Académique Documents

Professionnel Documents

Culture Documents

Project Scheduling and Monitoring: Current Research Status

Transféré par

المهندسالمدنيTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Project Scheduling and Monitoring: Current Research Status

Transféré par

المهندسالمدنيDroits d'auteur :

Formats disponibles

Construction Innovation 2004; 4: 1931

Project scheduling and monitoring: current

research status

V. Ahuja and V. Thiruvengadam Department of Building Engineering Management,

School of Planning and Architecture, New Delhi, India

Abstract: Project scheduling =rescheduling occurs in all stages of projects, from feasibility

stage to monitoring stage to completion. Since the late 1950s, network-based techniques

CPM (critical path method) and PERT (programme evaluation review technique) are the

techniques commonly used for project management. However, there are limitations in

working with these tools that need to be overcome. Also, the computing ef ciency of classic

CPM=PERT analysis needs to be enhanced. Substantial research has been carried out

globally in this eld covering all areas of project scheduling: time scheduling, resource

scheduling, cost scheduling, modern project management techniques, advanced mathematical models used for construction scheduling, and so on. To understand and document

this research status, the authors have carried out an extensive study of various journals,

published and unpublished research papers, and present this literature review.

Key words: project monitoring; project scheduling; research status; resource scheduling;

simulation techniques; time-cost optimization

Introduction

In the construction industry, unlike the manufacturing industries, each and every project is

unique in nature and thus the characteristics of every project vary. This causes a major

hindrance in the process of standardization of construction projects, also affecting project

scheduling and monitoring of projects. Project scheduling is an integral part of projects in all

stages from the feasibility stage of the project to completion. The critical path method (CPM)

and programme evaluation technique (PERT) are the techniques commonly used for project

scheduling and monitoring. Research to enhance the computing ef ciency of these techniques

as required in the changing requirements of the construction industry is ongoing.

The authors have compiled this paper as a literature review to understand and document the

global research in this area in the recent past. The topic has been covered under two major

areas: project scheduling and project monitoring and control. The structure of the paper is

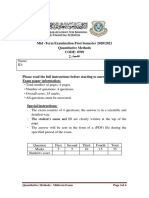

explained in Figure 1. Reference has been given to those papers (published 19952002) that

either deal with the subject Project scheduling and monitoring comprehensively or identify

milestones in the research process.

Project scheduling

The effort required for the initial drafting of a plan is often a real barrier in developing a

useful and high-quality schedule for a construction project. However, on the basis of past

Address for correspondence:Vanita Ahuja, Department of Building Engineering Management, School of Planning

and Architecture, New Delhi, India. E-mail: vanita_ahuja@yahoo.com

# Arnold 2004

10.1191=1471417504ci064oa

20

V. Ahuja and V. Thiruvengadam

Figure 1. Structure of the paper

experience and data, considering the risk trends and typical activities, the time schedule

estimation for any construction process is possible. This schedule may not be exact, but can

give a more or less satisfactory view of the total project duration.

Chevallier and Russell (2001) have demonstrated that an expert system with an editable

rule base can be combined with standard templates of modi able, prede ned knowledge

within a project management system in order to generate draft schedules based on limited

user input.

Uncertainities in activity durations

Ben-Haim and Laufer (1998) presented a new concept for improving the reliability of a

project schedule suffering from uncertainty in the duration of its activities. The paper shows

that the technique for applying the new concept requires minimal information, incorporates

subjective information, is simple to use, and assists in the preparation of project schedules at a

desirable level of reliability. Speci c examples demonstrate the use of the technique for:

1) calculating the reliability of the project schedule; 2) enhancing the reliability of the project

schedule; 3) reducing project duration without diminishing its reliability; and 4) examining

how overlapping of project activities affects its reliability.

Fuzzy set theory provides an approach to consider the subjective terms for the analysis of

activity durations and helps in providing a method of transformation of verbal statement to

numerical system. Mishra (1989) has developed a fuzzy set model that can be used for

determining the statistical distribution parameters and their level of adversity on duration.

Project scheduling and monitoring: current research status

21

Wang and Demsetz (2000) have explained the developed model NETCOR (NETworks

under CORrelated uncertainty), which can evaluate schedule networks when activity durations are correlated. They have demonstrated the practical application of NETCOR to a

current construction project. Using the same inputs, PERT and several simulation analyses

that do not consider correlation are also evaluated. A comparison of the results shows the

signi cance of considering correlation in scheduling analysis.

Limitations of CPM=PERT scheduling tools and development of new tools

Owing to an increasingly competitive environment, construction companies are becoming

more sophisticated, narrowing their focus, and becoming specialists in certain types of

construction. This specialization requires more focused scheduling tools that prove to be

better for certain types of projects. The most utilized scheduling tools in the construction

industry are CPM=PERT. However the limitations of these tools are also being realized and

research is going on to improve these tools and increase utilization of other tools such as

linear scheduling techniques, simulation techniques, genetic algorithms, and so on, for

construction activities. The following papers and studies document this research.

Fischer and Aalami (1996) state that the current scheduling tools require the manual

translation of design information to activities and typically do not provide dynamic links

between cost estimates and corresponding schedules. To take advantage of the increasingly

electronic and object-based descriptions of designs, schedules, and estimates, integration

mechanisms that translate design descriptions into schedule and cost views of projects are

needed. They have presented computer-interpretable models for the representation of construction methods as one such mechanism. These models support the automated generation of

realistic construction schedules.

Cottrell (1999) has developed and tested a simpli ed version of PERT for project planning.

The simpli cation has been understood to reduce the number of estimates required

for activity durations from three, as in conventional PERT, to two. This is accomplished by

applying the normal distribution, rather than the beta distribution to an activity duration. The

two required duration estimates are the most likely and the pessimistic.

Dawson and Dawson (1998) found the standard planning techniques, such as PERT, and the

popular software tools that support them, are inadequate for projects involving uncertainities in the

project direction and task durations. Probability distributions for task durations and generalized

activity networks with probabilistic branching and looping have long been established as viable

techniques to manage these project uncertainties. Unfortunately, their complexity has meant that

their use in industry is minimal. They have proposed extensions to existing software tools to

specify and manage such uncertainties that would be easy to learn and use.

Gong (1997) studied oats that are often used in project networks for resource allocations

and as an alternative for reducing project costs without causing negative impact on project

duration. However, when the time uncertainties of noncritical activities are great, the use of

oats can lead to an increased risk of project schedule overruns, and accordingly an increase

in project costs. He has presented a procedure to optimize the use of oats in a project

network. The procedure integrates schedule risk analysis and cost risk analysis.

Linear scheduling techniques. Linear scheduling techniques have not been applied widely to

construction projects even though they have been identi ed as very useful.

