Académique Documents

Professionnel Documents

Culture Documents

BPVC Viii-1 Udr-2

Transféré par

asniff08Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

BPVC Viii-1 Udr-2

Transféré par

asniff08Droits d'auteur :

Formats disponibles

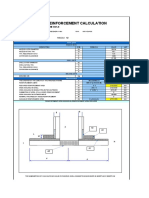

FORM U-DR-2 USERS DESIGN REQUIREMENTS FOR MULTI-CHAMBER PRESSURE VESSELS

Owner: Adam Sniff

Country of Installation:

USA

Operator: Adam Sniff

State/Province of

Installation:

OHIO

N/A

N/A

City of Installation:

AKRON

N/A

N/A

Chamber 2

Chamber 2

Service: Replacement Nuclear Steam Generator

Liquid Level:

Chamber 1

Specific Gravity: Chamber 1

Diameter: 81.5" Maximum

Shell Length, Tangent-to-Tangent:

54.5 feet

Type: Jacket

Shell and Tube

Special Service:

Lethal (L)

Direct Firing (DF)

Unfired Steam Boiler (UB)

Overpressure Protection:

Valve

Rupture Disk

Other

System Design

National Board

Registration Required:

Yes

No

Canadian

Registration Required:

Yes

No

OPERATING CONDITIONS:

Chamber 1

Chamber 2

Chamber 1

Chamber 2

1800psi

0F

650F

0psi

600psi

0F

600F

Seismic Loading: ASCE 7

UBC

IBC

Other

None

Nozzles

Int.

Ext.

10000 Cycles per

Wind Speed

year

0psi

Calculated by

Manufacturer:

Calculated by

Manufacturer:

Process

Other

Ambient Temperature

Due to: Process

Other

Ambient Temperature

Coil

Supports

Tubesheet

Tubes

SS

TS

Int.

Ext.

Int.

Ext.

Int.

Ext.

1085psi

Jacket

Int.

Ext.

Design Life

20

Classification

Category

years

Fatigue Analysis?

Exposure

Category

Topographic

Factor

Yes No

Elevation

Soil Profile Classification:

PWHT:

Per Code

Process Required

Insulated:

Yes No

By Manufacturer

By Others

Vessel Support: Legs

Heads

Int.

Ext.

1085psi

@

Same as Design

Pressure:

Same as Design

Pressure:

Due to:

2485psi

0F

0psi

Calculated by

Manufacturer:

Calculated by

Manufacturer:

0F

Chamber 2

2485psi

@

Same as Design

Pressure:

Same as Design

Pressure:

Minimum Design Metal Temperature

(MDMT) Case 1

Minimum Design Metal Temperature

(MDMT) Case 2

Corrosion Allowance:

Shell

Corrosive Service?

Int.

Ext.

Yes

No

Cyclic Service: Yes No

ASCE 7

IBC

None

Minimum Temperature Maximum Temperature

Maximum Pressure

Chamber 1

MAWP External:

Internal Coil

0psi

DESIGN CONDITIONS:

Internal Design Pressure:

External Design Pressure:

MAWP Internal:

N/a

Minimum Pressure

Case 1

Case 1

Case 2

Case 2

Wind Loading:

UBC

Other

Item No.:

Skirt

Type:

Chamber 1

Chamber 2

Lugs

Saddles

Thickness

Other Loadings per UG-22:

Temp. Gradients Deflagration

Diff. Thermal Exp.

Density

Fireproofing:

No

Yes

Coating Specification:

Permitted Prior to Pressure Test

Yes

No

Type:

Rating (hr):

MATERIALS

Component

Specification

Description

Component

SA-508

SA-508

Shell

Hemispherical Head

Toriconical Head

Nozzles

Stiffener Rings

Attachments

Reinforcing Pads

Jacket

Tubesheet

SA-508

SA-508

Number

Required

Size

Inlet and Outlet Nozzles

12"

Steam Outlet

12"

Flange

Type

Specification

Ellipsoidal Head

Torispherical Head

Conical Head

Flanges

Pressure Retaining Bolts

Internals

Coil

Tubes

Other

NOZZLE SCHEDULE

Class

Description

Alloy690

Number

Required

Size

Flange

Type

Class

07/10

SAVE

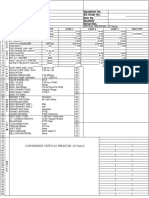

FORM U-DR-2 (Back)

