mol/s

CO2 removed in CO2 absorber = 0.078818.98 - 0.75

= 63.13 mol/s

CONDENSOR:

Steam formed in LTSC & HTSC is removed in this unit. Outlet for condenser is inlet for the

absorber. As other gases do not get affected, so we can balance flow rate for any other gas.

From earlier calculations,

xH2

0.436

0.736F1

xCO2

0.126

0.213 F1

xN2

0.145

0.245 F1

xCO

0.002

0.003 F1

xCH4

0.0012

0.0012 F1

xinert

0.0012

0.0012 F1

xsteam

0.289

0.488 F1

Equating flow of hydrogen

0.736F1 = 562.64

F1 = 764.46 mol/s

Using relations (1), (2), (3), (4) and (5)

F2 = 963.98 mol/s

F3 = F4 = F5 = 1291.8 mol/s

Air added in secondary reformer, A = 327.95 mol/s

Steam added in primary reformer = 502.25 mol/s

ENERGY BALANCE

PRIMARY REFORMER:

() www.final-yearproject.com | www.finalyearthesis.com

Reactions taking place in primary reformer are:

CH4 + H2O

CO + 3H2

H298 = +206 kJ/mol

CO + H2O

CO2 + H2

H298 = - 41 kJ/mol

Inlet temperature : 500C

Outlet temperature : 800C

1073

xi Cpi

298

H1073 = H298 +

Thus ,

Heat required by first reaction : Flow rate of methane (H1073 )1

=

1.87 107 J/s

Heat liberated by second reaction : Flow rate of carbon monoxide (H1073 )2

=

7.55 105 J/s

Enthalpy content of outlet stream :

(F .x .Cp.1073) = 4.05 107 J/s

Enthalpy content of inlet stream :

(F .x .Cp.773)

= 3.81 107 J/s

Additional heat required,

4.05 107 + 1.87 107 - 7.55 105 - 3.81 107 J/s

= 2.03 107 J/s

Part of this heat is provided by the steam (at 30 atm)

Steam enthalpy = 2802.3 kJ/Kg = 50491.9 J/mol

Enthalpy content in steam = 2.53 106 J/s

Rest of heating is done in convection zone of primary reformer using natural gas,

Heat utility of convection zone: (2.03 0.253) 107 J/s

() www.final-yearproject.com | www.finalyearthesis.com

= 1.78 107 J/s

Calorific value of natural gas = 39383.2 kJ/m3

Amount of natural gas required

1.78

3.94

m3/s = 0.451 m3/s

SECONDARY REFORMER:

Air added in secondary reformer = 327.95 mol/s

This is pre-heated to 800C before being fed to secondary reformer.

Heat required for heating air from 30C to 800C = 7106 J/s

Again natural gas is used for heating purpose,

Amount of natural gas required : (7106) / (3.94107) = 0.178 m3/s

CH4 + H2O

CO + 3H2

H = +ve

H2 + O2

H2O

H = - ve

CO+ O2

CO2

H = - ve

Heat required by reaction 1 at 1073 K = 0.34 107 J/s

Heat liberated by reaction 2 at 1073 K = 0.49 107 J/s

Heat liberated by reaction 3 at 1073 K = 0.221 107 J/s

Heat released due to the 3 reactions = 0.371 107 J/s

This heat increases temperature of outlet gas. Let this temperature be T

0.371107 = (F .x .Cp.(T-1073) )

solving ,

T = 1151.7 K

Outlet temperature of secondary reformer = 1151.7 K

HEAT RECOVERY BETWEEN SECONDARY REFORMER & HTSC:

() www.final-yearproject.com | www.finalyearthesis.com

Effluent from secondary reformer is cooled to 693 K before being fed to HTSC. This heat is

utilized for producing steam at 373 K and 1 atm.

H

CpT s

Steam produced:

H = heat recovered = (F .x .Cp.(1151-693) ) = 2.22107 J/s

4.067 107 J/kmol

Steam produced = 0.547 kmol/s

HIGH TEMPERATURE SHIFT CONVERTOR:

Inlet temperature: 693 K

CO + H2O

CO2 + H2

H = -ve

Heat released by the reaction: 0.133 107 J/s

Let outlet temperature of HTSC = T

H = (F .x .Cp.(T-693) )

T = 723.38 K

Outlet temperature of HTSC = 723.38 K

HEAT RECOVERY BETWEEN HTSC & LTSC:

Inlet temperature of LTSC = 473 K

Heat removed = (F .x .Cp.(723.38-473)) = 1.093 107 J/s

This heat is utilized for producing steam at 373 K and 1 atm.

Amount of steam produced :

H

CpT s

= 269.33 mol/s

() www.final-yearproject.com | www.finalyearthesis.com

LOW TEMPERATURE SHIFT CONVERTOR:

Inlet temperature : 473 K

CO + H2O

CO2 + H2

H = -ve

Heat released by this reaction in LTSC = 0.0422 107 J/s

Let outlet temperature of LTSC = T

(F .x .Cp.(T-473)) = 0.0422 107

T = 483 K

CONDENSER:

Exit stream from LTSC contains steam which is an unwanted load on absorber. In condenser,

steam is condensed at 373 K ( this is inlet temperature of absorber).

Exit gases ( other than steam) are also cooled from 483 to 373 K through a heat exchanger

H = (F .x .Cp.(483-373))

= 4.66 107 J/s

METHANATOR:

Inlet temperature : 623 K

After absorber, gases are heated from 373 K to 623 K .

Heat required = (F .x .Cp.(623-373))

= 0.554 107 J/s

Steam is used for heating,

Amount of steam utilized:

H

s

= 133 mol/s

Reaction taking place in methanator is :

CO2 + 3H2

CH4 + H2O

Heat released by this reaction in the methanator = 5.4 107 J/s

Let outlet temperature = T

5.4 107 = (F .x .Cp.(T-623))

T = 626 K

() www.final-yearproject.com | www.finalyearthesis.com

() www.final-yearproject.com | www.finalyearthesis.com

PROCESS DESIGNCO

Gas flow rate at bottom Gb = 818.98 mol/s = 7.2 Kg/s

ABSORBER

Gas out

MEA 0.001 CO2

Gas flow rate at the top Gt = 755.19 mol/s = 4.43 Kg/s

Yt =0.001

Yb =0.0845

PROPERTIES

Gas density g = 0.487 kg/m3

Liquid density l = 934.4 kg/m3`

Gas viscosity g= 0.0175 cP

Gas in

Liquid viscosity l = 0.299 cP

Gas diffusivity Dg = 1.65X10-5m2/s

Liquid diffusivity Dl = 1.96X10-5m2/s

Gas heat capacity Cpg = 2.094 kJ/kg K

Liquid heat capacity Cpl = 4.145 kJ/kg K

Equilibrium data for absorption of CO2 in MEA

X mol CO2 /mol inerts

Y mol CO2/mol MEA sol

0.1

0.2

0.002

0.25

0.004

0.3

0.008

0.35

0.016

0.4

0.03

0.45

0.052

0.48

0.08

CO2 rich MEA to stripper

() www.final-yearproject.com | www.finalyearthesis.com

0.49

0.09

From Graph

(Lin/Gin)min = 0.217

(Lin/Gin)actual = 1.50.217= 0.3255

Lin

= 0.325755.19

= 266.578 mol/s

Top Section

Lt = Ls (1+Xt)