22

V. Ahuja and V. Thiruvengadam

There is an abundance of highly developed CPM computer applications available today.

However, there is a limitation of comparable applications for linear scheduling. Harmelink

and Rowings (1998) have explained that the reasons for the shortage of applications is that

linear scheduling typically has been regarded as a visual technique lacking the analytical

qualities of CPM. Fundamental to the lack of an analytical perspective in linear scheduling is

its inability to determine a critical path. They have documented a method by which a

controlling activity path can be determined in a linear schedule. This fundamental ability

further forms the basis for the determination of oat for noncontrolling activities and provides

a means of updating linear schedules as per the actual status of the project.

Harmelink (2001) has also explained that for linear construction activities, the concept of

oat is somewhat different from that of traditional scheduling techniques. Production rate is a

more fundamental attribute of the oat for a linear activity. As such, for oat to be meaningful

for a linear activity, it must be re ective of the activitys major characteristic. Rate oat captures

this characteristic and presents information to construction planners and managers in terms that

are meaningful for linear projects. He describes rate oat as it applies to the linear scheduling

model developed by Harmelink and Rowings in 1998, as explained in the previous section.

Yamin and Harmelink (2001) have found that for certain types of projects, CPMs

usefulness decreases, because it becomes complex and dif cult to use and understand.

They provide a comparison of the CPM and the linear scheduling model, by identifying

critical attributes needed by both scheduling tools at the higher management level and at the

project level.

Simulation techniques. Simulation is widely applied as a practical tool for planning and

analysis in many industries. However, in the case of construction processes, it has not yet

emerged from the research stage into regular practice. The following papers and studies deal

with different aspects of construction projects scheduling with the help of simulation.

Lu and AbouRizk (2000) have recognized formal stochastic simulation study as a remedy

for the shortcomings inherent to classic CPM=PERT analysis. They have discussed derivation

of a PERT simulation model, which incorporates the discrete event modeling approach and a

simpli ed critical activity identi cation method. They have presented the ndings of a case

study conducted to validate the developed model and have compared it to classic CPM=PERT

analysis. The developed model shows marked enhancement in analysing the risk of project

schedule overrun, and determination of activity criticality, and can provide project management with a convenient tool to assess alternative scenarios based on computer simulation and

risk analysis. Fente et al. (2000) found that the lack of con dence in selection of a probability

distribution function (PDF) for an activity duration has limited the use of simulation as a

practical tool for constructors and presented a method to determine a beta PDF for use in

construction simulation modeling.

Shi (1999) has presented a unique simulation method ABC comprising the activity-based

construction (ABC) modeling and simulation method and has shown that ABC modeling

(ABC-Mod) uses one single element (for example, activity) for modeling general construction

processes instead of multiple elements as required by current simulation systems. ABC

simulation (ABC-Sim) is executed in three stages: 1) select activity; 2) advance simulation;

and 3) release simulation entities. He has shown that compared to existing simulation systems,

it has all the major features required for modeling and simulating the dynamic and random

behaviours of a construction process. It requires no more knowledge to use than CPM.

Project scheduling and monitoring: current research status

23

AbouRizk and Wales (1997) have applied combined simulation modelling to achieve

more accurate and exible modeling of random processes affecting construction progress. A

model is presented where a project schedule using CPM is transferred into a process

interaction-discrete event simulation model and then combined with a continuous change

weather process in the same model. They have shown that it is more effective than

deterministically adding the expected delay due to weather to the expected duration of the

project estimated from CPM. It is also more accurate than using straight Monte Carlo

simulation of the CPM schedule or discrete event simulation modeling.

Sawhney (1990) has presented a hierarchical simulation modeling (HSM) method, a

simulation-based method that enhances and combines the concepts of work breakdown

structure (WBS) and process modeling to arrive at an advanced framework for planning. It is

useful because of the random nature of conditions in which a project is undertaken. Also,

Sawhney and AbouRizk (1995) have found that the hierarchical and modular simulation

constructs form the basis of this method. The construction of a bridge (Peace River Bridge) is

used to illustrate HSM concepts and its advantages.

Senior (1995) has introduced an algorithm that uses the cyclic operation network technique

(CYCLONE), a discrete-event simulation method oriented to construction applications, to

compute task late-time and oat information. The critical path method has limitations to

model repetitive task chains. The suggested algorithm backtracks the event list resulting from

the standard simulation scheduling algorithm, and provides allowable delays for a given

resource utilization pattern. The technique has been found to be appropriate for deterministic

and statistically distributed duration estimates.

Senior and Halpin (1998) have also discussed a new scheduling system based on statistical

simulation. The system, called project-integrated cyclic analysis of serial system operations

(PICASSO), blends and enhances two existing techniques, namely, the CPM and the

CYCLONE simulation discussed in the previous section. A PICASSO project diagram consists of a circle for each modeled resource, a box for each repeated activity, and arrows

connecting these elements. The elements can be cycled as many times as required; thus each

repetitive activity chain needs to be depicted only once. The massiveness of CPM and similar

network techniques when applied to model repetitive projects is avoided altogether. The

PICASSO model also enhances the quality of the scheduling information normally found in

simulation. Its scheduling procedures yield resource utilization statistics and activity chain

oat.

Maio et al. (2000) have discussed the need for reliable simulation systems and also

recognize that the quality of a simulation models results are strictly related to the quality of

the input probability distribution functions. They present a research study where data were

acquired from the AtkinsonWashingtonZachry joint venture on the Eastside Reservoir

Project in California. The data were analysed using BestFit software to obtain the parameters

of the theoretical distribution functions that best described the eld data set. The research

validated previous warnings about the in uence of the class interval decision on the selection

of a distribution function when the chi-square tting test is utilized. A second issue of

importance that was encountered was the reliability of goodness-of- t tests when dealing with

large data sets.

Chehayeb and AbouRizk (1998) have discussed an approach to enable effective use of

systems simulation in the scheduling of construction projects. The approach was implemented

in a software program named SimCon, which enhances current simulation methods through

24

V. Ahuja and V. Thiruvengadam

the use of continuous production links for activities that comprise a project. It is shown that

the continuous production links provide construction managers with a exible representation

of activity sequencing. The procedure builds on existing CYCLONE fundamentals through

new constructs to connect processes in a simulation-based project plan. These constructs are

used to simplify the cyclic interprocess relationships, standardize the techniques for logical

linking of simulation processes, provide a better estimate of progress, and model a continuous

and smooth ow of construction. Various scheduling alternatives are modeled without the

need to change activity sequencing, as is required in current scheduling systems.

