Académique Documents

Professionnel Documents

Culture Documents

An Open Architecture Approach To Kinematic Analysis For Computer Aided Embodiment Design

Transféré par

jtorerocTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

An Open Architecture Approach To Kinematic Analysis For Computer Aided Embodiment Design

Transféré par

jtorerocDroits d'auteur :

Formats disponibles

PII: SOOlO-4485(97)00058-4

Computer-Aided

&sign, Vol. 30. No. 3, pp. 199-204, 1999

0 1999 Elsevier Science Ltd. All rights reserved

Printed in Great Britain

0010~4495/99i$19.00+oo.oo

An open architecture approach

to kinematic analysis for

computer-aided embodiment

design

Aylmer L Johnson

components such as shafts, cranks, and links; these carry

pointers to appropriate design rules which, given a set of

externally applied loads, allow the software to determine

suitable dimensions

for their satisfactory performance.

Once the dimensions have been chosen, the components

are able to make direct calls to one of the new generation

of core solid modeller libraries*, to generate the resulting

solid model without user intervention. Use of the technique

thus simply involves describing a proposed design in terms

of functional primitives instead of geometric primitives, and

can be conveniently termed functional modelling.

For many mechanical designs, a major element of the

loading on each component comes from the inertia of the

moving parts within the design. This effectively makes

the loads a dependent variable in the problem: redesigning

one moving part for greater strength will cause additional

loads on the other parts, as the redesigned part will also have

a greater inertia. The resulting design process therefore

inevitably becomes iterative, though it is usually convergent

for conceptually feasible designs.

These factors have raised the need for kinematic analysis

software which functions in a similar way to the solid

modelling functionality

described above. Most kinematic

packages, such as Mechanicas Applied Motion are used

via a graphical user interface: the requirement

for this

analysis is that it must be accessed directly from the

functional

modeller itself. Specifically,

procedures

are

required which can define the kinematic model, accept

specified input motions,

and calculate

the resulting

accelerations

of all the moving parts. This information

must then be combined with the mass and principal inertias

of each part to calculate the positions and magnitudes of the

inertia loads. Finally, these inertia loads must be combined

with other external loads on the design, and the resulting

interface forces between the parts of the design must be

calculated.

The remainder of this paper describes the resulting

software, which has been named Promech, and explains

the approaches which have been used to realise this

specification.

It should be emphasised that the present

requirement extends only to analysing mechanisms whose

conceptual intent has already been explicitly stated: this

work therefore differs in its goal from that of researchers

such as Gelsey loor Joskowicz , whose principal aim is to

In addition to providing tools for the conceptual design of

mechanisms, kinematic analysis is needed for the calculation of

inertia loads in mechanisms during the embodiment phase of

design. The goal of creating a computer-aided

embodiment

generator has raised the need to package this kinematic analysis

such that it can be invoked directly, without the need for a separate

user interface. This paper describes a set of kinematic and dynamic

analysis procedures which have been developed for this purpose,

explains how they work, and discusses their significance in the

progress of computer-aided embodiment generation. 0 1998

Elsevier Science Ltd. All rights reserved

Keywords: functional modelling, kinematic analysis, dynamic

analysis

INTRODUCTION

Traditional

computer-aided

design has tended to focus

largely on recording the shapes of proposed designs, as

specified by the designer. Some significant advances have

now been made in the direction of allowing shapes to be

generated automatically: either through parametric design ,

or by allowing users to specify design rules to be applied

under specific, well-defined conditions2. A more long-term

line of research at the Cambridge Engineering

Design

Centre is attempting to tackle the problem of generalised

embodiment design: that is, the fleshing out of conceptual

solution to almost any type of mechanical problem such that

the components

are automatically

assigned dimensions

which will guarantee their ability to carry out their intended

functions.

The details of the approach, the problems which it has

raised, and the current solutions to those problems have

been extensively

reported elsewhere3-.

The technique

essentially involves describing the parts of a proposed

design in terms of commonly

understood

engineering

Engineering Design Centre, Cambridge University, Trumpington Street,

Cambridge CB2 lF2, UK

199

Open architecture

kinematic analysis:

infer the kinematic behaviour

physical shape of its parts.

