Académique Documents

Professionnel Documents

Culture Documents

Jeas 0411 477

Transféré par

gokulTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Jeas 0411 477

Transféré par

gokulDroits d'auteur :

Formats disponibles

VOL. 6, NO.

4, APRIL 2011

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2011 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

PRELIMINARY STUDY ON THE PHYSICAL AND MECHANICAL

PROPERTIES OF TAPIOCA STARCH / SUGARCANE FIBER

CELLULOSE COMPOSITE

A. R. Jeefferie1, O. Nurul Fariha1, A. R. Mohd Warikh1, M. Y. Yuhazri1, Haeryip Sihombing2 and J. Ramli3

1

Engineering Materials Department, Universiti Teknikal Malaysia Melaka, Durian Tunggal, Melaka, Malaysia

Manufacturing Management Department, Universiti Teknikal Malaysia Melaka, Durian Tunggal, Melaka, Malaysia

3

Faculty of Mechanical Engineering, Universiti Malaysia Pahang, Kuantan, Pahang Darul Makmur, Malaysia

E-Mail: jeefferie@utem.edu.my

ABSTRACT

This study is to investigate the potential application of Tapioca Starch (TS) and Sugar Cane Fiber Cellulose

(SCFC) as a green composite for disposable packaging food container. The experiment is started by preparing and

characterizing the SCFC through various characterization tools, whereby the effect of various SCFC loading to the

fabricated TS composites was then studied to find the best formulation for TS/SCFC composites. Various engineering

properties for TS/SCFC composites were tested out to determine the mechanical and physical properties, beside the

fracture morphology by using the optical microscope observation. Through the morphological view on the mechanical and

physical testing fractured surfaces, it had significantly indicates the reinforcement role of various fiber loading into the

resulted properties of produced composites. Although the results have shown good performance of composites for both

mechanical and physical properties, but the adhesion between SCFC and TS matrix were not well attached. In overall, the

development of this new material for food packaging application will provide great potential solution to the environmental

friendly and safe packaging medium, either for food, consumer or environmental, as a whole.

Keywords: tapioca starch, sugarcane fiber cellulose composites, properties, disposable food packaging, fiber loading.

INTRODUCTION

This research is focused on the fabrication of two

natural components that were combined as biodegradable

polymer matrix composites for the application of

disposable food packaging. The considerable interest in

this research is to produce an alternative material by

compounding tapioca starch and sugar cane fiber cellulose

to replace the existing non-biodegradable plastic material

in the market. By using sugar cane fiber cellulose (SCFC)

as a bio based natural fiber and tapioca starch (TS) as

biodegradable matrix material, the development of this

product is based on natural green raw materials due to its

characteristics of biodegradable, non-toxic and nonallergenic bio environmental resources. Sugar cane is used

due to its properties as a natural filler reinforcement that

has played an important role in enhancing the composites

performance. By combining sugar cane with tapioca starch

that acts as a matrix, it will give many advantages to the

environment. This is due to the advantages of

renewability, low density, and high specific strength as

well as biodegradable and recyclable at a very reasonable

cost [1]. Besides, it is expected to give the benefit to the

environment due to non-degradable waste of plastic food

packaging caused by uncontrolled solid waste disposal.

The fibers outstanding properties such as high

specific strength and stiffness, impact resistance,

flexibility, and modulus make them an attractive

alternative over the traditional materials [2]. Specifically,

towards the properties of sugar cane fiber cellulose, which

includes good specific strengths and modulus, economical

viability, low density and low weight that make them a

promising reinforcement of choice by the industry. Thus,

natural fiber, like sugarcane, that can be used as a

replacement to the conventional fiber since the global

environmental issues, have led renews interest in the

development of bio-based industrial products [3].

