Académique Documents

Professionnel Documents

Culture Documents

Bob Neal Overunity Compression Unit - US2030759

Transféré par

John Carter0 évaluation0% ont trouvé ce document utile (0 vote)

124 vues5 pagesBob Neal Overunity Compression Unit - US2030759

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentBob Neal Overunity Compression Unit - US2030759

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

124 vues5 pagesBob Neal Overunity Compression Unit - US2030759

Transféré par

John CarterBob Neal Overunity Compression Unit - US2030759

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 5

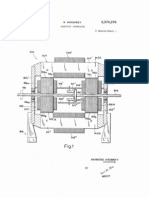

Feb.

1 l, 1936,

a. NEAL

COMPRESSOR UNIT

2,030,759

'

Filed Jan. 9, 19-34

5 Sheets-Sheet 1

INVENTOR.

' w,

ATTORNEY.

Feb. 11, 1936.

B. NEAL.

2,030,759

COMPRESSOR UNIT

Filed Jan. 9, 1934

3 Sheets-Sheet 2

"uIIIIIII_,III1IIIIIIII ..I

II

INVENTOR. -

A TTORNEY.

Feb. .11, 1936.

B. NEAL

2,030,759 _

COMPRESSOR UNIT

Filed Jan. 9', 1934

In

.III

I11I1III1IIIIIII

111/11,

s Sheets-Sheet 5

A TTORNEY.

Fatented Feb. 11, 1936

UNITED STATES PATENT

rrici:

2,030,759

COMPRESSOR UNIT

Bob Neal, Arkadelphia, Ark.

Application January 9, 1934, Serial No. 705,964

1 Claim. (Cl. 230.187)

. The invention relates to a, compressor con

struction, and more particularly to a combina

tion ?uid operated engine and compressor.

The primary object of the invention is the pro

1." vision of a compressor of this character, where

in there is arranged an automatically counter

balanced crank shaft and ?uid equalizers within

a storage tank, which makes it possible for the

said engine to operate on constant reserve tank

ing formed therein the series of compressor cyl

inders l I and the power cylinders l2, respective

ly, the block Ill being of the V-type and closing

the upper ends of said cylinders are the remov

able heads l3 and I4, respectively, which are se

cured in place by head bolts l5, as is conven

tional. Beneath the block I0 is the crank case

I5, which at opposite sides carries the detach

able plates ll, these being held in place by fas

pressure so as to actuate additional equipment,

tener's l8 and. such plates are seated so as to be

the pistons for the engine being also automati

cally balanced and suspended when the said en

gine is in operation.

Another object of the invention is the provi

sion of an engine. of this character, wherein the

leak proof. The block Ill is. chambered to pro

vide a, water jacket l9 about the cylinders, while

same is operated from air under pressure, the

said air being supplied by compressors, these be

ing in bank with the engine construction.

at the forward end of the said block are water

pumps 23 circulating water through the inlet pipe w

2|. which leads into. the jacket and letting said 15

water out therefrom through the outlet pipe 22

leading from said water jacket. Next to the

pumps 25 is a fan 23 operated from a belt 24

A further object of the invention is the provi

20 sion of an. engine of this character, wherein the

same is of novel construction, as the engine prop

rocating pistons 25, their rods 25 being slidable

er and the compressors are operated from the

same crank shaft which is of the automatically

through packing glands 2! and ?xed to cross

heads 28, which are slidably mounted upon guides

balanced type, so that high e?iciency is attained.

A still further object of the invention is the

provision of an engine of this character, which

is comparatively simple in construction, thor

oughly reliable and ef?cient in its operation,

29 secured within the crank case IE to opposite

side walls thereof. These crossheads 28 are 25

strong, durable,'and inexpensive to manufacture.

counter balanced crank shaft 34, which is mount

ed in supports 35 arranged in the crank case It, 30

25

With these and other objects in view the in

vention consists in the features of construction,

combination and arrangement of parts as will

be hereinafter more fully described, illustrated

in the accompanying drawings, which disclose

35 the preferred embodiment of the invention, and

pointed out in the claim hereunto appended.

30

In the accompanying drawings:

Figure 1 is a perspective view of the engine

constructed in accordance with the invention.

40

Figure 2 is a vertical transverse sectional View

through the compressor part of the engine.

Figure 3 is a vertical sectional View through

the power part of the engine.

Figure 4 is a detail elevation of the crank shaft

of the engine.

Figure 5 is an enlarged sectional view through

one of the electric heaters for the engine.

Figure 6 is a vertical longitudinal sectional

view through the air storage tank including the

equalizer.

Similar reference characters indicate corre

sponding parts throughout the several views in

the drawings.

Referring to the drawings in detail the engine

5 in its entirety comprises a cylinder block l0 hav

which also drives the, pumps.

Working within the cylinders H are the recip

?tted with wrist pins 33 pivotally connecting

therewith the connecting rods 3% which by the

bearings 32 are engaged with their cranks 33 of a

the shaft being supplied with the required bear

ings 36.

The inner ends of the cylinders H are ?tted

with inner end heads 31, which are provided with

air intake ports 38, these being ?tted with spring

ball inlet checks 39, the air having admission

through passages All opening exteriorly of the

block Ill. The glands 21 are associated with the

heads 31.

The heads l3 and 31 are provided with the 40

compressed air outlets 4| and 42, respectively,

these being ?tted with spring ball checks 43, the

heads l3 being also provided with the central air

inlets 44, which are ?tted with spring checks 45.

By couplings 46 are attached to the air outlets 4|

and 42 the outlet feed pipes ill and 48, respec

tively, these leading to a main conduit 49 located

in the center channel 50 in said block l9.

At the rear end of the block I!) and on the

shaft 34 is the fly wheel 5 I, this being of conven 50

tional type.

Working within the cylinders l2 are pistons 52,

their rods 53 sliding through packing glands 54

and ?xed in crossheads 55 slidably mounted upon

guides 56 which are secured within the crank

2.

>

'

2,030,759

case Hi at opposite side walls thereof.

The cross

heads 55 carry Wrist pins 5'! connecting there

with connecting rods 58, these being engaged by

bearings 59 with their respective cranks 60 of the

OX crank shaft 34, the inner ends of the cylinders l2

fbeing also closed by inner heads 6| with which

' are associated the glands 54.

freezing temperature when delivered from the

tank 1 lto the cylinders l2.

Supported on the block I0 is an electric gen

erator 85 which is driven from the shaft 31

through a belt 24 and this generator is included

in an electric circuit which also has the heaters

84 so that these will operate from current fur-'- V

On the cylinders I 2 are slide valve chests =62 in

which are the slide valves 63, these being oper

10 ated by throw rods 64 actuated by cams 651 and

such valves controlling the air admission and

exhaust of air to and from the cylinders l2

through the ports 66 and 67, and these valves 63

are provided with the ports 68 for the delivery of

air under pressure from the inlet passages 69

common to a lead?!) from a compressed air stor

nished by said generator.

The storage tank 1| with the equalizer-is so

constructed that it is possible to pump air into 10

the said tank with a tank pressure of two'hun

dred pounds, while the compressors are only

pumping against ?fteen pounds or atmospheric

pressure.

Outside air pressure source can be

coupled with the tank to augment that pressure

derived from the cylinders l I of the engine.

What is claimed is:

age tank 1 l .

The bottom of the crank case Hi is ?tted with a

In a structure of the kind described, a V-shaped

removable plate l2 which is secured in place by

fasteners l3, and when this plate is removed

cylinder block provided with upwardly divergent

access can be had to the crank shaft 34 and the

bearings for the engine, as well as other parts

opposite ends thereof, each head having valved

within said crank case, as should be obvious.

Leading into the cylinders II are the passages

25 74 of a lubricating system (not shown).

The storage tank ll for the'compressed air

cylinders, end heads ?tted to said cylinders at

inlets and outlets, a main outlet lead between

> the cylinders of the block for a storage tank and i

having lateral branches to the outlets at the

inner sides of said heads, one inlet being located

at the center of each head at the-outer ends

7 includes therein a double check discharge nozzle

of said cylinders while the remaining inlets are

75, this being supported by a member 16 and

leading to this equalizer is an air, inlet pipe 71

30 which has the communication 18 with the cham

ber 79 formed by said tank. In the equalizer 15

are the spaced spring ball checks 80 and 8|,

at the outer sides of the heads at the inner ends

h respectively, one being for the inlet side and the

and having rods extended into the crank case,

25

of said cylinders, a substantially V-shaped crank

case ?tted to the block beneath the cylinders, a

counterbalanced crank shaft journaled in the

crank case, pistons operating in the cylinders

other for the exhaust or outlet side of said equal

crosshead guides ?tted to the sides of said case

izer. This pipe I! is connected with the main

conduit 49, while a pipe 82 is connected with the

leads iii, the tank being also ?tted with an auto

matic relief valve 83 of any approved type.

About the pipes 10, for the passages 69 are the

interiorly thereof, crossheads connecting the rods 35

40 electric heating units 84 which are for the pur

pose of heating the air under pressure above a

with the guides and slidable onthe same and con

necting rods'operated by the crank shaft and

pivoted to the crossheads for reciprocation of

the pistons.

"

BOB NEAL; 4'01

Vous aimerez peut-être aussi

- Theory of Microwave Valves: International Series of Monographs on Electronics and InstrumentationD'EverandTheory of Microwave Valves: International Series of Monographs on Electronics and InstrumentationPas encore d'évaluation

- Overunity LEDDocument8 pagesOverunity LEDboo10626850Pas encore d'évaluation

- Laser spectroscopy IXD'EverandLaser spectroscopy IXMichael FeldPas encore d'évaluation

- ABC Vacuum Tube Catalog CombinedDocument15 pagesABC Vacuum Tube Catalog CombinedVincent J. CataldiPas encore d'évaluation

- Research and Development in Non-Mechanical Electrical Power Sources: Proceedings of the 6th International Symposium Held at Brighton, September 1968D'EverandResearch and Development in Non-Mechanical Electrical Power Sources: Proceedings of the 6th International Symposium Held at Brighton, September 1968Pas encore d'évaluation

- Back EMF in A Motor NotesDocument3 pagesBack EMF in A Motor NotesNisitha Tharushan DarmarathnaPas encore d'évaluation

- The MY1016 3BGS Pulse MotorDocument5 pagesThe MY1016 3BGS Pulse Motorpranalar100% (1)

- Libert NX Up TP 200 kVADocument112 pagesLibert NX Up TP 200 kVACat PowerPas encore d'évaluation

- Spiteri SpiteriDocument16 pagesSpiteri SpiteriklausPas encore d'évaluation

- Bloch Waves Block StatesDocument5 pagesBloch Waves Block StatesTeka Kam100% (1)

- Airmax 900 MHZ airMAX 2x2 MIMO PTP/PTMP YAGI AntennaDocument6 pagesAirmax 900 MHZ airMAX 2x2 MIMO PTP/PTMP YAGI AntennaMiguel Andres VanegasPas encore d'évaluation

- No. 390,721, Patented 00 T. 9, 1888.: Best Avalable Cop N, TeslaDocument4 pagesNo. 390,721, Patented 00 T. 9, 1888.: Best Avalable Cop N, TeslaAtharva Deshpande100% (1)

- 1 IntroductionDocument61 pages1 Introductionfiraol temesgenPas encore d'évaluation

- Diagnostic Sales Evening Component TestingDocument124 pagesDiagnostic Sales Evening Component TestingbibPas encore d'évaluation

- Over UnityDocument3 pagesOver UnityOrion MorganPas encore d'évaluation

- Bi Toroid Transformer DiscussionDocument781 pagesBi Toroid Transformer DiscussionLuisLazoPas encore d'évaluation

- MelnichenkoDocument5 pagesMelnichenkomitza22Pas encore d'évaluation

- En CD00201961 PDFDocument39 pagesEn CD00201961 PDFIrini Fountouli - LadopoulouPas encore d'évaluation

- Inductor and Flyback Transformer DesignDocument20 pagesInductor and Flyback Transformer Designbmmostefa100% (1)

- Ni Sbrio-9651: Getting Started With The Sbrio-9651 Som Development KitDocument2 pagesNi Sbrio-9651: Getting Started With The Sbrio-9651 Som Development Kitkhin600Pas encore d'évaluation

- Drive A CFL From 6v or 12vDocument1 pageDrive A CFL From 6v or 12vJohn ApostlePas encore d'évaluation

- 50 Watt Small Homemade InverterDocument25 pages50 Watt Small Homemade InverterMarlon CarinoPas encore d'évaluation

- Power Converters Lecture - 1: Dr. U. T. ShamiDocument78 pagesPower Converters Lecture - 1: Dr. U. T. ShamiM Waqar ZahidPas encore d'évaluation

- Jovan Marjanovic Veljko Milkovic Kinetic Energy and OverunityDocument11 pagesJovan Marjanovic Veljko Milkovic Kinetic Energy and Overunitylzk2d2Pas encore d'évaluation

- Permanent Magnet MotorsDocument36 pagesPermanent Magnet MotorskkarthiksPas encore d'évaluation

- Capacitive AntennaDocument8 pagesCapacitive AntennajohnlesliePas encore d'évaluation

- Submitted By: Rajat Garg C08541 EECE, 7th SemDocument22 pagesSubmitted By: Rajat Garg C08541 EECE, 7th Semrajatgarg90Pas encore d'évaluation

- FM Radio ReceiverDocument5 pagesFM Radio ReceiverRalph DimaandalPas encore d'évaluation

- Electronic CircuitsDocument120 pagesElectronic CircuitsAbhishek SurinPas encore d'évaluation

- WWW Youtube Com Watch V HyTplvO4i9UDocument2 pagesWWW Youtube Com Watch V HyTplvO4i9UJohnnyLarsonPas encore d'évaluation

- SSG STARTERS GUIDE-One PDFDocument18 pagesSSG STARTERS GUIDE-One PDFMihai Iulian CristeaPas encore d'évaluation

- Seebeck Coefficient of Thermocouples With VariationsDocument18 pagesSeebeck Coefficient of Thermocouples With VariationsNikhil JaisinghaniPas encore d'évaluation

- Analog ElectronicsDocument390 pagesAnalog ElectronicsAnthony Robert XPas encore d'évaluation

- Make The Joule Thief Circuit For Power A CFLDocument7 pagesMake The Joule Thief Circuit For Power A CFLRifi HadiPas encore d'évaluation

- EMS Lab Manual Ver 1.0 (Fall 2016)Document69 pagesEMS Lab Manual Ver 1.0 (Fall 2016)Fahad MahmoodPas encore d'évaluation

- Edge-Triggered Driver Circuit For Ultra-WidebandDocument4 pagesEdge-Triggered Driver Circuit For Ultra-WidebandTeePas encore d'évaluation

- English Service Manual RAINBOW 150Document54 pagesEnglish Service Manual RAINBOW 150Jaroslaw Brzozowski100% (2)

- March 19, 1968 - R, Kromrey I 3,374,376: Electric GeneratorDocument8 pagesMarch 19, 1968 - R, Kromrey I 3,374,376: Electric GeneratorVlad AdrianPas encore d'évaluation

- Fuente de 12 VDC Sin TransformadorDocument16 pagesFuente de 12 VDC Sin TransformadorElvis Fernando Ñaupari ChahuaPas encore d'évaluation

- Design Analysis and Simulation of Magnetic Biased Inductors With Saturation-Gap - EPE2014Document8 pagesDesign Analysis and Simulation of Magnetic Biased Inductors With Saturation-Gap - EPE2014andresPas encore d'évaluation

- Arduino Uno r3 PDFDocument9 pagesArduino Uno r3 PDFDANIEL ALEJANDRO LEMUS RINCONPas encore d'évaluation

- 6V To 220V Inverter SchematicDocument1 page6V To 220V Inverter SchematicthuylantPas encore d'évaluation

- Tesla Coil DriverDocument9 pagesTesla Coil DrivercatalinbrvPas encore d'évaluation

- Self Running Free Energy Device Muller Motor Generator Romerouk Version1 1Document25 pagesSelf Running Free Energy Device Muller Motor Generator Romerouk Version1 1Gary BaldiPas encore d'évaluation

- Physics Tesla CoilDocument12 pagesPhysics Tesla CoilSunidhi SharmaPas encore d'évaluation

- Experiment 6-The Self-Excited Shunt GeneratorDocument5 pagesExperiment 6-The Self-Excited Shunt GeneratorAlbany Smash0% (1)

- SANDIA CRS WithStorageDocument275 pagesSANDIA CRS WithStoragejvalverdegarciaPas encore d'évaluation

- Optimization of Four Wave Mixing Effect in Radio-Over-Fiber For A 32-Channel 40-GBPS DWDM SystemDocument6 pagesOptimization of Four Wave Mixing Effect in Radio-Over-Fiber For A 32-Channel 40-GBPS DWDM SystemLương Xuân Dẫn100% (1)

- DC Power SupplyDocument14 pagesDC Power Supplyrjjain07Pas encore d'évaluation

- Thorborg 31 PDFDocument6 pagesThorborg 31 PDFhanksoloPas encore d'évaluation

- 220V DC To 220V AC: DIY Inverter Part 2: InstructablesDocument10 pages220V DC To 220V AC: DIY Inverter Part 2: InstructablesTnT ElektricPas encore d'évaluation

- Joule Thief TDocument5 pagesJoule Thief TJohn WestfieldPas encore d'évaluation

- Physics Lab Manual Final1 03.11.08 PDFDocument50 pagesPhysics Lab Manual Final1 03.11.08 PDFWWE SuperstarsPas encore d'évaluation

- RAT Tube TesterDocument16 pagesRAT Tube TesterGreggPas encore d'évaluation

- Amplifier Anatomy - Part 1: By: Patrick Quilter, Chief Technical Officer QSC Audio Products, IncDocument13 pagesAmplifier Anatomy - Part 1: By: Patrick Quilter, Chief Technical Officer QSC Audio Products, Inckashif1234567890Pas encore d'évaluation

- Capacitive Discharge MotorDocument10 pagesCapacitive Discharge MotorjoetylorPas encore d'évaluation

- 555 Oscillator ApplicationsDocument17 pages555 Oscillator Applicationsgopir28Pas encore d'évaluation

- How To Make A Joule ThiefDocument1 pageHow To Make A Joule ThiefRestorEleCisco100% (1)

- Tesla Patent,,,,Rotating Magnetic Field Using... Und A Ferrite Toroid1Document5 pagesTesla Patent,,,,Rotating Magnetic Field Using... Und A Ferrite Toroid1anakedya13Pas encore d'évaluation

- Bloch Wall Generator: Website Inventor ImagesDocument1 pageBloch Wall Generator: Website Inventor ImagesDan BeesonPas encore d'évaluation

- Inba - Info Rodin Glossary of TermsDocument175 pagesInba - Info Rodin Glossary of TermsJohn CarterPas encore d'évaluation

- 1 1 A George Merkl - Chondriana & Life Crystals - Synthrophic Transducer !!! PDFDocument118 pages1 1 A George Merkl - Chondriana & Life Crystals - Synthrophic Transducer !!! PDFJohn Carter100% (1)

- Christians Were Wrong, Lucifer Is Not Evil, Scientist InsistsDocument4 pagesChristians Were Wrong, Lucifer Is Not Evil, Scientist InsistsJohn CarterPas encore d'évaluation

- Blood Washing - Sensitivity Training - General Discussion - The Dao Bums PDFDocument9 pagesBlood Washing - Sensitivity Training - General Discussion - The Dao Bums PDFJohn Carter100% (1)

- Regal Academy - Wikipedia PDFDocument9 pagesRegal Academy - Wikipedia PDFJohn CarterPas encore d'évaluation

- 32 Years Ago Today, The 1985 Mexico City Mega Earthquake Shook A Whole NatioDocument4 pages32 Years Ago Today, The 1985 Mexico City Mega Earthquake Shook A Whole NatioJohn CarterPas encore d'évaluation

- China Closes Nature Park! Did Kim's Nuclear Bomb Wake Up A SupervolcanoDocument6 pagesChina Closes Nature Park! Did Kim's Nuclear Bomb Wake Up A SupervolcanoJohn CarterPas encore d'évaluation

- Mind Control Technology 'Lilly Wave' Is Far Advanced Beyond What We KnowDocument6 pagesMind Control Technology 'Lilly Wave' Is Far Advanced Beyond What We KnowJohn Carter100% (1)

- The Best Mantras To Get That Your Dreams Become TrueDocument10 pagesThe Best Mantras To Get That Your Dreams Become TrueJohn CarterPas encore d'évaluation

- HAARP Manipulates Time-Physicist Dr. Fran de AquinoDocument10 pagesHAARP Manipulates Time-Physicist Dr. Fran de AquinoJohn Carter100% (1)

- The Best Mantras To Get That Your Dreams Become TrueDocument10 pagesThe Best Mantras To Get That Your Dreams Become TrueJohn CarterPas encore d'évaluation

- What Do John Wick's Tattoos Mean - QuoraDocument4 pagesWhat Do John Wick's Tattoos Mean - QuoraJohn CarterPas encore d'évaluation

- 1 - Jan Pajak - Monograph 1 On Primeval Beginnings of Everything PDFDocument102 pages1 - Jan Pajak - Monograph 1 On Primeval Beginnings of Everything PDFJohn CarterPas encore d'évaluation

- 30 Beautiful Photos of IranDocument16 pages30 Beautiful Photos of IranJohn CarterPas encore d'évaluation

- AAR Shell ProgrammingDocument13 pagesAAR Shell ProgrammingMarimuthu MuthaiyanPas encore d'évaluation

- Controlador DanfossDocument2 pagesControlador Danfossfrank.marcondes2416Pas encore d'évaluation

- Advantages Renewable Energy Resources Environmental Sciences EssayDocument3 pagesAdvantages Renewable Energy Resources Environmental Sciences EssayCemerlang StudiPas encore d'évaluation

- Channel & Lomolino 2000 Ranges and ExtinctionDocument3 pagesChannel & Lomolino 2000 Ranges and ExtinctionKellyta RodriguezPas encore d'évaluation

- Friday 25 Mar 12:15 AM Friday 25 Mar 5:30 AM: Emirates CGK DXBDocument3 pagesFriday 25 Mar 12:15 AM Friday 25 Mar 5:30 AM: Emirates CGK DXBDONI ARTAPas encore d'évaluation

- Assignment RoadDocument14 pagesAssignment RoadEsya ImanPas encore d'évaluation

- Module 2Document7 pagesModule 2karthik karti100% (1)

- Parts Manual: Generator SetDocument118 pagesParts Manual: Generator SetAhmed Kamal100% (2)

- ATAL Selected FDPs AY 2023 24Document15 pagesATAL Selected FDPs AY 2023 24parthiban palanisamy100% (2)

- Anviz T5 RFID ManualDocument52 pagesAnviz T5 RFID ManualLuis Felipe Olaya SandovalPas encore d'évaluation

- Antifraud PlaybookDocument60 pagesAntifraud PlaybookDani UsmarPas encore d'évaluation

- R15 Understanding Business CyclesDocument33 pagesR15 Understanding Business CyclesUmar FarooqPas encore d'évaluation

- Effect of Plant Growth RegulatorsDocument17 pagesEffect of Plant Growth RegulatorsSharmilla AshokhanPas encore d'évaluation

- Ankle Injury EvaluationDocument7 pagesAnkle Injury EvaluationManiDeep ReddyPas encore d'évaluation

- D. Das and S. Doniach - Existence of A Bose Metal at T 0Document15 pagesD. Das and S. Doniach - Existence of A Bose Metal at T 0ImaxSWPas encore d'évaluation

- Auto Turn-Off For Water Pump With Four Different Time SlotsDocument3 pagesAuto Turn-Off For Water Pump With Four Different Time SlotsKethavath Sakrunaik K100% (1)

- Barista Skills Foundation Curriculum enDocument4 pagesBarista Skills Foundation Curriculum enCezara CarteșPas encore d'évaluation

- Gmail - ICICI BANK I PROCESS HIRING FOR BACKEND - OPERATION PDFDocument2 pagesGmail - ICICI BANK I PROCESS HIRING FOR BACKEND - OPERATION PDFDeepankar ChoudhuryPas encore d'évaluation

- Personal Narrative RevisedDocument3 pagesPersonal Narrative Revisedapi-549224109Pas encore d'évaluation

- SKF Shaft Alignment Tool TKSA 41Document2 pagesSKF Shaft Alignment Tool TKSA 41Dwiki RamadhaniPas encore d'évaluation

- A Brief Tutorial On Interval Type-2 Fuzzy Sets and SystemsDocument10 pagesA Brief Tutorial On Interval Type-2 Fuzzy Sets and SystemstarekeeePas encore d'évaluation

- Assessing The Marks and Spencers Retail ChainDocument10 pagesAssessing The Marks and Spencers Retail ChainHND Assignment Help100% (1)

- Thesis On Retail Management of The Brand 'Sleepwell'Document62 pagesThesis On Retail Management of The Brand 'Sleepwell'Sajid Lodha100% (1)

- Controlled DemolitionDocument3 pagesControlled DemolitionJim FrancoPas encore d'évaluation

- Route Clearence TeamDocument41 pagesRoute Clearence Teamctenar2Pas encore d'évaluation

- ProjectDocument33 pagesProjectPiyush PatelPas encore d'évaluation

- Em FlexicokingDocument8 pagesEm FlexicokingHenry Saenz0% (1)

- DOST-PHIVOLCS Presentation For The CRDRRMC Meeting 15jan2020Document36 pagesDOST-PHIVOLCS Presentation For The CRDRRMC Meeting 15jan2020RJay JacabanPas encore d'évaluation

- VLT 6000 HVAC Introduction To HVAC: MG.60.C7.02 - VLT Is A Registered Danfoss TrademarkDocument27 pagesVLT 6000 HVAC Introduction To HVAC: MG.60.C7.02 - VLT Is A Registered Danfoss TrademarkSamir SabicPas encore d'évaluation

- Lab 2 - Permeability TestDocument9 pagesLab 2 - Permeability TestAinur NasuhaPas encore d'évaluation

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterD'EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterPas encore d'évaluation

- Electric Motors and Drives: Fundamentals, Types and ApplicationsD'EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsÉvaluation : 4.5 sur 5 étoiles4.5/5 (12)

- Electric Motor Control: DC, AC, and BLDC MotorsD'EverandElectric Motor Control: DC, AC, and BLDC MotorsÉvaluation : 4.5 sur 5 étoiles4.5/5 (19)

- Well Integrity for Workovers and RecompletionsD'EverandWell Integrity for Workovers and RecompletionsÉvaluation : 5 sur 5 étoiles5/5 (3)

- Introduction to Power System ProtectionD'EverandIntroduction to Power System ProtectionÉvaluation : 5 sur 5 étoiles5/5 (1)

- Solar Energy: Survive Easily on Solar Power Off the GridD'EverandSolar Energy: Survive Easily on Solar Power Off the GridPas encore d'évaluation

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesD'EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentD'EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialD'EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialPas encore d'évaluation

- Shorting the Grid: The Hidden Fragility of Our Electric GridD'EverandShorting the Grid: The Hidden Fragility of Our Electric GridÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsD'EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsPas encore d'évaluation

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingD'EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingPas encore d'évaluation

- Handbook on Battery Energy Storage SystemD'EverandHandbook on Battery Energy Storage SystemÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsD'EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Well Control for Completions and InterventionsD'EverandWell Control for Completions and InterventionsÉvaluation : 4 sur 5 étoiles4/5 (10)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AD'EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&APas encore d'évaluation

- Thermal Power Plant: Design and OperationD'EverandThermal Power Plant: Design and OperationÉvaluation : 4.5 sur 5 étoiles4.5/5 (23)

- Flow Analysis for Hydrocarbon Pipeline EngineeringD'EverandFlow Analysis for Hydrocarbon Pipeline EngineeringPas encore d'évaluation

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideD'EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideÉvaluation : 2 sur 5 étoiles2/5 (1)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsD'EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsPas encore d'évaluation

- Photovoltaic Solar Energy: From Fundamentals to ApplicationsD'EverandPhotovoltaic Solar Energy: From Fundamentals to ApplicationsPas encore d'évaluation