Académique Documents

Professionnel Documents

Culture Documents

Property of Lite-On Only Features

Transféré par

BLUEE009Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Property of Lite-On Only Features

Transféré par

BLUEE009Droits d'auteur :

Formats disponibles

LITE-ON

TECHNOLOGY

CORPORATION

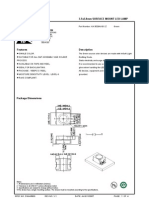

Property of Lite-On Only

Features

* Meet ROHS, Green Product.

* Dual color chip LED.

* Ultra bright InGaN / AlInGaP Chip LED.

* Package in 8mm tape on 7" diameter reels.

* EIA STD package.

* I.C. compatible.

* Compatible with automatic placement equipment.

* Compatible with infrared and vapor phase reflow solder process.

Package Dimensions

Devices

Part No.

Lens

LTST-C195TBKFKT

Water Clear

Source Color

Pin Assignment

InGaN Blue

1,3

AllnGaP Orange

2,4

Notes:

1. All dimensions are in millimeters (inches).

2. Tolerance is 0.10 mm (.004") unless otherwise noted.

Part

No. : LTST-C195TBKFKT

BNS-OD-C131/A4

Page :

of

11

LITE-ON

TECHNOLOGY

CORPORATION

Property of Lite-On Only

Absolute Maximum Ratings At Ta=25C

LTST-C195TBKFKT

Parameter

Unit

Blue

Orange

Power Dissipation

76

75

mW

Peak Forward Current

(1/10 Duty Cycle, 0.1ms Pulse Width)

100

80

mA

DC Forward Current

20

30

mA

0.25

0.4

mA/C

Derating Linear From 25C

Reverse Voltage

Operating Temperature Range

-20C

to + 80C

Storage Temperature Range

-30C

to + 100C

Wave Soldering Condition

260C For 5 Seconds

Infrared Soldering Condition

260C For 5 Seconds

Vapor Phase Soldering Condition

215C For 3 Minutes

Part

No. : LTST-C195TBKFKT

BNS-OD-C131/A4

Page :

of

11

LITE-ON

TECHNOLOGY

CORPORATION

Property of Lite-On Only

Suggestion Profile:

(1) Suggestion IR Reflow Profile For Normal Process

(2) Suggestion IR Reflow Profile For Pb Free Process

R e c o m m e n d e d P r o file B e t w e e n A s s e m b le A n d H e a t-R e s is t a n c e L in e

T h e P ro file is a v a ila b le t h a t m u s t t o u s e S n A g

Part

No. : LTST-C195TBKFKT

BNS-OD-C131/A4

Cu

Page :

s o ld e r p a s t e

of

11

LITE-ON

TECHNOLOGY

CORPORATION

Property of Lite-On Only

Electrical / Optical Characteristics At Ta=25C

Parameter

LTST-C195TBKFKT

Symbol

Luminous Intensity

IV

Unit

Test Condition

90.0

mcd

IF =20mA

Note 1

Blue

Orange

MIN.

18.0

45.0

TYP.

45.0

MAX.

21/2

TYP.

130

130

deg

Note 2 (Fig.6)

Peak Emission Wavelength

TYP.

468

611

nm

Measurement

@Peak (Fig.1)

Dominant Wavelength

TYP.

470

605

nm

IF =20mA

Note 3

Spectral Line Half-Width

TYP.

25

17

nm

MIN.

2.90

1.80

TYP.

3.30

2.00

MAX.

3.50

2.40

Viewing Angle

Forward Voltage

VF

IF =20mA

Reverse Current

IR

MAX.

10

10

VR = 5V

Capacitance

TYP.

40

PF

VF=0, f=1MHZ

Notes: 1. Luminous intensity is measured with a light sensor and filter combination that approximates the

CIE eye-response curve.

2. 1/2 is the off-axis angle at which the luminous intensity is half the axial luminous intensity.