MATERIALS AND METHODS

The raw materials used in this study are tapioca

starch (TS) as matrix material, sugar cane fiber cellulose

(SCFC) as the reinforcement material, and glycerol as

plasticizer. By applying several characterization

approaches, the SCFC properties were tested for density

test, water absorption test, drying characteristic test, and

the microscopic study at the first stage. Second, TS/SCFC

composites were pressed by using hot compression

molding machine. To select the best fabricated composites

based on mechanical properties, the test such as tensile

testing, flexural testing, and impact testing are carried out

according to ASTM D638, ASTM D790, and ASTM

D256, respectively. While for the physical properties

evaluation, the water absorption test (ASTM D570-98)

was carried out in order to get the suitability of produced

composites for any commercial application. In addition,

the thickness swelling test also is required as well as the

morphological investigation against the mechanical and

physical specimens by using the optical microscope.

SCFC drying profile study

The drying process is by using oven

(MEMMERT UFB 400). The investigation of the SCFC

drying behavior over the periods of time is required

through the reading (taken by three times per day) of the

weight and moisture profile changes of SCFC.

VOL. 6, NO. 4, APRIL 2011

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2011 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

Water absorption

Water absorption test against SCFC fiber is used

to determine the amount of water absorbed under the

specified conditions. The samples were weighed before

and after the water absorption process. The total

percentage of weight is labeled as Ww, which refer to the

percentage of water absorbed.

% Ww = [(Wf - Wi) / Wi] x 100

(1)

Density measurement

The density measurement of SCFC was

performed by using an Electronic Densimeter model MD300S. The measurement was repeatedly done for five

times for different sample of SCFC. Average value was

then calculated.

Microscopy study

To measure the SCFC sizes and the

morphological behavior of the fabricated composites, the

optical microscope with Vis Pro software is used for the

microscopy observation. This is also conducted for

dimensional study against the length of each single fiber

measured and microscopy study regarding the

fractography of composites surface specimens to

understand the reinforcement characteristic of the

fabricated composites.

Compounding of TS / SCFC composites

In order to compound the TS, SCFC and glycerol,

the formulations were divided into five main compositions

of weight ratios such as 53:0:47, 50:3:47, 47:6:47, 44:9:47

and 41:12:47 of fiber loading addition. The weight

percentage (wt %) was computed by using the following

formula;

Wtp %= [(Vp.p) / (Vp.p + Vf.f)] x 100

(2)

Wtf % = [(Vf.f) / (Vp.p + Vf.f)] x 100

(3)

Where Wtp % and Wtf % is the weight percentage of the

TS and SCFC; Vp represent the volume fraction of TS and

Vf represent the volume fraction of SCFC. p and f is

density of TS and SCFC, respectively.

Hot compression molding

The compounded TS/SCFC/glycerol composites

were compressed by using hot compression molding

machine. The compression period is about 10 minutes at

130C and the overall cooling period is about 5 minutes.

Tensile test

The tensile test was carried out in accordance to

ASTM D638 by utilizing the Universal Testing Machine

(UTM) model Instron. Three measurements were tested at

232C with 50 % of relative humidity and each obtained

values is averaged. The dimension for this test is about

165mm x 19mm x 3.2mm, which are Type 1 specimens at

a crosshead speed rate of 3.75 mm/min with a gauge

length of 50 mm.

Impact test

Notched Charpy impact strength was performed

in order to determine the Impact Strength (J/m) values (as

representing energy loss per unit specimen thickness) on

an Impact Tester according to ASTM method of D256.

Three measurements were tested at 232C with 50 % of

relative humidity and each obtained values is averaged.

Flexural test

The flexural test was performed by using a threepoint bending method in accordance to ASTM D790,

utilizing the Universal Testing Machine UTM. The

purpose of this test is to measure the flexural strength and

flexural modulus (Youngs Modulus) of the specimens.

The load applied to the specimens is on two supports with

constants speed of 2.5 mm/min and standard span length

of 160mm.

Water absorption test

This study is to determine the water absorption

behavior of TS/SCFC composites according to ASTM

D570-98. Samples was prepared in the form of bar with

dimension of 76.2 x 25.4 x 3.2 mm and dried in a vacuum

oven at 505C for 24 hours and then immersed in

distilled water to get weigh to the nearest 0.001 gram. The

value of Ww is an average value of three samples

measurements. The percentage increase in weight from the

solution is then calculated to the nearest 0.01 %, where

%wf is the final percentage increase in weight of the tested

sample.

