Académique Documents

Professionnel Documents

Culture Documents

1 s2.0 S0924013602004156 Main

Transféré par

smrajbeTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1 s2.0 S0924013602004156 Main

Transféré par

smrajbeDroits d'auteur :

Formats disponibles

Journal of Materials Processing Technology 125126 (2002) 3544

Microformingfrom basic research to its realization

U. Engel*, R. Eckstein

Chair of Manufacturing Technology LFT, University of Erlangen-Nuremberg, Egerlandstr. 11, 91058 Erlangen, Germany

Received 14 January 2002; accepted 20 January 2002

Abstract

The production of miniature parts is gaining importance due to the trend of miniaturization which is increasingly determining the development

of products ranging from mobile phones and computers to medical products. The application of conventional manufacturing processes for the

production of such microparts is possible, but there are problems that result from the small dimensions. This fact applies also in the eld of metal

forming, however, in the meantime many research projects in several countries could improve this situation. This paper gives a review of the problems

associated with miniaturization, the way of solution starting from basic research, and the results showing the progress of microforming today.

# 2002 Elsevier Science B.V. All rights reserved.

Keywords: Micro-metal forming; Material behaviour; Processes

1. Introduction

To start with, a denition: the term microforming, in the

context of metal forming, is understood to be the production

of parts or structures with at least two dimensions in the submillimetre range [1]. Parts of such a size are commonly used

and more and more required in extremely high numbers, in

particular for electronic components in micro-system technologies (MST) and micro-electromechanical systems

(MEMS) as they characterize today many products pushing

forward their miniaturization. Typical examples for such

parts are pins for IC-carriers, fasteners, micro-screws, lead

frames, sockets, and any kind of connecting element (Fig. 1).

Secondly, its history: in 1990 as awareness of the technology grew, the industry produced such partsactually by

turning and millingthe question arose as to why this could

not be done by metal forming. For the metal forming society

this is quite a justied question since forming is the predestined method of manufacturing near net shape parts

especially when high production numbers and high production rates are required. However, at this time it became

obvious, that there was no basic knowledge on microforming

and practically no application visible, not even in the prototype stage. But there were some visions. One was given by

Maeda [2] who proposed the development of a super microprecision press-machine. This was one of the occasions to

start basic research on microforming at the authors' institute.

*

Corresponding author.

E-mail address: u.engel@lft.uni-erlangen.de (U. Engel).

The rst and rapidly yielding nding was that the know-how

of metal forming cannot be easily scaled down to the microscale revealing simultaneously many other reasons why this

technology is not applied to this day. It is well-recognized

that it is not only the peculiarity of the process itself which

has to be understood, but there are also many problems

related to the tool and machine tool for which new solutions

must be found. Meanwhile, a lot of research activities have

been initiated worldwide covering this eld of problems and

showing that microforming is on a promising way towards

its application in industrial production. It is not the intention

of this paper to present the state of the art of microforming.

This was given recently elsewhere [1]. The intention is to

show by means of examples the necessity of basic research

to realize this special application of metal forming.

2. Microforming system

A microforming system can be split uplike conventional forming processesinto four groups as shown in

Fig. 2.

Beside the challenges that are also known in the eld of

conventional forming, like tool design, wear and appropriate

treatment of the material, problems appear in microforming

that are strongly coupled with miniaturization itself. These

problems are observed in all four groups:

The material behaviour changes with miniaturization,

caused by size effects that occur when a process is scaled

down from conventional size to the micro-scale. The ow

0924-0136/02/$ see front matter # 2002 Elsevier Science B.V. All rights reserved.

PII: S 0 9 2 4 - 0 1 3 6 ( 0 2 ) 0 0 4 1 5 - 6

36

U. Engel, R. Eckstein / Journal of Materials Processing Technology 125126 (2002) 3544

Fig. 1. Microparts: lead frame, pitch 0.3 mm (top) and extruded parts

(Shinko, NME).

stress, the anisotropy, the ductility and the forming limit of

materials are inuenced by these size effects, which has to

be considered when designing a microforming process.

Also phenomena that are assigned to the process depend

on the size. Examples are the forming forces, the spring-back,

the scatter of the results or friction. It should be emphasized

that the size effects concerning the material and the process

have to be considered during the process design and layout

and also affect the applicability of FE-based simulations.

The main problem regarding the tools lies in their manufacturing, since it is difcult to create the very small

contours, which are necessary. Especially inner shapes,

e.g. for extrusion dies, with close tolerances and an adequate

surface quality are difcult to make. However, new manufacturing methods have been developed in order to overcome these difculties. For instance, an embossing tool has

been developed with dimensions down to 200 nm made by

an electron beam lithography-etching process [1,3].

Also the problems associated with machines or equipment

grow with miniaturization. The clearance or the backlash

between the machine parts that are negligible for conventional forming processes may have a detrimental inuence

on the accuracy of the produced parts. The handling of

material and parts is difcult, since the surfaces where they

can be gripped are very small and the part weight is low

compared with adhesion forces; as a result, the parts do not

separate from a gripper by themselves. Additionally, they

have to be placed with tolerances of a few microns, e.g. into

a die of a multi-station former.