= 266.578 mol/s

Bottom Section

Lb = 266.578(1+Xb)

= 361.4798 mol/s

(as Xb = 0.356 , from graph)

14.5 wt% MEA souliton has molecular wt.= 20.08 kg/kmol

Lt = 5.35 kg/s

Lb = 7.258 kg/s

Thus amount of MEA required for absorber = 5.35 kg/s with 0.1% of CO 2 coming from

stripper.

CALCULATION OF COLOUMN DIAMETER

Choosing 38 mm pall rings (metal)

Void fraction = 0.95

Packing factor Fp = 28

Surface area a = 128 m2/m3

At the bottom (L/G)(gl) = 0 .023

At the top (L/G)(g/l) = 0.0275

() www.final-yearproject.com | www.finalyearthesis.com

Hence choosing the larger value of 0.027 (at top)

From Graph

Gf2Fpl0.2gl) = 0.01

Where

Gf = gas superficial velocity

Fp = packing factor = 28

= correction factor for density = 1

l = viscosity of liquid in cp = 0.299

g = density of gas = 0.487 kg/m3

l = density of liquid = 934.4 kg/m3

g = acceleration due to gravity

On substituting we obtain

Gf = 6.047 kg/m2 s

Operating G = 0.85Gf

= 5.1399 kg/m2s

Ac = Gt/G

Ac = 4.43/5.375

Ac = 0.86 m2

Di = 1.047 m

Design dia =1.05 m

Evaluation of tower height

Z = HOGNOG

HOG = Hg + m(Gm/Lm)Hl

For ring type of packings

(for 200 N/m2 per m pressure)

() www.final-yearproject.com | www.finalyearthesis.com

Hg = 0.017D1.24Z0.33Scg0.5/(Lf1f2f3)0.5

= parameter for a given packing = 75

D = column diameter

Scg = Schmidt no for gas phase =2.1778

L = liquid rate = 6.2 kg/m2s

f1 = (l/w) = 0.8243

f2 = (l/w) =1.0885

f3 = (w/l) = 1.0611

Substituting we get

Hg = 0.822Z0.33

Liquid phase transfer unit

Hl = (C/3.28)Scl0.5(Z/3.05)0.15

= correlation parameter for a given packing = 0.11

C = correlation parameter for high gas flow rates = 0.5

Scl = Schmidt no for liquid phase = .00163

Z = tower height

On substitution

Hl= .000573Z0.15

m = slope of the equilibrium curve =0.27

Lm = 266.578 mol/s

Gm = 755.19 mol/s

HOG = 0.822Z0.33 + 0.00044Z0.15

0.0845

dy

y y

0.001

NOG =

- ln[(1-yb)/(1-yt))

() www.final-yearproject.com | www.finalyearthesis.com

y*

1/(y-y*)

.001

1000

.01

0.0005

105.283

.02

.001

52.63

.03

.0015

35.08

.04

.0025

26.26

.05

.004

21.74

.06

.006

18.5

.07

.009

16.4

.08

.0125

14.8

.084

.0145

14.38

NOG = 4.78

Z = 3.93Z0.33 + 0.0021Z0.15

By iterations,

Z = 7.70 m

Height of bed in absorber = 7.7 m

Pressure drop = 1540 N/m2

() www.final-yearproject.com | www.finalyearthesis.com

AMMONIA CONVERTOR

Let fraction of feed goes to first bed and rest of 1- fraction mixes with effluent from 1st

bed as quench gas to maintain temperature of gas at 500C.

Also it is assumed that conversion in first bed is from 0 to 8 % , whereas in second converter

conversion of 14 % is achieved.

Heat liberated after first bed = F 0.08 0.215 2 46 103

=1582.4 F

After first Bed:

H2

(0.6450.92) F

0.5934 F

N2

(0.2150.92) F

0.1972 F

(20.2150.08+0.02 ) F =

0.0544 F

NH3

Inert

0.12 F

Total = 0.9656 F

Mole fraction

Cp (J/mol-K )

H2

0.614

29.572

N2

0.205

31.258

NH3

0.056

50.431

Inert

0.1242

20.796

For the gas mixture,

Cp = 30.66 J/mol-K

0.9656 F Cp T = 1582.4 F

T = 53C

(T1)out = 480+53 = 533C

0.9656 F Cp806 +(1- ) F Cp626 = F(0.9656 +1- ) Cp753

= 0.71

() www.final-yearproject.com | www.finalyearthesis.com

2nd bed inlet:

H2

0.5934 F + (1- ) F0.645 = 0.608 F

N2

0.1978 F + (1- ) F 0.215 = 0.208 F

NH3

0.0544 F + (1- ) F 0.02 = 0.0444 F

Inert

0.12 F

= 0.12 F

Flow rate = 0.9752 F

Inlet mole fraction

H2

0.623

N2

0.208

NH3

0.045

Inert

0.0123

= [( F NH3)out (F NH3)in] 46103

Heat liberated

= (2706.980.087 - 0.04442883.76) 46103

= 4162.54103 J/s

Out flow rate

= 2706.98 mol/s

Cp

= 30.5 J/mol-K

2706.98 30.5 T

= 4162.54103

T = 50.4 0C

Final Temp = 530.4 0C

Heat Exchanger

0.71F(753-626)

= 2706.98(803.5-T)

812.87- T

= (0.712883.76127)/2706.98

= 707.44 K

() www.final-yearproject.com | www.finalyearthesis.com

Volume of catalyst bed:

V1CAo / FAo =

Space velocity = 15000 hr-1 ( at standard conditions )

Space time = 0.0747 s

Space time at operating condition =( / CAo) CAo

CAo = (10.215)/(0.0821273)

= 9.6 mol/m3

CAo = (200.215)/ (.0821773)

= 678.4 mol/m3

Space time at operating conditions = 0.0747678.4/ 9.6

= 5.28 s

V1CAo / FAo = 5.28

Volume of first catalyst bed:

V1 =

=

(5.280.2152883.760.71)/(678.4)

3.375 m3

Volume of second catalyst bed :

V2 =

=

(5.280.2050.97522883.76)/(646.85)

4.695 m3

Volume of first bed:

3.375 m3

Volume of second bed:

4.695 m3

() www.final-yearproject.com | www.finalyearthesis.com

CO2 STRIPPING COLUMN

Liquid flow rate into stripping column = 266.578 mol/s

Molecular weight of liquid (15.3% MEA in H2O) = 20.08

X2 = .356 kmol

CO2/kmol MEA

CO2 + steam

Steam

X1 =

0.001 kmol CO2

kmol CO2

kmol steam

Y1=0

Kmol MEA

Equilibrium data:

X

0.001

0.003167

0.002

0.006347

0.05

0.17713

0.1

0.403061

0.15

0.701183

0.2

1.112676

0.25

1.717391

0.3

2.693182

0.35

4.532787

0.356

4.869114

() www.final-yearproject.com | www.finalyearthesis.com

For minimum steam rate from graphY2 = 0.75

kmol CO2

kmol steam

Minimum Gs = Ls(X2-X1)/(Y2-Y1)

= 266.578*(.356-.001)/(1.1-0)

= 86 mol steam/sec

for 1.5 times minimum, steam flow rate = 126.2 mole/sec

therefore Y2 = 1.1

also, x1 = 0.001, y1 = 0

x2 = 0.356, y2 = 1.1

we make a y-x plot to determine total number of stages which are found to be 4.8

TOWER DIAMETER

L

G

G

L

= 0.045

= 0.0744*t + 0.01173

= 0.0304*t + 0.015

reference: Page 169 Mass transfer operations by R E Treybal

let t = 0.75 m

= 0.06753

= 0.0378

CF = [0.06753 log

1

0.04 0.2

0.0378](

)

0.556

0.02

0.04

() www.final-yearproject.com | www.finalyearthesis.com

= 0.1339

L G 0.5

)

G

V F = CF

= 4.1554 m/s

we use 80% of floding velocity

V = 3.32 m/s

An = Q/V = 2.33/3.32 = 0.7 m2

tray area used by one downspout = 8.8%

At = 0.7/(1-0.088)

= 0.7685 m2

D = 0.989 m

Diameter = 1.00 m

height of tower = 5 * 0.75

= 3.75 m

Hieght of tower = 3.75 + 2

= 5.75 m

() www.final-yearproject.com | www.finalyearthesis.com

PROCESS UTILITY

Feed Gas Compression:

Natural gas fuel heater

Feed gas Compressor

Start-up Compressor

Natural gas knock-out drum

Reforming:

Process air saturator

Primary Reformer

Stem super heater

Reactant preheater

Combustion air heater

Boiler

Feed heater

Process air heater

First make gas boiler

Second gas make boiler

Make gas steam super heater

Saturator DMW heater

Saturator effluent cooler

Flue gas fan

Sulphur catch

Secondary reformer

Flue gas stack

Steam drum

() www.final-yearproject.com | www.finalyearthesis.com

Continuous blow down drum

Intermittent blow down drum

NOX reduction unit.

CO Shift:

Make gas BFW heater

HT shift MG BFW heater

HT shift steam super heater

Naphtha Vaporiser

Feed gas Heater

Saturator circuit heater

LP boiler

HT sift converter

LT shift converter.

CO2 Removal:

CO2 absorber

MEA regenerator

Flash column

MEA filter

MEA make up filter

Activated carbon filter

Deaerator feed heater

Lean MEA cooler

Rich/lean exchanger

Syngas trim cooler

Semi-lean pump

MEA make up pump

MEA filter pump

Condensate pump

Process condensate pump

Lean solution pump

() www.final-yearproject.com | www.finalyearthesis.com

Semi rich solution pump

Water make up pump

Hydraulic turbine

MEA solution storage tank

Methanation and Syngas Drying:

Methanator exchanger

Methanator start-up heater

Syngas cooler

Adsorber regeneration heater

Methanator

Syngas adsorber

Ammonia Synthesis:

NH3 converter start up heater

NH3 loop BFW heater

NH3 loop hot interchanger

NH3 loop cooler

NH3 loop cold interchanger

NH3 loop chillers

Ammonia product heater

Product ammonia pump

Absorber bottoms pump

NH3 converter

NH3 converter cartridge

NH3 flash vessels

LP NH3 absorber

Purge Gas Treatment:

NH3 absorber

NH3 still

NH3 absorber feed water cooler

NH3 solution interchanger

NH3 still condenser

Purge gas H2 recovery unit

() www.final-yearproject.com | www.finalyearthesis.com

Synthesis Gas Compression:

Synthesis gas compressor

NH3 loop circulator

Process Air Compression:

Process air compressor

Refrigeration:

Refrigeration condenser

Refrigeration compressor

Refrigeration receiver

() www.final-yearproject.com | www.finalyearthesis.com

CATALYST USED

1.

Desulphurization

Supported cobalt-molybdenum (Comox) or nickel-molybdenum (Nimox) catalyst is

used for hydrogenation of organic sulphur compounds in hydrocarbon feedstock to

H2S which is then removed.

H2S is absorbed in a ZnO bed.

Temperature:

350-400 oC

Pressure:

40 Kg/cm2

Catalyst name:

ZnO

Shape and size:

Extruded rods or globules 3-5 mm dia.

Bulk density:

1.05-1.15 Kg/lit

Typical chemical composition (% by wt):

ZnO

95

R2O3

Fe2O3 + Al2O3

Special features:

Low attrition loss.

Gains strength in use.

High H2S absorption efficiency.

2.

Primary reformer

Temperature:

700-800 oC

Pressure:

30-40 Kg/cm2

Catalyst name:

supported nickel catalyst

Shape and size:

Raschig rings (16616 or 18816 mm)

Bulk density:

.05-1.15 Kg/lit

() www.final-yearproject.com | www.finalyearthesis.com

Typical chemical composition (% by wt):

NiO

18

CaO

18

Al2O3 74

Special features:

Highly pure and refractory.

Al2O3 supports high activity and stability and long life

3.

Secondary reformer

Temperature:

950 oC

Pressure:

30-40 Kg/cm2

Catalyst name:

supported nickel catalyst

Shape and size:

Raschig rings (16616 or 18816 mm)

Bulk density:

1.1-1.2 Kg/lit

Typical chemical composition (% by wt):

NiO

12

CaO

12

Al2O3 76

Special features:

4.