% wf = [(Ww - Wc) / Wc] x 100

(4)

Thickness swelling test

Thickness swelling test is interrelated to water

absorption test. The thicknesses of the samples (3 samples)

were recorded after 24 hours of soaking period by using a

digital vernier caliper. The calculation of thickness

swelling is as follows:

Thickness Swelling = [(Tf - Ti) / Ti] x 100

(5)

Where: Ti is the thickness of specimens (mm) before

immersion and Tf is the thickness of specimen after 24

hours of immersion.

RESULTS AND DISCUSSIONS

Drying characteristic of SCFC

Drying characteristics is important criteria to

determine the utilizing of any natural fiber for composites

fabrication. In this study, the drying process was employed

as to investigate the drying behavior and kinetic of

moisture release from SCFC raw materials against the

initial and final weights of fibers. Figure-1 shows the daily

weight losses of the fibers. In overall, the percentages of

weight losses from SCFC showed the fluctuating pattern

up until 5th days of observation, before plateau formation

for another three following days.

In addition, to investigate the influences and

correlation of moisture to the resulted morphology and

VOL. 6, NO. 4, APRIL 2011

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2011 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

Percentages of weight losses (%)

properties of natural fiber, the study was also carried out

against the rate of moisture moves in SCFC (that depends

on relative humidity of surrounding air), the steepness of

the moisture gradient, and the internal temperature of the

SCFC. The higher the temperature of the SCFC, the faster

moisture will move from the wetter interior to the drier

surface. However, if the temperature is too high, strength

reduction may occur and influenced to the mechanical

properties of fabricated composites.

20

18

16

14

12

10

8

6

4

2

0

1

10

11

12

13

Day

Figure-1. Percentage of weight losses for SCFC.

attributed to the natural capillaries present in the natural

fiber, which is quickly attaining equilibrium with

hydration medium by capillary inhibition [4]. Hence, it

can be assumed that water concentration at the surface of

natural filler is raised to saturation almost instantaneously.

The periodic water absorption has also give the

negative impact on the quality of fabricated composites.

The amount of absorbed water in fiber is depends on

density and water diffusivity of fiber. Data obtained from

water absorption or sorption behavior could provide good

approximation of average liquid water diffusivity of the

material [5, 6].

% of water absorption

Water absorption behavior of SCFC

Understanding about the water absorption by

SCFC during the soaking period is one of practical

importance, since it will affects the mechanical properties

of resulted product. The characteristic of water absorption

for sugar cane fiber cellulose (SCFC) was determined

through the samples measured against the weight, before

and after the distilled water processing. Figure-2 shows

that the SCFC natural fiber is very prone to absorb water.

Due to water absorption, the average percentage of

hydrophilic characteristic of SCFC (that is 87%) must be

given higher consideration because it will greatly affect to

the structural integrity of resulted composites. This is

90%

85%

80%

75%

70%

1

10

Reading

Figure-2. Water absorption of sugarcane fiber cellulose (SCFC).

SCFC density measurement

The density of sugar cane fiber cellulose (SCFC)

was determined by using an electronic densimeter. The

following Figure-3 shows the comparison of density

measurement for other natural and industrial commercial

fibers with sugar cane fiber cellulose (SCFC). SCFC

shows the lowest density compared to other fibers such as

coir, jute, aramid, carbon, flax, sisal, soft wood craft and

VOL. 6, NO. 4, APRIL 2011

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2011 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

cotton. Based on these results, it can be declared that the

SCFC is very promising to be used for any light weight

application due to its lowest density value than other type

of fiber.

2.5

Density

2.5

2

1.5

1.4

1.4

1.5

1.5

1.55

1.3

1.5

1.2

Coir

Jute

Aramid

Carbon

Flax

Sisal

Soft

wood

kraft

Cotton

1

0.5

0.24

0

SCFC

E-glass

Types of Fiber

Figure-3. Comparison of density measurement with other fibers.