3. The dominant wavelength,d is derived from the CIE chromaticity diagram and represents the

single wavelength which defines the color of the device.

4. Caution in ESD:

Static Electricity and surge damages the LED. It is recommend to use a wrist band or anti-electrostatic glove

when handling the LED. All devices, equipment and machinery must be properly grounded.

Part

No. : LTST-C195TBKFKT

BNS-OD-C131/A4

Page :

of

11

LITE-ON

TECHNOLOGY

CORPORATION

Property of Lite-On Only

Bin Code List

Forward Voltage

Color : Blue , Unit: V @20mA

12

2.90

3.00

13

3.00

3.10

14

3.10

3.20

15

3.20

3.30

16

3.30

3.40

17

3.40

3.50

Tolerance on each Forward Voltage bin is +/-0.1 volt

Luminous Intensity

Color : Blue , Unit : mcd @20mA

Bin Code

Min.

Max.

18.0

28.0

28.0

45.0

45.0

71.0

71.0

112.0

Luminous Intensity

Color : Orange , Unit : mcd @20mA

Bin Code

Min.

Max.

45.0

71.0

71.0

112.0

112.0

180.0

Tolerance on each Intensity bin is +/-15%

Part

No. : LTST-C195TBKFKT

BNS-OD-C131/A4

Page :

of

11

LITE-ON

TECHNOLOGY

CORPORATION

Property of Lite-On Only

Typical Electrical / Optical Characteristics Curves

(25C Ambient Temperature Unless Otherwise Noted)

Part

No. : LTST-C195TBKFKT

BNS-OD-C131/A4

Page :

of

11

LITE-ON

TECHNOLOGY

CORPORATION

Property of Lite-On Only

Cleaning

Do not use unspecified chemical liquid to clean LED they could harm the package.

If clean is necessary, immerse the LED in ethyl alcohol or in isopropyl alcohol at normal temperature

for less one minute.

Suggest Soldering Pad Dimensions

Package Dimensions Of Tape And Reel

Notes:

1. All dimensions are in millimeters (inches).

Part

No. : LTST-C195TBKFKT

BNS-OD-C131/A4

Page :

of

11

LITE-ON

TECHNOLOGY

CORPORATION

Property of Lite-On Only

Notes:

1. Empty component pockets sealed with top cover tape.

2. 7 inch reel-4000 pieces per reel.

3. Minimum packing quantity is 500 pcs for remainders.

4. The maximum number of consecutive missing lamps is two.

5. In accordance with ANSI/EIA 481-1-A-1994 specifications.

Part

No. : LTST-C195TBKFKT

BNS-OD-C131/A4

Page :

of

11

LITE-ON

TECHNOLOGY

CORPORATION

Property of Lite-On Only

CAUTIONS

1. Application

The LEDs described here are intended to be used for ordinary electronic equipment (such as office

equipment, communication equipment and household applications).Consult Liteons Sales in advance

for information on applications in which exceptional reliability is required, particularly when the failure

or malfunction of the LEDs may directly jeopardize life or health (such as in aviation, transportation,

traffic control equipment, medical and life support systems and safety devices).

2. Storage

The storage ambient for the LEDs should not exceed 30C temperature or 70% relative humidity.

It is recommended that LEDs out of their original packaging are IR-reflowed within one week.

For extended storage out of their original packaging, it is recommended that the LEDs be stored in a

sealed container with appropriate desiccant, or in a desiccators with nitrogen ambient.

LEDs stored out of their original packaging for more than a week should be baked at about 60 deg C

for at least 24 hours before solder assembly.

3. Cleaning

Use alcohol-based cleaning solvents such as isopropyl alcohol to clean the LED if necessary.

4. Soldering

Recommended soldering conditions:

Reflow soldering

Pre-heat

Pre-heat time

Peak temperature

Soldering time

120~150C

120 sec. Max.

240C Max.

10 sec. Max.