High thermal shock resistance free of carry over problem

High activity

Excellent mechanical stability

Long life

High temperature shift converter

Temperature:

340-450 oC

Pressure:

30-40 Kg/cm2

Catalyst name:

iron chromium catalyst

() www.final-yearproject.com | www.finalyearthesis.com

Shape and size:

solid cylindrical tablets (66 or 106 or 1010 mm)

Bulk density:

1.0-1.1 Kg/lit

Typical chemical composition (% by wt):

Fe2O3 90

Cr2O3 10

S

0.015

Special features:

Extremely low Sulphur content with very low desulphurization time

High and stable activity and strength

5.

Low temperature shift converter

Temperature:

200-250 oC

Pressure:

30-40 Kg/cm2

Catalyst name:

supported copper catalyst

Shape and size:

solid cylindrical tablets (64 mm)

Bulk density:

1.25-1.3 Kg/lit

Typical chemical composition (% by wt):

CuO

25

ZnO

25

Al2O3

35

Fe2O3 + TiO2 5

Special features:

High and stable activity and strength

High resistance to poisons and steam condensation

6.

Methanation

() www.final-yearproject.com | www.finalyearthesis.com

Temperature:

300-400 oC

Pressure:

30-40 Kg/cm2

Catalyst name:

nickel supported on alumina catalyst

Shape and size:

solid cylindrical tablets (64 mm)

Bulk density:

1.25-1.3 Kg/lit

Typical chemical composition (% by wt):

NiO

20

R2O3

80

Special features:

Excellent thermal and mechanical stability

High activity and long life.

7.

Ammonia synthesis

Temperature:

400-500 oC

Pressure:

upto 1000 atm

Catalyst name:

doubly promoted iron catalyst

Shape and size:

solid cylindrical tablets (1.5-12 mm)

Bulk density:

2.1-2.3 Kg/lit

Typical chemical composition (% by wt):

Fe2O3

91

Al2O3

CaO

MgO

K2O

SiO2

0.5

Special features:

() www.final-yearproject.com | www.finalyearthesis.com

Product of Indian magnetite with high activity and mechanical strength

and stability

8.

Catalyst poisoning:

The active surface is sensitive to poisons.

Two classes of poisons are recognized: a) Permanent

b) Temporary

The permanent poison contains sulphur, phosphorus, arsenic, and chlorine and is represented

by such compounds as H2S and HCl. The temporary poisons contain oxygen and are

represented by such compounds as CO, CO2, O2, and H2O.

If exposure to temporary poisons does not last more than three to six days, the catalyst can

usually be brought back to normal activity simply by exposing it to pure synthesis gas. In the

presence of high concentration of hydrogen, the oxygenated compounds that make up the

temporary poisons are converted to H2O, which effectively blankets the active surfaces of the

catalyst. Thus, temporary poisons are all about equivalent on an oxygen basis, with 100 ppm

O2 having same effect as 100 ppm CO2 or 200 ppm H2O or CO.

() www.final-yearproject.com | www.finalyearthesis.com

PLANT SAFETY

Historical data show that the major accidents in ammonia plants are explosions and fires. In

addition there is also a potential of toxic hazard due to the handling and storage of liquid

ammonia.

The following credible major hazards events are identified in an ammonia production plant:

1. Fire/explosion hazard due to leaks from the hydrocarbon feed system.

2. Fire/explosion hazard due to leaks of synthesis gas in the CO removal/synthesis gas

compression areas (75% hydrogen).

3. Toxic hazard from the release of liquid ammonia from the synthesis loop.

In ammonia storage the release of liquid ammonia (by sabotage) is a credible major hazard

event.

Confined explosions in ammonia plants appear to be limited to explosions equivalent to a few

hundred kg TNT. Such explosions are normally not fatal for humans at 50-60m distance, and

thus in most cases not severe for people outside the plant fence. The same is true for fireballs

equivalent to 500kg hydrogen. Fires and explosions are usually not a hazard or only a minor

hazard to the local population although potentially most severe for the plant operators.

Appropriate precautions to protect both the operators and the local population are taken in the

design and operation of the plants.

The toxic hazard of a potential large release of liquid ammonia (ie. from a storage tank) may

be much more serious for the local population. An emergency plan for this event, covering

the operators and the local population must be maintained.

HAZARDS IDENTIFICATION

() www.final-yearproject.com | www.finalyearthesis.com

Human health:

Ammonia is toxic by inhalation, corrosive to all parts of the body and liquid splashes

can cause severe cold burns.

Skin Contact:

Liquid ammonia splashes may produce severe cold burns to skin. Vapour in presence

of moisture is an irritant to the skin.

Eye Contact:

Liquid ammonia splashes may cause permanent damage to eyes with the full effects

not being apparent for several days. Vapours can cause irritation and watering of eyes

and at high concentrations can cause severe damage.

Ingestion:

Will immediately cause severe corrosion and damage to the gastro-intestinal tract.

Inhalation:

Ammonia odour threshold 5-25ppm. Concentrations in the range 50-100ppm may

cause slight irritation following prolonged exposure. Immediate eye, nose and throat

irritation may occur with ammonia levels between 400-700ppm with symptoms of

slight upper respiratory tract irritation persisting beyond the period of exposure. At

higher concentrations, above 1000ppm, severe eye and upper respiratory tract

irritation can develop following a short period of exposure. Exposure to ammonia in

excess of 2000ppm for even short periods may result in severe lung damage and could

be fatal. Fluid build up on the lung (pulmonary dema) may occur up to 48 hours

after exposure and could prove fatal. Exposure to concentrations grossly in excess of

the occupational exposure limit may lead to permanent respiratory impairment.

Long term effects:

No evidence of adverse effects at exposure below occupational exposure limits.

Environment:

Free (non-ionised) ammonia in surface water is toxic to aquatic life, however the

ammonium ion which predominates in most waters is not toxic. In the event of water

contamination with ammonia, ammonium salts which may be formed will not present

a toxic hazard. Increases in pH above 7.5 leads to an increased level of non-ionised

ammonia.

Studies in fish have shown that repeated exposures produce adverse effects on growth

rate at concentrations greater than 0.0024mg/l.

() www.final-yearproject.com | www.finalyearthesis.com

Other:

Fire, heating and explosion

Flammable but difficult to ignite in open air. In enclosed space ammonia air mixtures

may be flammable/explosive.

Danger of tank or cylinder bursting when heated.

Large leaks of liquid ammonia may produce a dense cloud, restricting visibility.

FIRST-AID MEASURES

Speed is essential. Remove affected person from further exposure. Give immediate

first aid and obtain medical attention.

Skin Contact

Drench with large quantities of water. In case of frost bite (freeze burns) clothing may

adhere to the skin. Defrost with care using comfortable warm water. Remove clothing

and wash affected parts. Obtain immediate medical attention.