Microscopic observation of SCFC

In this study, the SCFC were crushed into the

smaller length by using a rotor mill machine that caused

the fibers lengths varied into wide range of size, within

890.13 to 2881.46 microns. This parameter will influence

the result of the final properties of the fabricated

composites. The fiber length is critical factor that need to

be considered due to its necessity for effective

strengthening and stiffening of the composites material

[7]. Figure-4 shows the picture of morphology of sugar

cane fiber cellulose (SCFC) by using the optical

microscope.

Figure-4. Morphology of sugar cane fiber cellulose (SCFC) at 20x of magnification.

Tensile properties of TS/SCFC composites

The fabricated composites samples were tested

with tensile test in order to obtain the tensile strength and

tensile modulus by following the ASTM D638 testing

standard. However, the value of the maximum stress and

Youngs modulus for each composites formulation cannot

be obtained from the testing due to early failure

phenomena at the sample grip. This is due to the nature of

soft sample texture which caused early damages during the

gripping stage. However, this is contradicted to

10

VOL. 6, NO. 4, APRIL 2011

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2011 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

Sirikhajornnam and Danwanichakul (2006), that in their

study for the preparation of biodegradable film from

starch, tensile strength is about 21MPa until 35MPa for

various composites formulation. They stated that, a film

with higher ratio of glycerol (which is typical plasticizer)

is poorer in its tensile strength, but show better flexibility

[8]. This is because the plasticizers increased the film

flexibility by reducing hydrogen bonding between the

polymer chains.

The impact response of the fiber composites is

highly influenced by the interfacial bond strength between

the matrix and the fiber. The impact energy is dissipated

by debonding fiber or matrix fracture and fiber pull-out

[10]. In this study, the failure mechanism was not obtained

and cannot be fully understood because of the soft nature

of the fabricated composites. Figure-6 depicts the surface

observation for TS/SCFC composite which undergone the

impact test.

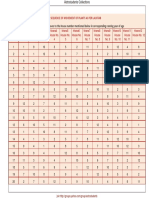

Impact properties of TS/SCFC composites

The Charpy impact test was done as to show the

ability of specimens to absorb the energy of pendulum

force. All of the specimens did not break off due to their

soft nature. These samples had been categories as nonbreak failure or totally ductile failure. The impact energy

results of the fabricated composites samples were shown

as in the following Table-1. The impact energy and impact

strength are proportionally increased with the increasing of

SCFC loading and glycerol percentages addition. The

impact strength data for TS/SCFC/Glycerol composite

produced in this research was integrated in the Figure-5, as

to compare the resulted properties with the other fiber

types composites [9].

Table-1. Impact properties of pure TS and TS/SCFC

composites with the presence of glycerol.

TS/SCFC/Glycerol

0.17

Impact

strength

(J/m)

0.0034

50/3/47

0.27

0.0062

47/6/47

0.47

0.0092

44/9/47

0.50

0.0096

41/12/47

0.67

0.0145

Composition of

TS/SCFC/glycerol

(Wt %)

53/0/47

Average of impact strength

0.0086

0.00858

50% Corn fiber

50% Soybean hulls

17

50% Peanut hulls

Types of fiber

Impact

energy (J)

18

50% Rice hulls

22

50% Wheat straw

22

50% Wood flour

22

50% Oat straw

23

50% Kenaf core

24

100% PP

25

50% Oat hulls

25

40% Talc

27

0 1

2 3

4 5

6 7 8

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28

Impact Strength, J/m

Figure-5. Charpy impact properties of various fibers (adapted from [9]).

11

VOL. 6, NO. 4, APRIL 2011

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2011 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

Figure-6. The surface of TS/SCFC composite with 41%

tapioca starch, 12% SCFC and 47% glycerol at the 20x of

magnification.

Flexural properties of TS/SCFC composites

The flexural test measures the required force to

bend a beam under the three point loading conditions in

accordance to ASTM D790 standard. Flexural modulus is

used as an indication of a material stiffness. The

increasing of flexural modulus results with the filler

loading increment showed that the movement of tapioca

starch (TS) molecules was more difficult with the

increasing of filler content. This trend is consistent with

the study conducted by [9] and [11]. Figure-7 shows the

results of flexural modulus test for five compositions of

the TS/SCFC composites.