Wave Soldering

Pre-heat

Pre-heat time

Solder wave

Soldering time

Soldering iron

100C Max.

60 sec. Max.

260C Max.

10 sec. Max.

Temperature

Soldering time

300C Max.

3 sec. Max.

(one time only)

5. Drive Method

An LED is a current-operated device. In order to ensure intensity uniformity on multiple LEDs

connected in parallel in an application, it is recommended that a current limiting resistor be incorporated

in the drive circuit, in series with each LED as shown in Circuit A below.

Circuit model A

LED

Circuit model B

LED

(A) Recommended circuit.

(B) The brightness of each LED might appear different due to the differences in the I-V characteristics

of those LEDs.

6. ESD (Electrostatic Discharge)

Static Electricity or power surge will damage the LED.

Suggestions to prevent ESD damage:

Part

Use of a conductive wrist band or anti-electrostatic glove when handling these LEDs.

All devices, equipment, and machinery must be properly grounded.

Work tables, storage racks, etc. should be properly grounded.

Use ion blower to neutralize the static charge which might have built up on surface of the LEDs

plastic lens as a result of friction between LEDs during storage and handling.

No. : LTST-C195TBKFKT

BNS-OD-C131/A4

Page :

of

11

LITE-ON

TECHNOLOGY

CORPORATION

Property of Lite-On Only

ESD-damaged LEDs will exhibit abnormal characteristics such as high reverse leakage current, low

forward voltage, or no lightup at low currents.

To verify for ESD damage, check for lightup and Vf of the suspect LEDs at low currents.

The Vf of good LEDs should be >2.0V@0.1mA for InGaN product and >1.4V@0.1mA for AlInGaP

product.

7. Reliability Test

Test Item

Classification

MIL-STD-750D:1026

MIL-STD-883D:1005

JIS C 7021:B-1

High Temperature

High Humidity

Storage

IR-Reflow In-Board, 2 Times

Ta= 655,RH= 9095%

*Test Time= 240HRS2HRS

MIL-STD-202F:103B

JIS C 7021:B-11

High Temperature

Storage

Ta= 1055

*Test Time= 1000HRS (-24HRS,+72HRS)

MIL-STD-883D:1008

JIS C 7021:B-10

Low Temperature

Storage

Ta= -555

*Test Time=1000HRS (-24HRS,+72H RS)

JIS C 7021:B-12

105 25 -55 25

30mins 5mins

30mins 5mins

10 Cycles

MIL-STD-202F:107D

MIL-STD-750D:1051

MIL-STD-883D:1010

JIS C 7021:A-4

IR-Reflow In-Board, 2 Times

85 5 -40 5

10mins

10mins 10 Cycles

MIL-STD-202F:107D

MIL-STD-750D:1051

MIL-STD-883D:1011

T.sol= 260 5

Dwell Time= 10 1secs

MIL-STD-202F:210A

MIL-STD-750D:2031

JIS C 7021:A-1

MIL-STD-750D:2031.2

J-STD-020C

IR-Reflow

Normal Process

Ramp-up rate(183 to Peak) +3/ second max

Temp. maintain at 125(25) 120 seconds max

Temp. maintain above 183 60-150 seconds

Peak temperature range 235+5/-0

Time within 5C of actual Peak Temperature (tp)

10-30 seconds

Ramp-down rate +6/second max

MIL-STD-750D:2031.2

J-STD-020C

IR-Reflow

Pb Free Process

Ramp-up rate(217 to Peak) +3/ second max

Temp. maintain at 175(25) 180 seconds max

Temp. maintain above 217 60-150 seconds

Peak temperature range 260+0/-5

Time within 5C of actual Peak Temperature (tp)

20-40 seconds

Ramp-down rate +6/second max

T.sol= 235 5

Immersion time 20.5 sec

Immersion rate 252.5 mm/sec

Coverage 95% of the dipped surface

MIL-STD-202F:208D

MIL-STD-750D:2026

MIL-STD-883D:2003

IEC 68 Part 2-20

JIS C 7021:A-2

Temperature

Cycling

Thermal

Shock

Solder

Resistance

Environmental

Test

Reference Standard

Ta= Under Room Temperature As Per Data Sheet

Maximum Rating

*Test Time= 1000HRS (-24HRS,+72HRS)*@20mA.

