Académique Documents

Professionnel Documents

Culture Documents

80L Hall Fiat Punto A3280 A3281 A3283

Transféré par

CapitanSalamiDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

80L Hall Fiat Punto A3280 A3281 A3283

Transféré par

CapitanSalamiDroits d'auteur :

Formats disponibles

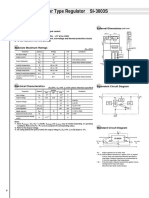

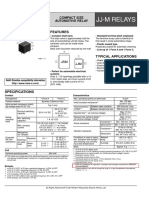

Data Sheet

27609.20

3280, 3281,

AND 3283

CHOPPER-STABILIZED, PRECISION

HALL-EFFECT LATCHES

Suffix 'LT' & 'UA' Pinning

PTCT

CC

OUTPUT

SUPPLY

GROUND

Dwg. PH-003-2

Pinning is shown viewed from branded side.

ABSOLUTE MAXIMUM RATINGS

at TA = +25C

Supply Voltage, VCC ........................ 26.5 V

Reverse Battery Voltage, VRCC .......... -30 V

Magnetic Flux Density, B ........... Unlimited

Output Off Voltage, VOUT ................... 26 V

Continuous Output Current,

IOUT ....................... Internally Limited

Reverse Output Current, IOUT ........ -50 mA

Package Power Dissipation, PD . See Graph

Junction Temperature, TJ ............... +170C

Operating Temperature Range, TA

Suffix E .................. -40C to +85C

Suffix L ................ -40C to +150C

Storage Temperature Range,

TS .............................. -65C to +170C

The A3280--, A3281--, and A3283-- Hall-effect latches are extremely temperature-stable and stress-resistant sensors especially suited

for operation over extended temperature ranges to +150C. Superior

high-temperature performance is made possible through dynamic offset

cancellation, which reduces the residual offset voltage normally caused

by device overmolding, temperature dependencies, and thermal stress.

The three devices are identical except for magnetic switch points.

Each device includes on a single silicon chip a voltage regulator,

Hall-voltage generator, small-signal amplifier, chopper stabilization,

Schmitt trigger, and a short-circuit protected open-collector output to

sink up to 25 mA. A south pole of sufficient strength will turn the

output on. A north pole is necessary to turn the output off. An on-board

regulator permits operation with supply voltages of 4.2 to 24 volts.

The first character of the part number suffix determines the device

operating temperature range; suffix E is for -40C to +85C and

L is -40C to +150C. Three package styles provide a magnetically

optimized package for most applications. Suffix LH is a miniature

low-profile surface-mount package, LT is a miniature SOT-89/TO243AA transistor package for surface-mount applications; while suffix

UA is a three-lead ultra-mini-SIP for through-hole mounting.

FEATURES

Symmetrical Switch Points

Resistant to Physical Stress

Superior Temperature Stability

Output Short-Circuit Protection

Operation From Unregulated Supply

Reverse Battery Protection

Solid-State Reliability

Small Size

Always order by complete part number: the prefix A + the basic fourdigit part number + a suffix to indicate operating temperature range +

a suffix to indicate package style, e.g., A3281ELH .

3280, 3281, AND 3283

CHOPPER-STABILIZED,

PRECISION

HALL-EFFECT LATCHES

FUNCTIONAL BLOCK DIAGRAM

SUPPLY

TO ALL

SUBCIRCUITS

DYNAMIC

OFFSET CANCELLATION

REG.

LOW-PASS

FILTER

OUTPUT

SAMPLE

& HOLD

CONTROL

CURRENT

LIMIT

<1

GROUND

Dwg. FH-020-1

Suffix LH Pinning

3

Suffix "UA"

RJA = 206C/W

400

Suffix "LT"

RJA = 258C/W

PTCT

Suffix "LH"

RJA = 248C/W

300

100

Suffix "E"

Suffix "L"

20

40

60

80

120

100

AMBIENT TEMPERATURE in C

140

160

180

Dwg. GH-046-2C

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright 2000 Allegro MicroSystems, Inc.

GROUND

200

CC

OUTPUT

500

600

SUPPLY

ALLOWABLE PACKAGE POWER DISSIPATION in MILLIWATTS

700

Dwg. PH-003-4

3280, 3281, AND 3283

CHOPPER-STABILIZED,

PRECISION

HALL-EFFECT LATCHES

ELECTRICAL CHARACTERISTICS over operating temperature range.

Limits

Characteristic

Symbol

Test Conditions

Min.

Typ.

Max.