WELDED PRESSURE JOINT REQUIREMENTS

DESIGN BASIS:

SHELL AND CONE THICKNESS BASED ON:

JOINT EFFICIENCY E =

JOINT LOCATION

UW-3

TYPE OF JOINT

(Use Types as Described in UW-12)

DISHED HEAD THICKNESS BASED ON:

JOINT EFFICIENCY E =

NDE WITH COMMENTS

Category A

Category B

Head-to-Shell

Other

Category C

Body Flanges

Nozzle Flanges

Tubesheets

Category D

BODY FLANGE REQUIREMENTS

Description

Type

Facing/Surface Finish

Gasket Style

Joint Assembly

(See ASME PCC-1)

SKETCH

GENERAL NOTES

CERTIFICATION

We certify that the statements made in this form are accurate and represent all details of design as per the user or his designated agent

[see U-2(a), Footnote 4]

Date:

User:

Signed:

(Representative)

Registration Identification:

(Optional)

Registration Seal (Optional)

03/08

SAVE

Vous aimerez peut-être aussi

- Chapter 04 Chemical EquilibriumDocument150 pagesChapter 04 Chemical Equilibriumnoel100% (6)

- API-650 Design Procedure ExampleDocument21 pagesAPI-650 Design Procedure Examplegdwvcd93% (14)

- Bottom Failure - Annex K - en 14015 - Rev 3Document3 pagesBottom Failure - Annex K - en 14015 - Rev 3KP SahuPas encore d'évaluation

- Autopipe Asme NB ExampleDocument31 pagesAutopipe Asme NB ExampleEl riza annamlPas encore d'évaluation

- Toriconical Head Ver 1.1Document4 pagesToriconical Head Ver 1.1Iqbal AhmadsPas encore d'évaluation

- SecVIII Div1 UW40Document2 pagesSecVIII Div1 UW40arianaseriPas encore d'évaluation

- Asme B31.8 Nozzles CalcDocument16 pagesAsme B31.8 Nozzles CalcSAMER OSMANPas encore d'évaluation

- 2520 z000 STD 1780 06 - B Anchor Bolt DetailDocument2 pages2520 z000 STD 1780 06 - B Anchor Bolt Detailabdul mujeebPas encore d'évaluation

- Ductile Iron Pressure Pipe: Standard Index of Specifications ForDocument2 pagesDuctile Iron Pressure Pipe: Standard Index of Specifications Forist93993Pas encore d'évaluation

- AHU CLCP Dimension DrawingsDocument92 pagesAHU CLCP Dimension DrawingsPhạm ĐạtPas encore d'évaluation

- Datasheet AcDocument9 pagesDatasheet AcMohan VarkeyPas encore d'évaluation

- Question For Practice Oracle (11g) With AnswersDocument32 pagesQuestion For Practice Oracle (11g) With AnswersAnonymous J8V2pZZ100% (4)

- Ordered Groups and Infinite Permutation Groups PDFDocument252 pagesOrdered Groups and Infinite Permutation Groups PDFmc180401877Pas encore d'évaluation

- Electronic Modular Control Panel II Paralleling Emcp II P Systems Operation Troubleshooting Testing and Adjusting CaterpillarDocument200 pagesElectronic Modular Control Panel II Paralleling Emcp II P Systems Operation Troubleshooting Testing and Adjusting CaterpillarAbdo MalkiPas encore d'évaluation

- Code Case 2695 in PV Elite - How To Use It PDFDocument2 pagesCode Case 2695 in PV Elite - How To Use It PDFMukeshChopra100% (1)

- Form U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsDocument3 pagesForm U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsssPas encore d'évaluation

- Car Washer CatalogueDocument24 pagesCar Washer Cataloguesra electricalsPas encore d'évaluation

- Oil Gas Construction Factory L.L.CDocument2 pagesOil Gas Construction Factory L.L.CRenny DevassyPas encore d'évaluation

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Document15 pagesFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaPas encore d'évaluation

- Sa 420Document10 pagesSa 420Widya widyaPas encore d'évaluation

- API Standard 620 - Design and Construction of Large, Welded, Low-Pressure Storage TanksDocument12 pagesAPI Standard 620 - Design and Construction of Large, Welded, Low-Pressure Storage TanksEC BaloncestoPas encore d'évaluation