The development of adequate measuring technology,

suited to measure the smallest contours of tools and parts,

respectively, is another challenge. Finally, the small dimensions demand production in clean rooms, which causes

additional costs. Therefore, the development and use of

small machines could lead to a more economic production.

In recent years many research activities have started

dealing with the investigation of these problems. The focus

of the present paper is on the area of materials and processes,

cf. the following section. In Section 4 an outline of actual

research will be given to show also the progress within other

areas that are altogether indispensable to push forward this

new technology.

3. Microforming process

Fig. 2. Problems in the microworld (LFT).

The comparison of microforming processes with conventional ones shows that some parameters remain constant

when scaling down the dimensions. The microstructure of

the material, for instance, is independent of the dimensions

of the process. Another example is the topography of the

surface, which is also invariant. As a result, the ratio between

the dimensions of a part and parameters of the microstructure or surface changes with miniaturization. This leads to

the so-called size effects, which prevent the application of

the know-how of conventional forming processes in the eld

of microforming. Therefore, investigations were necessary

in order to quantify these size effects. The strategy was to

scale down forming processes systematically [4,5].

At rst, studies with basic experiments have been realized. The investigated processes were simple with the aim

U. Engel, R. Eckstein / Journal of Materials Processing Technology 125126 (2002) 3544

37

to avoid complex tools as well as the problems connected

with their manufacturing. Additionally, more technologically oriented types of experiments made it possible to verify

the effects detected within the basic experiments. The

application of different materials has been managed for

the same reason.

3.1. Similarity

Scaling down a certain process is an accepted strategy to

investigate microforming processes and the effects of miniaturization [6]. With respect to an easy evaluation of the

experiments, it is recommended to ensure that the stress and

strain states and their rates remain constant, i.e. not affected

by the size of the process. Therefore, test series according to

the theory of similarity, especially conforming strictly to the

geometrical similarity, are well-suited for studies of microforming processes. This means that all dimensions of specimen and tools are multiplied by the geometric scale l. Fixing

the time scale to 1, the tool velocity has to be scaled by l as

well yielding the size-independent strain rate as desired.

Starting from these preconditions, the process forces

should be proportional to l2 and the ow stresses should

be size-independent. If the forces and stresses, respectively,

measured in experiments differ from theoretical ones, this

deviation is caused by the different dimensions of the processes and can be identied as a size effect. The strains of the

specimen are also independent of the process size, if processes

are geometrically similar. Hence, the strain distribution,

minimum and maximum strains should also be independent

of size, otherwise also a size effect has taken place.

3.2. General size effects

General size effects concern in particular the material

behaviour and friction, which are relevant for all forming

processes. The inuence of the miniaturization on the ow

stress has been investigated by geometrically similar tensile

and upsetting tests. As pointed out above, all stresses should

be size-independent, but the experiments have shown that

the ow stress decreases with increasing miniaturization. In

the eld of sheet metal forming, tensile tests using CuZn15,

CuNi18Zn20, copper and aluminium yielded a decrease of

up to 30% when reducing the sheet thickness from 2 mm

down to 0.17 mm. Bulge tests with sheets made of copper

alloy have shown the same tendency [710]. In the eld of

bulk metal forming the size effect on the ow stress has been

investigated by upsetting tests with copper, CuZn15 and

CuSn6 [6,11]. Again, the miniaturization resulted in lower

ow stresses (Fig. 3). It should be emphasized that the grain

size of the test specimen was held constant for all scales,

which means that the decrease of the ow curves is denitely

caused by the miniaturization and cannot be explained by

different grain structures.

The decrease of ow stress can be explained by the socalled surface layer model [12] which is based on the fact

Fig. 3. Decreasing flow curves (LFT).

that on small scales the material cannot be considered as an

homogeneous continuum any more [7,11]. The decisive

criterion is the ratio of grain size to the billets dimensions.

For microparts, the share of grains representing the surface

layer becomes high compared to the grains that are surrounded entirely by other grains. From metal physics theory

it is known that free surface grains show less hardening compared to the inner volume grains which can be explained by

the different mechanisms of dislocation movement and pileup and by the fact that they are less subjected to compatibility

restrictions. Thus, the integral ow stress that is measured in

upsetting or tensile tests is a function of the share of surface

grains. This share increases with grain size and with miniaturization as it can be seen in Fig. 4. It should be noted that the

above mentioned surface layer model can also be used in

modelling microforming processes by FEM [13].

Additional general size effects occur in tensile tests: The

vertical mean anisotropy of sheets decreases with miniaturization. This means that the forming characteristics become

worse with miniaturization, because the thickness reduction

increases, which is an undesired phenomenon in deep

drawing processes. Furthermore, the uniform elongation

(the strain, when global necking starts in tensile tests)

decreases with miniaturization, and also the necking elongation, which is the elongation between uniform and fracture

elongation [7].

The effect of miniaturization on friction has been investigated by ring compression and double cup extrusion (DCE)

38

U. Engel, R. Eckstein / Journal of Materials Processing Technology 125126 (2002) 3544

Fig. 4. Share of surface grains (LFT).

tests. The former is based on the fact that the evolution of the

inner diameter of a ring during compression depends quite

sensitively on friction. The investigations have shown that

friction increases with miniaturization in the case of lubrication with oil, while it is size-independent in the case of no

lubrication [6,11,14].