Units

4.2

24

Supply Voltage Range

VCC

Operating, TJ < 170C1

Output Leakage Current

IOFF

VOUT = 24 V, B < BRP

10

VOUT(SAT)

IOUT = 20 mA, B > BOP

185

500

mV

Output Saturation Voltage

Output Current Limit

IOM

B > BOP

30

60

mA

Power-On Time

tpo

VCC > 4.2 V

50

Chopping Frequency

fC

340

kHz

Output Rise Time

tr

RL = 820 , CL = 20 pF

0.2

2.0

Output Fall Time

tf

RL = 820 , CL = 20 pF

0.1

2.0

B < BRP, VCC = 12 V

3.0

8.0

mA

B > BOP, VCC = 12 V

4.0

8.0

mA

VRCC = -30 V

-5.0

mA

Supply Current

ICC

Reverse Battery Current

ICC

Zener Voltage

VZ + VD

ICC = 15 mA, TA = 25C

28

32

37

Zener Impedance

zz + z D

ICC = 15 mA, TA = 25C

50

NOTES:1. Maximum voltage must be adjusted for power dissipation and junction temperature.

2. BOP = operate point (output turns on); BRP = release point (output turns off).

3. Typical Data is at TA = +25C and VCC = 12 V and is for design information only.

MAGNETIC CHARACTERISTICS over operating supply voltage range.

Part Numbers1

A3280

Characteristic

Test Conditions

Operate Point, BOP

at TA = +25C and TA = max.

5.0

22

40

15

50

at TA = -40C

5.0

40

15

at TA = +25C and TA = max.

-40

-23

-5.0

at TA = -40C

-40

at TA = +25C and TA = max.

10

at TA = -40C

Release Point, BRP

Hysteresis, Bhys

(BOP - BRP)

Min.

A3281

Typ. Max.

Min.

A3283

Typ. Max.

Min.

Typ. Max.

Units

90

100

150

180

90

100

200

-90

-50

-15

-180

-150

-100

-5.0

-90

-15

-200

-100

45

80

30

100

180

300

360

80

180

400

NOTES:1. Complete part number includes a suffix to identify operating temperature range (E or L) and

package type (LH, LT, or UA).

2. As used here, negative flux densities are defined as less than zero (algebraic convention) and -50 G is less than +10 G.

3. Typical Data is at TA = +25C and VCC = 12 V and is for design information only.

www.allegromicro.com

3280, 3281, AND 3283

CHOPPER-STABILIZED,

PRECISION

HALL-EFFECT LATCHES

TYPICAL OPERATING CHARACTERISTICS

as a function of temperature

A3281* SWITCH POINTS

A3280* SWITCH POINTS

50

100

40

80

60

OPERATE POINT

SWITCH POINTS IN GAUSS

SWITCH POINTS IN GAUSS

30

20

10

0

VCC = 4.5 V

VCC = 24 V

-10

RELEASE POINT

-20

20

0

-40

-60

-40

-80

-25

25

50

75

100

AMBIENT TEMPERATURE IN C

125

150

Dwg. GH-026-3

VCC = 4.5 V to 24 V

-20

-30

-50

-50

OPERATE POINT

40

-100

-50

RELEASE POINT

-25

25

50

75

100

125

AMBIENT TEMPERATURE IN C

A3283* SWITCH POINTS

200

160

OPERATE POINT

SWITCH POINTS IN GAUSS

120

80

40

0

VCC = 4.5 V

VCC = 24 V

-40

-80

-120

RELEASE POINT

-160

-200

-50

-25

25

50

75

AMBIENT TEMPERATURE IN C

100

125

150

Dwg. GH-026-6

* Complete part number includes a suffix denoting operating temperature range (E or L) and package type (LH, LT, or UA).

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

150

Dwg. GH-026-4

3280, 3281, AND 3283

CHOPPER-STABILIZED,

PRECISION

HALL-EFFECT LATCHES

TYPICAL OPERATING CHARACTERISTICS

as a function of temperature (cont'd)

OUTPUT SATURATION VOLTAGE

SUPPLY CURRENT

6.0

300

IOUT = 20 mA

VCC = 12 V

5.0

SUPPLY CURRENT IN mA

SATURATION VOLTAGE IN mV

VCC = 12 V

200

100

4.0

OUTPUT ON, B > BOP

3.0

OUTPUT OFF, B < BRP

0

-50

-25

25

50

75

100

125

2.0

-50

150

-25

25

50

75

100

125

150

AMBIENT TEMPERATURE IN C

AMBIENT TEMPERATURE IN C

Dwg. GH-028-5

Dwg. GH-029-4

TYPICAL OPERATING CHARACTERISTICS

as a function of supply voltage

A3281* SWITCH POINTS

A3280* SWITCH POINTS

80

40

OPERATE POINT

OPERATE POINT

40

TA = 150C

TA = -40C

-20

-40

3.0

SWITCH POINT IN GAUSS

SWITCH POINT IN GAUSS

20

RELEASE POINT

3.5

4.0

4.5

5.0

24

TA = 150C

TA = -40C

-40

-80

3.0

RELEASE POINT

3.5

4.0

4.5

5.0

24

SUPPLY VOLTAGE IN VOLTS

SUPPLY VOLTAGE IN VOLTS

Dwg. GH-021-3

Dwg. GH-021-1

* Complete part number includes a suffix denoting operating temperature range (E or L) and package type (LH, LT, or UA).

