Académique Documents

Professionnel Documents

Culture Documents

Material Safety Data Sheet: Effective Date 15.11.2011

Transféré par

jinyuan74Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Material Safety Data Sheet: Effective Date 15.11.2011

Transféré par

jinyuan74Droits d'auteur :

Formats disponibles

Shell Spirax S4 ATF HDX

Version 1.1

Effective Date 15.11.2011

Material Safety Data Sheet

1. IDENTIFICATION OF THE SUBSTANCE/PREPARATION AND COMPANY/UNDERTAKING

: Shell Spirax S4 ATF HDX

Material Name

: Transmission oil.

Uses

Product Code

001D8301

Manufacturer/Supplier

The Shell Company of Thailand Ltd

Klongtoey

10 Soonthornkosa Road

Bangkok

10110

Thailand

:

:

(+66) 26579888

(+66) 26579609

0-2262-7333

Telephone

Fax

Emergency Telephone

Number

2. COMPOSITION/INFORMATION ON INGREDIENTS

: Highly refined mineral oil, severely hydrotreated slack wax and

Preparation Description

additives.

Hazardous Components

Chemical

CAS

Identity

Alkoxylated longchain alkyl amine

Additional Information

EINECS

Symbol(s)

R-phrase(s)

C, Xn

R22; R34;

R43; R52/53

Conc.

0.10 - 0.50 %

The highly refined mineral oil contains <3% (w/w) DMSOextract, according to IP346. Refer to chapter 16 for full text of

EC R-phrases.

3. HAZARDS IDENTIFICATION

EC Classification

Not classified as dangerous under EC criteria.

Health Hazards

Not expected to be a health hazard when used under normal

conditions. Prolonged or repeated skin contact without proper

cleaning can clog the pores of the skin resulting in disorders

such as oil acne/folliculitis. Used oil may contain harmful

impurities.

Oil acne/folliculitis signs and symptoms may include formation

of black pustules and spots on the skin of exposed areas.

Ingestion may result in nausea, vomiting and/or diarrhoea.

Not classified as flammable but will burn.

Not classified as dangerous for the environment.

Signs and Symptoms

Safety Hazards

Environmental Hazards

:

:

1/7

Print Date 16.11.2011

000000019773

MSDS_TH

Shell Spirax S4 ATF HDX

Version 1.1

Effective Date 15.11.2011

Material Safety Data Sheet

4. FIRST AID MEASURES

General Information

Inhalation

Skin Contact

Eye Contact

Ingestion

Advice to Physician

Not expected to be a health hazard when used under normal

conditions.

No treatment necessary under normal conditions of use. If

symptoms persist, obtain medical advice.

Remove contaminated clothing. Flush exposed area with water

and follow by washing with soap if available. If persistent

irritation occurs, obtain medical attention.

Flush eye with copious quantities of water. If persistent

irritation occurs, obtain medical attention.

In general no treatment is necessary unless large quantities

are swallowed, however, get medical advice.

Treat symptomatically.

5. FIRE FIGHTING MEASURES

Clear fire area of all non-emergency personnel.

Specific Hazards

Suitable Extinguishing

Media

Unsuitable Extinguishing

Media

Protective Equipment for

Firefighters

:

:

:

Hazardous combustion products may include: A complex

mixture of airborne solid and liquid particulates and gases

(smoke). Carbon monoxide. Unidentified organic and inorganic

compounds.

Foam, water spray or fog. Dry chemical powder, carbon

dioxide, sand or earth may be used for small fires only.

Do not use water in a jet.

Proper protective equipment including breathing apparatus

must be worn when approaching a fire in a confined space.

6. ACCIDENTAL RELEASE MEASURES

Avoid contact with spilled or released material. For guidance on selection of personal protective

equipment see Chapter 8 of this Material Safety Data Sheet. See Chapter 13 for information on

disposal. Observe the relevant local and international regulations.

Protective measures

Clean Up Methods

Additional Advice

7. HANDLING AND STORAGE

:

General Precautions

Print Date 16.11.2011

Avoid contact with skin and eyes. Use appropriate containment

to avoid environmental contamination. Prevent from spreading

or entering drains, ditches or rivers by using sand, earth, or

other appropriate barriers.