- 2 PN40 (WCB)Document2 pages2 PN40 (WCB)siddhesh_guessPas encore d'évaluation

- QT 16Cr PDFDocument1 pageQT 16Cr PDFYaroslav RuizPas encore d'évaluation

- Pipe Thickness Calculation Internal Pressure Design Thickness As Per ASME B313Document7 pagesPipe Thickness Calculation Internal Pressure Design Thickness As Per ASME B313mohamed samyPas encore d'évaluation

- Straddle Principle For FlangesDocument1 pageStraddle Principle For Flangesameybarve67% (3)

- How To Use Code Case in PV EliteDocument2 pagesHow To Use Code Case in PV EliteMukeshChopraPas encore d'évaluation

- What Is An ASME Appendix 2 Flange Design PDFDocument1 pageWhat Is An ASME Appendix 2 Flange Design PDFMangesh BanalePas encore d'évaluation

- Pressure Vessel RT TestDocument3 pagesPressure Vessel RT TestAriq FauzanPas encore d'évaluation

- Sampling Cylinder Thickness Calculation As Per B31.8Document4 pagesSampling Cylinder Thickness Calculation As Per B31.8SathiyaseelanPas encore d'évaluation

- WHRB-265!08!00 Front and Rear Mirrors, Shell CalculationDocument2 pagesWHRB-265!08!00 Front and Rear Mirrors, Shell CalculationmehmacarPas encore d'évaluation

- Nozzle Interference Error SolvingDocument2 pagesNozzle Interference Error SolvingSakthi VelPas encore d'évaluation

- Checklist For Above Ground Tanks-QueenslandDocument2 pagesChecklist For Above Ground Tanks-QueenslandmohanumaPas encore d'évaluation

- Annex V External PressureDocument26 pagesAnnex V External PressureJohnny VillarroelPas encore d'évaluation

- DIN 2633 Welding Neck Flange PN16Document3 pagesDIN 2633 Welding Neck Flange PN16Wedar Karibet100% (1)

- API 5L Grade X65 Pipe Chemical Composition and Mechanical PropertiesDocument1 pageAPI 5L Grade X65 Pipe Chemical Composition and Mechanical PropertiesGEORGE VARGASPas encore d'évaluation

- Garlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 enDocument1 pageGarlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 ennmosilvaPas encore d'évaluation

- Spectacle Blind FlangeDocument3 pagesSpectacle Blind Flangel kishorePas encore d'évaluation

- S275JR PDFDocument1 pageS275JR PDFEmrahCayboylu100% (1)

- Lethal Service - Quick Guide - Pressure Vessel EngineeringDocument4 pagesLethal Service - Quick Guide - Pressure Vessel EngineeringVilas AndhalePas encore d'évaluation

- Texas Flange - Product Catalog PDFDocument47 pagesTexas Flange - Product Catalog PDFFranco Saenz SolisPas encore d'évaluation

- Memoria de Calculo Recipiente A PresionDocument241 pagesMemoria de Calculo Recipiente A PresionArmando IP100% (1)

- Check Safety Requirements For Clutch Door According To ASMEDocument3 pagesCheck Safety Requirements For Clutch Door According To ASMEtranhonghakd5533Pas encore d'évaluation

- 4 2500 (F347H)Document2 pages4 2500 (F347H)siddhesh_guessPas encore d'évaluation

- TDC 1150Document3 pagesTDC 1150shazanPas encore d'évaluation

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocument5 pagesASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaPas encore d'évaluation

- B1a1 Pipe ClassDocument1 pageB1a1 Pipe Classbrujula27Pas encore d'évaluation

- Low-Pressure Hoselines SN 544: Double Nipple Welding NippleDocument2 pagesLow-Pressure Hoselines SN 544: Double Nipple Welding NippleNaveen Kumar Chauhan100% (1)

- Astm A 234 A234m-15Document9 pagesAstm A 234 A234m-15Mohammed AliPas encore d'évaluation

- PipestresDocument4 pagesPipestresRevankar B R ShetPas encore d'évaluation

- Spreadsheet As Per RCB RGP 10.7Document2 pagesSpreadsheet As Per RCB RGP 10.7vm153748763Pas encore d'évaluation

- PV Elite (Construccion de Recipiente) MDMTDocument8 pagesPV Elite (Construccion de Recipiente) MDMTAlejandro CanoPas encore d'évaluation