Operation Life

Endurance

Test

Test Condition

Solderability

8. Others

The appearance and specifications of the product may be modified for improvement without prior notice.

Part

No. : LTST-C195TBKFKT

BNS-OD-C131/A4

Page :

10

of

11

LITE-ON

TECHNOLOGY

CORPORATION

Property of Lite-On Only

9. Suggested Checking List

Training and Certification

1. Everyone working in a static-safe area is ESD-certified?

2. Training records kept and re-certification dates monitored?

Static-Safe Workstation & Work Areas

1. Static-safe workstation or work-areas have ESD signs?

2. All surfaces and objects at all static-safe workstation and within 1 ft measure less than 100V?

3. All ionizer activated, positioned towards the units?

4. Each work surface mats grounding is good?

Personnel Grounding

1. Every person (including visitors) handling ESD sensitive (ESDS) items wears wrist strap, heel

strap or conductive shoes with conductive flooring?

2. If conductive footwear used, conductive flooring also present where operator stand or walk?

3. Garments, hairs or anything closer than 1 ft to ESD items measure less than 100V*?

4. Every wrist strap or heel strap/conductive shoes checked daily and result recorded for all DLs?

5. All wrist strap or heel strap checkers calibration up to date?

Note: *50V for Blue LED.

Device Handling

1. Every ESDS items identified by EIA-471 labels on item or packaging?

2. All ESDS items completely inside properly closed static-shielding containers when not at

static-safe workstation?

3. No static charge generators (e.g. plastics) inside shielding containers with ESDS items?

4. All flexible conductive and dissipative package materials inspected before reuse or recycles?

Others

1. Audit result reported to entity ESD control coordinator?

2. Corrective action from previous audits completed?

3. Are audit records complete and on file?

Part

No. : LTST-C195TBKFKT

BNS-OD-C131/A4

Page :

11

of

11

Vous aimerez peut-être aussi

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsD'EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsPas encore d'évaluation

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- Refrigerator Service Manual GuideDocument50 pagesRefrigerator Service Manual GuideLarry JohnsonPas encore d'évaluation

- Commissioning Switches, Automatic TransferDocument44 pagesCommissioning Switches, Automatic Transferbookbum100% (5)

- Beginning Digital Electronics through ProjectsD'EverandBeginning Digital Electronics through ProjectsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Catalogue Long RodDocument10 pagesCatalogue Long RodTravis WoodPas encore d'évaluation

- Express Encore Battery Charger Service Manual: Model: Exe3Document56 pagesExpress Encore Battery Charger Service Manual: Model: Exe3ING. RUBENSPas encore d'évaluation

- Tesla SwitchDocument47 pagesTesla Switchlittledigger75% (8)

- Saes P 101Document9 pagesSaes P 101nuriaPas encore d'évaluation

- Tutorial - 4: Practice ProblemsDocument4 pagesTutorial - 4: Practice ProblemsParthaMoulikPas encore d'évaluation

- Advanced Microwave Circuits and Ed by Vitaliy Zhurbenko 2010)Document499 pagesAdvanced Microwave Circuits and Ed by Vitaliy Zhurbenko 2010)Luqiao Liu100% (3)

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1D'EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Évaluation : 4.5 sur 5 étoiles4.5/5 (3)

- LHIR13743 T50 (光源)Document5 pagesLHIR13743 T50 (光源)WenChenPas encore d'évaluation

- lsd815 65 XX PFDocument9 pageslsd815 65 XX PFDavid MoodyPas encore d'évaluation