A L Johnson

of a mechanism

from the

KINEMATIC INTERFACES

Designers who have attempted to specify three-dimensional

kinematic models will be well aware of the difficulty of

creating models which are not over- or under-constrained.

This difficulty is clearly made worse when (as in this case)

there is a requirement for the kinematic model to be

generated automatically from the initial, component-oriented,

description.

The approach to kinematic interfaces adopted in Promech

addresses this problem in two ways. Firstly, the kinematic

pairs between bodies are not specified explicitly by the user,

but are defined implicitly from the relevant features of the

two parts involved in the pair. For instance, if an offset

section of a crankshaft (i.e., a short length of shaft) is

connected to the big end of a connecting rod, a revolute

joint is automatically

implied: the combination

of a

cylindrical shaft and a cylindrical hole whose depth is not

negligible means that the joint must either be cylindrical or

revolute; and the crank webs at each end of the section of

shaft imply that the connecting rod cannot slide along the

shaft, making the joint revolute.

Secondly, the software has been written to make it easy to

relax some of the constraints implied by the joints, without

the need to re-specify the features of either part. For

instance, the connecting rod mentioned above might be

re-declared by the software to have a very short hole through

it, if the longer hole had the effect of over-constraining

it:

this effectively converts the revolute joint into a spherical

joint, without the need to redefine any physical aspect of the

bodies involved in the joint.

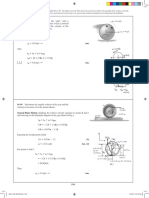

The kinematic pairs which Promech can currently handle

are made up from all possible combinations of the features

shown in Figure 1. A shaft element can be plain, or it can

have a circlip (to prevent axial motion) and/or a keyway (to

prevent rotation about its own axis). Likewise, holes can

either be shallow or deep, and in addition can either

The combination

rules are

be circular or slotted.

Groove

for Circlip

Keyway

08 nil

6 w

exceedingly simple: any type of shaft can be paired with

any type of hole. One of resulting combinations is trivial as

it implies a solid joint: the remaining 15 include five of the

six possible types of Lower Pair joints, plus 10 of the more

common types of Upper Pair joints found in mechanical

systems. Figure 1 shows these combinations

graphically,

and records for each pair the set of Joint Primitives which

are needed to describe it. The exact definition of the Joint

Primitives used by Promech is given in the next section.

SIMPLIFICATION OF THE KINEMATIC

CONSTRAINTS

Static constraints

As explained above, each combination of a shaft type with a

hole type gives a different kinematic pair. The analysis of

these 1.5 pairs is simplified considerably by specifying a

set of more basic kinematic constraints than the classic

pairs (cylindrical,

spherical etc.) which are used in the

literature 12. Packages such as ADAMS I3 and TLA14 have

already exploited

this finding,

and use seven Joint

Primitives to model their kinematic constraints. Promech

also uses seven Joint Primitives, but they have been defined

in a slightly different way so that they can be processed by

an even smaller number of sub-primitives, which have been

termed Vector Constraints.

The first step is to define four vectors for the shaft element

in each joint, and four for the hole element, as shown in

Figure 2. These vectors are held in terms of their respective

bodys local co-ordinate

system for storage, but are

converted to a common or global co-ordinate

system

when they are required for the kinematic analysis.

Vectors S and H define reference points on the centrelines

of the shaft and the hole, respectively: nominally, at the base

of the shaft and at the start of the hole. If the hole is circular

and a circlip is specified for the shaft, the requirement is

generated that the reference point on the shaft must be

coincident with the reference point of the hole.

Vectors S2 and H2 define reference directions on the

shaft and hole perpendicular

to their respective axes. If

the shaft has a keyway, the requirement is generated that

S2 must either point in the same direction as H2, or must at

least lie in the plane defined by H2 and Hl.

Finally, vectors S3 and H3 are defined as the cross

products of (Sl X S2) and (Hl X H2), respectively. This

creates a set of three mutually orthogonal directions for the

shaft and the hole, which are convenient for specifying the

Joint Primitives.

Table 1 shows the set of seven Joint Primitives used in

Promech, and gives a verbal and vectorial definition of each

of them. The final column of the table shows the number of

restraints (rotational or translational) which each of these

PLANAA

w

+A

$R

@A

$A

+A

@T

SPHERICAL

CPS

$A

a:

cD

Figure 1

200

4A

CYLINDRICAL

@p

Feature combination

REVCUTE

4s

PRISMATIC

and joint types.