Eye Contact

Immediately irrigate the eyes with eyewash solution or clean water for at least 10

minutes. Continue irrigation until medical attention can be obtained. Hold eyelids

open during flushing.

Ingestion

Do not induce vomiting. If the person is conscious, wash out mouth with water and

give 2 or 3 glasses of water to drink. Obtain immediate medical attention.

Inhalation

Move the injured person to fresh air at once. Keep the patient warm and at rest.

Administer oxygen if competent person is available. Apply artificial respiration, if

breathing has stopped or shows sign of failing. Obtain immediate medical attention.

Further medical advice

Keep under medical review for possibility of rapid or delayed tracheal, bronchial and

pulmonary edema. Progressive ocular damage may arise.

FIRE-FIGHTING MEASURES

() www.final-yearproject.com | www.finalyearthesis.com

Ammonia vapour and liquid spills are difficult to ignite, particularly in the open air. In an

enclosed space, mixtures of ammonia and air within the limits (16-27%), might cause

explosion if ignited. Cold, dense cloud of ammonia may impair visibility.

Attempt to isolate source of leak.

Use foam, dry powder or CO2.

Use water sprays to cool fire-exposed containers and structures, to disperse vapours

and to protect personnel. Do not spray water into liquid ammonia.

Wear self-contained breathing apparatus and full protective clothing.

ACCIDENTAL RELEASE MEASURES

Those dealing with major releases should wear full protective clothing including

respiratory protection.

Evacuate the area down-wind of the release, if it is safe to do so. If not, then stay

indoors, close all windows and switch off any extraction fans or electrical fires.

Isolate source of leak as quickly as possible by trained personnel.

Ventilate area of spill or leak to disperse vapours.

Remove ignition sources.

Consider covering with foam to reduce evaporation.

Contain spillages if possible.

Use water sprays to combat gas clouds. Do not apply water directly into large

ammonia spills.

Take care to avoid the contamination of watercourses.

Inform appropriate authority in case of accidental contamination of watercourses or

drains.

HANDLING AND STORAGE

Handling:

Avoid skin and eye contact and inhalation of vapours.

Provide adequate ventilation.

Control atmospheric levels in compliance with occupational exposure limits.

Wear full protective equipment where there is a risk of leaks or splashes.

Storage:

() www.final-yearproject.com | www.finalyearthesis.com

Store containers tightly closed in a cool, well ventilated area.

Keep away from heat, ignition sources and incompatible substances.

Do not permit smoking in the storage area.

Follow appropriate Industry or National codes for bulk and container (cylinder)

storage.

EXPOSURE CONTROL / PERSONAL PROTECTION

Recommended occupational exposure limits:

ACGIH [4] occupational exposure limits for ammonia and other components associated with

ammonia production are given in the table below. All the figures are ppmv:-

Component

TLV-TWA (8hr)

TLV-STEL (15min)

NH3

25

35

NO2

SO2

H2S

10

15

CO

50

400

CO2

5000

30000

The figures are subject to updating and may vary between countries.

Precautionary and engineering measures

Provide local exhaust ventilation where appropriate.

Provide safety showers and eye washing facility at any location where skin or eye

contact can occur.

Personal Protection:

Wear suitable breathing apparatus if exposure levels exceed the recommended limits.

Wear cold insulating PVC gloves, rubber boots, PVC suit.

() www.final-yearproject.com | www.finalyearthesis.com

EFFLUENT TREATMENT

EMISSIONS TO AIR

From steam reforming plants with a fired primary reformer emissions to air come from the

following sources:

Flue-gas from the primary reformer

Vent gas from CO2 removal

Breathing gas from oil buffers (seals/compressors)

Fugitive emissions (from flanges, stuffing boxes etc.)

Purge and flash gases from the synthesis section (usually added to the primary

reformer fuel)

Non-continuous emissions (venting and flaring)

1. Flue-gas from the primary reformer:

The flue-gas volume, at 3% (dry gas base) oxygen, for a gas-based conventional steam

reforming plant producing 200t/d, is approximately 26,667 Nm 3/h, containing about 8%

CO2 (dry gas base), corresponding to 500kg CO2/t NH3. The flue-gas volume from excess

air reforming may be lower. The other pollutants in the flue-gas are:

NOx: 200-400mg/Nm3, (98-195ppmv), or 0.6-1.3kg/t NH3 expressed as NO2

SO2: 0.1-2mg/Nm3, (<0.01kg/t), depending on fuel

CO: <10mg/Nm3, (<0.03kg/t)

The NOx emission depends on several factors and the following features reduce the

emission:

Low combustion air and fuel gas preheat

Steam/inert injection

Low ammonia content in injected purge-gas

Low excess oxygen

Low NOx burners

Post-combustion measures

The SO2 emission comes from the sulphur in the fuel gas and can be calculated by a

simple mass balance.

() www.final-yearproject.com | www.finalyearthesis.com

2. Vent gases from CO2 removal:

More or less of the CO 2 product may have to be vented, depending on the CO 2

requirements of other production facilities on the site. In some cases, high purity CO 2 is

used, while an air- CO2 mixture from a stripping column is vented. The CO2 contains

small traces of synthesis gas and absorption solvent vapour.

3. Breathing gas from oil buffers:

This contains traces of NH3, synthesis gas and lube oil.

4. Fugitive emissions:

The diffuse emissions from flanges, stuffing boxes etc. should be minimized.

5. Purge and flash gases:

The purge and flash gases from the synthesis section are usually washed with water to

remove/recover ammonia, and the purge gas may be treated in a recovery unit, before

routing the off-gases to the primary reformer fuel gas system. The off-gases are thus

combusted and end up as part of the flue-gas. It is important to remove the ammonia as

far as possible, as it will contribute considerably to the flue-gas NOx emission.

6. Non-continuous emissions:

Emission of NOx during flaring synthesis gas at start-up or trip situations is estimated to

be 10-20kg/hour as NO2 [1]. Some plants without a flare, vent to the atmosphere.

EMISSIONS TO WATER

Pollution problems related to water, during normal operation, may occur due to process

condensates or due to scrubbing of waste gases containing ammonia.

Process condensate is found primarily in the condensation section prior to the CO 2 removal,

in the order of 1m3 per ton NH3 produced. Without treatment this condensate can contain up

to 1kg of ammonia and 1kg methanol per m3. More than 95% of the dissolved gases can be

recovered by stripping with process steam and are recycled to the process. The stripped

condensate can be re-used as boiler feed water make-up after treatment by ion exchange.

Total recycle is obtained in this way. In some cases the process condensate is used for feedgas saturation and thus recycled to the process.