- Foto TransistorDocument7 pagesFoto TransistorMilton Eiji TakamuraPas encore d'évaluation

- Data SheetDocument9 pagesData SheetSerci ZasaPas encore d'évaluation

- PT1302B C2Document7 pagesPT1302B C2G Ivan Torres RPas encore d'évaluation

- Sensor Itr 8102 EncoderDocument6 pagesSensor Itr 8102 EncoderburdadebueyPas encore d'évaluation

- Technical Data Sheet Opto Interrupter: FeaturesDocument6 pagesTechnical Data Sheet Opto Interrupter: FeaturesAntonio CarrascoPas encore d'évaluation

- Technical Data Sheet 5mm Infrared LED, T-1 3/4: FeaturesDocument7 pagesTechnical Data Sheet 5mm Infrared LED, T-1 3/4: Featureskathycrisostomo27Pas encore d'évaluation

- 1.6X0.8Mm SMD Chip Led Lamp: AttentionDocument4 pages1.6X0.8Mm SMD Chip Led Lamp: AttentionTiago SilvaPas encore d'évaluation

- 3.2x1.6mm SMD CHIP LED LAMPDocument5 pages3.2x1.6mm SMD CHIP LED LAMPRicardo TrombettaPas encore d'évaluation

- Kingbright RGB Round LedDocument8 pagesKingbright RGB Round LedcybertechnicoPas encore d'évaluation

- Led InfrarrojoDocument7 pagesLed InfrarrojoPatrick SteinerPas encore d'évaluation

- Led RGB Super Bright SMD1206Document4 pagesLed RGB Super Bright SMD1206Mamduh Dliyaul JawwadPas encore d'évaluation

- IR TXN Data Sheet (IR 333)Document7 pagesIR TXN Data Sheet (IR 333)Justin JosePas encore d'évaluation

- TLP291 4 PDFDocument14 pagesTLP291 4 PDFBruno SilvaPas encore d'évaluation

- Especificacion Tecnica LEDDocument10 pagesEspecificacion Tecnica LEDJorge Herrero GarcíaPas encore d'évaluation

- Datasheet Led InfrarrojoDocument7 pagesDatasheet Led InfrarrojoAlfonso OsorioPas encore d'évaluation

- Datasheet ET1100Document10 pagesDatasheet ET1100Manal FeghaliPas encore d'évaluation

- Data Sheet For 8mm Super Bright White LED Dip Type 1/2watt High Power LED SeriesDocument2 pagesData Sheet For 8mm Super Bright White LED Dip Type 1/2watt High Power LED SeriesEtbn SnoaPas encore d'évaluation

- Everlight Electronics Co., LTD.: Infrared Remote-Control Receiver ModuleDocument8 pagesEverlight Electronics Co., LTD.: Infrared Remote-Control Receiver ModuleW Percy Huallpa CalizayaPas encore d'évaluation

- TA8207K Audio Power ICDocument10 pagesTA8207K Audio Power ICgusguicorPas encore d'évaluation

- T-1 3/4 (5Mm) Full Color Led Lamp: AttentionDocument9 pagesT-1 3/4 (5Mm) Full Color Led Lamp: AttentionAdindanvrynPas encore d'évaluation

- PT928 6C F DatasheetDocument7 pagesPT928 6C F DatasheetLuis PintoPas encore d'évaluation

- Circuito Integrado TA8207KDocument11 pagesCircuito Integrado TA8207KIberê CamposPas encore d'évaluation

- 0.36-Inch Single Digit Green LED Displays Technical Data SheetDocument5 pages0.36-Inch Single Digit Green LED Displays Technical Data SheetreybimPas encore d'évaluation

- TA8248K Audio Power Amplifier ICDocument12 pagesTA8248K Audio Power Amplifier ICsontuyet82100% (1)