+p

Figure 2

Vectors for shafts and holes

Open architecture kinematic analysis: A L Johnson

Table 1

Basic kinematic

constraints

Symbol

Description

Sliding constraint:

Axial constraint:

hole reference point on shaft base plane

hole reference point on shaft axis

Lateral constraint:

Crossing constraint:

Parallel constraint:

Twisting constraint:

= 0

(S - H)S2

(S - H)S3

= 0

= 0

(S - H).Hl = 0

(S - H).H3 = 0

shaft passes through slot line

(S - H) X H2)Sl

main axes parallel

Sl.H2

Sl.H3

shaft cant rotate about own axis

shaft axis parallel to plane of pocket

constraints imposes between the two bodies. Finally, the

cells in Figure 1 show which of these Joint Primitives is

required for each of the 15 kinematic pairs which Promech

currently allows.

The analysis can now be simplified still further by

observing the similarities

between the first three Joint

Primitives shown in Table I, and between the last three.

Promech carries out the position analysis5 of the mechanism

by means of a constraint matrix, the assembly of which is

carried out by just three procedures:

(1) ALIGN(V) which sets {(S - H).V= 0) and so carries

of 4S, ~#JAand 4L;

(2) CROSS which carries out the function of 4X;

(3) SETSQ(n,m) which sets {Sn.Hm = 0) and so carries

out the functions of 4P, 4T and 4R.The use of these

three vector constraints to analyse 15 types of kinematic

pairs compares favourably with, for instance, TLAs

use of seven Joint Primitives to analyse seven types of

kinematic pairs 14.

Driving constraints

In addition to the static kinematic constraints implied by the

joints between the various parts of the mechanism, so-called

driving constraints

must be specified to give it motion.

Promech currently allows two types of driving constraint,

which together can cover virtually all motions found in

practice: a rotary driver, which twists the shaft vectors S2

and S3 about the shaft axis vector Sl, and a linear driver

which moves the shaft reference point S along the shaft axis

vector. These two motions can be used to simulate rotary

input and linear actuators, respectively: in conjunction, they

can be used to simulate a screw. Since virtually all helical

joints in real mechanisms are part of a drive system, this

facility adequately overcomes the lack of a helical joint

amongst the static constraints.

No of constraints

(S - H)Sl

shaft reference point on slot line

Right angle constraint:

out the functions

Vector condition

2

= 0

= 0

= 0

S2.H3 = 0

Sl.H3

= 0

another body, as shown in Figure 3. Assembly of the bodies

consists firstly of evaluating the dot product of the two

vectors for the current positions of the two bodies:

Vs.VH= e.

(1)

The requirement is to rotate the two bodies through Euler

angles MA and bea, respectively, such that the error quantity

e becomes zero. Assuming that these angles are small, we

should choose MA and 60s such that:

(vs +

(6eA x v,b(v,

whence (MA X

x vspe,

or (Vu

+ (6eB x v,)) = 0

(2)

Vs).VH+ (6$ X V&Vs = - e

+ (V,x vH)-seB = e.

All equations of this type, plus all the (similar) equations

generated by ALIGN and CROSS can be assembled into a

matrix equation of the form:

_

A

orAS=e

_ 64

(3)

as shown in Figure 4, whence

6=A-e.

(4)

If the required adjustments to the position and orientation of

the bodies are small, they will be yielded by eqn (4). If they

are large, eqn (4) will not give precise answers, but it does

provide information

for a Newton-Raphson

style of

solution to the position analysis problem. Some care is

needed in applying the method: Promech typically scales

all proposed adjustments down so that no body is rotated

through more than 45. This avoids the potentially

CONSTRAINT ASSEMBLY AND SOLUTION

The position and orientation of each body is held by storing

the vector position of the bodys local origin, and a rotation

matrix which maps the bodys local axes onto a set of global

axes. Subsequent adjustments to a bodys position can then

be made by applying increments of the form 6R to its

position vector and rotational transforms 68 to its rotation

matrix, as shown in Figure 3.

All the constraints handled by the procedure SETSQ

above require that a vector on a shaft (Vs,say) on one

body be perpendicular to a vector on a hole (V,,say) on

Figure

Vector definitions for joints.

201

Open architecture

kinematic analysis: A L Johnson

J

Joint type:

Shaft in short

round hole

IbA

Previous

constraints

i

Current

constraints

ALIGN(

ALIGN(S3) +

Figure 4

Assembly of the constraint matrix.

behaviour reported by Kramer in Chapter

7 of Ref. 14.

For velocities, we note that each shaft vector Vs may in

general have an angular velocity ws relative to the body it

belongs to, in addition to the angular velocity 13of the body

itself. After a short time 6t we wish the dot product of the

two vectors still to be zero, which requires that:

unstable iterative

(Vs + (ws + e, X vs &).(V,

+ (4, x VJj) at) = 0

(3

Noting that VA.VB = 0, ignoring terms in lit*, and dividing

through by 6t gives:

(es x Vs).Vu + (4 x V).VS = (Vs X WS).V

(6)

or (V, X Vs)& + (V, X V,)4& = (Vs X os).VH

i.e. Ai=e

(7)

where d contains

bodies, whence

$=A-

the linear and angular

e,

velocities

of the

(8)

where the contents of A- are exactly as in the final iteration

of eqn (4). Velocities are thus calculated

by simply

evaluating the terms in e, which come from the righthand side of eqn (6) plus other similar equations from

ALIGN and CROSS. Most of these terms are zero, as only

driving constraints cause non-zero terms.

For accelerations, we simply differentiate eqn (7) with

respect to time to give:

_&+_A6 =eor&=e-A&=e

e,

(10)

where A- IS

again the same as for the previous calculations.

Thus, once the position analysis has been carried out,

velocities and accelerations are then both calculated exactly

without the need either for further matrix inversion or for

202

INERTIA LOADS

Once the linear and angular accelerations of each body have

been found, the resulting inertia (dAlembert) loads on the

mechanism can be calculated. It can readily be shown from

first principles I2that these loads can be expressed as a force

of - MaGacting though the centre of gravity plus a couple

of - J(? - 0 X (Jt9), where:

M is the mass of the body

aG is the acceleration of its centre of gravity and

(9)

where the elements in err are all in terms of V, w, cj and 8

which are all known. These elements

are calculated

individually

by differentiating

eqn (6) (and equivalent

equations from ALIGN and CROSS) and collecting the

terms not involving 6 or R onto the right-hand side. The

linear and angular accelerations

of the bodies are then

obtained from:

$=A-

numerical differentiation. This gives Promech a substantial

performance advantage, since step sizes can be kept fairly

large without compromising the accuracy of the kinematic

calculations.

Calculations of velocities and accelerations at subsequent

points in the mechanisms cycle are initiated by quoting an

elapsed time interval, and then calculating new trial orientations for the bodies using the velocities and accelerations

calculated in eqns (8) and (10) during the previous calculations. If the time interval is not too large, this will usually

yield an acceptably small set of values in e (eqn (4)), such

that there is no need to make any further adjustments to the

bodies positions. This means that the constraint matrix A

generally only needs to be assembled and inverted once for

each cycle of calculations, making for good computational

efficiency even in complex mechanisms.

or

I xx

-Ix,

- IXY

IYY

- Ixz

- IYZ

- Ixz

-I,,

Izz

.

I

The coefficients of the inertia matrix must expressed in the

global co-ordinate system, which requires a transformation

Open architecture kinematic analysis: A L Johnson

from the bodys own local co-ordinate

shown to come from the formula

system. This can be

J = RJRT,

where J is the inertia matrix in the bodys local co-ordinate

system, and R is the transform matrix which maps the

bodys co-ordinate system into the global system.

When these loads have been calculated, they can be

combined with any other external loads applied to the

mechanism, and used to calculate forces and couples at

the interfaces between the bodies. This process involves

using the same constraint information as was used in the

kinematic analysis to create and solve a set of simultaneous

equilibrium equations for the bodies. The method for doing

this is described in detail elsewhere16.

STRUCTURE OF THE SOFTWARE

Promech was initially written in FORTRAN and takes the

form of a library of subroutines, some of which are designed

to be called by the controlling program. These fall into five

main categories:

(1) Definition routines, which allow the main program to

define the required number of bodies, specify their

inertias, and add shafts and holes to them as required;

(2) Subroutine JOINT, which sets up joints between a shaft

on one body and a hole on another;

(3) Subroutines ROTATE and MOVE, which allow relative

motions to be specified between any shaft and its parent

body;

(4) Subroutine TSET, which sets the clock, and thus

defines how much motion has taken place between

successive calculations;

(5) Interrogation routines which report back the position,

velocity and acceleration of any defined part of the

mechanism, or the forces and couples being transmitted

through any joint.

The subroutines in (4) and (5) above are generally placed

in a loop in the main program, to allow the behaviour of the

mechanism to be analysed throughout its cycle. ROTATE

and MOVE can also be placed in the loop, if the input

velocities are not constant. A fresh set of calculations is

automatically

triggered the first time an interrogation

routine is called after any alteration to the position, velocity

or acceleration of a driving shaft.

CASE STUDY AND BENCHMARK

A case study has been carried out for this software as part of

the design of a deployable flight refuelling probe for British

Aerospace

Military Aircraft Division.

This essentially

consists of two hinged limbs (similar to a human arm),

each actuated by a separate hydraulic

cylinder.

An

important

aspect of the design was to ensure that

deployment would occur within a suitable timescale, despite

the inertia and aerodynamic

loads on the moving parts.

Promech was used to investigate the problem, and generated

an animated sequence of the mechanism in operation, as well

as a tabulation of the axial forces in the two hydraulic rams

at each stage of the deployment. The inertia component of

these forces was calculated quite automatically; evaluating

the aerodynamic

component

involved interrogating

the

Figure

Kinematic

model of the flight refuelling

probe.

position of the mechanism

after each assembly, then

calculating

and applying the appropriate

aerodynamic

forces on the various parts of the mechanism

before

completing the calculation of the joint loads. Three typical

frames from the animation sequence, with the probe at

different stages in its deployment, are shown in Figure 5.

A full description of the program written for this task is

beyond the scope of this paper, and has been published

separately.

It is, however, useful to record that it needed

fewer than 100 executable

statements to describe the

mechanism, record the joint forces and draw the simple

kinematic

models shown in Figure 5. The program

calculates and draws 180 pictures in 30 s on a 100 MHz

Pentium PC, which is the time in which the actual probe

is intended to be able to open and close. A Personal

Computer thus provides a real-time animation

of the

process, with a refresh rate of slightly greater than 6

frames per second. If the drawings are omitted from the

loop, the run time drops to just 18 s, or 0.1 s for each

calculation

of the mechanisms

behaviour.

The probe

mechanism consists of four moving bodies, and the run

time for more complex mechanisms would be proportional

to the square of the number of bodies; but this still

represents

an acceptable rate of calculation

for most

mechanical designs.

CONCLUSIONS AND FUTURE WORK

A new style of kinematic analysis software has been

presented, which is directly accessed by another calling

program, rather than via a user interface. The analysis

203

Open architecture kinematic analysis: A L Johnson

methods are essentially

well understood,

though the

identification of three vector constraints to cover 15 types

of kinematic pair makes the assembly of the constraint

matrix efficient both in terms of volume of code and speed

of execution. The specification of kinematic pairs is also

simpler than in many other analysis packages, as it is

automatically implied by the type of shaft and hole which

are involved in each joint.

The subroutine library described in this paper has been

fully written and tested, and work is now in progress to integrate it with the Functional Modellers constraint manager.

When this has been completed it will be possible to generate

suitable dimensions for any proposed mechanism, such that

specified stress limits in the parts and bearings are not

exceeded, without any intervention by the designer.

A current shortcoming of the system is that while it is

capable of generating a viable embodiment of any mechanism, it will not necessarily generate the best embodiment.

This is due to two reasons: firstly, no method has yet been

developed for improving

an unsatisfactory

design, for

instance by adding further features such as webs or pockets

to the parts; and secondly, because the criteria for what

constitutes the best design are relatively hard to define.

A simple criterion for the current work has been to minimise

the mass of the design, which is often the most desirable

goal in mechanism design; but manufacturing criteria must

also eventually be considered, as the lightest design is not

necessarily the cheapest to produce.

A second area for further development is to automate, as

far as possible, the re-specification

of constraints,

as

described in the section entitled Kinematic inte$aces.

Many mechanisms which work perfectly satisfactorily in

three dimensions are in fact over-constrained kinematically,

and work only because of play in the joints or flexibility in

their moving parts. While the Promech subroutines have the

facility to vary the amount of constraint in each joint to

mimic this, further work needs to be done in directing the

designer towards the location of such problems, and offering

guidance on the possible ways of resolving them. It is likely

that the final decision on how to vary the constraints should

always be left to the designer, as the calculated joint loads

can vary considerably, depending on what option is chosen.

Despite the clear need for further work, however,

the Promech subroutines

have effectively

provided an

interface-free route to kinematic and dynamic analysis in

the same way as the new generation of core modellers

does for solid modelling.

As such, they represent a

significant

and useful step towards the exciting and

challenging goal of computer-assisted

embodiment design.

204

REFERENCES

Roller, D., et al., Dimension-driven Geometry in CAD-a Survey.

Theory and Practice of Geometric ModeRing. North Holland, 1989.

Wagner, M. R., Understanding the ICAD System. ICAD Inc, 1990.

Johnson, A.L., Designing by functions. Design Studies, 1991, 12, No.

6.

I.

8

9.

10

Il.

12.

13.

14.

15.

16.

17.

Thornton, A. C., A support tool for constraint processes in embodiment design. In Proc. 6th Int. Conf on Design Theory and Methodology (DTM 94), ASME, 1994, pp. 231-239.

Thornton, A. C. and Johnson, A. L., Constraint specification and

satisfaction in embodiment design. In Proc. Int. Conf on Eng. Des.,

ZCED 93, The Hague, Netherlands. Hem&a, Zurich, 1993, pp. 13191326.

Yao, Z. and Johnson, A. L., Formalising knowledge for constraint

satisfaction in the design nrocess. In ICED 95. Prague. WDK, V

Hubka, Hemista, Zurich: 1995.

Yao, Z. and Johnson, A. L., On estimating the feasible solution space

of design. Computer-Aided Design, 1997, 29, 649-655.

Martin, E., Getting Started with the ACIS 30 Toolkit. Schemers, 1995.

Mechanica Applied Motion Users Manual, Rasna Corporation, San

Jose, 1995.

Gelsey, A., Automated reasoning about machines. Artificial Intelligence, 1995,74, l-53.

Joskowicz, L. and Sacks, E. P., Computational Kinematics. Artificial

Intelligence, 1991, 51, 381-416.

Haug, E.J., Computer-aided Kinematics and Dynamics of Mechanical

Systems Vol.1; Basic Methods, Ch. 9. Allyn and Bacon, 1989.

ADAMS Users Manual, Mechanism Dynamics Inc., Ann Arbor,

Michigan, 1987.

Kramer, G. A., Solving Geometric Constraint Systems. MIT Press.

Cambridge, MA.

Shigley, J. E. and Uicker, J. J., Theory of Machines and Mechanisms.

McGraw Hill, New York, 1980.

Johnson, A. L., Mechanism analysis by matrix reduction. Part I:

Statics. Proc. R. Sot. Lond. A, 1992, 439, 485-495.

Blessing, L. T. M. et al., Applying Systematic Design: the Flight

Refuellinn Probe Proiect. Cambridge EDC nublication CUED/CEDC/TR48, 1997.

Aylmer Johnson is a lecturer in

Mechanical Engineering and CAD at

the University of Cambridge. He

graduated from Cambridge in 1973,

and became leader of the development

team for the DUCT sutface modeller

over the period leading up to its first

commercial sales in 1979. He was 0

founder member of the Cambridge

Engineering Design Centre, and has

worked and published for the last

10 years in the area of Functional

Modelling

and

Computer-Aided

Embodiment Design. His other research interests include kinematics,

optimization and computer-based teaching.

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Kinematic ch3 Solution (John J. Uicker)Document85 pagesKinematic ch3 Solution (John J. Uicker)박종국Pas encore d'évaluation

- Relative Motion PDFDocument14 pagesRelative Motion PDFTanishq KapoorPas encore d'évaluation

- Planar Kinematics of Rigid Body NotesDocument79 pagesPlanar Kinematics of Rigid Body NotesYadanaPas encore d'évaluation

- Capitulo 16 (B) PDFDocument43 pagesCapitulo 16 (B) PDFLucas Santos100% (2)

- 15SV2GG4F60: Operating DataDocument4 pages15SV2GG4F60: Operating DatajtorerocPas encore d'évaluation

- FP 2.4 - Motor 1Document2 pagesFP 2.4 - Motor 1jtorerocPas encore d'évaluation

- Seleccion Bomba JockeyDocument3 pagesSeleccion Bomba JockeyjtorerocPas encore d'évaluation

- NSC 200-250/D271DC4-ADV: Technical DataDocument3 pagesNSC 200-250/D271DC4-ADV: Technical DatajtorerocPas encore d'évaluation

- Commercial, Irrigation and Agricultural Water: Single Phase, 6" Motors (1.15 S.F.) and Required Control BoxesDocument3 pagesCommercial, Irrigation and Agricultural Water: Single Phase, 6" Motors (1.15 S.F.) and Required Control BoxesjtorerocPas encore d'évaluation

- Performance Curve: 8100 6x4x10F-MDocument1 pagePerformance Curve: 8100 6x4x10F-MjtorerocPas encore d'évaluation

- Week Three Homework Problems: Fundamentals of ! Fluid PowerDocument2 pagesWeek Three Homework Problems: Fundamentals of ! Fluid PowerjtorerocPas encore d'évaluation

- Video Vocabulary Season 2 S2 #24 Working With Your German Skills!Document2 pagesVideo Vocabulary Season 2 S2 #24 Working With Your German Skills!jtorerocPas encore d'évaluation

- Video Vocabulary Season 2 S2 #12 It's A Jungle Out There: Let Show You An Easier Way!Document2 pagesVideo Vocabulary Season 2 S2 #12 It's A Jungle Out There: Let Show You An Easier Way!jtorerocPas encore d'évaluation

- All About #10 German Pop Culture: Lesson NotesDocument5 pagesAll About #10 German Pop Culture: Lesson NotesjtorerocPas encore d'évaluation

- Physica: Viscosity of Carbon Dioxide in The Liquid PhaseDocument32 pagesPhysica: Viscosity of Carbon Dioxide in The Liquid PhasejtorerocPas encore d'évaluation

- All About #15 Top Five Favorite Phrases From The Germanpod HostsDocument3 pagesAll About #15 Top Five Favorite Phrases From The Germanpod HostsjtorerocPas encore d'évaluation

- V S2L15 041610 Gpod101 PDFDocument2 pagesV S2L15 041610 Gpod101 PDFjtorerocPas encore d'évaluation

- LWPAV S1L14 041114 Daclass101Document6 pagesLWPAV S1L14 041114 Daclass101jtorerocPas encore d'évaluation

- Video Vocabulary Season 2 S2 #10 Oh, What A Tangled Web We Weave, When We Teach German Insect Vocabulary!Document2 pagesVideo Vocabulary Season 2 S2 #10 Oh, What A Tangled Web We Weave, When We Teach German Insect Vocabulary!jtorerocPas encore d'évaluation

- Physica/: Time-Dependent Behavior of Granular Material in A Vibrating BoxDocument20 pagesPhysica/: Time-Dependent Behavior of Granular Material in A Vibrating BoxjtorerocPas encore d'évaluation

- Index of Authors and Papers To Volume 239: See SeeDocument5 pagesIndex of Authors and Papers To Volume 239: See SeejtorerocPas encore d'évaluation

- Learn Finnish in Three Minutes #14 Talking About PossessionsDocument3 pagesLearn Finnish in Three Minutes #14 Talking About PossessionsjtorerocPas encore d'évaluation

- LFTM L1 060112 Finpod101Document2 pagesLFTM L1 060112 Finpod101jtorerocPas encore d'évaluation

- Ima J Appl Math 1973 Peraiah 75 90Document16 pagesIma J Appl Math 1973 Peraiah 75 90jtorerocPas encore d'évaluation

- Spectral Symmetry in Lattice Dynamical Models: J. List. Maths Applies (1968) 4, 375-398Document24 pagesSpectral Symmetry in Lattice Dynamical Models: J. List. Maths Applies (1968) 4, 375-398jtorerocPas encore d'évaluation

- Physlca: The Three-Dimensional Rotation Neural NetworkDocument16 pagesPhyslca: The Three-Dimensional Rotation Neural NetworkjtorerocPas encore d'évaluation

- ME203 MOM July2013 Position Velo Tout01Document6 pagesME203 MOM July2013 Position Velo Tout01Kumar RajeshPas encore d'évaluation

- 1st Year Physics Notes Chap05Document15 pages1st Year Physics Notes Chap05phoool83% (6)

- Kom MCQDocument11 pagesKom MCQSMHC23 Akshay DandadePas encore d'évaluation

- Lecture Note 6 (Sensor) - Sensor Based On Electric FieldDocument29 pagesLecture Note 6 (Sensor) - Sensor Based On Electric FieldBăng Trương ThanhPas encore d'évaluation

- Homework #09 (Phy 112) SolutionsDocument16 pagesHomework #09 (Phy 112) SolutionsKvn4N6Pas encore d'évaluation

- Grade 11 First Period Physics NotesDocument20 pagesGrade 11 First Period Physics NotesAlphonso TulayPas encore d'évaluation

- Analysis of Slider Crank Mechanism Using Computer ProgrammingDocument5 pagesAnalysis of Slider Crank Mechanism Using Computer ProgrammingTablet MultilaserPas encore d'évaluation

- MECHANICS OF MACHINES-Lecture7-1Document43 pagesMECHANICS OF MACHINES-Lecture7-1Abdul RahmanPas encore d'évaluation

- Adaptive Sliding Backstepping Control of Quadrotor UAV AttitudeDocument6 pagesAdaptive Sliding Backstepping Control of Quadrotor UAV AttitudeDalia MuraddPas encore d'évaluation

- Rotational Motion-1 PDFDocument66 pagesRotational Motion-1 PDFAnup KumarPas encore d'évaluation

- Lec23 PDFDocument24 pagesLec23 PDFAnand KumarPas encore d'évaluation

- Classical Dynamics: Example Sheet 3: A Ab B ADocument3 pagesClassical Dynamics: Example Sheet 3: A Ab B A김승수Pas encore d'évaluation

- (Deich) - Technical Gas DynamicsDocument649 pages(Deich) - Technical Gas DynamicsRaphael Pugliesi100% (1)

- Unified Maneuvering and Seakeeping TheoryDocument28 pagesUnified Maneuvering and Seakeeping TheoryGeoffjones4Pas encore d'évaluation

- Curl, Fluid Rotation in Three Dimensions (Article) - Khan AcademyDocument28 pagesCurl, Fluid Rotation in Three Dimensions (Article) - Khan Academyندى عمريPas encore d'évaluation

- All DPPDocument33 pagesAll DPPrainavin10100% (1)

- Ch4-Angular Momentum ConservationDocument44 pagesCh4-Angular Momentum Conservationsundry299Pas encore d'évaluation

- 07 - System of Particles and Rotational MotionDocument20 pages07 - System of Particles and Rotational Motionᴍᴏᴊᴏ JOJOPas encore d'évaluation

- Circular MotionDocument15 pagesCircular MotionARUNESH PRATAP SINGHPas encore d'évaluation

- MIT8 09F14 Chapter 2Document24 pagesMIT8 09F14 Chapter 2AnnaPas encore d'évaluation

- CATIA V5 FEA Release 21 - Step - by - StepDocument27 pagesCATIA V5 FEA Release 21 - Step - by - StepHerbert WeigeltPas encore d'évaluation

- Unit IIDocument38 pagesUnit IIMugilPas encore d'évaluation

- Grade 11 Physics Notes Unit 5-8Document85 pagesGrade 11 Physics Notes Unit 5-8hiwot kebedePas encore d'évaluation

- IITJEE 2012PaperIISolutionsDocument44 pagesIITJEE 2012PaperIISolutionsMahesh BabuPas encore d'évaluation

- Velocity AnalysisDocument38 pagesVelocity AnalysisChatur LingamPas encore d'évaluation