www.allegromicro.com

3280, 3281, AND 3283

CHOPPER-STABILIZED,

PRECISION

HALL-EFFECT LATCHES

TYPICAL OPERATING CHARACTERISTICS

as a function of supply voltage (contd)

SENSOR LOCATIONS

(0.005" [0.13 mm] die placement)

OUTPUT SATURATION VOLTAGE

Package Designator LH

250

ACTIVE AREA DEPTH

0.011"

0.28 mm

NOM

IOUT = 20 mA

TA = 150C

TA = +25C

TA = -40C

0.059"

1.49 mm

3

SATURATION VOLTAGE IN mV

0.038"

0.96 mm

A

1

2

Dwg. MH-025

Package Designator LT

ACTIVE AREA DEPTH

0.030"

0.76 mm

NOM

225

200

175

0.088"

2.24 mm

0.045"

1.14 mm

150

3.0

3.5

4.0

4.5

24

5.0

SUPPLY VOLTAGE IN VOLTS

Dwg. GH-055-1

SUPPLY CURRENT

Dwg. MH-008-8

8.0

Package Designators UA and UA-TL

ACTIVE AREA DEPTH

0.018"

0.46 mm

NOM

SUPPLY CURRENT IN mA

A

1

7.0

6.0

0.080"

2.04 mm

0.056"

1.44 mm

BRANDED

SURFACE

OUTPUT ON

TA = 150C

TA = +25C

TA = -40C

5.0

4.0

3.0

2.0

1.0

Dwg. MH-011-9A

0

3.0

Although sensor location is accurate to three sigma for a

particular design, product improvements may result in small

changes to sensor location.

4.0

5.0

6.0

7.0

8.0

9.0

SUPPLY VOLTAGE IN VOLTS

Allegro

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

10

11

12

Dwg. GH-058-4

3280, 3281, AND 3283

CHOPPER-STABILIZED,

PRECISION

HALL-EFFECT LATCHES

CRITERIA FOR DEVICE QUALIFICATION

All Allegro sensors are subjected to stringent qualification requirements prior to being released to production.

To become qualified, except for the destructive ESD tests, no failures are permitted.

Qualification Test

Test Method and Test Conditions

Test Length

Samples

Biased Humidity (HAST)

TA = 130C, RH = 85%

50 hrs

77

VCC = VOUT = 5 V

High-Temperature

Operating Life (HTOL)

JESD22-A108,

TA = 150C, TJ 170C

408 hrs

77

VCC = 24 V,

VOUT = 20 V

Accelerated HTOL

TA = 175C, TJ 190C

504 hrs

77

VCC = 24 V,

VOUT = 20 V

Autoclave, Unbiased

JESD22-A102, Condition C,

TA = 121C, 15 psig

96 hrs

77

High-Temperature

(Bake) Storage Life

MIL-STD-883, Method 1008,

TA = 170C

1000 hrs

77

Temperature Cycle

MIL-STD-883, Method 1010,

-65C to +150C

500 cycles

77

Latch-Up

Pre/Post

Reading

Electro-Thermally

Induced Gate Leakage

Pre/Post

Reading

ESD,

Human Body Model

CDF-AEC-Q100-002

Pre/Post

Reading

3 per

test

Test to failure,

All leads > 1500 V

ESD,

Macine Model

JESD22-A115

Pre/Post

Reading

3 per

test

Test to failure,

All leads > 200 V

Electrical Distributions

Per Specification

30

www.allegromicro.com

Comments

3280, 3281, AND 3283

CHOPPER-STABILIZED,

PRECISION

HALL-EFFECT LATCHES

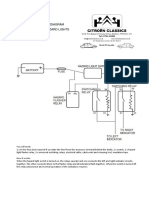

FUNCTIONAL DESCRIPTION

SAMPLE

& HOLD

REG

B

+V

Dwg. EH-012

HALL

VOLTAGE

+

Dwg. AH-011-2

+V

OUTPUT VOLTAGE

VCC

B RP

B OP

VOUT(SAT)

0

-B

Dwg. GH-034-5

SUPPLY

PTCT

OUTPUT

CC

0.1 F

www.allegromicro.com

+B

FLUX DENSITY

Chopper-Stabilized Technique. The Hall element can be

considered as a resistor array similar to a Wheatstone bridge. A

large portion of the offset is a result of the mismatching of these

resistors. These devices use a proprietary dynamic offset

cancellation technique, with an internal high-frequency clock to

reduce the residual offset voltage of the Hall element that is

normally caused by device overmolding, temperature dependencies, and thermal stress. The chopper-stabilizing technique

cancels the mismatching of the resistor circuit by changing the

direction of the current flowing through the Hall plate using

CMOS switches and Hall voltage measurement taps, while

maintaing the Hall-voltage signal that is induced by the external

magnetic flux. The signal is then captured by a sample-andhold circuit and further processed using low-offset bipolar

circuitry. This technique produces devices that have an

extremely stable quiescent Hall output voltage, are immune to

thermal stress, and have precise recoverability after temperature

cycling. This technique will also slightly degrade the device

output repeatability. A relatively high sampling frequency is

used in order that faster signals can be processed.