- Programmable Controllers AC / DC Input Module TelecommunicationDocument10 pagesProgrammable Controllers AC / DC Input Module TelecommunicationFidel ArroyoPas encore d'évaluation

- DS-0035 3W PM2L-3LLx-SD v1.6Document13 pagesDS-0035 3W PM2L-3LLx-SD v1.6Pavan KumarPas encore d'évaluation

- Datasheet Fotoacoplador EL817Document13 pagesDatasheet Fotoacoplador EL817Manoel Alves Feitosa FilhoPas encore d'évaluation

- Technical Data Sheet Opto Interrupter: FeaturesDocument6 pagesTechnical Data Sheet Opto Interrupter: FeaturesKRATOS_SPas encore d'évaluation

- Technical Data Sheet 0.56" Quadruple Digit SMD Displays: ELSF-511SYGWA/S530-E2Document8 pagesTechnical Data Sheet 0.56" Quadruple Digit SMD Displays: ELSF-511SYGWA/S530-E2StuxnetPas encore d'évaluation

- 5mm RGB Led Common CathodeDocument3 pages5mm RGB Led Common CathodeThushaniDeSilvaPas encore d'évaluation

- Foto Transistor 2Document7 pagesFoto Transistor 2Daly Carrasco MoralƏsPas encore d'évaluation

- Everlight Electronics Co.,Ltd.: Technical Data Sheet Infrared Remote-Control Receiver ModuleDocument10 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet Infrared Remote-Control Receiver ModulemajetulinPas encore d'évaluation

- Preliminary Spec: 10Mm (0.4inch) Dual Digit Numeric DisplayDocument4 pagesPreliminary Spec: 10Mm (0.4inch) Dual Digit Numeric DisplaycepimasterodroPas encore d'évaluation

- Optoacoplador 4n35Document8 pagesOptoacoplador 4n35zethramPas encore d'évaluation

- Digital Logic Ground Isolation Line Receiver Microprocessor System Interfaces Switching Power Supply Feedback Control Analog Signal IsolationDocument8 pagesDigital Logic Ground Isolation Line Receiver Microprocessor System Interfaces Switching Power Supply Feedback Control Analog Signal IsolationPétrus HoangPas encore d'évaluation

- Luckylight: 0.56" Triple Digit Numeric Displays Technical Data SheetDocument6 pagesLuckylight: 0.56" Triple Digit Numeric Displays Technical Data SheetSergiu BadalutaPas encore d'évaluation

- Everlight Electronics Co.,Ltd.: 5.0mm Round Type LED Lamps Part No.: FeaturesDocument4 pagesEverlight Electronics Co.,Ltd.: 5.0mm Round Type LED Lamps Part No.: FeaturesDhuck DhPas encore d'évaluation

- LTST C170GKTDocument7 pagesLTST C170GKTsnobic9379Pas encore d'évaluation

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.8" Single Digit DisplaysDocument6 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.8" Single Digit DisplaysStuxnetPas encore d'évaluation

- NDL7910P: Laser DiodeDocument9 pagesNDL7910P: Laser DiodeEdgar Ernesto Alonso GuadalupePas encore d'évaluation

- 3.5x2.8mm SURFACE MOUNT LED SPECDocument4 pages3.5x2.8mm SURFACE MOUNT LED SPECBab AbaPas encore d'évaluation

- Flame SensorDocument6 pagesFlame SensorGst Agung Ngrh ArjayaPas encore d'évaluation

- TLP741G: Office Machine Household Use Equipment Solid State Relay Switching Power SupplyDocument6 pagesTLP741G: Office Machine Household Use Equipment Solid State Relay Switching Power SupplyFranz WagnerPas encore d'évaluation

- 1W High Power LEDDocument16 pages1W High Power LEDCalvin BurtPas encore d'évaluation

- Rclamp 7535 MDocument9 pagesRclamp 7535 MAlan jorgePas encore d'évaluation

- Data Sheet: Thyristors Logic LevelDocument9 pagesData Sheet: Thyristors Logic LevelEduardo Ulises Maldonado IbañezPas encore d'évaluation