The advantages of the DCE test compared with the ring

compression test are a larger increase in the surface area,

larger strains and higher pressure between specimen and die.

This means, the conditions are more similar to typical

extrusion processes [15,16]. For the investigation of the

inuence of miniaturization on friction, scaled DCE tests

have been carried out. The diameters of the specimen were

varied between 4 mm down to 0.5 mm. Fig. 5 outlines the

Fig. 5. DCE test: (a) dependence of cup height on friction; (b)(d) FEM

calculation, development of the cups.

experimental setup: a cylindrical specimen is placed in a die

between a stationary and a moving punch of identical shape.

The upper punch moves down and causes the material to

form two cups with the cup heights hu and hl. In the

theoretical case of no friction (friction factor m 0) both

these cups have the same height, whereas the higher friction

gets, the more the forming of the lower cup is prevented.

Therefore, the ratio hu/hl is quite a sensitive measure for

friction. The amount of changes in friction conditions was

determined by a numerical identication with FE-simulation

using the software DEFORM-2D.

Fig. 6 shows the experimental results. An extrusion oil

was applied for lubrication. It can be seen that the cup height

ratio and thus, friction increases distinctly with miniaturization. For a quantitative approach the friction factor m can be

evaluated by numerical identication [15]. The results are

also shown in Fig. 6 revealing an increase in friction factor

from m 0:02 in the case of the 4 mm specimen up to 0.15

and higher for the smaller specimens. It should be noted that

constant friction conditions do not result in a constant cup

height ratio over the course of the process, as it is conrmed

by the experimental and simulation results as well.

This frictional behaviour can be explained by the model of

open and closed lubricant pockets, also called dynamic and

static lubricant pockets [11,15]. When a forming load is

applied to a lubricated workpiece surface, the asperities

(``roughness peaks'') start to deform plastically, thus

increasing the pressure of the lubricant which is trapped

in the ``roughness valleys'' in-between.

Roughness valleys that have a connection to the edge of

the surface cannot keep the lubricant. These are called

``open lubricant pockets''. With increasing normal pressure

the lubricant escapes and is not able to support or transmit

the forming load (Fig. 7). The forming load only acts on the

asperities which results in a higher normal pressure, a higher

degree of surface attening and higher friction. Closed

lubricant pockets on the contrary do not have a connection

to the edge of the surface. The lubricant gets trapped in those

pockets and pressurized during forming. The pressurized

Fig. 6. Increase of friction indicated by the cup height ratio of a DCE test

depending on punch travel.

U. Engel, R. Eckstein / Journal of Materials Processing Technology 125126 (2002) 3544

39

reason for this effect is that the random size and orientation

of the geometrical features characterizing the microstructure

(e.g. grain size) and topography (e.g. lateral extent of closed/

open lubricant pockets) become dominant when the specimen dimension is reduced.

3.3. Case studiestowards process realization

Fig. 7. Open and closed lubricant pockets (LFT).

lubricant helps to transmit the forming load, thus reducing

the normal pressure on the asperities, which results in lower

friction (Fig. 7). It can be summarized that closed lubricant

pockets reduce friction in contrast to open lubricant pockets.

Applying this model to the DCE test outlined above there

must be a scaling effect on the ratio of open to closed

lubricant pockets as shown in Fig. 8. It is obvious that there

is a region of constant width (denoted by x in Fig. 8) where

the open lubricant pockets become effective. This can be

conrmed by roughness measurements on the outer surface

of the specimens after extrusion, showing distinct attening

of asperities in the region of x. By reducing the specimen

size, the share of open lubricant pockets increases as well as

the friction factor. The model of open and closed lubricant

pockets has been conrmed by additional and independent

investigation. For example, tests with specimens of xed

diameter but varying height have been carried out. In

accordance to the model an increase in friction with decreasing height is observed. Another proof for the model arises

from the use of solid lubricants (or even dry conditions)

instead of a uid. In that case the mechanism postulated by

the model cannot become effective and consequently size

effects do not occur [16].

A further effect, which has been observed in many

experiments, is the increase of scatter, when the dimensions

of forming processes become less, cf. Figs. 3 and 6. The

Fig. 8. Effect of miniaturization on areas with open and closed lubricant

pockets (LFT).

Case studies show the signicance of size effects on

practical processes, which are inuenced by general size

effects and also, sometimes, by process specic phenomena.

They are necessary to formulate design rules for microforming processes and are a nal and indispensable step to

facilitate the realization of a certain process.

The inuence of miniaturization on extrusion has been

investigated among other things with full forward extrusion

processes. Similar to the experiments presented in the last

section, tests according to the theory of similarity have been

carried out. The diameters of the billets were 4 mm down to

0.5 mm and different lubricants have been applied. The most

important result is that downscaling the part dimensions

results in an increase of the punch pressure. This is caused

by the increase in friction, which has been veried by

FE-simulation. The friction factors determined by DCE tests

were applied in the calculations, and their results were in

good agreement with the experiments.

In order to study the material behaviour of a relatively

complex extrusion process, a combined forward rodbackward can extrusion process was chosen. Again, geometrically similar test series with billet diameters between 0.5 and

4 mm have been realized. Fig. 9 shows a specimen (billet

diameter of 0.5 mm) made within these tests. A specic

characteristic of this process is the ratio of cup height and

shaft length hC/lS (Fig. 10). The results show that this ratio

increases with miniaturization in the case of ne grained

material (grain size about 4 mm). Similar to the DCE test, the

increase of friction causes an increased material ow in the

direction of the moving punch, that means the cup becomes

larger with miniaturization.