More detailed descriptions of the circuit operation can be

found in: Technical Paper STP 97-10, Monolithic Magnetic

Hall Sensor Using Dynamic Quadrature Offset Cancellation

and Technical Paper STP 99-1, Chopper-Stabilized Amplifiers

With A Track-and-Hold Signal Demodulator.

Operation. The output of these devices switches low (turns

on) when a magnetic field perpendicular to the Hall sensor

exceeds the operate point threshold (BOP). After turn-on, the

output is capable of sinking 25 mA and the output voltage is

VOUT(SAT). Note that the device latches; that is, a south pole of

sufficient strength towards the branded surface of the device

will turn the device on; removal of the south pole will leave the

device on. When the magnetic field is reduced below the

release point (BRP), the device output goes high (turns off). The

difference in the magnetic operate and release points is the

hysteresis (Bhys) of the device. This built-in hysteresis allows

clean switching of the output even in the presence of external

mechanical vibration and electrical noise.

Applications. It is strongly recommended that an external

bypass capacitor be connected (in close proximity to the Hall

sensor) between the supply and ground of the device to reduce

both external noise and noise generated by the chopperstabilization technique.

The simplest form of magnet that will operate these devices

is a ring magnet. Other methods of operation, such as linear

magnets, are possible. Extensive applications information on

magnets and Hall-effect sensors is also available in the Allegro

Electronic Data Book AMS-702 or Application Note 27701, or

SUPPLY

Dwg. EH-013

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

3280, 3281, AND 3283

CHOPPER-STABILIZED,

PRECISION

HALL-EFFECT LATCHES

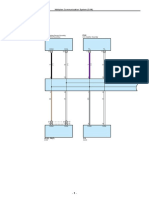

PACKAGE DESIGNATOR LH

(fits SC-74A solder-pad layout)

Dimensions in Inches

(for reference only)

3.10

2.90

0.122

0.114

0.020

0.012

0.083

0.073

0.0079

0.0050

0.118

0.106

3

1

0.020 MIN

0.022

REF

Dimensions in Millimeters

(controlling dimensions)

3

1

3.00

2.70

0.25 MIN

0 TO 8

REF

0.037

0.006

0.000

2.10

1.85

0.20

0.127

0.55

0 TO 8

BSC

0.50

0.30

0.95

BSC

0.043

0.035

0.049

0.035

0.15

0.00

1.10

0.90

1.25

0.90

Dwg. MA-010-3B mm

Dwg. MA-010-3B in

0.70

0.028

3

0.039

1.00

0.094

1

2.40

1

0.037

0.95

Dwg. MA-011-3 in

Dwg. MA-011-3 mm

NOTES: 1. Tolerances on package height and width represent allowable mold offsets. Dimensions given are

measured at the widest point (parting line).

2. Exact body and lead configuration at vendors option within limits shown.

3. Height does not include mold gate flash.

4. Where no tolerance is specified, dimension is nominal.

5. Add "LT" to part number for tape and reel.

www.allegromicro.com

3280, 3281, AND 3283

CHOPPER-STABILIZED,

PRECISION

HALL-EFFECT LATCHES

PACKAGE DESIGNATOR LT

(SOT-89/TO-243AA)

Dimensions in Inches

(for reference only)

0.181

0.173

0.072

0.064

0.167

0.155

0.063

0.055

Dimensions in Millimeters

(controlling dimensions)

0.0173

0.0138

0.090

0.084

0.102

0.090

4.25

3.94

0.0189

0.0142

0.0221

0.0173

0.047

0.035

0.059

BSC

4.60

4.40

1.83

1.62

BSC

3.00

BSC

Dwg. MA-009-3A in

Dwg. MA-009-3A mm

2.5

2.0

0.098

0.079

0.031

A

0.102

0.8

2.6

0.181

4.6

3 0.047

0.028

0.031

TYP

TYP

1.2

0.7

0.8

TYP

TYP

Pads 1, 2, 3, and A Standard SOT-89 Layout

Pads 1, 2, 3, and B Low-Stress Version

Pads 1, 2, and 3 only Lowest Stress, But Not Self Aligning

Pads 1, 2, 3, and A Standard SOT-89 Layout

Pads 1, 2, 3, and B Low-Stress Version

Pads 1, 2, and 3 only Lowest Stress, But Not Self Aligning

Dwg. MA-012-3 in

Dwg. MA-012-3 mm

NOTES: 1. Exact body and lead configuration at vendors option within limits shown.