Slippery when spilt. Avoid accidents, clean up immediately.

Prevent from spreading by making a barrier with sand, earth or

other containment material. Reclaim liquid directly or in an

absorbent. Soak up residue with an absorbent such as clay,

sand or other suitable material and dispose of properly.

Local authorities should be advised if significant spillages

cannot be contained.

Use local exhaust ventilation if there is risk of inhalation of

vapours, mists or aerosols. Properly dispose of any

contaminated rags or cleaning materials in order to prevent

fires. Use the information in this data sheet as input to a risk

assessment of local circumstances to help determine

2/7

000000019773

MSDS_TH

Shell Spirax S4 ATF HDX

Version 1.1

Effective Date 15.11.2011

Material Safety Data Sheet

Handling

Storage

Recommended Materials

Unsuitable Materials

Additional Information

:

:

appropriate controls for safe handling, storage and disposal of

this material.

Avoid prolonged or repeated contact with skin. Avoid inhaling

vapour and/or mists. When handling product in drums, safety

footwear should be worn and proper handling equipment

should be used.

Keep container tightly closed and in a cool, well-ventilated

place. Use properly labelled and closeable containers. Storage

Temperature: 0 - 50 C / 32 - 122 F

For containers or container linings, use mild steel or high

density polyethylene.

PVC.

Polyethylene containers should not be exposed to high

temperatures because of possible risk of distortion.

8. EXPOSURE CONTROLS/PERSONAL PROTECTION

If the American Conference of Governmental Industrial Hygienists (ACGIH) value is provided on

this document, it is provided for information only.

Occupational Exposure Limits

Material

Oil mist, mineral

Source

ACGIH

Type

ppm

TWA(Inhala

ble fraction.)

Exposure Controls

Personal Protective

Equipment

Respiratory Protection

Hand Protection

mg/m3

5 mg/m3

Notation

The level of protection and types of controls necessary will vary

depending upon potential exposure conditions. Select controls

based on a risk assessment of local circumstances.

Appropriate measures include: Adequate ventilation to control

airborne concentrations. Where material is heated, sprayed or

mist formed, there is greater potential for airborne

concentrations to be generated.

Personal protective equipment (PPE) should meet

recommended national standards. Check with PPE suppliers.

No respiratory protection is ordinarily required under normal

conditions of use. In accordance with good industrial hygiene

practices, precautions should be taken to avoid breathing of

material. If engineering controls do not maintain airborne

concentrations to a level which is adequate to protect worker

health, select respiratory protection equipment suitable for the

specific conditions of use and meeting relevant legislation.

Check with respiratory protective equipment suppliers. Where

air-filtering respirators are suitable, select an appropriate

combination of mask and filter. Select a filter suitable for

combined particulate/organic gases and vapours [boiling point

>65C(149 F)].

Where hand contact with the product may occur the use of

gloves approved to relevant standards (e.g. Europe: EN374,

US: F739) made from the following materials may provide

suitable chemical protection: PVC, neoprene or nitrile rubber

3/7

Print Date 16.11.2011

000000019773

MSDS_TH

Shell Spirax S4 ATF HDX

Version 1.1

Effective Date 15.11.2011

Material Safety Data Sheet

Eye Protection

Protective Clothing

Monitoring Methods

Environmental Exposure

Controls

gloves. Suitability and durability of a glove is dependent on

usage, e.g. frequency and duration of contact, chemical

resistance of glove material, glove thickness, dexterity. Always

seek advice from glove suppliers. Contaminated gloves should

be replaced. Personal hygiene is a key element of effective

hand care. Gloves must only be worn on clean hands. After

using gloves, hands should be washed and dried thoroughly.

Application of a non-perfumed moisturizer is recommended.

Wear safety glasses or full face shield if splashes are likely to

occur.

Skin protection not ordinarily required beyond standard issue

work clothes.

Monitoring of the concentration of substances in the breathing

zone of workers or in the general workplace may be required to

confirm compliance with an OEL and adequacy of exposure

controls. For some substances biological monitoring may also

be appropriate.

Minimise release to the environment. An environmental

assessment must be made to ensure compliance with local

environmental legislation.

9. PHYSICAL AND CHEMICAL PROPERTIES

Appearance

: Red. Liquid at room temperature.

Odour

: Slight hydrocarbon.

pH

: Not applicable.

Initial Boiling Point and

: > 280 C / 536 F estimated value(s)

Boiling Range

Pour point

: Typical -48 C / -54 F

Flash point

: Typical 185 C / 365 F (COC)

Upper / lower Flammability

: Typical 1 - 10 %(V)

or Explosion limits

Auto-ignition temperature

: > 320 C / 608 F

Vapour pressure

: < 0.5 Pa at 20 C / 68 F (estimated value(s))

Specific gravity

: Typical 0.847 at 15 C / 59 F

Density

: Typical 847 kg/m3 at 15 C / 59 F

Water solubility

: Negligible.

Solubility in other solvents

: Data not available

n-octanol/water partition

: > 6 (based on information on similar products)

coefficient (log Pow)

Dynamic viscosity

: Data not available

Kinematic viscosity

: Typical 33.2 mm2/s at 40 C / 104 F

Vapour density (air=1)

: > 1 (estimated value(s))

Evaporation rate (nBuAc=1) : Data not available

10. STABILITY AND REACTIVITY

:

Stability

:

Conditions to Avoid

:

Materials to Avoid

:

Hazardous

Decomposition Products

Stable.

Extremes of temperature and direct sunlight.

Strong oxidising agents.

Hazardous decomposition products are not expected to form

during normal storage.

11. TOXICOLOGICAL INFORMATION

: Information given is based on data on the components and the

Basis for Assessment

4/7

Print Date 16.11.2011

000000019773

MSDS_TH

Shell Spirax S4 ATF HDX

Version 1.1

Effective Date 15.11.2011

Material Safety Data Sheet

Acute Oral Toxicity

Acute Dermal Toxicity

Acute Inhalation Toxicity

:

:

:

Skin Irritation

Eye Irritation

Respiratory Irritation

Sensitisation

Repeated Dose Toxicity

Mutagenicity

Carcinogenicity

:

:

:

:

:

:

Reproductive and

Developmental Toxicity

Additional Information

:

:

toxicology of similar products.

Expected to be of low toxicity: LD50 > 5000 mg/kg , Rat

Expected to be of low toxicity: LD50 > 5000 mg/kg , Rabbit

Not considered to be an inhalation hazard under normal

conditions of use.

Expected to be slightly irritating. Prolonged or repeated skin

contact without proper cleaning can clog the pores of the skin

resulting in disorders such as oil acne/folliculitis.

Expected to be slightly irritating.

Inhalation of vapours or mists may cause irritation.

Not expected to be a skin sensitiser.

Not expected to be a hazard.

Not considered a mutagenic hazard.

Components are not known to be associated with carcinogenic

effects.

Not expected to be a hazard.

Used oils may contain harmful impurities that have

accumulated during use. The concentration of such impurities

will depend on use and they may present risks to health and

the environment on disposal. ALL used oil should be handled

with caution and skin contact avoided as far as possible.

12. ECOLOGICAL INFORMATION

Ecotoxicological data have not been determined specifically for this product. Information given is

based on a knowledge of the components and the ecotoxicology of similar products.

Acute Toxicity

Microorganisms

Mobility

:

:

Persistence/degradability

Bioaccumulation

Other Adverse Effects

Poorly soluble mixture. May cause physical fouling of aquatic

organisms. Expected to be practically non toxic: LL/EL/IL50 >

100 mg/l (to aquatic organisms) (LL/EL50 expressed as the

nominal amount of product required to prepare aqueous test

extract).

Data not available

Liquid under most environmental conditions. Floats on water. If

it enters soil, it will adsorb to soil particles and will not be

mobile.

Expected to be not readily biodegradable. Major constituents

are expected to be inherently biodegradable, but the product

contains components that may persist in the environment.

Contains components with the potential to bioaccumulate.

Product is a mixture of non-volatile components, which are not

expected to be released to air in any significant quantities. Not

expected to have ozone depletion potential, photochemical

ozone creation potential or global warming potential.

13. DISPOSAL CONSIDERATIONS

: Recover or recycle if possible. It is the responsibility of the

Material Disposal

waste generator to determine the toxicity and physical

properties of the material generated to determine the proper

waste classification and disposal methods in compliance with

applicable regulations. Do not dispose into the environment, in

drains or in water courses.

5/7

Print Date 16.11.2011

000000019773

MSDS_TH

Shell Spirax S4 ATF HDX

Version 1.1

Effective Date 15.11.2011

Material Safety Data Sheet

Container Disposal

Local Legislation

Dispose in accordance with prevailing regulations, preferably to

a recognised collector or contractor. The competence of the

collector or contractor should be established beforehand.

Disposal should be in accordance with applicable regional,

national, and local laws and regulations.

14. TRANSPORT INFORMATION

Land (as per ADR classification): Not regulated

This material is not classified as dangerous under ADR regulations.

IMDG

This material is not classified as dangerous under IMDG regulations.

IATA (Country variations may apply)

This material is either not classified as dangerous under IATA regulations or needs to follow

country specific requirements.

15. REGULATORY INFORMATION

The regulatory information is not intended to be comprehensive. Other regulations may apply to this

material.

EC Classification

EC Symbols

EC Risk Phrases

EC Safety Phrases

Chemical Inventory Status

EINECS

:

:

:

:

Not classified as dangerous under EC criteria.

No Hazard Symbol required

Not classified.

Not classified.

TSCA

Sensitiser not sufficient to

classify

All components

listed or polymer

exempt.

All components

listed.

Contains alkylamine. May produce an allergic reaction.

Other Information

Hazardous Substance Act. B.E. 2535

16. OTHER INFORMATION

R-phrase(s)

R22

R34

R43

R52/53

Not classified.

Harmful if swallowed.

Causes burns.

May cause sensitisation by skin contact.

Harmful to aquatic organisms, may cause long-term adverse effects in the

aquatic environment.

6/7

Print Date 16.11.2011

000000019773

MSDS_TH

Shell Spirax S4 ATF HDX

Version 1.1

Effective Date 15.11.2011

Material Safety Data Sheet

MSDS Version Number

1.1

MSDS Effective Date

15.11.2011

MSDS Revisions

MSDS Regulation

MSDS Distribution

Disclaimer

A vertical bar (|) in the left margin indicates an amendment

from the previous version.

The content and format of this safety data sheet is in

accordance with Commission Directive 2001/58/EC of 27 July

2001, amending for the second time Commission Directive

91/155/EEC.

The information in this document should be made available to

all who may handle the product.

This information is based on our current knowledge and is

intended to describe the product for the purposes of health,

safety and environmental requirements only. It should not

therefore be construed as guaranteeing any specific property

of the product.

7/7

Print Date 16.11.2011

000000019773

MSDS_TH

Vous aimerez peut-être aussi

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesD'EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesPas encore d'évaluation

- Corena S4 P68Document7 pagesCorena S4 P68Beryl FernandesPas encore d'évaluation

- Engine Oil MSDSDocument7 pagesEngine Oil MSDSSantos RexPas encore d'évaluation

- Corena S2 P68Document7 pagesCorena S2 P68Beryl FernandesPas encore d'évaluation

- Corena S3 R 32Document7 pagesCorena S3 R 32Beryl Fernandes0% (1)

- Corena S3 R 46Document7 pagesCorena S3 R 46Beryl FernandesPas encore d'évaluation

- Corena S2 P100Document7 pagesCorena S2 P100Beryl FernandesPas encore d'évaluation

- Alexia Ls - MsdsDocument7 pagesAlexia Ls - MsdsBeryl FernandesPas encore d'évaluation

- Corena S2 P150Document7 pagesCorena S2 P150Beryl FernandesPas encore d'évaluation

- MSDS - Shell Corena D - Screw Air Compressor OilDocument7 pagesMSDS - Shell Corena D - Screw Air Compressor OilAnonymous LfeGI2hMPas encore d'évaluation

- Omala S2 G 68Document7 pagesOmala S2 G 68Beryl FernandesPas encore d'évaluation

- Alexia 50 - MSDSDocument7 pagesAlexia 50 - MSDSBeryl FernandesPas encore d'évaluation

- Msds Shell Thermia BDocument7 pagesMsds Shell Thermia BNita FauPas encore d'évaluation

- Argina X40 - MSDSDocument7 pagesArgina X40 - MSDSBeryl FernandesPas encore d'évaluation

- MSDS - Shell Spirax - Gear OilDocument7 pagesMSDS - Shell Spirax - Gear OilAnonymous LfeGI2hMPas encore d'évaluation

- Morlina S4 B 220Document6 pagesMorlina S4 B 220Beryl FernandesPas encore d'évaluation

- Shell Turbo Oil T 46 (MSDS) 2Document8 pagesShell Turbo Oil T 46 (MSDS) 2Anonymous F2TxS3YoaPas encore d'évaluation

- Msds EthanolDocument11 pagesMsds EthanolAsih MiniartiPas encore d'évaluation

- Melina 30 - MSDSDocument7 pagesMelina 30 - MSDSBeryl FernandesPas encore d'évaluation

- MsdsbiodieselDocument10 pagesMsdsbiodieselHafid AlwanPas encore d'évaluation

- Gadus S5 U130D 2Document8 pagesGadus S5 U130D 2Beryl FernandesPas encore d'évaluation

- Msds Shell Thermia BDocument7 pagesMsds Shell Thermia BMuhammad Nurul AminPas encore d'évaluation

- 671 - Msds-Cassida Fluid GL 460Document8 pages671 - Msds-Cassida Fluid GL 460Alvin LimlengcoPas encore d'évaluation

- Propylene Glycol USP MSDSDocument6 pagesPropylene Glycol USP MSDSeprastyo_3Pas encore d'évaluation

- MSDS - Shell Madrela - Compressor OilDocument7 pagesMSDS - Shell Madrela - Compressor OilAnonymous LfeGI2hMPas encore d'évaluation

- Shell Omala 100Document7 pagesShell Omala 100PN RaoPas encore d'évaluation

- Ms Ds BiodieselDocument10 pagesMs Ds BiodieselOsckar DezPas encore d'évaluation

- Asg 33MSDocument8 pagesAsg 33MSNICKYPas encore d'évaluation

- Gadinia AL30 - MSDSDocument6 pagesGadinia AL30 - MSDSBeryl FernandesPas encore d'évaluation

- Asphalt MSDSDocument8 pagesAsphalt MSDSJunard M. Lu HapPas encore d'évaluation

- Msds EthaneDocument7 pagesMsds Ethanenirmal_subudhiPas encore d'évaluation

- Tellus T68Document8 pagesTellus T68kpeterson400Pas encore d'évaluation

- Msdsisomerate Msds Mixed PentanesDocument10 pagesMsdsisomerate Msds Mixed PentanesEmman Patpert KnuckleheadsPas encore d'évaluation

- Trichloroacetic AcidDocument10 pagesTrichloroacetic Acidwillyvh99Pas encore d'évaluation

- Shell Refrigeration Oil S2 FR-A 68Document8 pagesShell Refrigeration Oil S2 FR-A 68slvmr_estrada1259Pas encore d'évaluation

- MSDS-RIPSTAR 156-Part 1Document6 pagesMSDS-RIPSTAR 156-Part 1Ankita Baban GavadePas encore d'évaluation

- Minimum Oil Circuit BreakerDocument4 pagesMinimum Oil Circuit BreakergshdavidPas encore d'évaluation

- Gadinia 30 - MSDSDocument7 pagesGadinia 30 - MSDSBeryl FernandesPas encore d'évaluation

- Material Safety Data SheetDocument8 pagesMaterial Safety Data SheetMohamed SudanPas encore d'évaluation

- Acetic AcidDocument10 pagesAcetic AcidSunder Tukaram KelkarPas encore d'évaluation

- 15w50msds PDFDocument9 pages15w50msds PDFSkySupplyUSAPas encore d'évaluation

- Mirr Turbo Supreme Plus Api CK-4 Sae 10W40 SDSDocument8 pagesMirr Turbo Supreme Plus Api CK-4 Sae 10W40 SDSAbdul GhafoorPas encore d'évaluation

- Safety Data Sheet: Tokyo Chemical Industry Co., LTDDocument5 pagesSafety Data Sheet: Tokyo Chemical Industry Co., LTDJonny DenPas encore d'évaluation

- Pennzoil MsdsDocument7 pagesPennzoil MsdsSkySupplyUSAPas encore d'évaluation

- Gadus S2 V100 2Document8 pagesGadus S2 V100 2Beryl FernandesPas encore d'évaluation

- Nitric AcidDocument10 pagesNitric AcidCahyo ArdoyoPas encore d'évaluation

- Acetic AnhydrideDocument5 pagesAcetic AnhydrideChern YuanPas encore d'évaluation

- Gadus S2 A320 2Document8 pagesGadus S2 A320 2Beryl FernandesPas encore d'évaluation

- Isopar HDocument11 pagesIsopar Hwaxim26322Pas encore d'évaluation

- 2 Aminoterephthalic AcidDocument9 pages2 Aminoterephthalic AcidLila AdelPas encore d'évaluation

- Pfeiffer P3 MSDSDocument7 pagesPfeiffer P3 MSDSPin SantosPas encore d'évaluation

- Safety Data Sheet: Polytrol FL 32Document9 pagesSafety Data Sheet: Polytrol FL 32melvinkuriPas encore d'évaluation

- Hypogear 80W-90 - BP Australia Pty LTDDocument5 pagesHypogear 80W-90 - BP Australia Pty LTDBiju_PottayilPas encore d'évaluation

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesD'EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesD'EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesÉvaluation : 5 sur 5 étoiles5/5 (2)

- Cryogenics Safety Manual: A Guide to Good PracticeD'EverandCryogenics Safety Manual: A Guide to Good PracticePas encore d'évaluation

- Handbook of Air Pollution Prevention and ControlD'EverandHandbook of Air Pollution Prevention and ControlÉvaluation : 5 sur 5 étoiles5/5 (2)

- DC 4.75Document11 pagesDC 4.75jinyuan74Pas encore d'évaluation

- DPDocument19 pagesDPMohammad HusanPas encore d'évaluation

- Mud HopperDocument2 pagesMud Hopperjinyuan74Pas encore d'évaluation

- Rotary and Handling Tools Catalog PDFDocument190 pagesRotary and Handling Tools Catalog PDFjinyuan74100% (3)

- Offshore and Onshore Rig Cables - 1 PDFDocument152 pagesOffshore and Onshore Rig Cables - 1 PDFjinyuan74Pas encore d'évaluation

- HWDPDocument15 pagesHWDPjinyuan74Pas encore d'évaluation

- DME Exhaust Catalog 2013 PDFDocument72 pagesDME Exhaust Catalog 2013 PDFjinyuan74Pas encore d'évaluation

- MHD56251 Ed4Document152 pagesMHD56251 Ed4jinyuan74100% (1)

- Physics Notes RevisionDocument43 pagesPhysics Notes RevisionMatthew LiPas encore d'évaluation

- Ellk92led CsaDocument12 pagesEllk92led Csajinyuan74Pas encore d'évaluation

- CG - Eng .223 Drill Pipe Care and HandlingDocument12 pagesCG - Eng .223 Drill Pipe Care and Handlingjinyuan74Pas encore d'évaluation

- PR-1947 - Electrical Safety RulesDocument58 pagesPR-1947 - Electrical Safety Rulesjinyuan74Pas encore d'évaluation

- FIS Services Spec BookDocument22 pagesFIS Services Spec BookLuis A G. C.Pas encore d'évaluation

- Osborn Loadrunners English PDFDocument92 pagesOsborn Loadrunners English PDFjinyuan74Pas encore d'évaluation

- Flfe Series Lighting Fixtures For Fluorescent Tubes-1Document5 pagesFlfe Series Lighting Fixtures For Fluorescent Tubes-1jinyuan74Pas encore d'évaluation

- LAKELAND Chemical Resistant ApronDocument4 pagesLAKELAND Chemical Resistant Apronjinyuan74Pas encore d'évaluation

- Fire PumpDocument1 pageFire Pumpjinyuan74Pas encore d'évaluation

- HL Series Addendum - 08-26-14Document1 pageHL Series Addendum - 08-26-14jinyuan74Pas encore d'évaluation

- The Life-Saving Rules (April)Document1 pageThe Life-Saving Rules (April)jinyuan74Pas encore d'évaluation

- Loc TiteDocument2 pagesLoc Titejinyuan74Pas encore d'évaluation

- Chemistry Revision Pack - 2012Document20 pagesChemistry Revision Pack - 2012api-21735041071% (7)

- 50Hz UP5 11, UP5 15, UP5 18, UP5 22 60Hz UP6 15, UP6 20, UP6 25, UP6 30Document10 pages50Hz UP5 11, UP5 15, UP5 18, UP5 22 60Hz UP6 15, UP6 20, UP6 25, UP6 30jinyuan74Pas encore d'évaluation

- The Life-Saving Rules (April)Document1 pageThe Life-Saving Rules (April)jinyuan74Pas encore d'évaluation

- Lewis Oilfield ProductsDocument4 pagesLewis Oilfield Productsjinyuan74Pas encore d'évaluation

- 1907 - T - CardDocument1 page1907 - T - Cardjinyuan74Pas encore d'évaluation

- Product Compare: Products OverviewDocument2 pagesProduct Compare: Products Overviewjinyuan74Pas encore d'évaluation

- Lufkin CatalogDocument48 pagesLufkin Catalogjinyuan74Pas encore d'évaluation

- Ball ValveDocument12 pagesBall ValvemohamedfirozPas encore d'évaluation

- Loc TiteDocument2 pagesLoc Titejinyuan74Pas encore d'évaluation

- FLITTRAP (Floating Litter Trap) With Collecting System: A Critical ReviewDocument3 pagesFLITTRAP (Floating Litter Trap) With Collecting System: A Critical ReviewAaron Choco De Guzman0% (1)

- Effect of PH and Moisture Content On Composting of Municipal Solid WasteDocument3 pagesEffect of PH and Moisture Content On Composting of Municipal Solid WasteJASH MATHEWPas encore d'évaluation

- MSDS Benzoyl PeroxideDocument10 pagesMSDS Benzoyl PeroxideSuchanond KaewjindaPas encore d'évaluation

- PIOGA MSC TENORM Study Responses DEP StudyDocument15 pagesPIOGA MSC TENORM Study Responses DEP StudyDory HippaufPas encore d'évaluation

- Tailings Management: PasteDocument17 pagesTailings Management: PasteLMPas encore d'évaluation

- Welcome: Asia BRTS Conference 2012 AhmedabadDocument29 pagesWelcome: Asia BRTS Conference 2012 AhmedabadBasant KumarPas encore d'évaluation

- Tle-Agri Crop 2q-Week 3-Final (Waste Material Management)Document10 pagesTle-Agri Crop 2q-Week 3-Final (Waste Material Management)Mary Grace PesalboPas encore d'évaluation

- Tle As CSS 10 Q4 W8Document4 pagesTle As CSS 10 Q4 W8Francesca Madelene SulivaPas encore d'évaluation

- United States v. John J. Zagari Pasquale "Pat" Maselli, AKA Pat Frank Salerno Frank Trapani, AKA Harpo Angelo J. Dipalo, AKA Shorty Peter Del Cioppo, AKA Petey Del George Merusi James A. Rogan, AKA Jimmy Raymond E. Ryder David Zanolini Morton Wagner, AKA Morty, Donald Herzog Alfred Christiansen Charles Shay, 111 F.3d 307, 2d Cir. (1997)Document34 pagesUnited States v. John J. Zagari Pasquale "Pat" Maselli, AKA Pat Frank Salerno Frank Trapani, AKA Harpo Angelo J. Dipalo, AKA Shorty Peter Del Cioppo, AKA Petey Del George Merusi James A. Rogan, AKA Jimmy Raymond E. Ryder David Zanolini Morton Wagner, AKA Morty, Donald Herzog Alfred Christiansen Charles Shay, 111 F.3d 307, 2d Cir. (1997)Scribd Government DocsPas encore d'évaluation