A second identical set of experiments was performed with

a heat-treated specimen, which had a coarse microstructure

(grain size about 120 mm). The behaviour was similar to the

case of ne grained material for the diameters 4 and 2 mm.

By contrast, there is no further increase of the cup height,

Fig. 9. Forward rodbackward can extrusion; initial diameter is 0.5 mm

(LFT).

40

U. Engel, R. Eckstein / Journal of Materials Processing Technology 125126 (2002) 3544

Fig. 10. Combined full forward cup backward extrusion: effect of

specimen size and microstructure on shape of extruded part (LFT).

when the billet diameter is set to 0.5 mm. This is explained

by the microstructure. In the case of the considered specimen the grain size is larger than the thickness of the wall of

the cup (12075 mm). As observed in the case of bending

(see below), this reduces the ductility of the material. Therefore, it is easier for the material to ow in the shaft than in the

cup. This example clearly illustrates the importance of the

exact knowledge of miniaturization effects for process

design [15].

However, it is not only the process for which the miniaturization effects have to be considered but also the quality

of the formed parts. The geometrical accuracy as well as the

mechanical properties are affected which shall be shown by

two examples considering a backward can extrusion and a

full forward extrusion process, respectively. Fig. 11 shows

the shape formation of the cup wall of thickness 8 mm

pressed out of a 1.0 mm billet of coarse grain structure.

It can be seen that the formation of the rim is rather irregular

which can be explained by the fact that on different locations

grains of different size and orientation have to pass the

clearance between die and punch which is quite small

compared with the mean grain size, thus yielding inhomogeneous material ow and nally the observed irregular

shape [15].

Fig. 11. Backward can extruded part, thickness of the wall 8 mm, SEM

picture (left) and cross-sectional micrograph (LFT).

Fig. 12. Irregular hardness distribution of a coarse grained extruded

specimen, initial diameter of 0.5 mm (LFT).

Work hardening is important for the superior mechanical

properties of cold forged parts. It can be characterized by

the hardness distribution which usually reects the well

experienced or theoretically analysed distribution of induced

strain. In the case of micro-forward extrusion of a 0.5 mm

billet the result is quite different as shown in Fig. 12. The

maximum hardness is not found in the regions expected but

obviously assigned to specic grains which due to their size,

orientation and location have been deformed most heavily

[15]. That means also that the overall mechanical properties

might be different from part to part due to the random

character of the grain structure.

It should be noted that both phenomena are not observed

in conventional forming. They are more typical for microforming and must be taken into account in assessing the

quality of the product.

Another phenomenon has been observed in air bending

experiments. According to the surface layer model the ow

stresses decrease with miniaturization. As a result, the

bending forces relative to the scale should decrease with

miniaturization. Experiments have shown that this is valid in

most cases, but the model fails when only one single grain is

located over the thickness of the sheet. This effect of ``one

U. Engel, R. Eckstein / Journal of Materials Processing Technology 125126 (2002) 3544

41

Fig. 13. Bending forces and yield strength in bending tests. Effect of

miniaturization and grain size (LFT, mate).

Fig. 15. Inhomogeneous strain distribution of coarse grained material

(LFT).

grainhigh forces'' has been observed when scaling down a

process while the grain size was constant (115 mm in Fig. 13,

left-hand side) [7] and also increasing the grain size by heat

treatment while the process dimensions were constant

(Fig. 13, right-hand side) [9]. This contradicts the regular

theory, where the ow stress decreases, when the grain size

increases (HallPetch relation). In order to nd reasons for

this phenomenon, experiments have been carried out, which

apply the method of optical strain measurement to microforming processes.

Sheets made of CuZn15, 0.5 mm in thickness were bent.

Applying the material in the hard state with ne grains (grain

size approx. 10 mm) the deformed area shows a strain

distribution that is typical for the bending process

(Fig. 14): elongated material at the outer radius of the

arc, compressed material at the inner radius and an undeformed area in the middle. This layer structure is disturbed

when the material is coarsely grained (grain size approx.

70 mm, Fig. 15), which is caused by the different crystallographic orientation of the grains. Different orientation

could be the reason for the increasing bending forces when

there is only one grain in the normal direction of the surface

of the sheet. When the number of grains is larger, i.e. more

than 1, preferably those with lower resistance against deformation will be elongated. When the number is 1, each single

grain will be deformed according to the shape of the tool,

regardless of its possibly unfavourable orientation. This

leads to higher forces [17].

A further material phenomenon, which occurs in sheet

metal working processes, is the inuence of the sheet

anisotropy on the process. The effect of the anisotropy in

micro-sheet metal blanking processes has been investigated

in connection with the production of lead frames (Fig. 1).