Usually the ammonia absorbed from purge and flash gases is recovered in a closed loop so

that no aqueous ammonia emissions occur. Emissions to water from the production plant

during normal operation can thus be fully avoided.

() www.final-yearproject.com | www.finalyearthesis.com

SOLID WASTES

The ammonia processes do not normally produce solid wastes. Spent catalysts and sieves

have to be removed and valuable metals are recovered from them.

Environmental Hazards Associated with Emissions and Wastes:

The production of ammonia is relatively clean compared to many other chemical processes.

During the normal operation of a reforming plant, only the NOx and CO2 emissions have to be

considered. In partial oxidation plants with oil-fired auxiliary boilers the reduction of SO 2

emissions can be achieved by using low sulphur fuel oil. Generally the emissions from

modern ammonia plants have little environmental impact.

EMISSION MONITORING

The following emissions to air should be monitored as part of a proper supervision:

a) NOx in flue-gases.

b) SO2 in flue-gases (may be calculated by mass balance instead of monitoring emission,

if S input is known).

The other emissions to air need not be monitored. CO 2 emission can be calculated from fuel

specification and energy consumption, CO emission is fixed by the operating conditions and

usually stable and low. Non-continuous and fugitive emissions are difficult to measure.

The frequency of monitoring depends on local circumstances and the operating stability of

the actual plant. Under normal operating conditions, measurements once a month are usually

sufficient.

Methods for discontinuous and continuous measurements of NOx, SO2 and H2S are available

and are to a large extent standardized at national level. Chemiluminescence or photometry are

the most widely used methods for NO x. SO2 is determined by InfraRed (IR) absorption

techniques. Traces of H2S are measured by lead acetate.

Emissions to water from new plants are virtually zero as process condensates are recycled

and monitoring is not normally required. In existing plants without recycle of process

condensate, the ammonia and methanol content should be monitored.

() www.final-yearproject.com | www.finalyearthesis.com

Emissions to Air

An extractive gas sampling system for continuous gas monitoring will typically comprise:

A coarse filter (heated if necessary) which may be in the stack or duct or outside.

A heated line to convey the sample gas from the stack but this may not be necessary if

probe dilution is used.

A cooler may be used to reduce moisture.

A further drier installed before the analyser.

A pump, situated before or after the analyser, as appropriate, to pull the gas from the

stack or duct.

A fine filter may be put immediately before the analyser.

A description of available methods for monitoring emissions is given:

ONLINE METHODS

Infra red spectrometry:

In the simplest form of IR spectrometry, the equipment consists of an optical filter, the

sample cell and a detector. When the wavelength of the radiation is not selected using

a prism or diffraction grating, the instrument is known as a non-dispersive infra red

gas analyzer (NDIR). In a single-beam instrument a filter selects the part of the

spectral range most characteristic of the substance. In a twin-beam instrument, (the

most commonly used for on-line analysis) the radiation from the source is split and a

comparison is made of the two beams after one has passed through a reference cell

and the other through the sample gas.

The two beams are brought together onto a half-silvered mirror or rotating chopper

which alternately allows each beam to reach a detector cell which compares the heat

received, by capacitance or resistance measurements. The twin-beam method is

preferred in an on-line system as it overcomes some of the problems associated with

drift due to small changes in detector sensitivity and in the optical and spectral

properties of the optical filter. However, regular zeroing and calibration are needed to

correct zero and range drift.

() www.final-yearproject.com | www.finalyearthesis.com

Chemiluminescence:

These instruments use the property of fluorescence, which can take place with some

chemical reactions. By selecting two gases to react under carefully controlled

conditions, the chemiluminescence can be measured to determine the concentration of

reacting gases.

NOx measurement makes use of the reaction:

NO + O3 -> NO2 + O2 + kv

The sample gas is passed through a catalytic converter to change any nitrogen dioxide

to nitric oxide and is then reduced in pressure and reacted with ozone. The

chemiluminescence (kv) is measured by a photomultiplier tube after passing through

an appropriate band pass filter.

MANUAL METHODS

Sulphur dioxide:

Standard methods rely on the solubility and acidic nature of the gas. An oxidizing

agent is generally used to convert the SO 2 to SO3. National standard methods include

the use of hydrogen peroxide solution as the oxidizing agent with titration against

standard alkali or gravimetric analysis using barium chloride and hydrochloric acid to

precipitate the sulphate. An alternative to this uses a sample collected in hydrogen

peroxide solution and titration against barium perchlorate with thorin as indicator. A

method which draws the filtered gas through a standard solution of iodine in

potassium iodide is also used. The unreacted iodine is determined by titration with

sodium thiosulphate and the SO2 calculated from the amount of iodine used to oxidise

the SO2.

All the methods have errors associated with the interferences and the user should be

knowledgeable about the method and its suitability.

Oxides of nitrogen

The instrumental methods given under online methods are preferred.

() www.final-yearproject.com | www.finalyearthesis.com

Carbon monoxide/carbon dioxide:

These gases are generally measured by solution absorption into liquid reagents

specific for each gas.

Emissions to Water:

Whilst emissions to water are likely to be intermittent and of a low level, it is likely that any

site operating an ammonia plant will have at least one overall consent for emissions to water

and a requirement for plant monitoring. Typical monitoring methods may rely on flow

proportioned sample collection or high frequency spot sampling and flow measurement. In

either case the samples obtained may be analyzed as follows:

Ammonia/Ammoniacal N :

The spectrophotometric method for ammonia relies on

the reaction in which monochloramine is reacted with phenol to form an indophenol

blue compound. This method is particularly suitable for the determination of ammonia

in cooling waters derived from saline sources (dock, estuarine or sea water) and may

be used in continuous flow colorimetry.

Ion selective electrodes can also be used and are suitable for saline applications as

well as pure water.

Note that free ammonia exists in equilibrium with NH4+ as follows:

NH4+ + H2O is in equilibrium with NH3 + H3O+

and that the equilibrium depends on pH. The above method determines the NH4+

ammonia. Free ammonia is particularly toxic to fish and should an incident occur, it

may be more important to relate the NH4+ result to free ammonia. Any suitable pH

determination may be used and the free ammonia estimated as given in Hampson B

L, J Cons Int Explor, Mer, 1977,37. 11 and Whitfield M, J Mar Biol. Ass UK,

1974,54, 562.

Manual laboratory based methods may be used for spot checks using Kjeldahl

methods for the determination of organic and ammoniacal nitrogen in a mineralized

sample.

() www.final-yearproject.com | www.finalyearthesis.com

Methanol:

The spectrophotometric method for methanol relies on the oxidation

reactions of potassium permanganate under acid conditions to give formaldehyde. The

formaldehyde is reacted with acetylacetone in the presence of excess ammonium salt,

to form diacetyldihydrolutidine. The method may be used in continuous flow

colorimetry or gas chromatography.