- Use of Reclaimed Rubber Cell in Highway Pavement: An Experimental ResearchDocument6 pagesUse of Reclaimed Rubber Cell in Highway Pavement: An Experimental ResearchHazbullah ShajiPas encore d'évaluation

- Mid 1 Problem Solutions PDFDocument7 pagesMid 1 Problem Solutions PDFasdfrtyPas encore d'évaluation

- JELET SyllabusDocument10 pagesJELET SyllabusSubhashis DePas encore d'évaluation

- Incinerator: Water & Waste SolutionsDocument2 pagesIncinerator: Water & Waste SolutionsHenry San PedroPas encore d'évaluation

- 9 7 2015 1 20 25 03 Operation Maintenance of Sewage Treatment Plants and Pumping Stations (20150731PM)Document55 pages9 7 2015 1 20 25 03 Operation Maintenance of Sewage Treatment Plants and Pumping Stations (20150731PM)Elias RizkPas encore d'évaluation

- Cold Forming of Metals SafetyDocument19 pagesCold Forming of Metals SafetyHari KoneruPas encore d'évaluation

- Etaline SYTDocument52 pagesEtaline SYTjprakashusPas encore d'évaluation

- SWM Patna 1 - 2Document27 pagesSWM Patna 1 - 2Ujjwal anandPas encore d'évaluation

- High Density Polyethylene GF4950: DescriptionDocument1 pageHigh Density Polyethylene GF4950: Descriptioncesar1scribdPas encore d'évaluation

- 02 Green Skills II Important Questions AnswersDocument6 pages02 Green Skills II Important Questions Answersadityasharma6261srPas encore d'évaluation

- World of Darkness - Three Shades of NightDocument290 pagesWorld of Darkness - Three Shades of NightBilly Mott86% (7)

- Chapter 1Document20 pagesChapter 1Vera Carpentero LamisPas encore d'évaluation

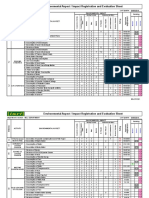

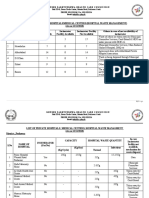

- Environmental Aspect / Impact Registration and Evaluation SheetDocument3 pagesEnvironmental Aspect / Impact Registration and Evaluation SheetrewrtegamingPas encore d'évaluation

- 2 Eco Mat Developmento of EcomatDocument4 pages2 Eco Mat Developmento of EcomatJuan C AguirrePas encore d'évaluation

- Incenrator Details 12 Nov 2018Document17 pagesIncenrator Details 12 Nov 2018ptaxPas encore d'évaluation

- User Manual: HM903DT A902MT-vDocument21 pagesUser Manual: HM903DT A902MT-vTony HamiltonPas encore d'évaluation

- Asphalt Plasto ReportDocument46 pagesAsphalt Plasto ReportMohammed Yaseen ShafeekPas encore d'évaluation

- Waste Glass Powder As Partial Replacement of CementDocument8 pagesWaste Glass Powder As Partial Replacement of CementdivyaPas encore d'évaluation

- Application of Floatation in Food IndustryDocument2 pagesApplication of Floatation in Food Industryvikasbnsl1Pas encore d'évaluation

- UTLDocument77 pagesUTLrajkumar_bhoraniyaPas encore d'évaluation

- Nonfiction Reading Test Garbage: Directions: Read The Following Passage and Answer The Questions That Follow. ReferDocument4 pagesNonfiction Reading Test Garbage: Directions: Read The Following Passage and Answer The Questions That Follow. ReferEdgar MatosPas encore d'évaluation