Hajjar and AbouRizk (2002) have discussed a new approach to facilitate the use of

simulation in the construction industry. It is discussed that previous attempts in this regard

have been hampered by the gap between the user and the simulation software, the power and

exibility of available tools, and the readiness of industry. A comprehensive new approach

(referred to as the Uni ed Modeling Methodology), which addresses the complete needs of

the construction simulations, is detailed. The methodology is used in the development of a

complete simulation tool development and utilization environment called Simphony.

Scheduling fast-track construction projects

The fast-tracking delivery method has received considerable attention over the last decade,

and its time saving feature has placed it as a possible alternative to the traditional more

sequential method. Along with its bene ts, however, fast-tracking also has greater potential to

impact the project development process than the traditional method. In the literature, this is

usually attributed to the increased level of uncertainty and research on fast-tracking has

mainly focused on uncertainty reduction but without explicit study of the feedback processes

involved in fast-tracking. However, closer observations of the project development process

suggest that to effectively handle uncertainty and minimize the negative impact of fasttracking, the feedback processes involved in fast-tracking need to be identi ed, and the

dynamic behaviour of construction resulting from those feedback processes needs to be dealt

with in a systematic manner.

As an effort to meet the above requirements, Pena-Mora and Park (2001) have presented

the Dynamic Planning Methodology, a planning methodology based on system dynamics. It

aims to improve the planning and management of fast-tracking building construction projects

by providing overlapping strategies, workforce control policies, and schedule adjustments that

will minimize the negative impact of fast-tracking.

Pena-Mora and Li (2001) have also presented a study where a dynamic planning and

control methodology is developed by integrating the applications of axiomatic design

concepts, concurrent engineering concepts, the graphical evaluation and review technique

(GERT), and the system dynamics modeling technique. The goal of the proposed methodology is to help create a dynamic project plan for design=build fast-track civil engineering and

architectural projects where unforeseen changes can be absorbed in the project schedule

without creating major interruptions. The axiomatic design concepts are applied to formulate

and evaluate various work methodologies, and to create a project plan based on the selected

work methodology. The concept of concurrent engineering is adapted to develop a fasttracking framework based on the task production rate, the upstream task reliability, and

downstream task sensitivity to the upstream error. The GERT diagramming scheme is used to

calculate the project duration probabilistically by incorporating the possible branches and

loops in the project. The system dynamics modeling technique is applied to analyse the

Project scheduling and monitoring: current research status

25

causality links of relevant factors in the construction system, and further identi es the

important variables that determine the success of a particular overlapping strategy.

Time-cost optimization

Time and cost are the essence of a contract for construction projects and these two factors are

the very primary objectives of project management. Research shows that time-cost optimization can be effectively achieved with the help of various mathematical models. Some of these

are described below based on the papers and studies documented.

Sahoo (1996) has discussed that a dynamic programming approach has advantages over

other techniques, such as linear programming and integer programming. It has been found

that in linear programming there is a restriction in the form of time-cost functions and in

integer programming there is a constraint in applying it in large networks with realistic timecost functions. A dynamic programming model can have multistage decision problems and

can be applied at the planning stage as well as the monitoring stage.

Lee and Yi (1999) have presented a research study that is a numerical approach to the

integration of the time and cost data sets for construction projects and also addresses the

con icts between them. Several mathematical matrices of time and cost data sets of construction

projects are de ned. The interrelationships among the matrices are investigated and several time

and cost related matrix equations are presented. Based on the equations, this research develops a

project planning and control algorithm that estimates the expected project cost and duration and

evaluates the project economy using the matrix equations derived in the study.

Liu et al. (1995) have shown that planners usually need to adjust the selection of resources

in order to shorten or lengthen the project duration. They have shown that a CPM network

with only eight activities, each with two options, will have 256 (28) alternatives. Exhaustive

enumeration is not economically feasible even with very fast computers. They have presented

a new algorithm using linear and integer programming to ef ciently obtain optimal resource

selections that optimize time and cost of a construction project.

Karim and Adeli (1999) have presented CONSCOM, an object-oriented (OO) information

model used for construction scheduling, cost optimization, and change order management,

based on the creation of a domain-speci c development framework. The framework

architecture is developed using generic software design elements, called patterns, which

provide effective low-level solutions for creating, organizing, and maintaining objects.

CONSCOM has been found to be particularly suitable for highway construction change

order management. It can be used by the owner as an intelligent decision support system in

schedule reviews, progress monitoring, and cost-time trade-off analysis for change order

approval. It has been shown that the object-oriented information model for construction

scheduling cost management can be integrated into a concurrent engineering model for the

architecture, engineering, and construction industry.

OBrien and Fischer (2000) have presented a practice-based critique of the assumptions

behind network planning methods from the perspective of subcontractors and suppliers. In the

context of a case example, the time-cost trade-off and its resource-oriented extensions are

critiqued as being incapable of representing the capacity costs and constraints of subcontractors and suppliers. These methods are also critiqued as being incapable of representing the

effects of site conditions on productivity, which in turn affects the capacity choices of

subcontractors. Restricting the focus to the general building industry, case ndings from

15 subcontractors and suppliers are presented to highlight these points.

26

V. Ahuja and V. Thiruvengadam

Que (2002) has presented an approach that makes genetic algorithm (GA) based time-cost

optimization viable for real-world problems. Practicability is incorporated through the

integration of a project management system to the GA system. The approach ensures that

all scheduling parameters, including activity relationships, lags, calendars, constraints,

resources, and progress, are considered in determining the project completion date, thus

allowing comprehensive and realistic evaluations to be made during optimization.

Leu and Yang (1999) have proposed a multicriteria computational optimal scheduling

model, which integrates the time=cost trade-off model, resource-limited model, and resource

leveling model. A searching technique using genetic algorithms (GAs) is adopted in the

model.

Feng et al. (2000) have presented a hybrid approach that combines simulation techniques

and genetic algorithms to solve the time-cost trade-off problem under uncertainty. The results

show that GAs can be integrated with simulation techniques to provide an ef cient and

practical means of obtaining optimal project schedules while assessing the associated risks in

terms of time and cost of a construction project. This new approach provides construction

engineers with a new way of analysing construction time=cost decisions in a more realistic

manner. Historical time=cost data and available options to complete a project can be modeled.

Also, what-if scenarios can be explored to decide the desired=optimal time and=or cost in

planning and executing project activities.

Li and Love (1997) have discussed that basic GAs may involve very large computational

costs and present several improvements to the basic GA and also demonstrate how these

improved GAs reduce computational costs and signi cantly increase the ef ciency in

searching for optimal solutions.

Resource allocation for repetitive construction activities=projects

Construction projects often contain multiple units wherein activities repeat from unit to unit

and also some organizations are dealing with multiple repetitive construction projects. These

projects require schedules that ensure the uninterrupted usage of resources from an activity in

one unit or project to a similar activity in the next unit or project. It has been seen that CPM

cannot assure this requirement because only technical precedence and resource availability

constraints are explicitly shown in CPM networks. Resource allocation for such requirements

is another area of research and is documented below.

As discussed before, Senior (1995) has introduced an algorithm that uses the CYCLONE, a

discrete-event simulation method. It provides allowable delays for a given resource utilization

pattern.

Harris and Ioannou (1998) have described a repetitive scheduling method (RSM) that

recognizes the technical constraints of CPM and also includes an additional resource

continuity constraint to ensure continuous resource usage. The RSM is a scheduling

methodology that simpli es and generalizes various multiunit scheduling procedures

previously proposed by several authors and it is known by a number of different names. It

applies to both vertical and horizontal projects containing either discrete or continuous

activities and controls both critical and noncritical activities.

El-Rayes (2001) has presented the development of an object-oriented model for scheduling

of repetitive construction projects such as high-rise buildings, housing projects, highways,

pipeline networks, bridges, tunnels, railways, airport runways, and water and sewer mains. He

provides an overview of the analysis, design, and implementation stages of the developed

Project scheduling and monitoring: current research status

27

object-oriented model. The model incorporates newly developed procedures for resourcedriven scheduling of repetitive activities, optimization of repetitive construction scheduling,

and integration of repetitive and nonrepetitive scheduling techniques. The model is named

LSCHEDULER and can be applied to perform regular scheduling as well as optimized

scheduling.

Kang et al. (2001) have attempted to develop a construction scheduling model using a

conceptual approach to improve the ef ciency of construction resources for a multiple,

repetitive construction process (MRCP). This study suggests some equations for estimating

the optimal number of horizontal repetitive work areas for a crew group and pursues a

conceptual model for MRCP, which can reduce the loss in manpower and use of construction

equipment that is caused by work interruption periods.

Management issues

Eldin (1997) has presented the results of a literature review conducted to identify a number of

schedule improvement tools and to determine their bene ts, success factors and implementation barriers. Selection was based on nding tools that lead to the reduction of project

delivery time without increasing project overall cost. Concurrent engineering (CE) was

identi ed as a schedule reduction tool (SRT) that met the selection criteria. The data collected

suggested that implementation of CE has the potential of reducing project delivery time by up

to 25% compared with historical data. Success factors, implementation barriers and lessons

learned were found to be related to management, employee and process issues.

El-Bibany (1997) has described the computational basis of a constraint-management

methodology as applied to planning and scheduling. It is shown that each problem may

be represented by interrelating its parameters using construction duration and precedence

knowledge. The parameter relationships may be viewed as mathematical constraints. The

paper provides a description of the computational methodology including the constraint

modeling process, the graphical representation of constraints and the evaluation of constraint

networks.

Taher and Sharad (1998) have found that global competition, unpredictable world economies,

new nations and their new sociopolitical-cultural scenarios, enlightened customers, information

explosion and rapid technological advances are some of the challenges of the 21st century.

It is further discussed that construction business, whether conducted in ones own country

or overseas, has to continue to march along with new concepts=developments in the eld

of management to remain pro table and the relevance of some of these new concepts

to professional construction management (PCM) is worth discovering. The paper discusses

these new concepts.

Construction planning

During the execution phase, the project managers at site need to effectively plan the

construction work with respect to work schedule, resources available and various other

factors. The following papers study research carried out in this regard.

Faniran et al. (1998) have provided a framework for the development of strategies for

improving construction planning practices. Interrelationships between construction planning

and situational factors in the environments within which construction planning is undertaken

are examined using regression analysis. Factors having a critical in uence on construction

planning are identi ed. Three critical factors identi ed are: 1) investment of substantial time

28

V. Ahuja and V. Thiruvengadam

for construction planning prior to the commencement of work on-site; 2) reduced emphasis

on developing schedules for monitoring and controlling project progress; and 3) increased

emphasis on developing operational plans for project implementation. Signi cant relationships between the projects environment, organizational characteristics of construction rms,

planners efforts, and construction planning effectiveness are discussed.

Choo et al. (1999) have developed a database program called WorkPlan that has been

created to systematically develop weekly work plans. It is shown that such work plans can be

used by crew foremen in scheduling work packages and allocating available labour and

equipment resources. WorkPlan adopts the Last Planner methodology, which implements

several lean construction techniques. A week prior to conducting work, WorkPlan guides the

user step by step through the process of spelling out work packages, identifying constraints,

checking constraint satisfaction, releasing work packages, and allocating resources; then at

the end of the week, collecting eld progress data and reasons for plan failure.

Project monitoring and controlling

As a project enters into the construction stage, actual progress is recorded and compared with

the plans. Owing to various unforeseen reasons the project may not proceed exactly according

to plans and schedules. Hence, it is essential that management is kept continually and accurately

informed of the progress of the works and that precise predictions are made of the effect of each

site occurrence on the available resources and future operations. Depending upon the extent of

departure between actual and planned progress, management has to initiate appropriate control

action such as re-planning, rescheduling or increasing the level of resources.

This dynamic cycle of reviewing the current status and forecasting the future requirements

so that work may be successfully completed, is a primary purpose of project monitoring and is

documented in the following papers and studies.

Shi et al. (2001) have presented a method for computing activity delays and assessing their

contributions to project delay. The method consists of a set of equations, which can be easily

coded into a computer program that allows speedy access to project delay information and

activity contributions. The proposed method contrasts the as-planned and as-built schedules.

It is not based on critical path analyses; therefore, it does not require the calculation or

updating of the critical path, and it is even not necessary to update the as-planned schedule, as

required by the traditional delay analysis methods. The results calculated from the proposed

method include various variations of activity schedules and their contributions (in days) to the

overall project delay. They provide an objective baseline for determining responsibilities of

delays. It has been shown that the method can be integrated into any delay analysis system

to further improve and automate the construction delay analysis process.

Because of the many sources and causes of construction delays, it is often dif cult to

analyse the ultimate liability in delay claims. The construction industry is a relatively secretive

place and the knowledge gained in one project, particularly in the emotive elds of planning

and control, is rarely quickly disseminated. The result of this is duplication of errors. Kabre

(1989) has discussed that knowledge-based expert systems, computer programs using

arti cial intelligence techniques, have been recently introduced to solve this problem in

the construction industry. Documentation of the problems and corrective measures adopted

onsite can be important for knowledge acquisition.

Project scheduling and monitoring: current research status

29

Barraza et al. (2000) have developed a new concept of project control. This new concept

uses stochastic S-curves (SS-Curves) as an alternative to using the deterministic S-curve

technique commonly employed in professional practice for monitoring of projects. SS-curves

are developed by determining the activity level variability in cost and duration. It is shown

that simulation is the recommended approach for obtaining SS-curves, similar to the way that

stochastic schedules are currently developed. SS-curves provide probability distributions for

expected cost and duration for a given percentage of work completed. Monitoring project

performance is achieved by comparing the most likely budget and duration values, obtained

from respective probability distributions for actual progress, with the projects actual data and

cumulative cost. The study shows that by using this method, an evaluation of actual project

performance can be developed that appropriately considers the natural variability of

construction costs and duration, rather than utilizing only one possible deterministic outcome.

Conclusions

This paper presents the research status in the eld of enhancement of tools=techniques used

for project scheduling and monitoring.

Deterministic project scheduling for construction projects is dif cult because of uncertainties inherent in the construction process. Time-cost optimization, an integral component of

project scheduling, requires analysis of various time-cost combinations. The literature

reviewed showed that the prime emphasis of the research is to augment the analytical

capabilities of traditional scheduling techniques CPM=PERT, reducing the limitations in their

use because of their deterministic scheduling model and also simplifying their use for

construction projects. Further research has been carried out to simplify and increase the use of

various mathematical scheduling models like linear scheduling, simulation techniques, fuzzy

set theories, genetic algorithms and comparison has also been made in the use of CPM=PERT

versus these models.

Research to study scheduling of fast-track construction projects, resource allocation for

repetitive construction activities =projects has also been documented.

Further research is required to simplify the use of mathematical models and also to develop

software that can integrate the use of these models and CPM=PERT. Such developed software

should be able to deal with all aspects=components of project scheduling.

Research regarding management issues has shown that the construction industry needs to

adopt new concepts=developments in the eld of management. The construction industry has

responded by adopting concepts like lean construction and concurrent engineering.

During the project execution stage or construction stage, project schedules initially prepared

need to be transformed into work plans. These are prepared periodically for scheduling work

packages taking into account the planning for allocation of manpower, equipment and other

resources. Research has been carried out to develop software that can create such work plans.

Ideally the software should be integrated with the project scheduling software for direct

interpretation of the schedules.

The work of project scheduling encompassing activity duration estimation, time-cost

optimization, resource allocation, and so on, continues in the project monitoring and

controlling stage, also taking into account actual project progress, delays and other site

occurrences. An important aspect of project monitoring is the assessment of delays and their

30

V. Ahuja and V. Thiruvengadam

effect on the overall project schedule and its reporting to the management for timely decision

making. Documented research regarding monitoring and control of projects is focused on

enhancement of delay management techniques and use of stochastic S-curves instead of

deterministic S-curve techniques.

Further research is required to incorporate these techniques in the project scheduling

software and to augment it with the required reporting formats.

Integrated software that could cover project scheduling and monitoring comprehensively

could be knowledge-based expert systems. With further research, use of such integrated

expert systems could be standardized and simpli ed for use in construction projects.

References

AbouRizk, S-M. and Wales, R-J. 1997: Combined

discrete-event=continuous simulation for project

planning. Journal of Construction Engineering

and Management 123 (1), 1120.

Barraza, G-A., Back, E-W. and Mata, F. 2000:

Probabilistic monitoring of project performance

using SS-curves. Journal of Construction

Engineering and Management 126 (2), 14248.

Ben-Haim, Y. and Laufer, A. 1998: Robust reliability

of projects with activity-duration uncertainty.

Journal of Construction Engineering and

Management 124 (2), 12532.

Chehayeb, N-N. and AbouRizk, S-M. 1998:

Simulation-based scheduling with continuous

activity relationships. Journal of Construction

Engineering and Management 124 (2), 10715.

Chevallier, N-J. and Russell, A-D. 2001: Developing

a draft schedule using templates and rules. Journal

of Construction Engineering and Management 127

(5), 39198.

Choo, H-J., Tommelein, I-D., Ballard, G. and

Zabelle, T-R. 1999: Workplan: constraint-based

database for work package scheduling. Journal of

Construction Engineering and Management 125

(3), 15160.

Cottrell, W-D. 1999: Simpli ed program evaluation and

review technique (PERT). Journal of Construction

Engineering and Management 125 (1), 1622.

Dawson, R-J. and Dawson, C-W. 1998: Practical

proposals for managing uncertainty and risk in

project planning. International Journal of Project

Management 16 (5), 299310.

El-Bibany, H.

1997: Parametric constraint

management in planning and scheduling

computational basis. Journal of Construction

Engineering and Management 123 (3), 34853.

Eldin, N-N. 1997: Concurrent engineering: a schedule

reduction tool. Journal of Construction Engineering

and Management 123 (3), 35462.

El-Rayes, K. 2001: Object-oriented model for repetitive

construction scheduling. Journal of Construction

Engineering and Management 127 (3), 199205.

Faniran, O-O., Oluwoye, J-O. and Lenard, D-J.

1998: Interactions between construction planning

and in uence factors. Journal of Construction

Engineering and Management 124 (4), 24556.

Feng, C-W., Liu, L. and Burns, S-A. 2000: Stochastic

construction time-cost trade-off analysis. Journal of

Computing in Civil Engineering 14 (2), 11726.

Fente, J., Schexnayder, C. and Knutson, K. 2000:

De ning a probability distribution function for

construction simulation. Journal of Construction

Engineering and Management 126 (3), 23441.

Fischer, M-A. and Aalami, F. 1996: Scheduling with

computer-interpretable

construction

method

models. Journal of Construction Engineering and

Management 122 (4), 33747.

Gong, D. 1997: Optimization of oat use in risk

analysis-based network scheduling. International

Journal of Project Management 15 (3), 18792.

Hajjar, D. and AbouRizk, S-M. 2002: Uni ed modeling

methodology for construction simulation. Journal

of Construction Engineering and Management 128

(2), 17485.

Harmelink, D-J. 2001: Linear scheduling model: oat

Journal

of

Construction

characteristics.

Engineering and Management 127 (4), 25560.

Harmelink, D-J. and Rowings, J-E. 1998: Linear

scheduling model: development of controlling

activity path. Journal of Construction Engineering

and Management, 124 (4), 26368.

Harris, R-B. and Ioannou, P-G. 1998: Scheduling

projects with repeating activities. Journal of

Construction Engineering and Management 124

(4), 26978.

Kabre, C. 1989: Delay management: a software

approach. Masters thesis, School of Planning and

Architecture, New Delhi.

Project scheduling and monitoring: current research status

Kang, L-S., Park, I-C. and Lee, B-H. 2001: Optimal

schedule planning for multiple, repetitive

construction process. Journal of Construction

Engineering and Management 127 (5), 38290.

Karim, A. and Adeli, H. 1999: CONSCOM: an OO

construction scheduling and change management

system. Journal of Construction Engineering and

Management 125 (5), 36876.

Lee, H-S. and Yi, K-J. 1999: Application of

mathematical matrix to integrate project schedule

and cost. Journal of Construction Engineering and

Management 125 (5), 33946.

Leu, S-S. and Yang, C-H. 1999: GA-based

multicriteria optimal model for construction

scheduling. Journal of Construction Engineering

and Management 125 (6), 42027.

Li, H. and Love, P. 1997: Using improved genetic

algorithms to facilitate time-cost optimization.

Journal of Construction Engineering and

Management 123 (3), 23337.

Liu, L., Burns, S-A. and Feng, C-W. 1995:

Construction time-cost trade-off analysis using

LP=IP hybrid method. Journal of Construction

Engineering and Management 121 (4), 44654.

Lu, M. and AbouRizk, S-M. 2000: Simpli ed

CPM =PERT simulation model. Journal of

Construction Engineering and Management 126

(3), 21926.

Maio, C., Schexnayder, C., Knutson, K.

and Weber, S. 2000: Probability distribution

functions for construction simulation. Journal of

Construction Engineering and Management 126

(4), 28592.

Mishra, G-C. 1989: Subjective evaluation of duration

of construction activities for probabilistic project

management. Masters thesis, School of Planning

and Architecture, New Delhi.

OBrien, W-J. and Fischer, M-A. 2000: Importance

of capacity constraints to construction cost and

schedule. Journal of Construction Engineering

and Management 126 (5), 36673.

Pena-Mora, F. and Li, M. 2001: Dynamic planning

and control methodology for design=build

fast-track construction projects. Journal of

Construction Engineering and Management 127

(1), 117.

31

a-Mora, F. and Park, M. 2001: Dynamic planning for

PeN

fast-tracking building construction projects. Journal

of Construction Engineering and Management

127 (6), 44556.

Que, B-C. 2002: Incorporating practicability into

genetic algorithm-based time-cost optimization.

Journal of Construction Engineering and

Management 128 (2), 13943.

Sahoo, D. 1996: A dynamic programming approach

to time-cost trade off. Masters thesis, School of

Planning and Architecture, New Delhi.

Sawhney, A. 1990: Construction scheduling of civil

works of an industrial project a fuzzy set

approach. Masters thesis, School of Planning and

Architecture, New Delhi.

Sawhney, A. and AbouRizk, S-M. 1995: HSMSimulation-based

planning

method

for

construction projects. Journal of Construction

Engineering and Management 121 (3), 297303.

Senior, B-A. 1995: Late-time computation for task

chains using discrete-event simulation. Journal of

Construction Engineering and Management 121

(4), 397403.

Senior, B-A. and Halpin, D-W. 1998: Simpli ed

simulation system for construction projects.

Journal of Construction Engineering and

Management 124 (1), 7281.

Shi, J-J., Cheung, S-O. and Arditi, D. 2001:

Construction delay computation method. Journal

of Construction Engineering and Management 127

(1), 6065.

Shi, J-J. 1999: Activity-based construction (ABC)

modeling and simulation method. Journal of

Construction Engineering and Management 125

(5), 35460.

Taher, K. and Sharad, D. 1998: Relevance of new

project management concepts to PCM. International

Journal of Project Management 16 (5), 29398.

Wang, W-C. and Demsetz, L-A. 2000: Application

example for evaluating networks considering

correlation. Journal of Construction Engineering

and Management, 126 (6), 46774.

Yamin, R-A. and Harmelink, D-J. 2001: Comparison

of linear scheduling model (LSM) and critical path

method (CPM). Journal of Construction

Engineering and Management 127 (5), 37481.

Vous aimerez peut-être aussi

- Integrated Project Planning and Construction Based on ResultsD'EverandIntegrated Project Planning and Construction Based on ResultsPas encore d'évaluation

- Project Control Stages A Complete Guide - 2019 EditionD'EverandProject Control Stages A Complete Guide - 2019 EditionPas encore d'évaluation

- Advanced Planning and Scheduling APS Complete Self-Assessment GuideD'EverandAdvanced Planning and Scheduling APS Complete Self-Assessment GuidePas encore d'évaluation

- Project Scheduling ConstraintsDocument25 pagesProject Scheduling ConstraintsOSCARTAWNPas encore d'évaluation

- Project SchedulingDocument51 pagesProject SchedulingkjsPas encore d'évaluation

- Project Delivery Method A Complete Guide - 2020 EditionD'EverandProject Delivery Method A Complete Guide - 2020 EditionPas encore d'évaluation

- Improvement and Efforts to Minimize Project DelaysD'EverandImprovement and Efforts to Minimize Project DelaysPas encore d'évaluation

- Project SchedulingDocument7 pagesProject SchedulingkookyymwaPas encore d'évaluation

- Project management process A Complete Guide - 2019 EditionD'EverandProject management process A Complete Guide - 2019 EditionPas encore d'évaluation

- Lecture 9 - Project Planning and SchedulingDocument27 pagesLecture 9 - Project Planning and SchedulingLouise Luy100% (3)

- Project ControlDocument45 pagesProject ControlSanchit BatraPas encore d'évaluation

- Critical Path Method: A Guide to CPM Project SchedulingDocument6 pagesCritical Path Method: A Guide to CPM Project SchedulingFaizan AhmadPas encore d'évaluation

- Planning & SchedulingDocument16 pagesPlanning & SchedulingManav Anil JainPas encore d'évaluation

- Project ScheduleDocument18 pagesProject ScheduleSuleman Tariq100% (3)

- Pert and CPMDocument93 pagesPert and CPMbhargav duttaPas encore d'évaluation

- Planning and SchedulingDocument57 pagesPlanning and SchedulingAmneet Arora100% (2)

- Project Management Planning ProcessDocument6 pagesProject Management Planning ProcesssaivigneshfacebookPas encore d'évaluation

- PMP-Projects Time ManagementDocument152 pagesPMP-Projects Time ManagementProf. Dr. Abdalla ElDaoushy100% (1)

- Resource SchedulingDocument5 pagesResource SchedulingRomen Real100% (1)

- Construction Project Life Cycle PhasesDocument10 pagesConstruction Project Life Cycle Phasesaymanmomani2111100% (1)

- PM05 - Project Monitoring and ControlDocument24 pagesPM05 - Project Monitoring and ControlCedric Dela CostaPas encore d'évaluation

- Why Construction Project FailsDocument6 pagesWhy Construction Project FailsrngwenaPas encore d'évaluation

- SchedulingDocument47 pagesSchedulingwanghechen0076174Pas encore d'évaluation

- Earned Value Management For Design and Construction ProjectDocument21 pagesEarned Value Management For Design and Construction ProjectEditor IJTSRDPas encore d'évaluation

- Project MonitoringDocument60 pagesProject MonitoringAnonymous qPt2MHzXTPas encore d'évaluation

- Project Management Success Factors and ToolsDocument22 pagesProject Management Success Factors and Toolss_alimazharPas encore d'évaluation

- CEng 572 Construction Scheduling TechniquesDocument21 pagesCEng 572 Construction Scheduling Techniquesmuliye tarekegnPas encore d'évaluation

- Project Planning & Scheduling PDFDocument80 pagesProject Planning & Scheduling PDFprajjwal patidar100% (2)

- Construction Project Planning and ManagementDocument32 pagesConstruction Project Planning and Managementሽታ ዓለሜ100% (1)

- Critical Path MethodDocument25 pagesCritical Path MethodUpasna HandaPas encore d'évaluation

- Project Planning Appraisal and Control AssignmentDocument31 pagesProject Planning Appraisal and Control AssignmentMpho Peloewtse Tau50% (2)

- MBA Project ManagementDocument29 pagesMBA Project ManagementGokaSinghPas encore d'évaluation

- (Group 3) - Planning and SchedulingDocument40 pages(Group 3) - Planning and SchedulingHafidha Dwi Putri AristienPas encore d'évaluation

- Good Scheduling PracticeDocument13 pagesGood Scheduling PracticeCad NovicePas encore d'évaluation

- Project Management For Construction - Construction PlanningDocument19 pagesProject Management For Construction - Construction PlanningFarid MorganPas encore d'évaluation

- Work Breakdown Structure (WBS)Document15 pagesWork Breakdown Structure (WBS)Haseeb HassanPas encore d'évaluation

- Pre-COntract Cost ControlDocument3 pagesPre-COntract Cost ControlYash TohoolooPas encore d'évaluation

- Work Breakdown StructureDocument11 pagesWork Breakdown StructureKamal Shah100% (2)

- Project SchedulingDocument48 pagesProject SchedulingSue BabaranPas encore d'évaluation

- Critical Planning Process in Construction ProjectDocument16 pagesCritical Planning Process in Construction ProjectJonathan KewPas encore d'évaluation

- Planning Interview Questions and AnswersDocument2 pagesPlanning Interview Questions and AnswersWilly K. Ng'etich0% (1)

- Guidelines To Monitoring and Evaluation - CARE UgandaDocument153 pagesGuidelines To Monitoring and Evaluation - CARE UgandaDejan ŠešlijaPas encore d'évaluation

- Critical Path MethodDocument4 pagesCritical Path MethodAbhijeet BPas encore d'évaluation

- Sample Project Management Plan PMPDocument29 pagesSample Project Management Plan PMPSam_1_100% (1)

- Resource Allocation IDocument17 pagesResource Allocation ISanchit Batra100% (1)

- PM-ORG-STRUCTDocument24 pagesPM-ORG-STRUCTshawar69Pas encore d'évaluation

- Theories and Practice in Project SchedulingDocument67 pagesTheories and Practice in Project SchedulingStephen Kamau100% (2)

- Lecture 6 - Network Scheduling TechniquesDocument35 pagesLecture 6 - Network Scheduling TechniquesNen Tran Ngoc60% (5)

- NPV CalculationDocument7 pagesNPV CalculationnasirulPas encore d'évaluation

- MCOM Project Implementation ProcessDocument16 pagesMCOM Project Implementation ProcessPreeti100% (1)

- PM Assignment 1Document3 pagesPM Assignment 1Zohaib GondalPas encore d'évaluation

- PM life cycle: Initiate, plan, execute, monitor projectsDocument5 pagesPM life cycle: Initiate, plan, execute, monitor projectssachin0% (1)

- Project Management Techniques in Planning and ControllingDocument518 pagesProject Management Techniques in Planning and Controllingawokeget100% (1)

- Project Management Methodology: Project Concept and DefinitionDocument22 pagesProject Management Methodology: Project Concept and Definitionmonu100% (1)

- 06 ProjectTimeManagement PDFDocument57 pages06 ProjectTimeManagement PDFNguyễn Xuân HùngPas encore d'évaluation

- Project ManagementDocument71 pagesProject ManagementAmer RahmahPas encore d'évaluation

- Managing & Controlling Airport Construction Projects - Jan 2001Document10 pagesManaging & Controlling Airport Construction Projects - Jan 2001TATATAHERPas encore d'évaluation

- Schedule Management Plan DescriptionDocument2 pagesSchedule Management Plan Descriptionpriya_psalms0% (1)

- Work Breakdown StructureDocument25 pagesWork Breakdown StructureQURAN PAK TilawatPas encore d'évaluation

- انكليزي- جعفر الدجيليDocument103 pagesانكليزي- جعفر الدجيليالمهندسالمدنيPas encore d'évaluation

- Ims Deywania 1436hDocument1 pageIms Deywania 1436hالمهندسالمدنيPas encore d'évaluation

- Project Portfolio Selection ProblemsDocument1 pageProject Portfolio Selection ProblemsالمهندسالمدنيPas encore d'évaluation

- 12221Document4 pages12221المهندسالمدنيPas encore d'évaluation

- Health Ar Chapter3Document0 pageHealth Ar Chapter3karameltobshyPas encore d'évaluation

- 12221Document4 pages12221المهندسالمدنيPas encore d'évaluation

- Stochastic Project SchedulingDocument1 pageStochastic Project SchedulingالمهندسالمدنيPas encore d'évaluation

- Ims Deywania 1436hDocument1 pageIms Deywania 1436hالمهندسالمدنيPas encore d'évaluation

- An-Najah National UniversityDocument1 pageAn-Najah National UniversityHassan KhaledPas encore d'évaluation

- Multi-Project SchedulingDocument1 pageMulti-Project SchedulingالمهندسالمدنيPas encore d'évaluation

- Leadership Skills and Their Impact On Strategic Planning Analytical Field Research in The Ministry of Planning and Development CooperationDocument1 pageLeadership Skills and Their Impact On Strategic Planning Analytical Field Research in The Ministry of Planning and Development CooperationالمهندسالمدنيPas encore d'évaluation

- General Project ManagementDocument1 pageGeneral Project ManagementالمهندسالمدنيPas encore d'évaluation

- 343Document2 pages343المهندسالمدنيPas encore d'évaluation

- The Fast Forward MBA in Project ManagementDocument19 pagesThe Fast Forward MBA in Project Managementالمهندسالمدني0% (1)

- What Is Error SC 672Document2 pagesWhat Is Error SC 672المهندسالمدنيPas encore d'évaluation

- مساعد الترجمهDocument2 pagesمساعد الترجمهالمهندسالمدنيPas encore d'évaluation

- Assessing Municipal Accountability ToolsDocument43 pagesAssessing Municipal Accountability ToolsالمهندسالمدنيPas encore d'évaluation