Achievable Emission Levels for New Plants :

The following emission levels can be achieved for new ammonia plants. These levels

relate to steady-state production, not accounting for peaks which can occur during the

unsteady transient conditions of start-up and shut-down and during emergencies.

Emissions to air

NOx (as NO2 at 3% O2)

ppmv

mg/Nm3

kg/t of product

75

150

0.45

Emissions to water

NH3 or NH4 (as N)

0.1kg/t of product

Waste material

Spent catalysts etc.

<0.2kg/t of product

In new reforming plants the total energy consumption should not exceed 32.5 GJ

(HHV)/t and process condensate recycle should be a pre-requisite.

COST OF POLLUTION CONTROL MEASURES

The costs of pollution control measures in the fertilizer industry are difficult to generalize as

they depend on a number of factors such as:

The emission target or standard to be met

The type of process, the degree of integration with other processes on site, production

volumes, type of raw materials being used etc.

whether the plant is new so that the design can be optimised with respect to pollution

abatement, or whether the plant is an existing one requiring revamping or end-of-pipe

pollution abatement equipment

Generally, it is more economical to incorporate the pollution abatement system at the process

design stage rather than revamping or adding-on equipment at later stage.

() www.final-yearproject.com | www.finalyearthesis.com

STORAGE, HANDLING AND TRANSOPRTATION OF AMMONIA

Storage:

Ammonia is stored in :

Cylindrical pressure vessels with dished ends called Bulets.

Spherical pressure vessels Horton Sphere.

Cylindrical, flat bottom Atmospheric storage tanks.

The choice of type of storage depends upon the quantity of ammonia to be stored.

Choice of Storage:

Large quantities of ammonia in storage constitute a potential hazard. Storage under

pressure involves considerable amounts of potential energy and because any escaping

liquid is above its atmospheric boiling point, large quantities of gaseous ammonia will be

released immediately into the atmosphere. Refrigerated storage, however, involves little

potential energy and if the ammonia is cooled to its atmospheric boiling point, there will

be no spontaneous production of gas from spilled liquid. Gas will, of course, still be

released partly due to the difference in partial pressure between the ammonia and the

atmosphere, and partly due to the heat gain from the surroundings. However, the amount

of gas liberated in this manner can be minimized by good binding.

For these reasons, a spill from an atmospheric storage tank constitutes lesser hazard than

a spill from a pressure tank. All ammonia storage installations are required to be

intrinsically safe. Nevertheless, the possibility of a spill cannot be excluded when

selecting a storage facility, and on a congested site, or on a site close to public roads,

hospitals, schools, or private dwellings, it would be advisable to choose potentially less

dangerous atmospheric storage.

It is unlikely that spheres greater than 3,000 tons capacity and working at pressure in the

order of 3.3kg/cm2 gauge will ever be built even if the building of such spheres were

economically attractive.

Handling and Transportation of Ammonia:

Anhydrous ammonia is transported in liquid form under pressure either in small cylinders, or

in road and rail tankers. A number of small ships are also in service capable of carrying

quantities upto 1,000 tons in pressure tanks. Recently, a number of marine carriers have

commenced shipping large quantities (upto 8,000 tons) of ammonia at atmospheric pressure

in refrigerated tanks specially built for the purpose. This practice is likely to grow.

The transfer of liquid between storage and carrier presents the greatest safety hazard. All

known serious accidents in the past few years have occurred during transfer operations.

Stringent safety precautions must be enforced at filling points.

() www.final-yearproject.com | www.finalyearthesis.com

SITE SELECTION AND PLANT LAYOUT

SITE SELECTION

The location of the plant can have a turning effect on the overall viability of a process plant,

and the scope for future expansion. Many factors must be considered when selecting a

suitable plant site. The most important factors are as follows:

1.

2.

3.

4.

5.

6.

7.

8.

9.

Location, with respect to the marketing area

Raw material supply

Transport facilities

Availability of labour

Availability of suitable land

Environmental impact and effluent disposal

Local community consideration

Climate

Political and strategic consideration

Location with Respect to Marketing Area:

For materials that are produced in bulk quantities where the cost of the product per tonne

is relatively low and the cost of transport a significant fraction of the sales price, the plant

should be located close to the primary market. This consideration will be less important

for low volume production, high-priced products like Pharmaceuticals.

Raw Materials:

The availability and price of suitable raw materials will often determine the site location.

Plants producing bulk chemicals are best located close to the source of the major raw material

where this is also close to the marketing area.

Transport:

The transport of materials and products to and from the plant will be an overriding

consideration in site selection. If practicable, a site should be selected such that is close to at

least two major forms of transport: road, rail, waterway (canal or river), or a sea port. Road

transport is being increasingly used, and is suitable for long- distance transport of bulk

chemicals. Air transport is convenient and efficient for the movement personnel and essential

equipment and supplies, and the proximity of the site to a major airport should be considered.

Availability of Labour:

Labour will be needed for construction of the plant and its operation. Skilled construction

workers will usually be brought in from outside the site area, but there should be an adequate

() www.final-yearproject.com | www.finalyearthesis.com

pool of unskilled labour availability locally and labour suitable for training to operate the

plant. Skilled tradesmen will be needed for plant maintenance. Local trade union customs and

restrictive practices will have to be considered when assessing the availability and suitability

of the local labour for recruitment and training.

Availability of Utilities (Services):

Chemical processes invariably require large quantities of water for cooling and general

process use, and the plant must be located near a source of water of suitable quality. Process

water may be drawn from a river, from wells, or purchased from a local authority. At some

sites, the cooling water required can be taken from a river or lake, or from the sea; at other

locations cooling towers will be needed.

Electrical power will be needed at all sites. Electrochemical processes that require large

quantities of power; need to be located close to a cheap source of power. A competitively

priced fuel must be available on site for steam and power generation.

Environmental Impact and Effluent Disposal:

All industrial processes produce waste products, and full consideration must be given to the

difficulties and cost of their disposal. The disposal of toxic and harmful effluents will be

covered by local regulations, and the appropriate authorities must be consulted during the

initial site survey to determine he standards that must be met. An environmental impact

assessment should be made for each new project or major modification or addition or an

existing process.

Local Community Considerations:

The proposed plant must be fit in with and be acceptable to the local community. Full

consideration must be given to the safe location of the plant so that it does not impose a

significant additional risk to the community. On a new site, the local community must be able

to provide adequate facilities for the plant personnel: schools, banks, housing, and

recreational and cultural facilities.

