Académique Documents

Professionnel Documents

Culture Documents

Monthly PM and Testing For CAT Generators

Transféré par

Adel FawziDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Monthly PM and Testing For CAT Generators

Transféré par

Adel FawziDroits d'auteur :

Formats disponibles

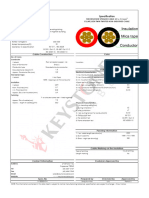

PM Sheet for CAT generator

Prepared by/ Adel Muhamed Fawzy

Monthly PM and testing for CAT generators

Date

Position

Team members

Estimated time for PM

Substation

Alternator type

Alternator

Consumed AMP.

Description of the generator

to

Serial Number

be tested:

Last PM (hours)

Check all exposed electrical

connections for tightness.

Not OK

Check all lead wires and electrical

connections for proper clearance.

Not OK

Electrical Connections - Check

Transformers

Check the following devices for

Voltage regulator

loose mounting or for physical

Load sharing modules

damage

A vacuum cleaner should be used to

pick up the following items: dry

Applied

dirt, dust, and carbon.

Not-Applied

A small brush may be attached to

Cleaning

the vacuum hose in order to loosen

Applied

dirt that is more firmly attached

to

(Assembled Generators)"Note(2)"

the surface

Compressed air maximum of (30

psi) may be used to remove the

Applied

remaining dust and dirt.

Not-Applied

Not-Applied

Main stator temperature

Main rotor temperature

Exciter stator temperature

Exciter rotor temperature

Front bearing temperature

Thermograph "Note(3)" & "Note(4)"

Rear bearing temperature

(on Running genset)

Area of concern (hot spots)

Corrective actions

Battery terminals and cables

Applied

cleaning "Note(5)"

Not-Applied

Recommended action.

1 | Page

PM Sheet for CAT generator

Prepared by/ Adel Muhamed Fawzy

6-Month PM and testing for CAT generators

Date

Position

Team members

Estimated time for PM

Substation

Alternator type

Alternator Consumed AMP.

Description of the generator

Serial Number

to be tested:

Last PM (hours)

Ambient temperature

Check all exposed electrical

connections for tightness.

Electrical Connections -

Generator Inspect

Not OK

Check all lead wires and electrical

Not

connections for proper clearance.

Check

Transformers

Check the following devices for

Voltage regulator

loose mounting or for physical

Load sharing modules

damage

OK

Insulation material should be

"Note(1)"examined for cracks, carbon, salt

Not OK

and dirt and dust that is saturated

with moisture

L1 to

Main stator insulation

resistance

Main rotor insulation

resistance

ground

L2 to ground

1st wire to ground

wire to ground

Insulation resistance

"Note(6)", "Note(7)","Note(8)","Note(9)"&

Exciter rotor insulation

"Note(10)"

resistance

wire

Exciter stator insulation

resistance

to ground

L3 to ground

wire to ground

wire to ground

wire to ground

wire to ground

wire to ground

F1to ground

F2 to ground

Recommended action

Main stator temperature

Main rotor temperature

Exciter stator temperature

Exciter rotor temperature

Thermograph "Note(3)" & "Note(4)"

Front bearing temperature

(on Running genset)

Rear bearing temperature

Area of concern (hot spots)

Corrective actions

Battery terminals and cables

Applied

Not-Applied

2 | Page

PM Sheet for CAT generator

Prepared by/ Adel Muhamed Fawzy

cleaning

"Note(5)"

Recommended action.

1- Switchgear inspection

On de-energized equipment

Turn power off and perform zero energy check.

Ensure good grounding value (less than 5ohms)

Ground all buses, verify that all components are de-energized. Bus maintenance

typically requires a bus outage for work on or in the neighborhood of energized

equipment. Work is performed only after equipment is verified de-energized and

alternate feeds are isolated. Ensure all energy sources are tagged out to

preclude inadvertent energizing. Remove any stored electrical energy by

grounding. Mechanical stored energy should be removed by discharging spring

mechanisms prior to work.

Procedure

Result

Look for physical damagecracks, breaks, delamination, warping,

blisters, flaking, or crazing of insulated parts.

Not OK

Check for foreign objects and loose tools or fallen parts, warped or

distorted insulated bus, and rusty or bent structural framework.

Not OK

Inspect low points in bus for signs of moisture debris accumulation.

Not OK

Inspect the (internal) bus supports for structural integrity and signs

of cracks.

Not OK

Inspect insulation materials for discoloration and cracking.

Not OK

2- Contact resistance testing of Bus bars

Pole resistance Micro ohms readings

Pole#1

Pole#2

Pole#3

As found (Micro-Ohms)

As left (Micro-Ohms)

As found (Micro-Ohms)

As left (Micro-Ohms)

As found (Micro-Ohms)

As left

(Micro-Ohms)

3- Insulation resistance testing of Bus bars

Time resistance test (M)

Second

Phase to ground

Phase (A)

(A) to (B)

Phase to Phase

Phase (B)

(B) to (C)

Phase (C)

(C) to (A)

30

60

DAR

DAR =

Resistance reading at 60 s

Resistance reading at 30 s

3 | Page

PM Sheet for CAT generator

Prepared by/ Adel Muhamed Fawzy

Corrective action

1. Clean insulation, insulators, bus hardware, and joint covers with a cleaner that is

suitable for the material and application.

2. All dust and dirt should be vacuumed from the switchgear enclosure and

components. Wiping with a dry, clean cloth buses, insulators, cables, and the

like.

3. The surface of all insulating members should be inspected before any cleaning

or dusting, as well as after cleaning for signs of electrical distress, tracking,

corona, and thermal heating.

4. Clean ventilating openings and filters, Make sure that fans are functioning

properly

5. Lubricate hinges, locks, latches, and so on.

6. Compare equipment nameplate information with latest one-line diagram and

report discrepancies.

7. A torque procedure includes initially tightening the bolts finger tight followed

by the use of a torque wrench to half of the recommended torque value. The

torque sequence should ensure a uniform pressure applied to the mating

connection surfaces. The appropriate symmetrical torque sequence can

ensure full clamping force and contact area.

8. Cleaning of C.B should be carried out using a cloth or brush that is perfectly clean

and dry, without using any solvents, avoiding greased parts except for grease on

electrical contacts. Application of products under pressure or containing solvents

(trichloroethane, trichloroethylene, WD40) is strictly forbidden.

9. Greasing: Grease must not be over applied because the excess, if mixed with

dust, may result in mechanism malfunctions. Generally speaking, under normal

operating conditions, the pole-operating mechanism does not require any

regreasing as it is greased for the life of the product.

Lubrication of the Mechanism

The clusters and disconnecting-contacts must be greased according to

the defined intervals using the greases indicated by manufacture.

The main contacts must not be greased.

Thermography or low resistant measurement is an alternate method to determine the

suitability of a connection. Perform a comparison of measured values.

4 | Page

PM Sheet for CAT generator

Prepared by/ Adel Muhamed Fawzy

Quarterly (3-months) PM and testing of low voltage

switchgear

The following PM is applied on L.V switchgear

1-

Thermographic surveys

Reason of survey:

Description of equipment to be tested:

Equipment name

Ampere rating

Last thermograph survey (Date):

Temperature difference between the area of

concern and the reference area.

Probable cause of temperature difference.

Areas inspected. Identify inaccessible and

unobservable areas and equipment.

Identify load conditions at time of inspection.

Provide photographs and/or thermographs of the

deficient area.

Recommended action.

2Visual inspection

On energized equipment

Procedure

Result

5 | Page

PM Sheet for CAT generator

Prepared by/ Adel Muhamed Fawzy

Listen for popping, spitting, or cracking sounds produced by

electrical dischargesalso humming noises or vibration produced

by resonance.

Not OK

With lights out, look for blue or purple corona halos. Orange or red

sputter arcs are created by intermittent sparking.

Not OK

Ozone, produced by corona or overheating of organic materials,

can usually be detected by their scents.

Not OK

3-

Data recording

Procedure

Result

Record Voltage THD

Record Neutral current

Gen#1

Gen#3

Gen#2

Gen#4

Gen#1

Gen#3

Gen#2

Gen#4

Note(1)

i.

If there is an insulation resistance value that is below normal, a conductive

path may be present which may produce shorts.

ii. Cleaning is advisable if heavy accumulations of dirt or dust can be seen. If

excess dirt is the cause of a restriction in the ventilation, cleaning is also

advisable. Restricted ventilation will cause excessive heating.

iii. To avoid the possibility of deterioration to the generator windings, do not

clean the generator unless there is visual, electrical, or thermal evidence

that dirt is present.

Note(2)

Cleaning may be required at the point of installation.

i.

In this case, a vacuum cleaner should be used to pick up the following items:

dry dirt, dust, and carbon. This will prevent the spreading of these

contaminants.

ii. A small nonconductive tube may need to be connected to the vacuum

cleaner. This will allow the vacuum cleaner to clean the surfaces that are not

exposed. After most of the dust has been removed, a small brush may be

attached to the vacuum hose in order to loosen dirt that is more firmly

attached to the surface.

iii. After the initial cleaning with a vacuum, compressed air may be used to

remove the remaining dust and dirt. Compressed air that is used for cleaning

should be free of moisture and free of oil. Air pressure should be a maximum

of (30 psi) in order to prevent mechanical damage to the insulation.

Note(3)

Thermograph determines the highest point of temperature (hot spots) in the winding. The hotspot is the location in stator windings with the highest temperature. A hot-spot is located

approximately in the center of each stator slot and approximately in the center of each field

winding.

Note(4)

6 | Page

PM Sheet for CAT generator

Prepared by/ Adel Muhamed Fawzy

SR5 generators are limited to a 20C (257F) temperature rise over the same conditions SR4

generators.

Note(5)

Use a fine grade of sandpaper to clean the terminals and the cable clamps. Clean the items

until the surfaces are bright or shiny. DO NOT remove material excessively. Excessive removal

of material can cause the clamps to not fit properly.

Note(6)

i.

Insulation must prevent electrical breakdown between components, but it

must also be used as sparingly as possible. Less insulation means more

space available for copper and better heat dissipation. More copper and

better heat dissipation improves maximum output from the generator.

ii. Before the generator is stored, does an insulation resistance check and

record the readings to get a data base. Always do insulation resistance check

before starting up any generator that has been in storage.

Note(7)

Note(8)

Recommended Procedure for the Insulation Test

i. Take the generator out of service.

ii. Visually inspect the generator for moisture. If moisture exists, do not

perform this insulation test. dry and clean the unit first.

iii. Inspect the installation. Determine the equipment that will be tested by

the insulation tester.

iv. Discharge the capacitance of the windings.

v. Disconnect T0 from ground.

7 | Page

PM Sheet for CAT generator

Prepared by/ Adel Muhamed Fawzy

vi. Disconnect the sensing lead wires for the regulator. This may be

accomplished by unplugging the harness connectors.

vii. Disconnect the PT leads of the load share module.

viii.

Use the 30/60 Time Resistance Method:

ix. Evaluate the readings.

Field-Winding Test

Individual Stator Winding Test

Note(9)

6wire exciter rotor is existed in case of 1400 frame (3500 series generator).

Note(10)

Recommended action may be:

If test readings are accepted Cleaning assembled generator.

If test readings aren't accepted an intensive cleaning [Cleaning

disassembled generator] then repeat insulation test.

o If test readings are accepted OK

o If test readings aren't accepted Re-varnish suspected part of

alternator to increase insulation resistance then repeat insulation

test.

If test readings are accepted OK

If test readings aren't accepted A complete rewound of

suspected part of alternator.

A high pressure wash is normally an effective way to clean windings. This includes windings that

have been exposed to flooding or windings that have been contaminated by salt. A solution of hot

water and detergent is used for this method of cleaning.

A high pressure wash sprays a high velocity fluid stream of this solution over the generator that is

being cleaned. This detergent washing is followed by multiple sprays of clean water. The clean

water is used in order to remove the detergent or the clean water is used in order to dilute the

detergent.

8 | Page

PM Sheet for CAT generator

Prepared by/ Adel Muhamed Fawzy

Allow the generator to dry at room temperature.

Check the insulation resistance. The insulation resistance should now be normal. If the insulation

resistance is not normal, repeat the procedure. It may be necessary to use solvents if the

generator is contaminated with oil or if the generator is contaminated with grease.

9 | Page

Vous aimerez peut-être aussi

- 250X SMPS With Power MosfetDocument13 pages250X SMPS With Power MosfetAislan Souza0% (1)

- ControlDocument134 pagesControljarolPas encore d'évaluation

- Hunger VKM3.1 Valve Griding Machine PDFDocument2 pagesHunger VKM3.1 Valve Griding Machine PDFOrlando GalvanPas encore d'évaluation

- PROJECT CAT IPP2-Diesel, Production Drawings PDFDocument28 pagesPROJECT CAT IPP2-Diesel, Production Drawings PDFDelio DuranPas encore d'évaluation

- Exhaust Gas Recirculation (Egr) System (4A FE)Document6 pagesExhaust Gas Recirculation (Egr) System (4A FE)Hongda Zhuo100% (1)

- DGPT2 en 6 PDFDocument16 pagesDGPT2 en 6 PDFSISWANTOPas encore d'évaluation

- Installation and Adjustments Manual Incorporating The Commissioning ProceduresDocument54 pagesInstallation and Adjustments Manual Incorporating The Commissioning ProceduresSimion Cosmin - AlinaPas encore d'évaluation

- SEBU7789-00 - Operation & Maintenance, Service InformationDocument5 pagesSEBU7789-00 - Operation & Maintenance, Service InformationSayed Younis SadaatPas encore d'évaluation

- Power Generation Cep LoadDocument34 pagesPower Generation Cep LoadHermain Fayyaz KarimPas encore d'évaluation

- PD PDFDocument86 pagesPD PDFRached DouahchuaPas encore d'évaluation

- Automatic Board For Emergency Gen-Sets: ManualDocument14 pagesAutomatic Board For Emergency Gen-Sets: ManualLuis JesusPas encore d'évaluation

- Teste Do VaristorDocument3 pagesTeste Do Varistorwagner_guimarães_1Pas encore d'évaluation

- 701 Key Start Module Operating Instructions: Author:-John RuddockDocument11 pages701 Key Start Module Operating Instructions: Author:-John RuddockAmir MohammedPas encore d'évaluation

- R250 RegulatorDocument12 pagesR250 Regulatoremerson212121100% (2)

- Dse7520 Installation InstDocument2 pagesDse7520 Installation InstRamon Thales DomeniconiPas encore d'évaluation

- Upgrade AMS 6500 ATG Firmware From Version 1.x To 2.xDocument12 pagesUpgrade AMS 6500 ATG Firmware From Version 1.x To 2.xPaulo LeitePas encore d'évaluation

- West Control STGDocument5 pagesWest Control STGKathiravanRskPas encore d'évaluation

- Parking Cooler System Nitecool Tcc-100: Installation and Service InstructionsDocument12 pagesParking Cooler System Nitecool Tcc-100: Installation and Service Instructionsebuk123Pas encore d'évaluation

- mk2200 ManualDocument56 pagesmk2200 ManualRosmadi AbdullahPas encore d'évaluation

- Digital Voltage Regulator: FeaturesDocument8 pagesDigital Voltage Regulator: Featuresvictor.ciprianiPas encore d'évaluation

- DMN FST Manual Sp-Ec-Rot-Mt Reset Module en 20100713-MsDocument2 pagesDMN FST Manual Sp-Ec-Rot-Mt Reset Module en 20100713-MsadrianpashnicPas encore d'évaluation

- Product Information: Reference OnlyDocument4 pagesProduct Information: Reference Onlyjesus silvaPas encore d'évaluation

- Speed Control of DC Motor Using PWM Meth PDFDocument19 pagesSpeed Control of DC Motor Using PWM Meth PDFMANDULA PRASHANTHPas encore d'évaluation

- InteliLite MRS 16 DatasheetDocument4 pagesInteliLite MRS 16 DatasheetPeter CardonaPas encore d'évaluation

- KUHSEDocument25 pagesKUHSESyed Mohammad Naveed100% (1)

- Gensets CatlogueDocument10 pagesGensets CatloguejengandxbPas encore d'évaluation

- Remote CommunicationDocument4 pagesRemote Communicationwagner_guimarães_1100% (1)

- DEIF TCM 2 Datasheet 4921240329ukDocument6 pagesDEIF TCM 2 Datasheet 4921240329ukAnonymous T3qDfvPas encore d'évaluation

- Gu301 ADocument3 pagesGu301 AJosé Da Silva MataPas encore d'évaluation

- Schedle Maintenance JenbacherDocument3 pagesSchedle Maintenance JenbacherEnrique Garcia0% (1)

- lm386 PDFDocument11 pageslm386 PDFNicolás MoraPas encore d'évaluation

- 5 KVA Engien Alternator-Ashok LeylandDocument7 pages5 KVA Engien Alternator-Ashok LeylandmohdrashidPas encore d'évaluation

- ComAP Powermanagement Load Reserve Calculation - V3Document4 pagesComAP Powermanagement Load Reserve Calculation - V3Luis JesusPas encore d'évaluation

- Mu 2300Document68 pagesMu 2300Nandkumar ChinaiPas encore d'évaluation

- Easypact MVS: CatalogueDocument96 pagesEasypact MVS: Catalogueanant7388Pas encore d'évaluation

- 150RZGDocument4 pages150RZGJorge Andre Olivera Aranibar100% (1)

- Riello G3X Owner ManualDocument16 pagesRiello G3X Owner ManualKonstantaras YiannisPas encore d'évaluation

- Candy Auto Test Za Cld135Document5 pagesCandy Auto Test Za Cld135Zoran KovacevicPas encore d'évaluation

- FA 250 CertificateDocument12 pagesFA 250 CertificateNurocman KelikPas encore d'évaluation

- Carregador CCL Sentinel 150Document8 pagesCarregador CCL Sentinel 150José Da Silva MataPas encore d'évaluation

- Expt 6 The Split Phase MotorDocument4 pagesExpt 6 The Split Phase MotorCapalar KylePas encore d'évaluation

- Cat DSLC PanelDocument5 pagesCat DSLC Paneljuan_34fierroPas encore d'évaluation

- Autostart 700 (Model Numbers AS3/E ) : Engine/Generator Controller Installation Reference SheetDocument2 pagesAutostart 700 (Model Numbers AS3/E ) : Engine/Generator Controller Installation Reference SheetMH..2023Pas encore d'évaluation

- AC31 ConnectDocument40 pagesAC31 ConnectNenoPas encore d'évaluation

- SGPDocument5 pagesSGPgopala krishnanPas encore d'évaluation

- Leroy Somer LSA 50.2 From Macfarlane Generators PDFDocument12 pagesLeroy Somer LSA 50.2 From Macfarlane Generators PDFAnonymous 3RS6JNcPas encore d'évaluation

- Gep 400-4Document33 pagesGep 400-4Sayed Younis SadaatPas encore d'évaluation

- Ataengine Altronic PDFDocument12 pagesAtaengine Altronic PDFdg_cd7340Pas encore d'évaluation

- 1.KW Meter (Kilowatt Meter) : Quick DetailsDocument54 pages1.KW Meter (Kilowatt Meter) : Quick DetailsGerry Dendhi SukmaPas encore d'évaluation

- La501-2t R2 eDocument2 pagesLa501-2t R2 egiathinh123456789100% (1)

- 3WT Accessories: SENTRON Automatic Transfer Controller ATC5300Document1 page3WT Accessories: SENTRON Automatic Transfer Controller ATC5300ersanjeeb_456Pas encore d'évaluation

- InteliCompact NT Datasheet 2011-11 CPLEICNTDocument6 pagesInteliCompact NT Datasheet 2011-11 CPLEICNTThao Nguyen XuanPas encore d'évaluation

- Voltage Regulators - AVR 04-2017Document4 pagesVoltage Regulators - AVR 04-2017S G BavishkumarPas encore d'évaluation

- DSR Report PDFDocument1 pageDSR Report PDFSayed Younis SadaatPas encore d'évaluation

- Entrelec Single Function Timers PDFDocument105 pagesEntrelec Single Function Timers PDFembasianPas encore d'évaluation

- 5 Engine Specification SheetDocument6 pages5 Engine Specification SheetpyrodidoPas encore d'évaluation

- Catalist: Crompton Instruments Preferred Range CatalogueDocument28 pagesCatalist: Crompton Instruments Preferred Range CataloguemunhPas encore d'évaluation

- Thermographic Scanning of Electrical Equipment Kindly Put A Mark in The Box If This Is Included andDocument3 pagesThermographic Scanning of Electrical Equipment Kindly Put A Mark in The Box If This Is Included andCollen Noel MabasaPas encore d'évaluation

- Maintenance Schedule For SubstationDocument21 pagesMaintenance Schedule For SubstationSajid Shaikh100% (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionD'EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Lnterte Course Gas Vapou: MultiDocument21 pagesLnterte Course Gas Vapou: MultiAdel FawziPas encore d'évaluation

- Risk Assessment SheetDocument5 pagesRisk Assessment SheetAdel FawziPas encore d'évaluation

- Mechanical Safety Systems and DSEAR Compliance: M HillsDocument20 pagesMechanical Safety Systems and DSEAR Compliance: M HillsAdel FawziPas encore d'évaluation

- Typical Ramped Voltage Test Result For Epoxy-Mica Winding Insulation (Where The Absorption Current Component Is Relatively Small)Document2 pagesTypical Ramped Voltage Test Result For Epoxy-Mica Winding Insulation (Where The Absorption Current Component Is Relatively Small)Adel FawziPas encore d'évaluation

- Megger TableDocument3 pagesMegger TableAdel FawziPas encore d'évaluation

- Flanged Joint Spigot Joint Screwed Joint: Junction BoxesDocument2 pagesFlanged Joint Spigot Joint Screwed Joint: Junction BoxesAdel FawziPas encore d'évaluation

- مواصفات الكابلاتDocument17 pagesمواصفات الكابلاتAdel FawziPas encore d'évaluation

- Ge Shreveport - Voltage Regulators - Short CourseDocument62 pagesGe Shreveport - Voltage Regulators - Short CourseAdel FawziPas encore d'évaluation

- Sa 083081 enDocument1 pageSa 083081 enAdel FawziPas encore d'évaluation

- Classification of Service-Aged Insulating Oil: 7.1 GeneralDocument2 pagesClassification of Service-Aged Insulating Oil: 7.1 GeneralAdel FawziPas encore d'évaluation

- D923 - 07 Standard Practices For Sampling Electrical Insulating LiquidsDocument14 pagesD923 - 07 Standard Practices For Sampling Electrical Insulating LiquidsAdel Fawzi100% (2)

- Oracle QualitrolDocument1 pageOracle QualitrolAdel FawziPas encore d'évaluation

- Is There Any Advantage To Changing From Sealed Bearings To Non-Sealed Bearings and Providing Greasing Facilities ?Document1 pageIs There Any Advantage To Changing From Sealed Bearings To Non-Sealed Bearings and Providing Greasing Facilities ?Adel FawziPas encore d'évaluation

- Game of ThronesDocument32 pagesGame of ThronesAdel FawziPas encore d'évaluation

- Hany Elhossiny Elhossiny Abdelrahman: EgyptDocument4 pagesHany Elhossiny Elhossiny Abdelrahman: EgyptAdel FawziPas encore d'évaluation

- Circuit Construction Kit Ac Virtual Lab HTML Guide - enDocument4 pagesCircuit Construction Kit Ac Virtual Lab HTML Guide - enkavithaPas encore d'évaluation

- Edc PDFDocument173 pagesEdc PDFsivaPas encore d'évaluation

- L4-Superconductivity Lecture NotesDocument34 pagesL4-Superconductivity Lecture NoteswellplacedcommaPas encore d'évaluation

- Features: 833H - 1A - F - CDocument3 pagesFeatures: 833H - 1A - F - CDaniboy1994Pas encore d'évaluation

- Aristocrat PS Parts List3Document26 pagesAristocrat PS Parts List3German ParceroPas encore d'évaluation

- Ch.4 Lecture Slides For Chenming Hu Book: Modern Semiconductor Devices For ICsDocument79 pagesCh.4 Lecture Slides For Chenming Hu Book: Modern Semiconductor Devices For ICsChenming Hu100% (1)

- On Brick Construction: Technical NotesDocument13 pagesOn Brick Construction: Technical NotesamokhtaPas encore d'évaluation

- Industrial Arts6 WeeK7 MELCDocument70 pagesIndustrial Arts6 WeeK7 MELCEriz Geneveive FernandoPas encore d'évaluation

- Ohm'S Law: General Physics 2Document16 pagesOhm'S Law: General Physics 2ChricellFPas encore d'évaluation

- Metals For Bus BarsDocument19 pagesMetals For Bus BarsYuttapong SupattaravongPas encore d'évaluation

- LABORATORY-EXERCISE (2) Assemblying MultimeterDocument15 pagesLABORATORY-EXERCISE (2) Assemblying MultimeterAliah Joy JunioPas encore d'évaluation

- Com 223 Basic Hardware Maintenance TheoryDocument83 pagesCom 223 Basic Hardware Maintenance TheoryProsper EmonenaPas encore d'évaluation

- High Volume Armature Testing: Lance Straughn Slaughter CompanyDocument10 pagesHigh Volume Armature Testing: Lance Straughn Slaughter Companyronald allan liviocoPas encore d'évaluation

- MAZDA 323 16v I B6Document51 pagesMAZDA 323 16v I B6Ch4ng083% (6)

- PEGS 10008-STD-6-STA-015-R00 - Thermal Insulation Material & Applications PDFDocument136 pagesPEGS 10008-STD-6-STA-015-R00 - Thermal Insulation Material & Applications PDFsuriya100% (1)

- Keystone Fire Alarm Cables (Twisted Pair Non Sheathed)Document3 pagesKeystone Fire Alarm Cables (Twisted Pair Non Sheathed)Edwin LoquinaPas encore d'évaluation

- 4a's Lesson Plan (Resistor Color Coding)Document4 pages4a's Lesson Plan (Resistor Color Coding)Jessa Bahi-an67% (3)

- 380kV CT-VT Calculation C4 Rev D 17.12.09Document137 pages380kV CT-VT Calculation C4 Rev D 17.12.09was00266Pas encore d'évaluation

- Single Phase PreventerDocument17 pagesSingle Phase PreventerAtharv ChitkalwarPas encore d'évaluation

- MCP4011 Digital PotDocument60 pagesMCP4011 Digital Potundes100% (1)

- Impedance and Conductance TestingDocument0 pageImpedance and Conductance Testingjesus_hfPas encore d'évaluation

- Marine Electrical 101Document59 pagesMarine Electrical 101Muhammad Adam100% (1)

- 2365 02 l2 202 Handout 7Document6 pages2365 02 l2 202 Handout 7dvm4yfptzmPas encore d'évaluation

- Transmission MediaDocument19 pagesTransmission MediaIGNACIO, Nemiel (3B)Pas encore d'évaluation

- Nvent RAYCHEM XPI Series Heating Cable High Temperature 4 JDocument2 pagesNvent RAYCHEM XPI Series Heating Cable High Temperature 4 JCataloghi TecniciPas encore d'évaluation

- Physics InvestigatoryDocument24 pagesPhysics InvestigatoryAyushDowerah54% (26)

- Example DC Motor DrivesDocument2 pagesExample DC Motor DrivesSyam Kushaini100% (1)

- 1st - & - 2nd - Sem - Diploma SyllabusDocument50 pages1st - & - 2nd - Sem - Diploma Syllabusvj4249Pas encore d'évaluation

- AC-825IP Hardware Installation and User Manual 200316Document45 pagesAC-825IP Hardware Installation and User Manual 200316Mladin DorianPas encore d'évaluation