- 2W Mono Amplifier: DescriptionDocument6 pages2W Mono Amplifier: DescriptionMiloud ChouguiPas encore d'évaluation

- White Backlight LED Technical SpecificationDocument6 pagesWhite Backlight LED Technical SpecificationanzuresinkPas encore d'évaluation

- Datasheet LEDDocument4 pagesDatasheet LEDevhyajahPas encore d'évaluation

- Analog Devices PSRRDocument3 pagesAnalog Devices PSRRBLUEE009Pas encore d'évaluation

- Charge PumpsDocument18 pagesCharge PumpsBLUEE009Pas encore d'évaluation

- Class D Audio Amplifier Basics PDFDocument14 pagesClass D Audio Amplifier Basics PDFJulian De MarcosPas encore d'évaluation

- Tact SMD Horizontal RohsDocument1 pageTact SMD Horizontal RohsBLUEE009Pas encore d'évaluation

- NPN BRT Dtc143tm3t5g (Sot-723) RohsDocument10 pagesNPN BRT Dtc143tm3t5g (Sot-723) RohsBLUEE009Pas encore d'évaluation

- Ssm3k36mfv 0.5a20v Sot-VesmDocument5 pagesSsm3k36mfv 0.5a20v Sot-VesmBLUEE009Pas encore d'évaluation

- Esd Esd9b5.0st5g 5v 1a Sod923 RohsDocument4 pagesEsd Esd9b5.0st5g 5v 1a Sod923 RohsBLUEE009Pas encore d'évaluation

- Led Philips Flash Led 2.04X1.64X0 - 0.7MMDocument13 pagesLed Philips Flash Led 2.04X1.64X0 - 0.7MMBLUEE009Pas encore d'évaluation

- LQP03TN - 02 Series 0603 (MM) 0201 (Inch)Document4 pagesLQP03TN - 02 Series 0603 (MM) 0201 (Inch)BLUEE009Pas encore d'évaluation

- TR Pmos Fdma905p - 10a-12v Microfet 2x2Document6 pagesTR Pmos Fdma905p - 10a-12v Microfet 2x2BLUEE009Pas encore d'évaluation

- VARISTOR CHIP 5.5V20A 100PF 0402 RoHSDocument10 pagesVARISTOR CHIP 5.5V20A 100PF 0402 RoHSBLUEE009Pas encore d'évaluation

- 20 PDocument1 page20 PBLUEE009Pas encore d'évaluation

- LQG15HS Series (0402 Size)Document2 pagesLQG15HS Series (0402 Size)BLUEE009Pas encore d'évaluation

- Led Red Green SMD 4p 0.80x1.6x0.55mmDocument12 pagesLed Red Green SMD 4p 0.80x1.6x0.55mmBLUEE009Pas encore d'évaluation

- Miniflex 5-Bfn Ii: 0.5mm PitchDocument2 pagesMiniflex 5-Bfn Ii: 0.5mm PitchBLUEE009Pas encore d'évaluation

- FUSB2500 FullDocument56 pagesFUSB2500 FullBLUEE009Pas encore d'évaluation

- SMD Led: Product Data SheetDocument16 pagesSMD Led: Product Data SheetBLUEE009Pas encore d'évaluation

- Host-Side Single Cell Lithium Battery Gauge: General Description FeaturesDocument14 pagesHost-Side Single Cell Lithium Battery Gauge: General Description FeaturesBLUEE009Pas encore d'évaluation

- Fpf1203 / Fpf1203L / Fpf1204 / Fpf12045: Intellimax™ Ultra-Small, Slew-Rate-Controlled Load SwitchDocument12 pagesFpf1203 / Fpf1203L / Fpf1204 / Fpf12045: Intellimax™ Ultra-Small, Slew-Rate-Controlled Load SwitchBLUEE009Pas encore d'évaluation