2. Supplied in bulk pack (500 pieces per bag) or add "TR" to part number for tape and reel.

10

2.29

2.13

0.56

0.44

1.50

BSC

2.60

2.29

0.44

0.35

0.48

0.36

1.20

0.89

0.118

1.60

1.40

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

3280, 3281, AND 3283

CHOPPER-STABILIZED,

PRECISION

HALL-EFFECT LATCHES

PACKAGE DESIGNATOR UA

Dimensions in Millimeters

(for reference only)

Dimensions in Inches

(controlling dimensions)

0.164

0.159

4.17

4.04

0.062

0.058

45

1.57

1.47

45

3.10

2.97

0.122

0.117

45

45

0.085

0.031

2.16

0.79

MAX

MAX

0.640

0.600

16.26

15.24

0.0173

0.0138

0.0189

0.0142

SEE NOTE

0.44

0.35

0.48

0.36

SEE NOTE

1.27

0.050

BSC

BSC

Dwg. MH-014E in

Dwg. MH-014E mm

Surface-Mount Lead Form (order A328xxUA-TL)

0.095

2.41

0.005

0.002

0.051

MAX

MAX

0.004 08

MAX

0.13

0.10

0.020

MIN

FLAT

MAX

Dwg. MH-015 in

08

0.51

MIN

FLAT

Dwg. MH-015 mm

NOTES: 1. Tolerances on package height and width represent allowable mold offsets. Dimensions given are

measured at the widest point (parting line).

2. Exact body and lead configuration at vendors option within limits shown.

3. Height does not include mold gate flash.

4. Recommended minimum PWB hole diameter to clear transition area is 0.035" (0.89 mm).

5. Where no tolerance is specified, dimension is nominal.

6. Supplied in bulk pack (500 pieces per bag).

www.allegromicro.com

11

3280, 3281, AND 3283

CHOPPER-STABILIZED,

PRECISION

HALL-EFFECT LATCHES

The products described herein are manufactured under one or

more of the following U.S. patents: 5,045,920; 5,264,783; 5,442,283;

5,389,889; 5,581,179; 5,517,112; 5,619,137; 5,621,319; 5,650,719;

5,686,894; 5,694,038; 5,729,130; 5,917,320; and other patents

pending.

Allegro MicroSystems, Inc. reserves the right to make, from time to

time, such departures from the detail specifications as may be required

to permit improvements in the performance, reliability, or

manufacturability of its products. Before placing an order, the user is

cautioned to verify that the information being relied upon is current.

Allegro products are not authorized for use as critical components

in life-support appliances, devices, or systems without express written

approval.

The information included herein is believed to be accurate and

reliable. However, Allegro MicroSystems, Inc. assumes no responsibility for its use; nor for any infringements of patents or other rights of

third parties that may result from its use.

12

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Vous aimerez peut-être aussi

- Ecm (Engine Control Module) MR 140Document22 pagesEcm (Engine Control Module) MR 140jorge luis guevara martinezPas encore d'évaluation

- Pakyaw RatesDocument36 pagesPakyaw RatesKesMercado100% (5)

- 3S-GE Codes ListDocument6 pages3S-GE Codes ListGiancarlo CostantiniPas encore d'évaluation

- System CircuitsDocument234 pagesSystem CircuitsEme Elibe Johnson EmestarPas encore d'évaluation

- Combination M EterDocument4 pagesCombination M Eterwilder100% (1)

- DTC C1249/49 Open in Stop Light Switch Circuit: DescriptionDocument4 pagesDTC C1249/49 Open in Stop Light Switch Circuit: DescriptionAmil AnAmPas encore d'évaluation

- 5 - 12 Section 5 - Diagnosis J-1 ECM Connector Identification (1 of 2 J-1)Document8 pages5 - 12 Section 5 - Diagnosis J-1 ECM Connector Identification (1 of 2 J-1)MyBriggsPas encore d'évaluation

- I30 Electric Scheme PDF FreeDocument207 pagesI30 Electric Scheme PDF Freepedrodany9098Pas encore d'évaluation

- Electrochemi Toyota Land Cruiser Prado 2004 DemoDocument15 pagesElectrochemi Toyota Land Cruiser Prado 2004 DemoVinsensius Agus Priyono100% (1)

- Engine Control Module (Ecm) I/O SignalDocument3 pagesEngine Control Module (Ecm) I/O SignalCristian Pino CidPas encore d'évaluation

- Fuse Box E120Document3 pagesFuse Box E120Shahmeer AhmedPas encore d'évaluation

- Terminals of Ecm: DiagnosticsDocument6 pagesTerminals of Ecm: Diagnosticsbob loblawPas encore d'évaluation

- Engine Compartment Fuse Box (Type 2) : 1 - 2 Head (RH) 10 Right Hand Headlight 3 Head (LH) 10 Left Hand HeadlightDocument7 pagesEngine Compartment Fuse Box (Type 2) : 1 - 2 Head (RH) 10 Right Hand Headlight 3 Head (LH) 10 Left Hand HeadlightCarlos Alberto LopezPas encore d'évaluation

- Vdo Ecu PinDocument3 pagesVdo Ecu PinjjoehairyPas encore d'évaluation

- LG Split Type Air Conditioner Complete Service ManualDocument104 pagesLG Split Type Air Conditioner Complete Service ManualCapitanSalami100% (1)

- 1,4l 4AV (AHW+AKQ) PDFDocument11 pages1,4l 4AV (AHW+AKQ) PDFcristi_drg100% (1)

- Fastener TrainingDocument20 pagesFastener TrainingJesus Barragán Ramos100% (2)

- Fibre Reinforced Concrete PDFDocument6 pagesFibre Reinforced Concrete PDFAref AbadelPas encore d'évaluation

- Ewd ,,uzj FZJ HDJ HZJ 100-105Document447 pagesEwd ,,uzj FZJ HDJ HZJ 100-105nightevery100% (1)

- PCM Ford Laser 2.0LDocument9 pagesPCM Ford Laser 2.0LBenixon AvendañoPas encore d'évaluation

- Terminals of Ecu: Diagnostics Engine (5L)Document1 pageTerminals of Ecu: Diagnostics Engine (5L)Zainul Arifin100% (1)

- Korando Ewd CewdDocument192 pagesKorando Ewd CewdsatthatPas encore d'évaluation

- Scooters: Service ManualDocument34 pagesScooters: Service ManualCapitanSalami50% (2)

- Terminals of Ecm: E8 E7 E6 E5 E4Document11 pagesTerminals of Ecm: E8 E7 E6 E5 E4Benjamin hPas encore d'évaluation

- Eeprom FlashDocument12 pagesEeprom FlashperoPerPas encore d'évaluation

- MicroencapsulationDocument658 pagesMicroencapsulationmanan1991100% (2)

- SM 1Document87 pagesSM 1Gilberto BerdealPas encore d'évaluation

- En71 SGSDocument46 pagesEn71 SGSMax Arias100% (1)

- Fire and Gas Detection SpecificationDocument4 pagesFire and Gas Detection SpecificationAris KancilPas encore d'évaluation

- FBE Installation Manual PDFDocument60 pagesFBE Installation Manual PDFMario R. KallabPas encore d'évaluation

- LPG Lecho Sec Eco InstructionDocument37 pagesLPG Lecho Sec Eco InstructionZoli Borbely100% (1)

- Course OutlineDocument3 pagesCourse OutlineLIM ChanthaPas encore d'évaluation

- Hydro Blasting StandardsDocument16 pagesHydro Blasting Standardsgorankajganic100% (1)

- Manual Rodillo Compactador Series Ca250 Dynapac PDFDocument70 pagesManual Rodillo Compactador Series Ca250 Dynapac PDFMarcel Foshino Osorio Perez100% (1)

- Headlight: 110 Toyota Tacoma (Em01D0U)Document6 pagesHeadlight: 110 Toyota Tacoma (Em01D0U)DanielPas encore d'évaluation

- Em12r1u PDFDocument482 pagesEm12r1u PDFAnwar ZaibPas encore d'évaluation

- DTC P0130 Oxygen Sensor Circuit Malfunction (Bank 1 Sensor 1)Document4 pagesDTC P0130 Oxygen Sensor Circuit Malfunction (Bank 1 Sensor 1)williamPas encore d'évaluation

- Toyota Mil CodeDocument3 pagesToyota Mil CodeinayyerPas encore d'évaluation

- Starter Cut Relay PDFDocument2 pagesStarter Cut Relay PDFPhang KumwingPas encore d'évaluation

- Honda Stream 18 i-VTEC PDFDocument5 pagesHonda Stream 18 i-VTEC PDFFabian Carrasco Naula100% (1)

- SK 3003 SDocument2 pagesSK 3003 SAhmad MahrojiPas encore d'évaluation

- Hazard Light Circuit DiagramDocument1 pageHazard Light Circuit DiagramariboroPas encore d'évaluation

- Wiring Diagram Yaris MPX-CAN PDFDocument4 pagesWiring Diagram Yaris MPX-CAN PDFHenryHutabaratPas encore d'évaluation

- Overall Electrical Wiring DiagramDocument144 pagesOverall Electrical Wiring DiagramArnuphap SudwaiyonPas encore d'évaluation

- Porsche ECU Pins....Document4 pagesPorsche ECU Pins....José BenavidesPas encore d'évaluation

- Philips Az787-61 Ver 1 0Document26 pagesPhilips Az787-61 Ver 1 0Roman servisPas encore d'évaluation

- Page 11-31 Engine Control SystemDocument24 pagesPage 11-31 Engine Control SystemDaniel Mamani ParedezPas encore d'évaluation

- PDFDocument5 pagesPDFJohn Mark CorralesPas encore d'évaluation

- Ewd 3C eDocument1 pageEwd 3C eallaucaamor100% (1)

- BSD104DV H3axDocument21 pagesBSD104DV H3axTiborPas encore d'évaluation

- Power Source: 78 HIACE (EWD622E)Document4 pagesPower Source: 78 HIACE (EWD622E)Egoro KapitoPas encore d'évaluation

- Toyota 2AZ-FSEDocument4 pagesToyota 2AZ-FSEТимPas encore d'évaluation

- P0770 Shift Solenoid E MalfunctionDocument2 pagesP0770 Shift Solenoid E MalfunctionwilfredoPas encore d'évaluation

- Grand Am Continental Tire Sports Integrating ECU PDFDocument31 pagesGrand Am Continental Tire Sports Integrating ECU PDFsenthilvlPas encore d'évaluation

- 0103mn DatasheetDocument12 pages0103mn DatasheetPierre BussacPas encore d'évaluation

- Kenwood KRC 288 Service ManualDocument19 pagesKenwood KRC 288 Service ManualmaxPas encore d'évaluation

- PDFDocument17 pagesPDFGermautos VolkswagenPas encore d'évaluation

- ECM Mitsubishi Pajero - FULL MOTORES CHECKDocument5 pagesECM Mitsubishi Pajero - FULL MOTORES CHECKJuan Felipe Romero Rayo100% (1)

- Pin Out Nissan Sensor MAFDocument3 pagesPin Out Nissan Sensor MAFAlbertiniCongoraAsto100% (1)

- Special Tool ManualDocument66 pagesSpecial Tool ManualKleber OrdóñezPas encore d'évaluation

- 27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)Document8 pages27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)autocomtrucksPas encore d'évaluation

- Datasheet U1620Document3 pagesDatasheet U1620Valter VasconcelosPas encore d'évaluation

- Toyota Rav4 2.2 2ad FHV Pin Out Engine PDFDocument10 pagesToyota Rav4 2.2 2ad FHV Pin Out Engine PDFMiguel Angel Alvarado AlarconPas encore d'évaluation

- DTC 61 No. 2 Speed Sensor Circuit MalfunctionDocument3 pagesDTC 61 No. 2 Speed Sensor Circuit Malfunctioncelestino tuliaoPas encore d'évaluation

- The Specifications of M59556FP: Details PDFDocument1 pageThe Specifications of M59556FP: Details PDFjulio montenegroPas encore d'évaluation

- 428L2 PDFDocument13 pages428L2 PDFesquisofPas encore d'évaluation

- Electronically Controlled Transmission Communication CircuitDocument3 pagesElectronically Controlled Transmission Communication CircuitErln Lima100% (1)

- Vigo Elec Wiring DiagramDocument18 pagesVigo Elec Wiring DiagramVinh PhạmPas encore d'évaluation

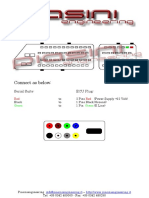

- Connect As Below:: Serial Suite: ECU PlugDocument2 pagesConnect As Below:: Serial Suite: ECU PlugOsmar Augusto100% (1)

- 1Nz-Fe Engine Mechanical: Service DataDocument3 pages1Nz-Fe Engine Mechanical: Service Dataalbert phiriPas encore d'évaluation

- Basic of MPX (Multiplex Communication) 1. GeneralDocument7 pagesBasic of MPX (Multiplex Communication) 1. Generaldima65Pas encore d'évaluation

- Continuous-Time Switch Family: A1101, A1102, A1103, A1104, and A1106Document13 pagesContinuous-Time Switch Family: A1101, A1102, A1103, A1104, and A1106Nicolás Arango NarváezPas encore d'évaluation

- RC 1082 OmDocument56 pagesRC 1082 OmCapitanSalamiPas encore d'évaluation

- RB 1562 1572 OmDocument46 pagesRB 1562 1572 OmCapitanSalamiPas encore d'évaluation

- RC 1550 OmDocument64 pagesRC 1550 OmCapitanSalamiPas encore d'évaluation

- Parts Book: 2566C/2766C Articulated TrucksDocument428 pagesParts Book: 2566C/2766C Articulated TrucksCapitanSalamiPas encore d'évaluation

- KENWOOD TS 940 Serv ManualDocument108 pagesKENWOOD TS 940 Serv ManualCapitanSalamiPas encore d'évaluation

- RB 1070 OmDocument35 pagesRB 1070 OmCapitanSalamiPas encore d'évaluation

- RMB 1565 1575 OmDocument46 pagesRMB 1565 1575 OmCapitanSalamiPas encore d'évaluation

- 150 Um007 - Es PDocument171 pages150 Um007 - Es PCapitanSalamiPas encore d'évaluation

- Ra 1520 OmDocument68 pagesRa 1520 OmCapitanSalamiPas encore d'évaluation

- Controller For Adaptive 100/120Hz Current Ripple Removing CircuitDocument11 pagesController For Adaptive 100/120Hz Current Ripple Removing CircuitCapitanSalamiPas encore d'évaluation

- PZT2222AT1 NPN Silicon Planar Epitaxial TransistorDocument3 pagesPZT2222AT1 NPN Silicon Planar Epitaxial TransistorCapitanSalamiPas encore d'évaluation

- Pyranometer: Owner'S ManualDocument19 pagesPyranometer: Owner'S ManualCapitanSalamiPas encore d'évaluation

- Preobrazovatel DavlenijaDocument14 pagesPreobrazovatel DavlenijaCapitanSalamiPas encore d'évaluation

- Bafang SW102Document20 pagesBafang SW102CapitanSalamiPas encore d'évaluation

- Jetting Chart Dell'Orto VHSB 34 (Aprilia RS 125) - HartrusionDocument1 pageJetting Chart Dell'Orto VHSB 34 (Aprilia RS 125) - HartrusionCapitanSalamiPas encore d'évaluation

- RS125 96-98 Wiring PDCI-12 Ver2-1Document1 pageRS125 96-98 Wiring PDCI-12 Ver2-1CapitanSalamiPas encore d'évaluation

- LCD Module Technical Specification: OptrexDocument17 pagesLCD Module Technical Specification: OptrexCapitanSalamiPas encore d'évaluation

- Service Manual: Issue Date: 30 November 2004Document29 pagesService Manual: Issue Date: 30 November 2004CapitanSalamiPas encore d'évaluation

- ZeelProg PDCI-12 ManualDocument9 pagesZeelProg PDCI-12 ManualCapitanSalamiPas encore d'évaluation

- ULN2803A Darlington Transistor Arrays: 1 Features 3 DescriptionDocument21 pagesULN2803A Darlington Transistor Arrays: 1 Features 3 DescriptionCapitanSalamiPas encore d'évaluation

- 2MP HD Analog Camera: Instruction ManualDocument24 pages2MP HD Analog Camera: Instruction ManualCapitanSalamiPas encore d'évaluation

- MR 2000 ManualDocument44 pagesMR 2000 ManualCapitanSalamiPas encore d'évaluation

- Electrical System PDFDocument1 pageElectrical System PDFCapitanSalamiPas encore d'évaluation

- P5K64 Ws Motherboard Qualified Vendors List (QVL) Ddr3-800Mhz CapabilityDocument1 pageP5K64 Ws Motherboard Qualified Vendors List (QVL) Ddr3-800Mhz CapabilityCapitanSalamiPas encore d'évaluation

- RA8835 Simple SpecDocument6 pagesRA8835 Simple SpecCapitanSalamiPas encore d'évaluation

- JJM1 12V Panasonic Datasheet 110054Document4 pagesJJM1 12V Panasonic Datasheet 110054CapitanSalamiPas encore d'évaluation

- GT-I9300 Service ManualDocument121 pagesGT-I9300 Service ManualJose RodriguezPas encore d'évaluation

- Fmu860 862Document16 pagesFmu860 862CapitanSalamiPas encore d'évaluation

- Biogas From BiomassDocument32 pagesBiogas From Biomassahmad fauziPas encore d'évaluation

- Manual Instrucciones TyphoonDocument46 pagesManual Instrucciones TyphoonGabriel TanasePas encore d'évaluation

- Plant Mass Flow-50080091 - A4-P - 5.0 - ENDocument9 pagesPlant Mass Flow-50080091 - A4-P - 5.0 - ENHassan raufPas encore d'évaluation

- How Can I Help To Protect The Ozone Layer?Document2 pagesHow Can I Help To Protect The Ozone Layer?Muhammad AhmedPas encore d'évaluation

- TeslaDocument6 pagesTeslaSharif EisaPas encore d'évaluation

- Acta Materialia: Dirk Herzog, Vanessa Seyda, Eric Wycisk, Claus EmmelmannDocument22 pagesActa Materialia: Dirk Herzog, Vanessa Seyda, Eric Wycisk, Claus EmmelmannKarteek RaghuPas encore d'évaluation

- Timken Corrosion Resistant Poly Round Plain Bearing Housed Unit Catalog - 11259Document80 pagesTimken Corrosion Resistant Poly Round Plain Bearing Housed Unit Catalog - 11259Leroy AraoPas encore d'évaluation

- 3Document24 pages3Dennis AleaPas encore d'évaluation

- SOP Reach Stacker01Document7 pagesSOP Reach Stacker01vozefjadav100% (1)

- Rotary Pallet Rack CenterDocument1 pageRotary Pallet Rack CenterKittisak SungsanaPas encore d'évaluation

- CH 02Document7 pagesCH 02hedayatullahPas encore d'évaluation

- Cellulose Kraft Pulp Reinforced Polylactic Acid (PLA) Composites: Effect of Fibre Moisture ContentDocument14 pagesCellulose Kraft Pulp Reinforced Polylactic Acid (PLA) Composites: Effect of Fibre Moisture ContentariaerenjaegerPas encore d'évaluation

- She 29Document124 pagesShe 29fitashah2634Pas encore d'évaluation

- Experiment 2 Tray DryerDocument7 pagesExperiment 2 Tray DryerJAIDEEP VAIDYAPas encore d'évaluation

- Hi Roller Custom Accessories Press-1Document12 pagesHi Roller Custom Accessories Press-1wald84Pas encore d'évaluation

- BETE TF MetricDocument2 pagesBETE TF Metricajo2402Pas encore d'évaluation

- M 501Document24 pagesM 501darby1028100% (1)

- IncinerationDocument50 pagesIncinerationinder4180100% (1)

- AdhesivesDocument10 pagesAdhesivesAjisolaPas encore d'évaluation

- Msds For BenzilDocument5 pagesMsds For BenzilArfin FardiansyahPas encore d'évaluation