Availability of Land:

Sufficient suitable land must be available for the proposed plant and for future expansion.

The land should ideally be flat, well drained and have suitable load-bearing characteristics. A

full site evaluation would be made to determine the need for piling or other special

foundations.

Climate:

Adverse climatic conditions at a site will increase costs. Abnormally low temperatures will

require the provision of additional insulation and special heating for equipment and pipe runs.

Stronger structures will be needed at locations subject to high winds (cyclone/hurricane) or

earthquakes.

() www.final-yearproject.com | www.finalyearthesis.com

Political and Strategic Considerations:

Capital grants, tax concessions, and other inducements are often given by governments to

direct new investment to preferred locations such as areas of high unemployment. The

overriding of such grants can be the overriding considerations in site selection.

In addition to the main plant, we also have to consider the associated services which have to

be amalgamated within a particular plant site. Canteens, parks, general utilities, emergency

medical services and places for storage must also be taken into consideration while deciding

on a particular site.

Actual Site Selection:

The plant has to be located at a place where cost of raw materials is less. Another factor

which has to be considered is demand for product in vicinity of production area. Reliance in

partnership with Canadian firm Niko Resources has discovered significant gas reserves in

Krishna Godavari basin estimated at 7 trillion cubic feet. Also demand for fertilizers in this

region is also high. According to FAI (2000) data, consumption of N + P2O5 + K2O is 154.9

kg/ha. This reserve is one of the biggest Natural Gas reserve of India and will amount to

around 50% of Indias total Natural Gas consumption.

We hence propose the site for the new Ammonia plant to be Kakinada Industrial

Area,Andhra Pradesh. The major reasons in support of this selection are as follows:

Available Market:

According to FAI (Fertilizer Association of India) reports, the region wise consumption of

Nitrogen based Fertilizers in the Southern Region is around 26% of the total consumption of

India, while only around 10% of the total Ammonia Production Capacity lies in the Southern

Region. So Southern Region has to import it from other Regions. Hence a suitable market is

present.

Availability of Raw Materials:

The huge reserves of Natural Gas at the Krishna River Basin in Andhra Pradesh, provides a

suitable source of our major raw material.

Availability of Transport, Labor & Utilities:

As the area is itself an industrial area, so infrastructure for all these is sufficient. Cheap labour

is easily available. Power and other utilities are also available at a reduced rate.

Availability of Land:

() www.final-yearproject.com | www.finalyearthesis.com

The area being an industrial area, the procurement of land should not be a problem.

Political considerations:

As Andhra Pradesh is a Industrially Oriented state, so there are no problems. Infact the state

encourages setup of industries and gives some special exemptions like lower taxes, etc.

PLANT LAYOUT

The economic construction and operation of a process unit will depend on how well the plant

equipment specified on the process flow sheet and laid out. The principal factors to be

considered are:

1.

2.

3.

4.

5.

6.

Economic consideration: construction and operation cost.

The process requirement

Convenience of operation

convenience of maintenance

Safety

Future expansion

Costs:

The cost of construction can be minimized by adopting a layout that gives shortest run of

connecting pipes between equipment, and adopting the least amount of structural steel work.

However, this will not necessarily be the best arrangement for operation and maintenance.

Process Requirement:

All the required equipment have to be placed properly within process. Even the installation of

the auxiliaries should be done in such a way that it will occupy the least space.

Operation:

Equipment that needs to have frequent operation should be located convenient to the control

room. Valves, sample points, and instruments should be located at convenient position and

height. Sufficient working space and headroom must be provided to allow easy access to

equipment.

Maintenance:

Heat exchangers need to be sited so that the tube bundles can be easily withdrawn for

cleaning and tube replacement. Vessels that require frequent replacement of catalyst or

() www.final-yearproject.com | www.finalyearthesis.com

packing should be located on the outside of buildings. Equipment that requires dismantling

for maintenance, such as compressors and large pumps, should be placed under cover.

Safety:

Blast walls may be needed to isolate potentially hazardous equipment, and confine the effects

of an explosion. At least two escape routes for operator must be provided from each level in

the process building.

Plant Expansion:

Equipment should be located so that it can be conveniently tied in with any future expansion

of the process. Space should be left on pipe alleys for future needs, service pipes oversized to

allow for future requirements.

PLANT LAYOUT

Main Sections:

A complex chemical plant is divided into sections to limit the capital at risk, some of these

areas should be located in areas where there is no fire risk. Care should be taken to give

enough vacant space so as to avoid a chain reaction during the times of fire ao any other

emergencies.

Pipe Bridges:

Equipments can be under pipe bridges but avoid large inventories of flammable materials or

say pumps, moving liquids above atmospheric temperature. Enough bends should be given

for the lines carrying hot liquids, otherwise thermal expansion may damage the lines.

Loading and Off-loading:

Locate the loading and offloading facilities at the terminal parts of the plant so that regular

traffic through the plant is minimized. Road tanker loading or offloading should be classified

as danger areas and should be located at the periphery of the plant. These facilities should be

so located that they are close to the railway terminal.

Plant Roads:

Plant roads should give access to plants and should be arranged so that vehicles do not pass

through process areas. Dead end roads should be avoided while access from any point to any

part of the plant should be from two directions. Hazardous areas should not overlap the plant

limits.

Administrative Block:

() www.final-yearproject.com | www.finalyearthesis.com

This can be located at any place, but preferably at a place away from the plant. Normally it is

kept at an enclosure slightly away from the production units. It should house the offices and

rooms meant for conferences and emergency meetings. A refreshment room can also be

provided in the building.

() www.final-yearproject.com | www.finalyearthesis.com

8

12

5

4

PLANT LAYOUT

() www.final-yearproject.com | www.finalyearthesis.com

NOMENCLATURE OF VARIOUS PLACES SHOWN IN THE ABOVE PLANT

LAYOUT

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

Administrative Block

Fire & Safety Department

Plant Utilities

Emergency Water

Packaging Plant

Process Plant

Expansion

Laboratory

Store

Stray Yard

Canteen

Storage Vessels

Workshops

Connecting Roads

() www.final-yearproject.com | www.finalyearthesis.com

COST ESTIMATION

Capacity of plant = 200 tonnes per day

Cost (FCI) in 1990 for 100,000 tonnes per year for ammonia plant = $ 20 million.

=

$ 20(200/273.9)0.53 million

$ 16.9298 million

Cost index of 1990

356

Cost index for 2004

420

Cost (FCI) in 1990 for 200 tonnes per day

Cost of ammonia plant of capacity 200 TPD in 2004 = 19.973 million dollar

i.e., Fixed Capital Cost (FCI)

= Rs. 918775150

Estimation of total investment cost:

1) Direct cost: