Académique Documents

Professionnel Documents

Culture Documents

Catalog

Transféré par

Rachel IngramCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Catalog

Transféré par

Rachel IngramDroits d'auteur :

Formats disponibles

LAKASA Marketing & Distribution

Our Marketing & Sales Staff

LAKASA

Jason Lee 016-337 2528

Michael Lee 016-311 2387

Commitment:

To deliver best quality product & service at the most

competitive price

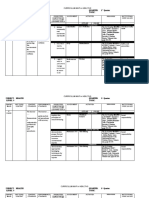

Content

Page

Environment Quality Act, 1974

Article Extract (Waste Water Treatment)

Type of Stainless Steel & Comparison

LAKASA Biomatic Grease Interceptor

57

LAKASA Biomatic Liquid Enzyme

89

LAKASA Auto-Dosing Unit (ADU)

10 11

LAKASA Sediment Interceptor

12

LAKASA Floor Sediment Trap

12

Installation for LAKASA Grease and

sediment Interceptor & Floor Sediment Trap

13

LAKASA Oil Interceptor

14 17

LAKASA Neutralization Tank

18 19

SIRIM Test Neutralization Tank

20

# Local Authority Approval letters &

SIRIM Test Reports & Project Reference

List are compiled separately. #

As product improvement is an ongoing process and in pursuit of excellence,

LAKASA reserves the right to change specification or design without prior notice.

Updated November 2013

LAKASA Marketing & Distribution

Environmental Quality Act, 1974

(Sewage and Industrial Effluents Regulations)

1.

First Schedule

List of Discharges to which These Regulations Do NOT Apply

Processing of oil-palm fruit or oil-palm fresh fruit bunches into crude palm oil, whether as an

intermediate or final product;

Processing of natural rubber in technically specified form, latex form including prevulcanised or the

form of modified and special purpose rubber, conventional sheet, skim or scrap rubber;

Mining activities;

Processing, manufacturing, washing or servicing of any other products or goods :

i. That produce effluent of less than 60 cubic metres (13,000 imperial gallons) per day ;

ii. That the effluent of which does not contain those contaminants listed as parameters (vi) to

(xvi) in the first column of the Third Schedule ;

iii. Where the total load of biochemical oxygen demand of the effluent fixed at 20 degree

centigrade for 5 days or suspended solid or both, shall not exceed 6 kilogrammes per day

(concentration 100 miligrammes per litre) ;

iv. In any housing or commercial development or both of less than 30 units, without affecting

the generality of the (iii) above.

2.

Second Schedule

Standard Methods Of Analysis of Effluent

I. Standard Methods of the Examination of Water and Wastewater published jointly by the American

Public Health Association, the American Water Works Association and the Water Pollution Control

Federation of the United State; or

II. Analysis of Raw, Potable and Wastewaters published by the Department of the Environment of the

United Kingdom.

3.

Third Schedule

Parameter Limits Of Effluent Of Standards A and B

No

I.

II.

III.

IV.

V.

VI.

VII.

VIII.

IX.

X.

XI.

XII.

XIII.

XIV.

XV.

XVI.

XVII.

XVIII.

XIX.

XX.

XXI.

XXII.

XXIII.

Parameter

Temperature

pH Value

o

BOD5 at 20 C

COD

Suspended Solids

Mercury

Cadmium

Chromium, Hexavalent

Arsenic

Cyanide

Lead

Chromium, Trivalent

Copper

Manganese

Nickel

Tin

Zinc

Boron

Iron (Fe)

Phenol

Free Chlorine

Sulphide

Oil and Grease

Unit

o

C

-mg/l

mg/I

mg/l

mg/l

mg/l

mg/l

mg/l

mg/l

mg/l

mg/l

mg/l

mg/l

mg/l

mg/l

mg/l

mg/l

mg/l

mg/l

mg/l

mg/l

mg/l

Standard

A

40

6.0-9.0

20

50

50

0.005

0.01

0.05

0.05

0.05

0.10

0.20

0.20

0.20

0.20

0.20

1.00

1.00

1.00

0.001

1.00

0.50

Not Detectable

40

5.5-9.0

50

100

100

0.05

0.02

0.05

0.10

0.10

0.50

1.00

1.00

1.00

1.00

1.00

1.00

4.00

5.00

1.00

2.00

0.50

10.00

LAKASA Marketing & Distribution

Article Extract

THE CITY OF NEW YORK

DEPARTMENT OF ENVIRONMENTAL PROTECTION

Wastewater Treatment

Preventing Grease Discharges Into Sewers

Guidelines for New York City Businesses

A thriving business community is vital to New York City and its neighborhoods. A

healthy economy benefits every New Yorker. But when businesses disregard

sewer use regulations and improperly dispose of grease, fat or oil, sewer lines

can become clogged, causing sewage to back up into basements of homes and

commercial establishments. When that happens, the entire community suffers.

The New York City Department of Environmental Protection (DEP) is

responsible for maintaining the Citys sewage system - 6,000 miles of sewers

and 14 wastewater treatment plants that process about 1.3 billion gallons of

sewage per day. Sewer back-ups are a major sewer system problem that

damages property and affects public health. In some areas, back-ups are

frequently caused by grease clogging the local sewers. To address this problem,

DEP is helping businesses comply with the Citys sewer use regulations. DEP is

educating not only restaurant owners but also operators of nursing homes, fruit

and vegetable stands, laundries, and dry cleaners, among others, to keep

grease and other materials and chemicals out of the sewer system.

To work effectively, sewer systems need to be properly maintained, from the

drain to the treatment plant. If wastes are disposed of correctly, the Citys sewer

system can handle them without any problem. Grease is an example of a

waste that the sewer system cannot handle, and therefore should not be put

down the drain. The City needs businesses and individuals to do their part to

maintain the system because repeated repairs are disruptive to residences

and businesses alike. Furthermore, proper disposal by commercial

establishments is required by law.

SEWER REGULATIONS CONCERNING GREASE

To ensure the proper disposal of animal fats and vegetable oils, and to prevent

sewage back-ups, the City requires grease-generating establishments to

correctly install, operate and maintain properly sized and designed grease

interceptors. These grease interceptors must be routinely cleaned to ensure

proper operation.

On November 9, 1998, the City amended the Sewer Use Regulations. These

amendments clarify existing requirements and provide for self-certification of

grease interceptors by a NYS licensed Professional Engineer or Registered

Architect. Self-certification relieves regulated establishments from a lengthy

departmental review process.

LAKASA Marketing & Distribution

Type of Stainless Steel & Comparison

1.

SUS 202 Non Magnetic

4% nickel alloy.

Bad resistance to corrosion and oxidation as compared to SUS 304 and SUS 439

2.

SUS 304 Non Magnetic

8% nickel, 18% chromium alloy, No titanium content.

Excellent resistance to stress cracking.

Good resistance to corrosion.

Good oxidation resistance.

Good weldability.

3.

SUS 316 Slightly magnetic after forming

Highly corrosion resistance

4.

SUS 439 - Magnetic

A Titanium stabilized, 18% chromium alloy. No nickel content.

Excellent resistance to stress cracking.

Good resistance to corrosion.

Good oxidation resistance.

Good weldability.

High thermal conductivity coefficient.

Low thermal expansion coefficient.

5.

SUS 444 Magnetic

Equal in corrosion resistance to SUS 316.

Test Results Comparison SUS 304 and SUS 439

1.

Typical Chloride Stress Cracking test results in boiling solutions

Alloy

SUS 304

SUS 316

SUS 439

Conclusion :

2.

42% MgC

20 hours

21 hours

1000 hours

33% LiCl

96 hours

21 hours

1000 hours

26% NaCl

744 hours

1000 hours

1000 hours

SUS 439 Seems to have better chloride stress cracking resistance as

Compared to SUS 304 and SUS 316.

Typical General Corrosion (Rusty) Data

Boiling Solution

20% Phosphoric Acid

10% Sodium Bisulfate

10% Sulfamic Acid

Conclusion :

Corrosion rate in inches per month (millimeters per year)

SUS 439

SUS 304

0.00002 (0.006)

0.00002 (0.006)

0.00001 (0.003)

0.005 (1.53)

0.00008 (0.025)

0.013 (4.0)

SUS 439 appears to have better corrosion (rusty) resistance as

compared to SUS 304 at the above mentioned boiling solutions.

LAKASA Marketing & Distribution

LAKASA Biomatic Grease Interceptor

Need for Good Grease Interceptor System!

Direct discharge of greasy and oily wastewater from

restaurants, fast food stores, centralized food courts in

commercial and institutional buildings as well as traditional

individual shops into the drain lines has significantly

increase pollution to server plants, rivers, lakes and other

waterways. The increasing difficulties in dealing with these

problems are in the form of frequent pipeline and manhole

blockages, obnoxious and rancid odors. This calls for a

compulsory adoption of effective waste effluent pretreatment.

LAKASA Biomatic Grease Interceptor is designed to

provide an effective, hygienic and environmental friendly

solution to grease contamination.

LAKASA Biomatic

Grease Interceptor is recommended for use in kitchens,

restaurants, institutions, and all types of food processing

areas, with wastewater containing grease, fats and oil

(FOG) and solid starch.

LAKASA Biomatic Grease

Interceptor is completed with two individual chambers to

take care both the solid waste and starch, as well as

grease and oil which are frequently exist in kitchen

wastewater. The solid waste and starch is filtered out

effectively from the sediment trap (first chamber), while the

grease and oil is intercepted from the second chamber.

The interceptor can be used for manual removal of oil and

grease or used in conjunction with LAKASA Biomatic

Liquid Enzyme for waste digestion.

ADU &

Enzyme

Sink

LAKASA

Grease Interceptor

Semi-recessed

ADU &

Enzyme

LAKASA

Beam

Pipes

Grease Interceptor

Pre-cast Sump

Suspended over the floor slab

ADU &

Enzyme

LAKASA

Pipes

To manhole/sewer

Sump

Grease Interceptor

Fully recessed underground

Type of Installation

Specification of LAKASA Grease Interceptor

The unit is completed with two chambers and with two separate interceptor covers. The first chamber comes with

a perforated stainless steel bucket and is able to effectively filter away incoming solid waste and starch. The

interceptor cover for first chamber can be easily opened with hinges support for easy maintenance. The second

chamber is completed with checker plate aluminium cover; a proper design removable baffle assembly which can

effectively control flow velocity and turbulence of incoming wastewater; enzyme dosing connection and deep seal

integral trap with rodding access.

How LAKASA Grease Interceptor Functions

Wastewater from kitchen sink, dishwasher that contains air, grease and food particles are flushed and enters the

inlet of interceptor at high velocity. Food particles will be trapped and filtered in the stainless steel perforated

basket, leaving only greasy water to continue its journey to the next chamber. At the inlet to second chamber,

wastewater is immediately directed downward by the main deflecting baffles, at the same time allowing trapped

air bubbles to rise to the surface. The baffles will effectively reduce the velocity and turbulence of the incoming

liquid. The turbulence of the liquid flow is further reduced when the wastewater passes through the remaining

baffles. These baffles are arranged in unique positions to allow effective and efficient separation of grease, fats,

and oils from wastewater and rise above the normal established water line of the interceptor.

Sizing & Selection

(i)

(ii)

(iii)

(iv)

Check the flowrate of wastewater from each fixture.

Calculate total flowrate from all the fixtures connected to one particular grease interceptor.

Identify and assume the simultaneous discharge diversity factor for all the fixtures.

Refer to the table for sizes available and select proper interceptor of equivalent or next higher rate.

LAKASA Marketing & Distribution

Selection Tables: Fixture Size

Sinks:

Dishwashers:

Sink Size

Interior Measurements

12" x 18" x 6"

14" x 16" x 8"

18" x 20" x 8"

16" x 18" x 8"

18" x 20" x 8"

20" x 30" x 8"

20" x 24" x 12"

20" x 22" x 8"

20" x 22" x 12"

24" x 24" x 12"

# Bowls

1

1

1

2

2

1

1

2

2

2

Capacity

in Gallons

Water Flowrate

Capacity

Size

GPM

In Gallons

GPM

4.2

5.8

9.4

15.0

18.7

15.5

18.7

23.0

34.0

44.9

7

7

10

15

20

20

20

25

35

50

15-20

20-30

30-50

50-70

70-100

15

20

25

35

100

EXAMPLE OF CALCULATION

Fixtures

Floor drains

Double bowl sink

(18x20x8)

Hand washing sink

(14x16x8)

Dishwasher

(50 gallon capacity)

No. of

fixtures

2

2

Fixture value

(GPM)

12

20

Total value

(GPM)

24

40

10

20

35

35

Total

119

Diversity

factor

Flow rating

(GPM)

75%

89 GPM

** Diversity factor only applicable to Low activity (cooking and washing) environment. Water Retention Time

of more than 30 minutes will generally achieve >99.9% of Grease removal percentage.

The model recommended is LK2100 (100 GPM) OR LK2200 (200 GPM) for busy environment.

Operation and Maintenance Guide

1.

Sediment trap chamber is to be cleaned up on daily basis. However, the frequency of cleaning can be once

a few days if the incoming volume is low.

2.

Grease trap chamber is designed to intercept incoming grease and oil. The grease and oil which is trapped

in this chamber can be cleaned either

by manual scoop (once a week). In this case, Grease Interceptor shall be maintained in efficient

operating condition by periodic removal of the accumulated grease. No such collected grease shall

be introduced into any drainage piping, or public or private sewer.

OR

by biomatic liquid enzyme, which actually converts grease into water and carbon dioxide. If a

thickening of the contents is noted, with a distinct caking effect across the surface, or an

offensive, pungent odour is emitted, then gradually increase the suggested dosage rate to

compensate. If the contents appear to remain in a minimal semi-liquid state with little or no

odour, this indicates successful degradation of the grease. Whenever tank is cleaned, the

initial dosing procedure must be repeated.

3.

With the introduction of biomatic enzyme, periodic cleaning for grease is about once every 6 months. For

manual cleaning (without using biomatic enzyme), cleaning for grease is about once a week. However, more

frequent cleaning is required when there are more activities and/or when incoming grease content is high.

4.

Additional aeration system is suggested for larger size grease interceptor. The aeration pump is pre-set to

run at the right timing and duration to achieve optimum performance.

LAKASA Marketing & Distribution

LAKASA Biomatic Grease Interceptor

Use in restaurant, food court, cafeteria, school canteen, etc.

A (length)

Stainless steel cover

with hinges support

id

th

Perforated

(w

B

Pe

rfo

Enzyme supply

connector

Removable

baffles

t

or

pp

Su

ce ber

n

m

a

en Nu

int ct

Ma onta

C

Aluminium checker plate cover (Gasketted Air-Tight)

E

C (height)

Air-relief valve &

rodding access

ed

rat

et

ck

LAKASA

bu

(trade mark)

Baffles

Deep seal

integral trap

SIRIM TESTED

(Ref. No. 237/16/206)

(Job No. J114/01)

Sediment trap chamber

Grease interceptor chamber

Schematic View

ONE YEAR WARRANTY ON WELDING JOINTS (LEAKAGE) FOR LAKASA GREASE INTERCEPTOR

Interceptor Material:

Advantages:

Stainless Steel :

Interceptor body, Perforated bucket, baffles, integral

trap, inlet & outlet pipe sleeve.

Stainless Steel :

Interceptor Cover.

Complete with sediment interceptor.

Baffle design to avoid blockage by sediment waste.

Baffle is removable for periodic cleaning.

Easy opening cover with hinges support makes

cleaning works much easier.

Dimensional Data (All dimension in mm)

Model

Flowrate

(GPM)

LK2012S

LK2015S

LK2020S

12

15

20

LK2012

LK2015

LK2020

LK2025

LK2035

LK2050

LK2075

LK2100

LK2150

LK2200

LK2250

LK2300

LK2350

LK2400

LK2450

LK2500

LK2600

LK2700

LK2800

12

15

20

25

35

50

75

100

150

200

250

300

350

400

450

500

600

700

800

Flowrate

(litre/sec)

Inlet

A

B

C

&

(length)

(width)

(height)

outlet

Shallow Range (under the sink installation)

Grease

capacity

0.91

10 kg

50

630

340

300

80

85

1.14

14 kg

50

690

370

320

90

95

1.50

18 kg

75

730

400

330

90

95

Standard Range (floor-mounted, suspended or semi/fully recessed installation)

0.91

1.14

1.50

1.89

2.65

3.78

5.68

7.57

11.35

15.14

18.92

22.70

26.49

30.28

34.05

37.84

45.41

52.98

60.55

10 kg

14 kg

18 kg

23 kg

32 kg

46 kg

68 kg

91 kg

136 kg

182 kg

227 kg

273 kg

318 kg

363 kg

409 kg

454 kg

545 kg

635 kg

726 kg

50

50

75

75

100

100

100

100

100

150

150

150

150

150

150

150

200

200

200

610

650

720

780

820

920

1220

1220

1700

1820

1960

2200

2350

2440

2550

2650

2850

2950

3050

290

310

330

360

440

490

580

720

760

860

940

980

1070

1180

1140

1220

1220

1220

1220

360

400

400

420

430

500

530

740

810

910

1010

1110

1140

1140

1310

1410

1600

1770

1900

90

100

100

100

100

110

110

150

150

180

180

180

180

180

180

180

210

210

210

100

110

110

110

110

130

130

180

180

210

210

210

210

210

210

210

250

250

250

Weight

*(full)

215

225

235

65kg

80kg

100kg

260

290

290

310

320

370

400

560

630

700

800

900

930

930

1100

1200

1350

1520

1650

65kg

80kg

100kg

135kg

160kg

200kg

350kg

700kg

1000kg

1200kg

1800kg

2000kg

2200kg

2500kg

3000kg

4000kg

5000kg

6000kg

7000kg

* Full weight means when full with water & solid waste

Sole Agent : LAKASA Marketing & Distribution

Tel: 03-6120 6895

Fax: 03-6120 1852

LAKASA Marketing & Distribution

LAKASA Biomatic Liquid Enzyme

From ADU

LAKASA Biomatic Liquid Enzyme is a blend of highly

specialized microorganisms (multiple strain) designed

specifically to promote rapid degradation of excessive, difficult

to digest organic waste. These organic wastes include grease,

fats and oils (FOG), detergents, starches, protein, cellulose and

hydrocarbons. With the introduction of LAKASA Biomatic Liquid

Enzyme, FOG is converted into harmless compounds of CO2

(carbon dioxide) and H2O (water). It is an effective pretreatment for organic waste to prevent it from passing over to

the municipal wastewater system.

Flexible Hose

Biomatic Liquid

Enzyme

Steel Weight

Characteristic of LAKASA Biomatic Enzyme Concentrate

Strainer

LAKASA Biomatic Enzyme is designed for use to enhance the

decomposition (degradation) of organic waste compounds in food processing

wastewater treatment.

Microorganisms Strains:

Bacillus subtilis (3 strains)

Bacterial Cultures:

Bacillus subtilis (3 strains)

Bacillus Licheniformis

Bacillus Megaterium

Bacillus Polymyxa

1. Selected microbes produce

enzyme

Superior producer of protease, amylase,

cellulase and lipase enzyme activity

Bacillus Licheniformis

Excellent producer of protease and

amylase activity and requires facultative

condition for growth

Bacillus Megaterium

Excellent producer of protease, lipase

and cellulase activity and requires

facultative condition for growth

Bacillus Polymyxa

Excellent producer of lipase activity and

requires facultative condition for growth

Enzymes

Protease, Amylase, cellulase, Pectinase,

Beta glucanase, xylanase and lipase

Other Ingredients

Essential nutrient and amino acid

complexes

Benefits

(i)

Effectively and rapidly reduce/eliminate BOD and COD in

wastewater.

(ii)

Decomposes and permanently converts organic wastes into water

soluble compounds.

(iii)

Keeps drain lines flowing smoothly; reduces the amount of

pumpouts.

(iv)

Non-corrosive: will not damage drain lines & grease interceptor

(v)

Controls and reduces odors

(vi)

Contains no polluting phosphates

(vii)

Non-toxic, Non-pathogenic (non-disease causing)

(viii)

Environmentally safe & friendly

2. Enzymes liquefy organic

waste

3. Microbes digest liquefied

organic waste

4. After digesting liquefied

waste, microbes give off

harmless carbon dioxide (CO2)

and water (H2O) byproducts

Biodegradation Process Summary

FFA

FFA

FFA

CO2

+

H2O

Glycerol

VFAs

FFA

Glycerol

5. Microbes multiply and

continue this process until all

organic waste is eliminated

LAKASA Marketing & Distribution

Why Biomatic Enzyme is NOT working in some cases

I.

II.

III.

IV.

V.

Inadequate dosage.

Inappropriate dosing time the water temperature might be too high or the enzyme might have been flushed

out before it has enough time to react.

The grease content might be too high for biological process. In this case, manual cleaning is required once

a month or more frequent if needed.

Inadequate oxygen for microbe to perform, additional aeration might be required, especially for large

interceptor.

Wastewater might be too acidic or contains high chlorine mixture which can kill microbes.

Enzyme Dosage

(Actual dosage required might vary according to actual grease content)

Model

LK2012

LK2015

LK2020

LK2025

LK2035

LK2050

LK2075

LK2100

LK2150

LK2200

to

LK2500

Daily meals

up to 80

80 150

150 250

250 300

300 400

400 600

600 1000

1000 2000

2000 3000

3000 and above

Starter

dose

(ml)

90

90

180

180

270

360

450

540

900

1080

Monthly dose

(litres)

LOW

HIGH

grease

grease

0.6

1.8

0.6

1.8

1.0

2.7

1.0

2.7

1.5

3.6

1.8

4.5

2.0

5.4

2.0

5.4

3.0

9.0

3.6

10.8

SIRIM LAB TEST

Day

Day 1

Day 7

Day 14

Grease & Oil

0.5945 g

0.2280 g

0.1182 g

Conclusion:

The results clearly showed

positive impacts of LAKASA

BIOMATIC ENZYME in the

degradation of FOG.

Wastewater from main kitchen always contain high % of grease, whereas those from hand washing sink / basin

and secondary centralized Grease Interceptor usually does not have much grease and oil.

For best performance

Characteristics

1.

2.

3.

4.

5.

Follow the initial and daily dosing procedures.

Optimum dosing time is 1 hour after kitchen closes.

Do not discharge very hot water into the interceptor

immediately before or immediately after dosing.

Do not discharge chlorine, strong caustics, concentrated

disinfectants, bleach or sanitizers into the interceptor.

Do not deliberately discharge cooking oil or grease into

the interceptor

Appearance

: Liquid

Odour

: Pleasantly perfumed

pH

: 8.2 8.8

Effective pH range : 5.5 9.0

Effective temperature: 5 50oC

Stability

: 2 years

During the first few weeks of dosing operation, regular inspection of the internal condition of the interceptor

should be conducted to gauge the performance of the dosage. If a thickening of the contents is noted, with a

distinct caking effect across the surface, or an offensive, pungent odour is emitted, then gradually increase the

suggested dosage rate to compensate. If the contents appear to remain in a minimal semi-liquid state with little or

no odour, this indicates successful degradation of the grease. Whenever tank is cleaned, the initial dosing

procedure must be repeated.

Health & Safety

The Lakasa biomatic liquid enzyme concentrate is safe in normal use. The biologically active nature of the

product may cause skin irritation in some cases. It is essential that rubber gloves are worn at all times.