- مساعد الترجمهDocument2 pagesمساعد الترجمهالمهندسالمدنيPas encore d'évaluation

- What Is Error SC 672Document2 pagesWhat Is Error SC 672المهندسالمدنيPas encore d'évaluation

- Test Bank For Health Psychology 3rd Canadian Edition by TaylorDocument7 pagesTest Bank For Health Psychology 3rd Canadian Edition by Taylorالمهندسالمدني50% (4)

- AJBMR 17 26i1n8a1Document7 pagesAJBMR 17 26i1n8a1hasabannaPas encore d'évaluation

- SSRN Id950398Document13 pagesSSRN Id950398المهندسالمدنيPas encore d'évaluation

- A Review of Techniques For Risk Management in ProjectsDocument15 pagesA Review of Techniques For Risk Management in ProjectsالمهندسالمدنيPas encore d'évaluation

- SSRN Id950398Document13 pagesSSRN Id950398المهندسالمدنيPas encore d'évaluation

- New Developments in Project SchedulingDocument3 pagesNew Developments in Project SchedulingالمهندسالمدنيPas encore d'évaluation

- Project Management Assets and Project Management Performance OutcomesDocument24 pagesProject Management Assets and Project Management Performance OutcomesالمهندسالمدنيPas encore d'évaluation

- Howtobea Successful Project Manager: by Robert D. BowenkampDocument4 pagesHowtobea Successful Project Manager: by Robert D. BowenkampالمهندسالمدنيPas encore d'évaluation

- The Relationship Between Improving The Management of Projects and The Use of KMDocument14 pagesThe Relationship Between Improving The Management of Projects and The Use of KMالمهندسالمدني100% (1)

- Ethods & Ools: Going Against The StreamDocument36 pagesEthods & Ools: Going Against The StreamالمهندسالمدنيPas encore d'évaluation

- A Review of Techniques For Risk Management in ProjectsDocument15 pagesA Review of Techniques For Risk Management in ProjectsالمهندسالمدنيPas encore d'évaluation

- VTU NOTES & QUESTION PAPERSDocument46 pagesVTU NOTES & QUESTION PAPERSAnusha KulalPas encore d'évaluation

- Chapter 5 Linear ProgrammingDocument9 pagesChapter 5 Linear ProgrammingBiraj GhimirePas encore d'évaluation

- An Application of Branch and Cut To Open Pit Mine SchedulingDocument2 pagesAn Application of Branch and Cut To Open Pit Mine SchedulingLeo Damian Pacori ToquePas encore d'évaluation

- Assignment ProblemsDocument425 pagesAssignment ProblemsPhông ÁoPas encore d'évaluation

- Applied Optimal Control: Optimization, Estimation, and ControlDocument3 pagesApplied Optimal Control: Optimization, Estimation, and ControlisraelPas encore d'évaluation

- Duality 1 PDFDocument26 pagesDuality 1 PDFNoel Saycon Jr.Pas encore d'évaluation

- Projection of SolidsDocument6 pagesProjection of SolidsMahesh J. UmaPas encore d'évaluation

- Mid-Term Quantitative Methods ExamDocument4 pagesMid-Term Quantitative Methods ExamNourhan KhaledPas encore d'évaluation

- Lecture 5Document6 pagesLecture 5Tony AbhishekPas encore d'évaluation

- Recoverable Robust Single Day Aircraft Maintenance Routing ProblemDocument16 pagesRecoverable Robust Single Day Aircraft Maintenance Routing ProblemfaisalPas encore d'évaluation

- 8 3 Simplex MethodDocument6 pages8 3 Simplex MethodARIJIT BRAHMAPas encore d'évaluation

- Uso de Modelos de Eficiencia PDFDocument5 pagesUso de Modelos de Eficiencia PDFCarlos BlancoPas encore d'évaluation

- Linear Optimization and Extensions - Problems and Solutions (PDFDrive)Document450 pagesLinear Optimization and Extensions - Problems and Solutions (PDFDrive)Thelma DancelPas encore d'évaluation

- Chemistry Class 12 SyllabusDocument13 pagesChemistry Class 12 SyllabusHunter AakashPas encore d'évaluation

- A Modified Simplex Method For Solving Linear-Quadratic and Linear Fractional Bi-Level Programming ProblemDocument13 pagesA Modified Simplex Method For Solving Linear-Quadratic and Linear Fractional Bi-Level Programming ProblemGlobal Journal Of advanced Research100% (2)

- Summative Test #1Document2 pagesSummative Test #1Ed TabsPas encore d'évaluation

- Weather Wax Bertsimas Solutions ManualDocument20 pagesWeather Wax Bertsimas Solutions Manualchencont0% (8)

- Chapter 2-3 The Simplex MethodDocument19 pagesChapter 2-3 The Simplex MethodHACHALU FAYEPas encore d'évaluation

- Transportation Research Part E: Jianfeng Zheng, Zhuo Sun, Ziyou GaoDocument12 pagesTransportation Research Part E: Jianfeng Zheng, Zhuo Sun, Ziyou Gaolegislatif FTKPas encore d'évaluation

- Ortiz Origami NCTM April 2012Document37 pagesOrtiz Origami NCTM April 2012symphoniePas encore d'évaluation

- Linear Programming: To Accompany by Render, Stair, and Hanna Power Point Slides Created by Brian PetersonDocument106 pagesLinear Programming: To Accompany by Render, Stair, and Hanna Power Point Slides Created by Brian Petersonbeauty 4uPas encore d'évaluation

- MPC Morari LeeDocument16 pagesMPC Morari LeeVictor_Rocha100% (1)

- Linear Programing Example Excel Solver PDFDocument13 pagesLinear Programing Example Excel Solver PDFAli MohsenPas encore d'évaluation

- chapter 2 تحليل كميDocument27 pageschapter 2 تحليل كميAhmed El KhateebPas encore d'évaluation

- Linear and Nonlinear Programming With Maple An Interactive, Applications-Based ApproachDocument419 pagesLinear and Nonlinear Programming With Maple An Interactive, Applications-Based ApproachMohammad AbdelaalPas encore d'évaluation

- Assignment # 1 - SolutionDocument6 pagesAssignment # 1 - SolutionMusab IrfanPas encore d'évaluation

- Mod BDocument32 pagesMod BRuwina Ayman100% (1)

- The Karmarkar Revolution: 1.1 Classical Portrait of The FieldDocument2 pagesThe Karmarkar Revolution: 1.1 Classical Portrait of The FieldDominicPas encore d'évaluation

- Course Structural Optimization PythonDocument1 pageCourse Structural Optimization Pythonmesfin DemisePas encore d'évaluation

- Or-Week 2 - Introduction To LP - Simplex MethodDocument31 pagesOr-Week 2 - Introduction To LP - Simplex MethodMadina MukhamejanPas encore d'évaluation