- Aluminum Electrolytic Capacitors GuideDocument193 pagesAluminum Electrolytic Capacitors GuidePaola Segura CorreaPas encore d'évaluation

- AMTNoT013 02Document44 pagesAMTNoT013 02Long LeoPas encore d'évaluation

- Reliability 1Document71 pagesReliability 1AyoPas encore d'évaluation

- Plano Electrico Cargador 938KDocument34 pagesPlano Electrico Cargador 938KANDRES FUENTES FANDIÑOPas encore d'évaluation

- 22 Calculated Magnetic Properties of Co Doped CdTe V P - 2017 - Computational CondDocument4 pages22 Calculated Magnetic Properties of Co Doped CdTe V P - 2017 - Computational CondMounia El YousfiPas encore d'évaluation

- CAN Data Link (RENR5059)Document3 pagesCAN Data Link (RENR5059)PramodPas encore d'évaluation

- MBR10150CTDocument3 pagesMBR10150CTluis_h_t_79Pas encore d'évaluation

- Type Testing A 420 KV 63 Ka 50 and 60 HZ Circuit Breaker Based On C4 FNCO2O2 Mixture TechnologyDocument10 pagesType Testing A 420 KV 63 Ka 50 and 60 HZ Circuit Breaker Based On C4 FNCO2O2 Mixture TechnologyChiranjeev SahooPas encore d'évaluation

- DiodeDocument16 pagesDiodeGilberto ManhattanPas encore d'évaluation

- Siemens PLM Using Simulation To Address NVH Issues of Hybrid and Electric Vehicles - White Paper - tcm27-58304Document8 pagesSiemens PLM Using Simulation To Address NVH Issues of Hybrid and Electric Vehicles - White Paper - tcm27-58304Henry MenaPas encore d'évaluation

- LBX 9014DS VTMDocument2 pagesLBX 9014DS VTMAlex PereiraPas encore d'évaluation

- Lagos City Polytechnic: Lecture NoteDocument28 pagesLagos City Polytechnic: Lecture NoteOlatidoye EzekielPas encore d'évaluation

- ATRT-03A S2: Automatic, 3-Phase Transformer Turns Ratio TesterDocument6 pagesATRT-03A S2: Automatic, 3-Phase Transformer Turns Ratio TesterBRSantanaPas encore d'évaluation

- Highschool ScienceDocument13 pagesHighschool SciencejjjjPas encore d'évaluation

- SIGNAL & TOWER LIGHT GUIDEDocument11 pagesSIGNAL & TOWER LIGHT GUIDEJafet CabreraPas encore d'évaluation

- OnGrid - Off.hybrid - Solutions (1) .PDF Version 1Document8 pagesOnGrid - Off.hybrid - Solutions (1) .PDF Version 1Reymart ManablugPas encore d'évaluation

- EE 302 Final Exam and Histogram F12 PDFDocument4 pagesEE 302 Final Exam and Histogram F12 PDFAnonymous BKSqKEQhnuPas encore d'évaluation

- Transfer Function and Impulse Response Simulation of Power Line ChannelDocument7 pagesTransfer Function and Impulse Response Simulation of Power Line ChannelIjsrnet EditorialPas encore d'évaluation

- Dieu Khien Smartgen - HGM6110,6120 (EN)Document5 pagesDieu Khien Smartgen - HGM6110,6120 (EN)khanh khanhPas encore d'évaluation

- Computer Network Architecture GuideDocument19 pagesComputer Network Architecture GuideCarl CarlPas encore d'évaluation

- EM Scale ModellingDocument7 pagesEM Scale ModellingMahesh GorlePas encore d'évaluation

- Durabrand DCT1303R - DCT1903R Manual de ServicioDocument55 pagesDurabrand DCT1303R - DCT1903R Manual de ServicioaldoPas encore d'évaluation