They contain long and narrow slots made by blanking, which

means that the shearing lines have a distinct direction. It has

been shown that the maximum punch force depends on the

angle between the rolling direction and the shearing lines F

(Fig. 16) [18,19]. Furthermore, the anisotropy has an effect

on the material ow during a blanking process: experiments

have been carried out applying punches with rectangular

shape. The width of the punch wP was half the thickness of

the sheet (Fig. 16). This ratio has been investigated, since

narrow slots are typical for lead frames. During the rst

phase of the blanking process (until the cutting edge of the

punch has reached about the middle of the sheet), the

material ow causes a lateral expansion D of the material,

dened as the increase of the distance between the two

X-marks in Fig. 16. The experiments have shown that D

clearly depends on F. During the second phase (until

material separation takes place) D remains nearly constant.

It should be emphasized that the amount of D is a function of

further material parameters (e.g. recrystallized or hard state)

and must be taken into account when blanking is continued

subsequently in the immediate vicinity.

4. Research in progress

Fig. 14. Strain distribution of fine grained material (LFT).

The trend towards even smaller products leads to new

approaches in basic research. Taking up considerations

made in the 1950s in the Bell Telephone Labs, the plastic

deformation should be analysed not only in terms of strain

but also of strain gradients, in particular, when the dimensions of the deformed area are in the range of 10 mm or

smaller [2023]. In contrast to the effects explained by the

42

U. Engel, R. Eckstein / Journal of Materials Processing Technology 125126 (2002) 3544

Fig. 17. Warm forging: flow stress and scatter decreasing with temperature

(LFT).

Fig. 16. Effect of anisotropy on material flow in a blanking process.

surface layer model the forces relative to the scale increase

with miniaturization. This has been observed, for example,

bending nickel foils 50 mm down to 12.5 mm in thickness

[24]. The strain gradient plasticity postulates that the density

of dislocations increases with the strain gradient, which

becomes larger with miniaturization, and therefore the hardening of the material as well.

Since the material behaviour gets worse with miniaturization (e.g. worse ductility, increased scatter), new strategies

have to be developed. One idea is warm forming which

combines the benets of cold forming such as high surface

quality and strain hardening and the advantages of hot forming, for example, lower process forces and larger formability.

Additionally, it is assumed that deformation is more homogeneous within a warm forming process compared to a cold

forming process, because more slide systems can be activated

at increased temperature. Therefore, scatter should become

smaller. First results obtained in warm compression tests

conrm these assumptions (Fig. 17) [25].

Up to now, mainly tensile, bending and punching tests

have been carried out in the eld of micro-sheet metal

working. By contrast, the micro-deep drawing process

which is more complex since friction and anisotropy have

an increased meaning, was investigated only in a few

projects [26]. Therefore, a new project started recently in

order to examine micro-deep drawing processes with foils

down to 20 mm in thickness applying different materials and

lubricants.

In addition to the forming process itself, the production of

material and manufacturing of specimen and billets, respectively, gains importance. Up to now, sophisticated specimens

made by turning, heat treating, embedding, grinding, polishing and so one have been applied to extrusion experiments.

Obviously, this procedure is not adequate for industrial

needs. An economical production process demands delivering rates of higher than 300 billets per minute. This can be

realized (as it is done conventionally) by shearing. In case of

producing micro-billets from thin wire special attention has

to be directed to shearing failures like edge draw-in, fractured area and burr, which could affect the extrusion and the

geometrical accuracy of the part. Therefore, the shearing

process and the inuence of sheared billets on the extrusion

process will be investigated in a new research project. The

aim is to develop a shearing process that allows the manufacture of billets that are suited for extrusion of microparts. The inuence of temperature, punch velocity and

stress state on the shearing process will be investigated.

Problems of tool manufacturing and handling are tackled

in some projects and studies. Conventional methods of tool

manufacturing can be also appliedwith restrictionsto

microforming tools. Wire EDM applying wires down to

10 mm in diameter enables the production of very narrow

punching and extrusion dies [27]. Smallest punches have

been made by grinding, achieving punch diameters down to

60 mm [1,28], structures with dimensions in the range of

10 mm by laser ablation [29,30]. Electron beam lithographyetching processes make it possible to create structures even

down to 200 nm in width [3]. Besides tool manufacturing,

handling of microparts is another topic of investigation.

Particularly, part transfer in multi-stage formers demands

U. Engel, R. Eckstein / Journal of Materials Processing Technology 125126 (2002) 3544

fast and accurate positioning of very small parts despite the

unfavourable effect of adhesion between part and gripper.

The result of a research project is a prototype of a transfer

system containing a vacuum gripper that enables the transport of 4.3 parts per second, the transfer length is 25 mm and

the accuracy is 5 mm [31].

Finally, one may ask what has come of the vision of the

super micro-precision press-machine mentioned in the introduction? There is already an answer: in 2000 a Japanese

research group presented a desktop machining microfactory

consisting of machine tools such as a lathe, a milling

machine, handling devices, and a press, ready to produce

miniature parts [32] not yet suited for mass production but

certainly another milestone within the development of

micro-technologies and also for microforming.

5. Conclusion

The conclusion which can be drawn from this review

might be twofold. The specic one is that the research of the

last 10 years has substantially contributed to gain fundamental insight into the peculiarities of the microforming

process and an improved understanding of the mechanisms

which are the basis to realize nally processes of industrial

relevance. Although the break through of microforming in

industrial production is not nalized yet the technology

development obviously is on a good way since the ventures

have stimulated so many other activities covering now the

whole system of microforming. These are the optimum

preconditions to come through the problems adequately in

near future.