Figure-7. Flexural modulus of pure TS and TS/SCFC

composite with the presence of glycerol.

The composites with random distribution of

fibers indicate a better performance due to the possibility

of homogenous distribution between the fiber and matrix.

The stress transferred between the fiber and matrix is more

effective and will positively affect to the flexural

performance of the fabricated composites. The

introduction of glycerol as a plasticizer is also influences

to the improvement in the flexural properties for better

flexibility. This was also reported by [8]. This is because

the plasticizer increased the ability to reduce hydrogen

bonding between the polymer chains. However, it cannot

be clearly observed the fractured region of the specimens

through the optical microscope observation. Although, TS

and SCFC was strongly bonded by the glycerol and

resulting the increment values of the flexural strength of

the fabricated composites. The addition of glycerol gives

significant improvement to the sugar cane fiber surface

wetting by the tapioca starch matrix. As a result, addition

of glycerol will contributes to the formation of stronger

adhesion between the SCFC and the TS matrix in

composites. The increase of the flexural properties in the

composites can be explained via the increasing adhesion

between the fiber and its matrix.

Water absorption properties of TS/SCFC composites

Figure-8 shows the percentage of water

absorption versus five different TS/SCFC composite

specimens which immersed in water at the ambient

temperature (23C). With the addition of sugar cane fiber

cellulose (SCFC), the weight of each specimens increases

after being immersed in water for 24 hours. This indicates

the increasing percentage of water absorption with the

increment of SCFC fiber loading that contributes to the

negatives effects in term of structural integrity to the

fabricated composites. The highest water absorption was

in the specimen contained of 12wt% of SCFC with the

presence of 41% of tapioca starch and 47wt% of glycerol

whereas the formulation 53/0/47 and 50/3/47 of

composites absorbed the very minimal amount of water at

about 51% of absorption. A similar trend was previously

obtained shows that the water absorbability depends to the

size of filler particle [8]. The water absorption of

composites is relatively high due to hygroscopic nature of

the filler [12]. As the filler content is increased, the water

absorption is expected to be increased [13]. In case of

starch, the water absorbability might be depending to the

percentage of fibers that has higher value of water

solubility than the other materials [14].

12

VOL. 6, NO. 4, APRIL 2011

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2011 Asian Research Publishing Network (ARPN). All rights reserved.

% water absorption

www.arpnjournals.com

55%

54%

53%

52%

51%

50%

49%

54%

51%

51%

53/0/47

50/3/47

53%

53%

47/6/47

44/9/47

41/12/47

Formulation / Ratio

Figure-8. Water absorption characteristic of TS/SCFC/Glycerol composites

at different composition.

modulus properties was noted to be more significant than

the strength properties [13]. This is due to droopiness

occurred in intermolecular bonding of the filler.

The following Figure-9 shows the comparison of

water absorption characteristics of TS/SCFC/Glycerol

with the other natural fibers. It is clearly shown that the

TS/SCFC is among the lowest in term of its water

absorption properties, in comparison to the types of natural

fiber based composites. From this result, we can expect

that this bio composites material would be suitable for

application like interior panels and food packing material

[15]. The rate of water absorption in natural fiber based

composites shows two distinct regions; a short term, where

the kinetic absorption is noted to be relatively fast, and a

long term where the kinetics of absorption is noted to be

slow and leads to plateau regions.

% Water Absorption

The action of water may have resulted in further

disruption of the interfacial adhesion between the starch

granules and sugar cane fiber cellulose. Subsequently,

these will probably lead to the formation of additional

voids in the starch based composites, which would then be

filled with water (water entrapment in the matrix). Upon

drying, these voids will act as stress concentration region,

which could then initiate matrix cracking that leading to

reduction in both stiffness and strength of the composites.

At high water absorption, the interfacial bond strength is

reduced and affects both stiffness and strength of the

samples [13]. Another factor that is noted to affect the

properties from high water sorption is the effect as fibers

swell to accommodate the water, resulting in internal

stresses or cracks and greater interaction between micro

fibrils. Flexural strength and modulus to drop with

immersion time and filler content, where the drop in

180

160

140

120

100

80

60

40

20

0

155

65

63

73

53

43

Coconut

Sisal

Bamboo

Wood fiber

Sugar cane

bagasse

TS/SCFC

Types of fiber

Figure-9. Water absorption characteristic of different types of fiber (adapted from [7]).

Thickness swelling properties of TS/SCFC composites

Thickness swelling testing was employed

concurrently with water absorption procedure. Figure-10

shows the increment of thickness swelling of the

specimens by increasing the fiber content. Previous study

found that the percentage of thickness swelling is

increased as the increment content of fibers used in the

fabricated composite [16]. The highest percentage value of

the thickness swelling was obtained in the specimen of

12wt% SCFC whereas the 53wt% of tapioca starch with

the 47wt% glycerol specimen absorbs the very minimal

amount of water at around 2% and caused the swelling at

0.09%. Thickness swelling of bio composites occurs when

the cell walls in the agro-flour is swelled by water [17].

The larger particle size results in increased water

absorption compared to the smaller particle size and,

13

VOL. 6, NO. 4, APRIL 2011

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2011 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

therefore, to greater swelling of the cell wall than in the

case of smaller particle size.

[4] Kumar A. and Flynn P.C. 2006. Uptake of Fluids by

Boreal Wood Chips: Implications for Bioenergy.

Journal of Fuel Processing Technology. 87(7): 605608.

[5] Kumaran M.K. 1999. Moisture Diffusivity of Building

Materials from Water Absorption Measurements.

Journal of Thermal Envelope and Building Science.

22(4): 349-355.

Figure-10. Comparison of thickness deflection

TS/SCFC/Glycerol composites at different composition.

CONCLUSIONS

The results shown that the mechanical properties

of fabricated composites had increased by increment of

SCFC content, especially for flexural and impact

properties. However, poor performance was obtained to

the resulted tensile strength properties. For the physical

test, the result showed bad performance on both water

absorption and thickness swelling test. This is due to both

of the tests showed the increasing absorption and swelling

trend by increment of the fiber loading in the resulted

composites. Through the morphological study on the

mechanical and physical testing of the fractured surfaces,

it was clearly found that the adhesion between SCFC and

TS matrix is not well adhered. The best compounding

formulation of the fabricated composite was observed at

the weight fraction of 41 wt% of TS, 12 wt% of SCFC

with 47 wt% of glycerol.

The study proves that combination of

TS/SCFC/Glycerol could have possibilities to be applied

as one of the candidates alternatives materials for food

packaging application. However, further major study is

still required to establish and improves the necessary

properties for the application of food disposable packaging

container.

ACKNOWLEDGEMENTS

The author acknowledges Universiti Teknikal

Malaysia Melaka (UTeM) for supporting this research

work under the short term grant PJP/10/2009/S579.

REFERENCES

[1] Ochi S. 2008. Mechanical Properties of Kenaf Fiber

and Kenaf/PLA Composites. Journal of Mechanics of

Materials. 40(4-5): 446-452.

[2] Sgriccia N., Hawley M.C. and Misra M. 2008.

Characterization of Natural Fiber Surfaces and Natural

Fiber Composites. Composites: Part A. 39(10): 16321637.

[3] Chen J.C.P. and Chung C.C. 1993. Cane Sugar

Handbook. 12th Edition. John Wiley and Sons Inc.,

Singapore. pp. 21-29.

[6] Malkov S.Y., Kuzmin V.A., Baltakhinov V.P. and

Tikka P. 2004. Modeling the Process of Water

Penetration into Softwood Chips. Journal of Pulp and

Paper Science. 25: 123-129.

[7] Callister W.D. 2003. Materials Science and

Engineering: An Introduction. 6th Edition. John Wiley

and Sons Inc., Singapore. pp. 451-566.

[8] Sirikhajornnam P. and Danwanichakul P. 2006. A

Preliminary Study of Preparing Biodegradable Film

from Starch. 32nd Congress on Science and

Technology of Thailand (STT 32). 10-12 October

2006. [STT 32-J1_J0013]. pp. 1-3.

[9] Rowel R.M., Sanadi A.R., Caulfield D.F. and

Jacobson R.E. 1997. Utilization of Natural Fibers in

Composites: Problems and Opportunities in LignoCellulosic-Plastic Composites. Eds. Leao, A.,

Carvalho, F.X. and Frollini, E., USP/UNESP

Publishers, Sao Paulo. pp. 23-51.

[10] Wambua P., Vangrimde B., Lomov S. and Verpoest I.

2003. The Response of Natural Fiber Composites to

Ballistic Impact by Fragment Simulating Projectiles.

Composites Structure Journal. 77(2): 232-240.

[11] Hassan A. and Sivaneswaran. 2001. Effect of Titanate,

Zirconate and Silane Coupling Agents in Rice Husk

Ash Filled PVC-U Composites. Journal of the

Institute of Materials Malaysia. 2(2): 31-42.

[12] Xanthos M. 1983. Processing Conditions and

Coupling Agent Effects in Polypropylene/Wood Flour

Composites. Journal Plastic Rubber Process

Application. 3(3): 223-228.

[13] Lin Q.X., Zhou G. D. and Y. Bi. 2002. Some Studies

on Mechanical Properties of Wood Flour Continuous

Glass Mat/ Polypropylene Composites. Journal of

Applied Polymer Science. 85(2): 536-544.

[14] Rashdi A.A.A., Sapuan S.M., Ahmad M.M.H.M. and

Khalina A. 2009. Water Absorption and Tensile

Properties of Soil Buried Kenaf Fibre Reinforced

Unsaturated Polyester Composites. Journal of Food,

Agriculture and Environment. 7(3-4): 908-911.

14

VOL. 6, NO. 4, APRIL 2011

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2011 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

[15] Hee S.K. 2004. Physico-Mechanical Properties and

Biodegradability of Agro-Flour Filled Aliphatic

Thermoplastic

Polyester

Bio-Composites.

Unpublished Master Thesis, B.S., Seoul National

University.

[16] Sanadi A.R., Young R.A., Clemons C., Rowell R.M.

1994. Recycled Newspaper Fibers as Reinforcing

Fillers in Thermoplastics: Analysis of Tensile and

Impact Properties in Polypropylene. Journal of

Reinforced Plastics and Composites. 13(1): 54-67.

[17] Rozman H.D., K.W. Tan, R.N. Kumar, A. Abu bakar,

Z.A.M. Ishak and H. Ismail. 2000. The Effect of

Lignin as a Compatibilizeron: The Physical Properties

of Coconut Fiber-Polypropylene Composites.

European Polymer Journal. 36(7): 1483-1494.

15

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Chapter 2 Axial and Torsional ElementsDocument57 pagesChapter 2 Axial and Torsional ElementsAhmad FaidhiPas encore d'évaluation

- Design Calculation FOR Rigid Pavement/RoadDocument5 pagesDesign Calculation FOR Rigid Pavement/RoadghansaPas encore d'évaluation

- ZH210LC 5BDocument24 pagesZH210LC 5BPHÁT NGUYỄN THẾ0% (1)

- Aspen Plus User ModelsDocument339 pagesAspen Plus User Modelskiny81100% (1)

- IA 05 Formal MethodsDocument5 pagesIA 05 Formal MethodsAuthierlys DomingosPas encore d'évaluation

- GoodElearning TOGAF Poster 46 - Adapting The ADMDocument1 pageGoodElearning TOGAF Poster 46 - Adapting The ADMFabian HidalgoPas encore d'évaluation

- 1 s2.0 S1877705811005273 MainDocument6 pages1 s2.0 S1877705811005273 MaingokulPas encore d'évaluation

- 1 s2.0 S1877705811005753 MainDocument5 pages1 s2.0 S1877705811005753 MaingokulPas encore d'évaluation

- Landing Gear Design and DevelopmentDocument12 pagesLanding Gear Design and DevelopmentJavier UribePas encore d'évaluation

- Carlson 99 ToleranceDocument17 pagesCarlson 99 TolerancegokulPas encore d'évaluation

- Datum SystemsDocument16 pagesDatum Systemstemp83a69% (13)

- 0604 SteyDocument6 pages0604 SteygokulPas encore d'évaluation

- Rules and Fallacies For Categorical SyllogismsDocument5 pagesRules and Fallacies For Categorical SyllogismsFatima Ismael PortacioPas encore d'évaluation

- Package-Related Thermal Resistance of Leds: Application NoteDocument9 pagesPackage-Related Thermal Resistance of Leds: Application Notesalih dağdurPas encore d'évaluation

- Evolution DBQDocument4 pagesEvolution DBQCharles JordanPas encore d'évaluation

- FmatterDocument12 pagesFmatterNabilAlshawish0% (2)

- EE 8602 - Protection and Switchgear Unit I - MCQ BankDocument11 pagesEE 8602 - Protection and Switchgear Unit I - MCQ Bankpoonam yadavPas encore d'évaluation

- Anth 09 3 247 07 386 Yadav V S TTDocument3 pagesAnth 09 3 247 07 386 Yadav V S TTShishir NigamPas encore d'évaluation

- An Overview and Framework For PD Backtesting and BenchmarkingDocument16 pagesAn Overview and Framework For PD Backtesting and BenchmarkingCISSE SerignePas encore d'évaluation

- 2021 Bookmatter BasicSciencesOfNuclearMedicineDocument12 pages2021 Bookmatter BasicSciencesOfNuclearMedicineBeatriz MartinhoPas encore d'évaluation

- BS 07533-3-1997Document21 pagesBS 07533-3-1997Ali RayyaPas encore d'évaluation

- Test Report: Tested By-Checked byDocument12 pagesTest Report: Tested By-Checked byjamilPas encore d'évaluation

- 1974 - Roncaglia - The Reduction of Complex LabourDocument12 pages1974 - Roncaglia - The Reduction of Complex LabourRichardPas encore d'évaluation

- Kimura K.K. (KKK) : Can This Customer Be Saved? - Group D13Document6 pagesKimura K.K. (KKK) : Can This Customer Be Saved? - Group D13Mayuresh GaikarPas encore d'évaluation

- Vectors Notes (Answers)Document24 pagesVectors Notes (Answers)ScionPas encore d'évaluation

- Electromechani Cal System: Chapter 2: Motor Control ComponentsDocument35 pagesElectromechani Cal System: Chapter 2: Motor Control ComponentsReynalene PanaliganPas encore d'évaluation

- Data Sheet: Item N°: Curve Tolerance According To ISO 9906Document3 pagesData Sheet: Item N°: Curve Tolerance According To ISO 9906Aan AndianaPas encore d'évaluation

- Sim Educ101Document101 pagesSim Educ101Rolando AmadPas encore d'évaluation

- ECON 401/601, Microeconomic Theory 3/micro 1: Jean Guillaume Forand Fall 2019, WaterlooDocument3 pagesECON 401/601, Microeconomic Theory 3/micro 1: Jean Guillaume Forand Fall 2019, WaterlooTarun SharmaPas encore d'évaluation

- Curriculum Improvement v2Document47 pagesCurriculum Improvement v2Nica Lagrimas100% (1)

- Agenda - Meeting SLC (LT) - 27.06.2014 PDFDocument27 pagesAgenda - Meeting SLC (LT) - 27.06.2014 PDFharshal1223Pas encore d'évaluation

- 2022 Summer Question Paper (Msbte Study Resources)Document4 pages2022 Summer Question Paper (Msbte Study Resources)Ganesh GopalPas encore d'évaluation

- Climatol GuideDocument40 pagesClimatol GuideFressiaPas encore d'évaluation

- Sta404 07Document71 pagesSta404 07Ibnu Iyar0% (1)

- Lalkitab Varshphal Chart PDFDocument6 pagesLalkitab Varshphal Chart PDFcalvinklein_22ukPas encore d'évaluation

- Effect of Heater Geometry On The High Temperature Distribution On A MEMS Micro-HotplateDocument6 pagesEffect of Heater Geometry On The High Temperature Distribution On A MEMS Micro-HotplateJorge GuerreroPas encore d'évaluation