Skin contact

Should the concentrate come in contact with skin, wash with plenty of clean water.

Eye contact

If the concentrate splashes into the eyes or is rubbed in by hand, flush eyes with plenty of

clean running water.

Ingestion

Avoid ingesting the concentrate but should an accident occur, wash mouth thoroughly with

water. Do not induce vomiting. Drink plenty of water or milk. Seek medical advice

immediately after the initial treatment has been given.

This product should be stored, handled and used in accordance with good industrial hygiene practices. The

information contained herein is based on the present state of our knowledge and is intended to describe all

products from the point of view of health and safety requirements. It should not therefore be construed as

guaranteeing specific properties.

LAKASA Marketing & Distribution

LAKASA Auto-Dosing Unit (ADU)

LAKASA Auto-Dosing Unit (ADU) is highly recommended to

install in conjunction with grease interceptor. It will ensure

the dosing of biomatic liquid enzyme at regular intervals

consistently. It enhances the efficiency of the operation and

significantly reducing the build-up of grease and frequency of

cleaning.

Control Panel (Digital

based with backup

battery)

RUN

TO 0

7

5 6

3 4

1 2

I AU

0:00

m

h

P

1...7

R

Specification of Auto-Dosing Unit

The unit is a temporized dosing system, activated by a

programmable digital clock. It comes together with a

peristaltic pump, 2.5 m electric wiring and 4.0m (6mm )

flexible polythene enzyme supply tube.

Pump

Head

The advantages of LAKASA Auto-Dosing Unit

1.

There is a digital timer to control setting for the dosage

and timing of dosing the biomatic enzyme. The

reliability and accuracy for the timing and dosage setting

is important and critical, because this will ensure the

optimum performance of the enzyme and to avoid the

wastage of enzyme.

2.

The setting is digital type and is user-friendly. Easy and

fast to learn and understand. Do not require any

specially-trained technician to come and adjust the

setting.

3.

There is a Back-up battery for the setting in case of

power failure. The setting will still be valid and when the

power supply is resumed. The auto-dosing system will

continue to run as normal and do not have to re-set

again. This is another important point to ensure the

proper running of the Biomatic Grease Interceptor

System!

4.

Auto-Dosing Unit is usually installed at the wet area

(Kitchen). The casing of LAKASA Auto-Dosing Unit is of

standard IP56 - Waterproof. This is to avoid breakdown

caused from water to the electronic component and

motor.

5.

The whole unit is fully imported from an established

manufacturer from Europe. From the past record, there is

seldom any breakdown complaint. This proves the

reliability and quality of LAKASA Auto-Dosing Unit.

Refer page 8 for ADU

setting assistance

Technical Characteristics

Power supply

230 V

13 amp fuse

Single phased

3 pin plug

Power consumption 5 W

Timer

Digital clock

ADU dimension

150 x 190 x 110 mm

Cabinet

(lockable)

Hanging

Panel

Material: Stainless Steel

Installation

The LAKASA ADU is located in close proximity to the grease interceptor. A conduit pipe (>7mm ) for the

enzyme supply tube is recommended to link the auto-doser to the grease interceptor. The recommended

distance is not more than 5 meters for effective transmission of enzyme from the source to the destination.

Operating Instruction for ADU

I.

II.

III.

IV.

Connect the ADU to a 13 amp power point.

Set the current time at the digital clock.

Set the dosing ON time (2 hours after the

kitchen is closed) and the dosing OFF time for

a correct dosing duration according to

recommended enzyme dosage.

Run manual dosing with the initial dosage and

to ensure the ADU is running properly.

10

Control panel and Digital clock setting

I = manual operated dosing

Auto = Auto operated dosing

O = Off

= set time

Run = normal run

= program

= choose program for dosing ON and OFF

1 7 = set dosing day (Mon to Sun)

h = hour

m = minute

R = reset

LAKASA Marketing & Distribution

Flexible Hose Connection

Wall

Automatic Dosing Unit (ADU)

(150 x 190 x 110 mm)

Method 1:

Exposed Only

Method 2:

Exposed or for

Underground

Connection

13 Amp Power Point

From ADU

From ADU

Connector

Flexible

Hose

Lock

ADU Cabinet (lockable type)

(265 x 610 x 175 mm)

Copper or

other pipe

Connector

Biomatic Liquid Enzyme

(5 liters)

Connector

Flexible Hose

(6 mm)

Interceptor Wall

Socket (5/8")

Floor

Inlet

After installation, the gap

is back-filled with cement

and sand

Socket (5/8")

Outlet to Sewer

LAKASA Grease Interceptor

(Refer catalogue for dimension)

LAKASA Auto-Dosing Unit (ADU) is installed close proximity to Grease Interceptor

The Setting of LAKASA Auto-Dosing Unit (ADU)

(1)

(2)

(3)

(4)

(5)

(6)

(7)

Ensure button is pointing to <Auto> in between < I > and < O >.

P

Set Today / Current Date & Time.

RUN

TO 0

7

I AU

(a) Push the button from <Run> mode to the < > mode.

5 6

3 4

1 2

(b) Press <17> button to point to the current day. For instance,

pressing arrow until its pointed to number 3 which means

0:00

Wednesday.

m

h

(c) Press <h> button to show current hour. For instance, pressing

1...7

P

R

11 means 11.00am and pressing 22 means 10.00pm.

(d) Press <m> button to show current minute. For instance

pressing 45 means 45 minutes.

(e) Once the date & time is confirmed, push the button back to the

<Run> mode.

Set Everyday Auto-Dosing Operation Start Time.

(a) Push the button from <Run> mode to the < P > mode.

P=1appears on screen.

(b) Press <17> button several times until 7 arrows appear at the bottom of the 7 numbers from 1 to 7.

This implies operation day is from Monday to Sunday.

(c) Press <h> and <m> to set the dosing start time. For instance, 00:00 means ADU will start running at

0.00am.

Set Everyday Auto-Dosing Duration Before Operation Stop.

(a) Press <P> button for one time. P=2 appears on screen.

(b) Press <17> button several times until 7 arrows appear at the bottom of the 7 numbers from 1 to 7 (i.e.

Monday to Sunday).

(c) Press <h> and <m> to set the dosing stop time. For instance, 00:20 means ADU will stop running at

0.20am.

(d) The ADU is running at 7ml / minute.

(e) Push the button from < P > mode back to the <Run> mode.

Once steps 1 to 4 are completed, the ADU is in Auto mode and is ready for operation.

To manually run the ADU, push the button from <Auto> to < I > mode.

To switch off the ADU, push the button from <Auto> to < O > mode, which means OFF.

Note : <R> button will clear/ reset all the settings which has been done before.

11

LAKASA Marketing & Distribution

LAKASA Sediment Interceptor

LAKASA Sediment Interceptor is completed with a perforated bucket and able to act as an effective strainer to

avoid drain lines clogging by foreign solid particles. The perforated bucket should be cleaned on daily basis or as

frequent as possible to avoid overflow of solid waste and interrupting free flow of wastewater in the drain lines.

Open Handle

Advantages

Schematic View

Rodding Access

(openable)

1.

2.

3.

Hinges Support

Cin

Deep Integral Trap

Inlet

LAKASA

Outlet

4.

Din

Cout

Easily open cover to ease cleaning

work.

Prevent the pipeline being clogged

with solid waste.

Stainless steel interceptor material to

avoid rusty and corrosion over long

period.

Deep integral trap to avoid smell in

manhole from entering the building

thru pipeline.

Dout

Perforated Bu

cket

Material : stainless steel (304)

Dimensional Data

Model

Pipe Size

A

B

C in

(mm)

(mm)

(mm)

(mm)

LKS 9434

75

400

400

100

LKS 9545

100

500

500

110

LKS 9656

100

600

600

120

LKS 9767

100

700

700

120

LKS 9878

100

800

800

130

Various dimensions is available upon request or to suit site requirement

C out

(mm)

200

250

300

300

350

D in

(mm)

200

290

380

480

670

D out

(mm)

100

150

200

300

350

E

(mm)

300

400

500

600

700

LAKASA Floor Sediment Trap

Type A

LFS 5series

LFS

4150Floor Sediment Trap

LAKASA

(stainless steel 304)

150mm

150mm

Floor Surface

(cement or tile)

m

20m

Perforated Bucket

170mm

50mm

Outlet Pipe

(50/75/100mm)

Other dimension is

available to suit site

requirement

Type B

Advantage:

1) Prevent the pipeline being clogged with solid waste.

2) Stainless steel material to avoid rusty and corrosion over long period.

3) Perforated sediment bucket is removable to make cleaning work easy.

4) Type B c/w deep seal integral trap prevent outside air entering into building.

Material: Stainless Steel

Dimensional Data

MODEL

LFS 4150

LFS 5150

LFS 5200

LFS 5250

LFS 5300

LFS 5400

INLET

(mm)

50

50

75

75

75

OUTLET

(mm)

50

75

75

100

100

100

A

(mm)

150

150

200

250

300

400

B

(mm)

150

150

200

250

300

400

12

C

(mm)

150

300

350

400

500

500

D

(mm)

180

200

220

250

250

E

(mm)

120

150

180

250

250

LAKASA Marketing & Distribution

Installation for LAKASA Grease and Sediment Interceptor & Floor Sediment Trap

LAKASA Biomatic Grease Interceptor

(Typical Installation: Suspended Type)

AUTOMATIC DOSING UNIT

C/W BIOMATIC LIQUID

ENZYME 5 LITRE

13A

S.S.O.

SK

SK

FLEXIBLE

HOSE

50

CHEQUER

PLATE COVER

SEDIMENT

INTERCEPTOR

430

75

BIOMATIC

GREASE

INTERCEPTOR

100/150 GPM

100 UPVC (1:100)

150x150 FLOOR DRAIN

C/W S/S. PERFORATED

BUCKET

100 UPVC PIPE

RUN THRU BEAM

1000

50

400

350

2000 x 860

OUTLET

Cross Section

50 UPVC

DRAIN PIPE TO

DROPPER PIPE

2000

CHEQUER PLATE BY

MAIN CONTACTOR

LAKASA BIOMATIC

GREASE INTERCEPTOR

100/150 GPM

860

200

275

BEAM OPENING REQ.

Detail of Pre-Casted Sump

Plan View

100 UPVC INLET

50

DRAIN OUTLET

LAKASA BIomatic Grease Interceptor System

Installation: Suspended with hanger support

Model: LK2035 (35 GPM)

2000

AUTOMATIC

DOSING UNIT

(13Amp)

WALL

DOUBLE BOWL SINK

200mm

TILES AND

CEMENT SCREED

FLOOR SLAB

FASTERNED WITH

ANCHOR

(WALL PLUG)

INLET

330mm

CONDUIT PIPE

PRECAST

INTO CONCRETE

100mm

UPVC

BS4514

C-CHANNEL

HANGERS

NOTE:

1. C-Channel hanger able to take load 200kg.

2. Slab opening required 870mm x 490mm

OUTLET

100mm

UPVC

BS4514

320mm

300mm

INTERCEPTOR COVER

820mm(L) x 440mm(W)

Testing & Commissioning Method Statement

Grease Interceptor

1. Place at a firm & balance concrete base.

2. Inlet & outlet is connected accordingly and properly.

3. Interceptor is to be filled up with clean water until it reaches static water level.

Auto-Dosing Unit (ADU)

1. To mount the ADU to wall with a lockable cabinet.

2. To connect ADU to a 13 Amp power point.

3. To set current time and dosing time (set 1 hour after kitchen close).

4. To set the dosing duration according to recommended dosage. The unit is running at a speed of 30 mL/min.

5. To connect a short flexible hose to enzyme bottle. Use steel weight and strainer provided to ensure the hose

reaches the bottom of the bottle.

6. To connect a long hose (with conduit pipe) to the grease interceptor. To use the connector provided to join

the connection.

7. To switch to manual dose to ensure pump head is rotating and enzyme is sucked up and delivered to

interceptor.

8. To switch to Auto and the ADU will run automatically according to the preset time.

Biomatic Enzyme

1. Avoid direct sunlight and should be kept inside the ADU cabinet.

2. To top up enzyme periodically.

13

LAKASA Marketing & Distribution

LAKASA Oil Interceptor

LAKASA Oil Interceptor is required wherever

lubricating oil, cutting oil, kerosene, gasoline,

naptha, paraffin, trisod phosphate and

numerous other light density and volatile liquids

are present in the drainage. In commercial

establishments such as service stations,

garages, auto-repair shops, dry cleaners,

laundries industrial plants or process industries

having machine shops, metal treating process

rooms, chemical process or mixing rooms, etc,

there is always the problem of flammable or

volatile liquids entering the drainage system

which can contaminate the sewer line and

cause a serious fire or explosive condition. The

discharge of oily wastewater, which consists of

high degree of BOD (Biological Oxygen

Demand), COD (Chemical Oxygen Demand),

FOG (Fat, oil and grease), and other organic

wastes into natural waterways has disastrous

impacts on aquatic life and the environments.

Inlet

From Source (car wash bay,

washing sink etc)

Vent

Outlet to Sewer

Suction

Connection

Inspection

access cover

Gravity Draw-off Line

LAKASA Oil Interceptor

Oil Storage Tank

Install at Carwash bay, Service & repair

workshop, carpark, petrol station, oil

distribution depot, garage etc.

LAKASA Oil Interceptor is a preliminary

treatment for oily (hydrocarbon) wastewater discharged from sources such as service & repair workshop,

carwash bays etc. The effluent from the interceptor should be channeled to sewer line for further process and

treatment. LAKASA Oil Interceptor is designed to allow introduction of any liquid types for separation as long as

there is sufficient specific gravity differential to permit gravitational separation. When the liquid temperature is

o

about 20 C, the Water Specific Gravity is 0.998; whereas, the Oil Specific Gravity is 0.92

It is also take into account that the water flow is intermittent and variable and the oil or any combination is nonemulsified oil/water mixtures. The design also allows the intercepted oil to be automatically drawn-off for storage

in a continuous operation. Sediment should be removed from sediment bucket at regular intervals. To eliminate

pressure build-up inside the interceptor, a vent connection on side of the body allows the venting of interceptor.

Oil in Water Coalescing Media How It Works

LAKASA Oil Interceptor contains a coalescing medium or media. This media provides a suitable surface for oil

droplets to meet and grow, or coalesce, into larger droplets. As oil droplets grow in size the buoyancy of the

droplets increases. The droplets rise towards the surface of the water due to the fact that the specific gravity of oil

is less than the specific gravity of water. In this way the oil will form a layer that can be skimmed manually or to be

channeled into a separate storage tank, pending for proper disposal.

As oil droplets coalesce into larger droplets, the

buoyancy of the droplets increases. This reflected in

the known rise time for a given size of oil droplet. The

more efficient the coalescence action of the media,

the larger the oil droplets become. Larger oil

droplets result in reduced rise time. Shorter rise

time will certainly increase and improve the

efficiency and effectiveness of Oil Interceptor.

Time needed for oil droplet (0.85Sp.Gr.)

in water to rise 3 inches

Droplet size, microns

Rise Time

300

150

60

12 seconds

42 seconds

4 min 12 seconds

Coalescing plates offer high efficiency and low operating and maintenance costs because there are no moving

parts and no replacement parts are needed or spent absorbents generated.

14

LAKASA Marketing & Distribution

LAKASA Oil Interceptor

Used at garage, carwash area, servi ce & repair workshop etc.

e

nc

r

na

be

te

um

in rt

Ma ppo ct N

su nta

Co

Stainless Steel

Cover with

Hinges Support

Overflow

Exit

Gasketted Aluminium

Checker Plate

Vent

Connection

Coalescer

Pack

l

ro er

nt b

Co um

it l N

Un eria

S

E

Air-Relief

Valve &

Rodding

Access

Oil Draw-off Sleeve

(adjustable level)

Inlet

C

F

Outlet

E

al

se ap

p al tr

e

De tegr

In

Perforated

bucket

Schematic View

G

SIRIM TESTED

(Ref. No. 237/16/206)

(Job No. J197/01)

ONE YEAR WARRANTY ON WELDING JOINTS (LEAKAGE) FOR LAKASA OIL INTERCEPTOR

Dimensional Data (All dimension in mm)

Model

Flowrate

(GPM)

LK3015A

LK3020A

LK3025A

LK3035A

LK3050A

LK3075A

LK3100A

LK3150A

LK3200A

LK3250A

LK3300A

LK3350A

LK3400A

LK3450A

LK3500A

LK3600A

LK3700A

LK3800A

15

20

25

35

50

75

100

150

200

250

300

350

400

450

500

600

700

800

Flowrate

(litre /

sec)

1.14

1.50

1.89

2.65

3.78

5.68

7.57

11.35

15.14

18.92

22.70

26.49

30.28

34.05

37.84

45.41

52.98

60.55

Inlet &

outlet

pipe

50

75

75

100

100

100

100

100

150

150

150

150

150

150

150

200

200

200

A

(length)

B

(width)

600

780

800

880

930

1200

1450

1650

1850

2050

2250

2300

2400

2440

2600

2800

2950

3050

450

470

500

550

600

800

900

1000

1100

1200

1220

1350

1400

1550

1800

1930

1950

2050

Sole Agent : LAKASA Marketing & Distribution

C

(height)

Weight

*(full)

(kg)

430

110

320

200

150

120

450

110

340

220

200

150

480

110

370

250

250

200

500

110

390

270

300

240

550

130

420

300

350

300

620

130

490

370

400

550

750

180

570

450

450

1000

850

180

670

550

500

1500

1000

210

790

670

550

1800

1140

210

930

810

600

2700

1350

210

1140

1020

650

3000

1400

210

1190

1070

700

3300

1500

210

1290

1170

750

3800

1700

210

1490

1370

800

4500

1850

210

1640

1520

850

6000

1930

250

1680

1560

900

8500

2100

250

1850

1730

950

10,000

2200

250

1950

1830

950

12,000

* Full weight means when full with water & solid waste

Tel: 03-6120 6895

Interceptor Materials:

Stainless Steel :

Interceptor Body, Perforated Bucket, Integral

Trap, Inlet/Outlet Pipe Sleeve, Coalescer Pack.

Stainless Steel:

Interceptor Cover.

Fax: 03-6120 1852

Advantages:

1. Complete with sludge interceptor.

2. Easy opening cover with hinges support makes

cleaning works much easier.

3. Coalescer pack is removable for periodic

cleaning.

4. Complete with oil draw-off, to channel oil into a

separate container for proper disposal

15

LAKASA Marketing & Distribution

Environmental Quality Act, 1974

In the effort to meet the requirement of the Environment Quality Act, 1974, Standard B on the oil & grease of

10mg/l of effluent quality, LAKASA Oil Interceptor should be sized with the Water Retention Time (WRT) of more

than 30 minutes. This will produce the effluent result with >99.9% grease & oil removal.

Operation and Maintenance Guide

The oil shall be skimmed and dirt, sand and sludge shall be removed on a quarterly basis at a minimum. Oil shall

be handled as a hazardous waste stored and sent to a used oil recycler. If the oil is too thin to pump or skim, oil

absorbent pads or pillows can be used to remove the oil. These can be sent for disposal or recycling, or if oil can

be removed from them they can be reused (oil collected and sent for recycling).

The first quarters sludge/dirt shall be sent for waste characterization to determine if it can be disposed off as

ordinary waste or hazardous waste. If hazardous, sludge shall be stored in labeled drums and picked up by a

licensed hauler. If non-hazardous, sludge shall be disposed off to a landfill, and is not to be deposited on-site.

1.

Manual draw off of oil. A routine inspection of oil interceptors should be

undertaken at least once every 3 months by the inspection technician.

Using a dipstick, the amount of accumulated oil and solids shall be

measured to determine if a clean-out is required.

Servicing and clean-out of oil to a separate storage tank pending for

proper disposal whenever is necessary.

2.

Normal Water

Operating Line

Adjustable

Draw-Off Sleeve

2mm

Static Water Line

Interceptor Wall

Automatic draw off of oil. During the first 2 weeks of operation, check

the oil storage tank for oil build up to determine the frequency it needs to

be emptied.

To Oil Storage

Tank

If water is found entering the draw-off sleeve into the oil storage tank

during normal working condition, adjust the draw off level upwards from 2

mm to 5 mm.

Important Notes to follow in order to generate good effluent:

1.

Sizing of interceptor meets the requirement. Water flow rates are within the specification. Adequate water

retention time will ensure proper separation of oil/ water mixture.

2.

Perforated bucket at sludge chamber should be inspected and cleaned on a regular basis. The amount of

debris such as sand, gravel, dirt, leaves, grass cuttings, etc., permitted to enter the system must be

minimized. Automotive and truck engine crankcase oil should not be drained into the system. Sludge and

deposits present in the oil will significantly reduce the effectiveness of the interceptor.

3.

Hydrocarbons entering the separator will be in a free non-emulsified state and capable of being separated

from water by gravity separation.

4.

Detergent will emulsified the oil and allow it to enter the sanitary sewer system because detergents have a

definite affinity for hydrocarbons. Wash water from truck washing racks must be routed directly to a sanitary

sewer or treated with special equipment.

Installation

1.

2.

3.

4.

5.

6.

Place at a firm & balance concrete base.

Inlet & outlet is connected accordingly and properly.

Interceptor is to be filled up with clean water until it reaches static water level.

Connect a ventilation pipe to the interceptor. This is to eliminate pressure build-up inside the interceptor.

For automatic oil draw off by gravity flow, connect the interceptor to an oil storage tank for receiving and

storing oil pending for proper disposal. For manual draw off of oil, seal up the connection.

The LAKASA Oil Interceptor is ready for operation.

16

LAKASA Marketing & Distribution

Sizing of LAKASA Oil Interceptor

In order to work properly the amount of wastewater flowing into the interceptor needs to be calculated. An

estimate of the peak waterflow during the washing process, the pattern of waterflow (continuous flow throughout

the day or just on and off waterflow for every interval period).

Grease

Removal %

Water Retention Time

1. >30 min, >99.9% removal

2. >20 min, >95% removal

99.9%

30 min

Retention

Time

1 hour

1) Calculation by number of fixtures

Peak flow rate

Example

Total nos. of hose outlet, equipments etc. that continuous discharging to drain line at a

particular time

A carwash bay, with total 2 water hoses are used for car washing during peak washing

session. Each hose power is about 8 GPM (example). Thus the estimated peak water

flow is 8 GPM x 2 = 16 GPM .

Scenario 1 (Very busy working environment)

If continuous waterflow at every short period interval.

To achieve Retention Time of 30 minutes : 16GPM x 30 min = 480GPM (To propose LK3500A)

Scenario 2 (Not busy working environment)

If Waterflow continuously for 5 minutes at every interval of 30 minutes.

To achieve Retention Time of 30 minutes : 16GPM x 5 = 80GPM (To propose LK3100A)

2) Calculation by area (open area, subject to rainfall, example : Car Park)

Estimated waterflow during heavy rainfall :

Average Peak

Waterflow

Total area (length x width in meter) x heavy rainfall

Length 30m, width 15m, collection of water : 75mm / 15 minutes

Calculation = 30 x 15 x 75 900 = 37.5 liter/sec = 500 GPM

Sizing of Oil Storage Tank

1.

2.

3.

Estimate the volume of oil into the interceptor

Frequency of maintenance routine (once a month, twice a month, etc)

Calculate the tank size required to cater for the total accumulated oil during the period. To allocate tank size

50% bigger to meet contingency.

Oil Storage Tank Dimensional Data

Model

LS0300

LS0600

LS1000

LS1600

LS2000

Capacity

(litres)

300

600

1000

1600

2000

Length

(mm)

650

800

960

1080

1160

Width

(mm)

600

720

880

980

1050

Height

(mm)

880

1170

1400

1720

1850

Recommended

for

15-35 GPM

50-100 GPM

150-250 GPM

300-400 GPM

450-500 GPM

Note : Select higher capacity of storage Tank should the application anticipate high volume of waste oil.

17

LAKASA Marketing & Distribution

LAKASA Neutralization Tank

LAKASA Neutralization Tank is also called Dilution Tank, designed to receive, dilute and neutralize corrosive and

harmful chemical wastes before allowing such materials to be discharged into the public sewers or the

environment, is suitable for centralized installation for neutralizing and dilution of laboratory acids and chemicals.

Neutralization of corrosive, toxic and flammable wastes is necessary to the environment and piping systems, even

when quantities and concentrations are small. Such wastes can cause physical damage to a building's piping or

outside sewer systems and, if effluent is being discharged to the environment (such as rivers and lakes), severe

damage can result to wildlife and water sources.

Neutralization is the process whereby acids and alkalis are rendered harmless. The degree of neutralization can

be measured by a system known as pH (positive Hydronium ions). The degree of measurement is a pH number

of 7, which is neutral. Acids range from 0 to 6.99. Alkalis range from 7.01 to 14. The smaller the number, the

higher the content of acidic waste. The higher the pH number, the higher the alkaline waste.

End-results of Neutralization Process

The chemical reaction between Calcium Carbonate and acidic waste water will produce by-products of

neutralized waste, carbon dioxide and neutral salts that can be safely discharged into municipal sewer

Calcium Carbonate

Neutralizing Agent

Acidic

Neutralized Waste,

Waste Water

Carbon Dioxide & Neutral Salts

Places recommended for use

Recommended to be installed in acid waste drainage systems for medical and research laboratories, industrial

battery charging stations, educational institutions and processing equipment. LAKASA Neutralization Tank is

recommended for preliminary treatment for acidic wastewater. Therefore the effluent should be channeled to

nearest sewer for further process.

PH

7

Neutralization is a slow process.

Retention time of more than 45 minutes

will normally achieve a safe pH level

and optimum neutralization process.

5

3

0

30 min

1 hour

Retention

Time

Capacity & Sizing

LAKASA Neutralization Tank is designed for intermittent flow of acidic wastewater which attempts to achieve an

average retention time of > 30 minutes, as such the interaction and dilution to be taken place between the acidic

wastewater and the calcium carbonate based neutralizing agent.

Proper functioning of the LAKASA Neutralizing System requires determining water flow or the volume of incoming

acidic waste water, in order to achieve sufficient retention time for the neutralizing process to take place (see

figure i). The initial rate of neutralization is rapid, however, as the pH of the acid waste rises, the rate of

neutralization slows down. Neutralization reaction time of more than 45 minutes should achieve a safe pH level or

a level which is considered high enough to be easily diluted with sanitary waste.

Environmental Quality Act, 1974

According to the Environment Quality Act, the effluent with pH value of 5.5 to 9.0 is acceptable under its standard

B requirement.

18

LAKASA Marketing & Distribution

SIRIM TESTED

(Ref. No.237/16/206)

(Job No.R080/04)

Dimension Data

Model

LN030

LN050

LN085

LN125

LN150

LN200

LN300

LN400

LN500

LN600

LN700

No. of

Sink/

Tab

1~4

5~10

1~20

21~30

31~40

41~60

61~90

91~130

131~180

181~250

251-350

Capacity

(litres)

30

50

85

125

150

200

300

400

500

600

700

Inlet &

Outlet

(mm)

50

75

75

75

75

100

100

150

150

150

150

A

(mm)

B

(mm)

C

(mm)

D

(mm)

E

(mm)

F

(mm)

G

(mm)

450

500

650

720

800

870

1100

1220

1440

1570

1700

310

380

520

540

580

610

700

800

830

880

930

310

380

400

440

470

510

530

550

570

590

600

90

100

100

100

100

110

130

130

150

150

150

220

280

300

340

370

400

400

420

420

440

450

100

110

110

120

120

130

150

160

180

180

180

210

270

290

320

350

380

380

390

390

410

420

Material: Stainless Steel 444 / 316 or equivalent.

Maintenance

The volume of limestones (Calcium Carbonate based neutralizing agents) and thus the neutralizing capacity

of the system will be reduced gradually during the neutralizing process. There are various factors such as

flow rate, concentration of acid waste, and temperature, determine the consumption rate of the Calcium

Carbonate Neutralizing Agent. To ensure maximum performance, a full charge of the neutralizing agent

should be maintained. Initially, inspection of the agent level should be made once a month. When the rate of

consumption is determined. A maintenance schedule should be established to observe and maintain proper

limestone levels in the tank. Limestone replacement should be performed at regular intervals. Typically, once

every one to three months is sufficient. However, these intervals can be increased or decreased based upon

application needs and performance.

The limestone supplied are 1-3" in diameter and have a calcium carbonate content certified to be in excess of

90%. Solids in the waste stream can plug the tank and should be avoided.

Installation

1.

2.

3.

4.

5.

For underground installation, construct a solid manhole sump for housing the Neutralization Tank.

Place at a firm & balance concrete base.

Inlet & outlet is connected accordingly and properly.

Neutralization Tank is to be filled up with full baskets of limestones (Calcium Carbonate based).

Neutralization Tank is to be filled up with clean water until it reaches static water level. Water added to

the tank helps facilitate dilution.

19

LAKASA Marketing & Distribution

SIRIM Test Report

SIRIM Test Results (Ref : ETC 237/16/206 (R 080/04))

on LAKASA Neutralization Tank.

Test 1 Results

Rate of Neutralization of diluted acidic plating solution from initial pH of 1.55

0

Sampling Time

pH

Temperature ( C)

Weight of limestone

(minutes)

0

1.55

31

10

1.92

31

11.2 kg

20

2.02

31

(Test 1a)

30

2.39

31

40

2.57

31

50

4.87

31

22.4 kg

(Test 1b)

60

4.88

31

Test 2 Results

Rate of Neutralization of diluted acidic plating solution from initial pH of 2.30

0

Sampling Time

pH

Temperature ( C)

Weight of limestone

(minutes)

0

2.30

31

10

4.42

31

30.0 kg

20

4.88

31

(Test 2)

26

4.97

31

30

4.97

31

Summary of neutralization rate and pH change

Test

pH range

1a

1b

2

1.55 2.57

2.57 4.88

2.30 4.97

Rate of Neutralization

per minute

0.06

0.12

0.08

pH change per kg

limestone

0.09

0.10

0.09

Conclusion :

1. Retention time of > 45 minutes will normally achieve optimum neutralization process.

2. LAKASA Neutralization Tank can increase pH of acidic water of initial pH~1.6 to pH~5.0 at

the average of 0.12/minute and limestone requirement of 12kg/unit pH change.

3. The pH change is about 0.10 per kg limestone used.

4. The temperature of the water remains stable during the whole neutralization process.

5. The performance evaluation exercise on the LAKASA Neutralization Tank was limited in

simulating the actual mode of application. There was no actual movement of liquid

through the limestone during the study conducted by SIRIM. The efficiency of the

neutralization tank is expected to increase with flow rate adjustment in an actual

installation.

6. The volume of limestones (Calcium Carbonate based neutralizing agents) and thus the

neutralizing capacity of the system will be reduced gradually during the neutralizing

process.

7. A maintenance schedule should be established to observe and maintain proper limestone

levels in the tank. Limestone replacement should be performed at regular intervals.

20

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Subsoil DrainageDocument11 pagesSubsoil DrainageRachel IngramPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Modern Methods of Construction Full PDFDocument81 pagesModern Methods of Construction Full PDFKenneth PunlaPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Welding Galvanized SteelDocument6 pagesWelding Galvanized SteelmperelmuterPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Book Reviews 10.25.10Document4 pagesBook Reviews 10.25.10Rachel IngramPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Punch List: University of Delaware-Facilities Design Standards Facilities Planning & Construction CSI: SECTION 17000Document2 pagesPunch List: University of Delaware-Facilities Design Standards Facilities Planning & Construction CSI: SECTION 17000Rachel IngramPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Information Sheet Work of Minor NatureDocument3 pagesInformation Sheet Work of Minor NatureRachel IngramPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- (Sample) - Schedule of FinishesDocument5 pages(Sample) - Schedule of FinishesRachel IngramPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- 168PMixing Tips MortarDocument1 page168PMixing Tips MortarRachel IngramPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- L3493 PilingDocument1 pageL3493 PilingRachel Ingram100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Lot 3493 - InsuranceDocument1 pageLot 3493 - InsuranceRachel IngramPas encore d'évaluation

- General Notes For Civil EngineeringDocument1 pageGeneral Notes For Civil EngineeringRachel IngramPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Proposed 6 Storey Executive Suites With Commercial Space On Lot 3493, Bintulu Town District at Jalan Tun Razak, BintuluDocument3 pagesProposed 6 Storey Executive Suites With Commercial Space On Lot 3493, Bintulu Town District at Jalan Tun Razak, BintuluRachel IngramPas encore d'évaluation

- Forwarded Message - From: Joseph Wong Date: 12 December 2012 07:37 Subject: Re: Paling Executive Suites To: Joshua SiaDocument2 pagesForwarded Message - From: Joseph Wong Date: 12 December 2012 07:37 Subject: Re: Paling Executive Suites To: Joshua SiaRachel IngramPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- L3493 MaterialDocument13 pagesL3493 MaterialRachel IngramPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Building Ordinance SarawakDocument327 pagesBuilding Ordinance SarawakRachel Ingram100% (2)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Lot 3493 - Brick Work, ACDocument6 pagesLot 3493 - Brick Work, ACRachel IngramPas encore d'évaluation

- M&E Perunding Dynatech Perunding Elecmec SDN BHD: Type ConsultantDocument21 pagesM&E Perunding Dynatech Perunding Elecmec SDN BHD: Type ConsultantRachel IngramPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Lot3493 Brickwalls (New)Document22 pagesLot3493 Brickwalls (New)Rachel IngramPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument18 pagesDisclosure To Promote The Right To InformationRachel IngramPas encore d'évaluation

- Lot 3493 - Rooms AreaDocument66 pagesLot 3493 - Rooms AreaRachel IngramPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Lot 3493 - Door QtyDocument3 pagesLot 3493 - Door QtyRachel IngramPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Soho 3494 Ceiling HeightDocument6 pagesSoho 3494 Ceiling HeightRachel IngramPas encore d'évaluation

- Lot 3493 - Rooms AreaDocument66 pagesLot 3493 - Rooms AreaRachel IngramPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument15 pagesDisclosure To Promote The Right To InformationRachel IngramPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument12 pagesDisclosure To Promote The Right To InformationRachel IngramPas encore d'évaluation

- Is-4365 1967Document22 pagesIs-4365 1967Abhay SisodiaPas encore d'évaluation

- Conquas - ExampleDocument7 pagesConquas - ExampleChan Siew ChongPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Disclosure To Promote The Right To InformationDocument15 pagesDisclosure To Promote The Right To InformationRachel IngramPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument19 pagesDisclosure To Promote The Right To InformationRachel IngramPas encore d'évaluation

- Disclosure To Promote The Right To Information: IS 4351 (2003) : Steel Door Frames - (CED 11: Doors, Windows and Shutter)Document14 pagesDisclosure To Promote The Right To Information: IS 4351 (2003) : Steel Door Frames - (CED 11: Doors, Windows and Shutter)Rachel IngramPas encore d'évaluation

- Peter H. Rossi - Mark W. Lipsey - Howard E. Freeman - Evaluation - A Systematic ApproachDocument417 pagesPeter H. Rossi - Mark W. Lipsey - Howard E. Freeman - Evaluation - A Systematic ApproachHector Urzua50% (2)

- 1402AHS Prac Manual - 2023 - FINALDocument200 pages1402AHS Prac Manual - 2023 - FINALRuan BritsPas encore d'évaluation

- TC Colorcode PDFDocument7 pagesTC Colorcode PDFPatrick MonteroPas encore d'évaluation

- Sex Education in The PhilippinesDocument3 pagesSex Education in The PhilippinesChinchin CañetePas encore d'évaluation

- M 17Document5 pagesM 17amhm2000100% (1)

- 2 Day ALS Programme 24 Candidates IO ARS (March 2016) PDFDocument2 pages2 Day ALS Programme 24 Candidates IO ARS (March 2016) PDFCojocariu Emanuel50% (2)

- DolphinsDocument1 pageDolphinsDebra OkwuziPas encore d'évaluation

- HC SB 61 227Document22 pagesHC SB 61 227Hamed BarjestehPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Nurs 512 Andersen Behavioral TheoryDocument7 pagesNurs 512 Andersen Behavioral Theoryapi-251235373Pas encore d'évaluation

- The Learner The Learner : 1 QuarterDocument4 pagesThe Learner The Learner : 1 QuarterRode Jane SumambanPas encore d'évaluation

- LMA An. I-Sem 1-Engleza LEC-The Category of Aspect & Aspect 3-Reedited OnDocument4 pagesLMA An. I-Sem 1-Engleza LEC-The Category of Aspect & Aspect 3-Reedited OnIlie IonelPas encore d'évaluation

- JeromeDocument2 pagesJeromeNads DecapiaPas encore d'évaluation

- Identification of Plastics Identification of PlasticsDocument41 pagesIdentification of Plastics Identification of PlasticsSoumickPas encore d'évaluation

- Drying Operation: Meika Syahbana RusliDocument69 pagesDrying Operation: Meika Syahbana RusliFrida GinaPas encore d'évaluation

- Devoir de Contrôle N°2 - Anglais - 2ème Economie & Gestion (2015-2016) Mme Chaima JallebDocument3 pagesDevoir de Contrôle N°2 - Anglais - 2ème Economie & Gestion (2015-2016) Mme Chaima JallebSassi LassaadPas encore d'évaluation

- Vision Medilink Product DetailsDocument4 pagesVision Medilink Product DetailsRaj SekarPas encore d'évaluation

- 'Last Season's Man'Document7 pages'Last Season's Man'Bishal Kumar SahuPas encore d'évaluation

- Australian TaxationDocument45 pagesAustralian TaxationEhtesham HaquePas encore d'évaluation

- Am Jf211 - Jul 04Document4 pagesAm Jf211 - Jul 04ilham_metallurgy6744Pas encore d'évaluation

- Daftar Irregular VerbsDocument8 pagesDaftar Irregular VerbsWawan MarwanPas encore d'évaluation

- Antithesis Essay Joseph JaroszDocument3 pagesAntithesis Essay Joseph JaroszJoseph JaroszPas encore d'évaluation

- ISO 9001: 2015 Certified Semen Freezing LaboratoryDocument43 pagesISO 9001: 2015 Certified Semen Freezing LaboratoryShubhamPas encore d'évaluation

- 2015 English Grade 7Document16 pages2015 English Grade 7AyushPas encore d'évaluation

- Kim Lighting Landscape Lighting Catalog 1988Document28 pagesKim Lighting Landscape Lighting Catalog 1988Alan MastersPas encore d'évaluation

- DSE8620 MKII Operator ManualDocument224 pagesDSE8620 MKII Operator Manualhenrygrados44Pas encore d'évaluation

- Minibeasts Differentiated Reading Comprehension ActivityDocument15 pagesMinibeasts Differentiated Reading Comprehension Activitymariam helmyPas encore d'évaluation