The more general one is that: although the fast moving

technological world is characterized by many problems

which require short-termed solutions and which the engineering community is in fact able to solve adequately, there

are many ideas which a priori are recognized as not transferable into industrial application in a short period. These

topics need long-termed, basic research and will only succeed when there are self-multiplying effects of scientic

interest, industrial support and many widely distributed

activities picking up the specic vision as a challenge which

today mostly demands for an interdisciplinary approach. In

the case of microforming, all these preconditions seem to be

fullled already on a quite advanced line. Although, meanwhile there are processes already established in industry

mainly in the sheet metal working area, e.g. for the production of lead frames, this technology might enable manufacturing of a much wider spectrum of products. Hence, there

still remains a challenge for the metal forming community.

Acknowledgements

All the research done by the LFT was supported by the

German Research Foundation (DFG).

43

References

[1] M. Geiger, M. Kleiner, R. Eckstein, N. Tiesler, U. Engel,

Microforming, Ann. CIRP 50 (2) (2001) 445462.

[2] T. Maeda, A proposal of developing of super micro-precision pressmachine, 1989 Annual Report 11, The Japan Society for Technology

of Plasticity (publ.), 1990, pp. 1213.

[3] Y. Saotome, A. Inoue, New amorphous alloys as micromaterials and

the processing technology, in: Proceedings of the IEEE 13th Annual

International Conference on MicroElectroMechanicalSystems, 2000,

pp. 288292.

[4] M. Geiger, U. Engel, F. Vollertsen, R. Kals, A. Mener, Metal

forming of microparts for electronics, Prod. Eng. 2 (1) (1994) 1518.

[5] U. Engel, R. Kals, A. Mener, F. Vollertsen, Umformtechnische

Herstellung metallischer Kleinstteile, VDI-Z 136 (9) (1994) 7678.

[6] M. Geiger, A. Mener, U. Engel, Production of micropartssize

effects in bulk metal forming, similarity theory, Product. Eng. 4 (1)

(1997) 5558.

[7] R.T.A. Kals, Fundamentals on the Miniaturization of Sheet Metal

Working Processes, M. Geiger, K. Feldmann (Eds.), Reihe Fertigungstechnik Erlangen, Band 87, Meisenbach, Bamberg, 1999.

[8] A. Kocanda, T. Prejs, The effect of miniaturisation on the final

geometry of the bent products, in: Pietrzyk, et al. (Eds.), Metal

Forming 2000, Proceedings of the Eighth International Conference

on Metal Forming, A.A. Balkema, Rotterdam, 2000, pp. 375378.

[9] L.V. Raulea, L.E. Govaert, F.P.T. Baaijens, Grain and specimen size

effects in processing metal sheets, in: Geiger, M. (Ed.), Advanced

Technology of Plasticity 1999, Proceedings of the Sixth International

Conference on Technology of Plasticity Nuremberg, Vol. II,

September 1924, 1999, Springer, Berlin, pp. 939944.

[10] P. Picard, J.F. Michel, Characterization of the constitutive behaviour

for very small components in sheet metal forming, in: Proceedings of

the Second ESAFORM Conference on Material Forming, Guimaraes,

Portugal, 1999, pp. 169170.

[11] A. Mener, Kaltmassivumformung metallischer Kleinstteile-Werkstoffverhalten, Wirkflachenreibung, Prozeauslegung, M. Geiger, K.

Feldmann (Eds.), Reihe Fertigungstechnik Erlangen, Band 75,

Meisenbach, Bamberg, 1998.

[12] M. Geiger, A. Mener, U. Engel, R. Kals, F. Vollertsen, Design of

Micro-forming processesfundamentals, material data and friction

behaviour, in: P. Standring (Ed.), Chipless 2000Advancing

Chipless Component Manufacture, Proceedings of the Ninth International Cold Forging Congress, Solihull, UK, May 1995, FMJ Int.

Publ. Ltd., Redhill, 1995, pp. 155164.

[13] U. Engel, A. Mener, M. Geiger, Advanced concept for the FEsimulation of metal forming processes for the production of

microparts, in: T. Altan (Ed.), Advanced Technology of Plasticity

1996, Proceedings of the Fifth ICTP, Vol. II, October 710, 1996,

Columbus, OH, pp. 903907.

[14] U. Engel, A. Messner, N. Tiesler, Cold forging of micropartseffect

of miniaturization on friction, in: J.L. Chenot, et al. (Eds.),

Proceedings of the First ESAFORM Conference on Materials

Forming, Sophia Antipolis, France, 1998, pp. 7780.

[15] N. Tiesler, Grundlegende Untersuchungen zum Fliepressen metallischer Kleinstteile, M. Geiger, K. Feldmann (Eds.), Reihe Fertigungstechnik Erlangen, Band 132, Meisenbach, Bamberg, 2002, in press.

[16] N. Tiesler, U. Engel, Microformingeffects of miniaturization, in:

M. Pietrzyk, et al. (Eds.), Metal Forming 2000, Proceedings of the

Eighth International Conference on Metal Forming, A.A. Balkema,

Rotterdam, 2000, pp. 355360.

[17] R. Eckstein, U. Engel, Behaviour of the grain structure in sheet metal

working, in: M. Pietrzyk, et al. (Eds.), Metal Forming 2000,

Proceedings of the Eighth International Conference on Metal

Forming, A.A. Balkema, Rotterdam, 2000, pp. 453459.

[18] R. Eckstein, M. Geiger, U. Engel, Specific characteristics of microsheet metal working, in: M. Geiger, et al. (Eds.): Sheet Metal 1999,

44

[19]

[20]

[21]

[22]

[23]

[24]

[25]

U. Engel, R. Eckstein / Journal of Materials Processing Technology 125126 (2002) 3544

Proceedings of the Seventh International Conference on Sheet Metal

(SheMet'99), Meisenbach, Bamberg, 1999, pp. 529536.

W.B. Lee, C.F. Cheung, L.K. Chan, W.M. Chiu, An investigation of

process parameters in the dam-bar cutting of integrated circuit

packages, J. Mater. Process. Technol. 66 (1997) 6372.

J.F. Nye, Some geometrical relations in dislocated crystals, Acta

Metall. 1 (1953) 153162.

N.A. Fleck, J.W. Hutchinson, Strain gradient plasticity, Adv. Appl.

Mech. 33 (1997) 295361.

N.A. Fleck, J.W. Hutchinson, A reformulation of strain gradient

plasticity, J. Mech. Phys. Solids 49 (2001) 22452271.

J.Y. Chen, Y. Huang, K.C. Hwang, Z.C. Xia, Plain-stress deformation

in strain gradient plasticity, J. Appl. Mech. 67 (2000) 105111.

J.S. Stolken, A.G. Evans, A microbend test method for measuring the

plasticity length scale, Acta Mater. 46 (14) (1998) 51095115.

E. Egerer, T. Neudecker, U. Engel, Grundlagenuntersuchungen zum

Halbwarm-mikroumformen, in: Kopp (Ed.), Tagungsband zum DFGKolloquium im SPP 1074 am, September 1112, 2001.

[26] Y. Saotome, K. Yasuda, H. Kaga, Microdeep drawability of very thin

sheet steels, J. Mater. Process. Technol. 113 (2001) 641647.

[27] T. Masuzawa, State of the art of micromachining. keynote paper,

Ann. CIRP 49 (2) (2000) 473488.

[28] http://www.mpk-kemmer.de.

[29] R. Erhardt, F. Schepp, D. Schmoeckel, Micro-forming with local part

heating by laser irradiation in transparent tools, in: M. Geiger, et al.

(Eds.), Sheet Metal 1999, Proceedings of the Seventh International

Conference on Sheet Metal (SheMet'99), Meisenbach, Bamberg,

1999, pp. 497504.

[30] D. Hellrung, S. Scherr, Zuverlassige Herstellung miniaturisierter

Pragewerkzeuge, wt Werkstattstechnik 90 (1112) (2000) 520521.

[31] M. Geiger, E. Egerer, U. Engel, Cross-transport in a multi-station

former for microparts, Prod. Eng. 9 (2002), in press.

[32] K. Ashida, N. Mishima, H. Maekawa, T. Tanikawa, K. Kaneko, M.

Tanaka, Development of desktop machining microfactory, in:

Proceedings of the JapanUSA Flexible Automation Conference,

July 2326, 2000, Ann Arbor, Michigan, USA.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Single Line DiagramDocument1 pageSingle Line DiagramGhanshyam Singh100% (2)

- Connecting To Primavera DatabaseDocument8 pagesConnecting To Primavera DatabasesmrajbePas encore d'évaluation

- Primavera Gateway - April2016Document48 pagesPrimavera Gateway - April2016smrajbePas encore d'évaluation

- IlakkanamDocument59 pagesIlakkanamsmrajbePas encore d'évaluation

- D67338GC10 - Sg1-Managing Projects in Primavera P6 Professional Rel 8.0 Ed 1 - Student Guide Vol IDocument412 pagesD67338GC10 - Sg1-Managing Projects in Primavera P6 Professional Rel 8.0 Ed 1 - Student Guide Vol IJaime Carranza Chavez100% (1)

- FMRE Demo SlidesDocument25 pagesFMRE Demo SlidessmrajbePas encore d'évaluation

- Primavera UnifierDocument11 pagesPrimavera UnifiersmrajbePas encore d'évaluation

- Chapter (5) Case Study: Arab Academy For Science and Technology and Maritime TransportDocument77 pagesChapter (5) Case Study: Arab Academy For Science and Technology and Maritime Transportsmrajbe100% (1)

- Project Planning - CPM Original DataDocument2 pagesProject Planning - CPM Original DatasmrajbePas encore d'évaluation

- Pressure Vessel DesignDocument83 pagesPressure Vessel Designsmrajbe100% (3)

- Oracle Prime Features: Presented by Mohan Raj SDocument15 pagesOracle Prime Features: Presented by Mohan Raj SsmrajbePas encore d'évaluation

- Wound Field MachineDocument52 pagesWound Field MachinesmrajbePas encore d'évaluation

- Bulk Micro MachiningDocument3 pagesBulk Micro MachiningsmrajbePas encore d'évaluation

- Additive ManufacturingDocument2 pagesAdditive ManufacturingsmrajbePas encore d'évaluation

- Auto Setting DataDocument6 pagesAuto Setting Datahalo91Pas encore d'évaluation

- U90 Ladder Tutorial PDFDocument72 pagesU90 Ladder Tutorial PDFMarlon CalixPas encore d'évaluation

- National School Building Inventory (NSBI) Encoding For SY 2021-2022Document31 pagesNational School Building Inventory (NSBI) Encoding For SY 2021-2022Renato Rivera100% (1)

- International Advertising: Definition of International MarketingDocument2 pagesInternational Advertising: Definition of International MarketingAfad KhanPas encore d'évaluation

- IMO - PowerpointDocument16 pagesIMO - PowerpointMahen Fernando100% (3)

- Diodat PDFDocument4 pagesDiodat PDFFatmir KelmendiPas encore d'évaluation

- Triptico NIC 16Document3 pagesTriptico NIC 16Brayan HMPas encore d'évaluation

- A Laboratory Study of Hot Carbon Dioxide Injection Into Fractured and Conventional CoresDocument13 pagesA Laboratory Study of Hot Carbon Dioxide Injection Into Fractured and Conventional Coresmsmsoft90Pas encore d'évaluation

- The Influence of The Transformational LeaderDocument9 pagesThe Influence of The Transformational Leaderkenmuira100% (1)

- Business Ethics Final Work Brief 2Document6 pagesBusiness Ethics Final Work Brief 2KALIZA TRESSY MEGHANPas encore d'évaluation

- Design of Posterior Lumbar Interbody Fusion Cages With Various Infill Pattern For 3D Printing ApplicationDocument7 pagesDesign of Posterior Lumbar Interbody Fusion Cages With Various Infill Pattern For 3D Printing ApplicationdhazliPas encore d'évaluation

- Functional Specifications For Purchase Order: 1. Business RequirementsDocument5 pagesFunctional Specifications For Purchase Order: 1. Business RequirementsTom MarksPas encore d'évaluation

- 1Document7 pages1gosaye desalegnPas encore d'évaluation

- Spice Board BBLDocument24 pagesSpice Board BBLvenkatpficoPas encore d'évaluation

- Management of Health Care Services For Ood Victims: The Case of The Shelter at Nakhon Pathom Rajabhat University Central ThailandDocument7 pagesManagement of Health Care Services For Ood Victims: The Case of The Shelter at Nakhon Pathom Rajabhat University Central ThailandAnonymous C06qenyfkmPas encore d'évaluation

- (L) Examples of Machine Shop Practice (1910)Document54 pages(L) Examples of Machine Shop Practice (1910)Ismael 8877100% (1)

- Woman Magazine Who Was Changing Jobs To Be The Editor Of: Family Circle AdweekDocument11 pagesWoman Magazine Who Was Changing Jobs To Be The Editor Of: Family Circle AdweekManish RanaPas encore d'évaluation

- 9 PNB V Andrada Electric & Engineering Co., GR No. 142936, April 17, 2002Document9 pages9 PNB V Andrada Electric & Engineering Co., GR No. 142936, April 17, 2002Edgar Calzita AlotaPas encore d'évaluation

- Piping Tie in Procedure Rev A PDFDocument15 pagesPiping Tie in Procedure Rev A PDFMohammed Sibghatulla100% (1)

- Lower Gasket Kit (S/N E/ 9Fz999 & Below) : Model Number: 335 Serial Number: A9KA11001 & Above, AAD111001 & AboveDocument2 pagesLower Gasket Kit (S/N E/ 9Fz999 & Below) : Model Number: 335 Serial Number: A9KA11001 & Above, AAD111001 & Abovezeeshan tanveerPas encore d'évaluation

- No. 3 - Republic vs. DiazDocument7 pagesNo. 3 - Republic vs. DiazMark Gabriel MarangaPas encore d'évaluation

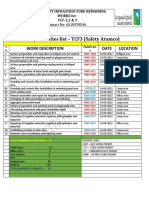

- Daily Activities List - TCF3 (Safety Aramco) : Work Description Date LocationDocument2 pagesDaily Activities List - TCF3 (Safety Aramco) : Work Description Date LocationSheri DiĺlPas encore d'évaluation

- BeechDocument1 pageBeechperovojPas encore d'évaluation

- SeminarDocument88 pagesSeminarMaha MuflehPas encore d'évaluation

- Ojsadmin, 12 ZhangG 19Document14 pagesOjsadmin, 12 ZhangG 19Kristel MitraPas encore d'évaluation

- Computation of Total Income: Zenit - A KDK Software Software ProductDocument2 pagesComputation of Total Income: Zenit - A KDK Software Software ProductKartik RajputPas encore d'évaluation

- Sustainability and Economy - A Paradigm For Managing Entrepreneurship Towards Sustainable DevelopmentFDocument21 pagesSustainability and Economy - A Paradigm For Managing Entrepreneurship Towards Sustainable DevelopmentFArmando Tarupí MontenegroPas encore d'évaluation

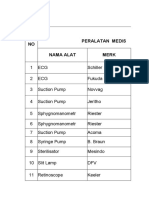

- Daftar Kalibrasi Peralatan MedisDocument34 pagesDaftar Kalibrasi Peralatan Medisdiklat rssnPas encore d'évaluation

- Brochure PVM enDocument36 pagesBrochure PVM enBenny Kurniawan LimPas encore d'évaluation