- Anodes in Cooling Water Exchangers PDFDocument12 pagesAnodes in Cooling Water Exchangers PDFcbrittaivPas encore d'évaluation

- New Storage Tanks Design GuidelinesDocument6 pagesNew Storage Tanks Design GuidelinespaaryPas encore d'évaluation

- Form U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsDocument2 pagesForm U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsOscar Anthony Aguirre ChumbisllaPas encore d'évaluation

- User'S Design Requirements For Single Chamber Pressure VesselsDocument8 pagesUser'S Design Requirements For Single Chamber Pressure VesselspjsanchezmPas encore d'évaluation

- Design Basis Rev 0 - Static EqptDocument57 pagesDesign Basis Rev 0 - Static Eqptdineshkumar1234100% (1)

- Data Sheet Buffer Tank 60-BT-01 - Rev0.1Document4 pagesData Sheet Buffer Tank 60-BT-01 - Rev0.1bandithaguru6338Pas encore d'évaluation

- Datasheet Phe OnwjDocument1 pageDatasheet Phe OnwjMamank Ira Sudrajat100% (1)

- Tank Calculation Kasikan Gs Rev BDocument20 pagesTank Calculation Kasikan Gs Rev BTrian Desta Rizal80% (5)

- Submittal Cw-20-015, Regina - Tiger.Document233 pagesSubmittal Cw-20-015, Regina - Tiger.MUBASHIRPas encore d'évaluation

- Handbook v1.0Document23 pagesHandbook v1.0Kiran KommireddyPas encore d'évaluation

- Data Sheet For Absorber Reflux Drum (GTPT-V-250-003)Document4 pagesData Sheet For Absorber Reflux Drum (GTPT-V-250-003)Mohamed hamza souissiPas encore d'évaluation

- Sample8 DrawingDocument1 pageSample8 DrawingRam Kumar NPas encore d'évaluation

- Import Data From Excel To Sap TableDocument11 pagesImport Data From Excel To Sap TableSajjadPas encore d'évaluation

- Enhancement of IDoc TypeDocument12 pagesEnhancement of IDoc TypeRakesh RaiPas encore d'évaluation

- MAJOR14Document14 pagesMAJOR14swathi100% (1)

- 351 DatasheetDocument14 pages351 DatasheetRafael NavarroPas encore d'évaluation

- Penn State University Press Is Collaborating With JSTOR To Digitize, Preserve and Extend Access To Philosophy & RhetoricDocument16 pagesPenn State University Press Is Collaborating With JSTOR To Digitize, Preserve and Extend Access To Philosophy & RhetoricvanduongPas encore d'évaluation

- Chapter 2 Maternal Anatomy WilliamsDocument60 pagesChapter 2 Maternal Anatomy WilliamsDiskaAstariniPas encore d'évaluation

- 23-Article Text-89-3-10-20200704Document16 pages23-Article Text-89-3-10-20200704cholifah agumPas encore d'évaluation

- LS Retail Data Director User GuideDocument28 pagesLS Retail Data Director User GuideJad EL HittiPas encore d'évaluation

- IC Project Report Dashboard 10673 0Document6 pagesIC Project Report Dashboard 10673 0Anonymous Sls6WCF100% (2)

- SolutionsDocument8 pagesSolutionsJavid BalakishiyevPas encore d'évaluation

- DefaultDocument49 pagesDefaultmaruka33100% (1)

- Plate Fin Heat ExchangerDocument14 pagesPlate Fin Heat ExchangerTushar PanchalPas encore d'évaluation

- Evaluating Capital ProjectsDocument254 pagesEvaluating Capital Projectsariff_sodriPas encore d'évaluation

- Hillside College of Engineering Department of Civil EngineeringDocument2 pagesHillside College of Engineering Department of Civil EngineeringRamsharan DhakalPas encore d'évaluation

- Physics Investigatory Project On Transformers.Document17 pagesPhysics Investigatory Project On Transformers.sridevikamaraj16Pas encore d'évaluation

- Module 3Document10 pagesModule 3Michael godsonPas encore d'évaluation

- Ubd Planning Template With QuestionsDocument3 pagesUbd Planning Template With Questionsapi-217297849Pas encore d'évaluation

- National Telecommunication Corporation (NTC)Document40 pagesNational Telecommunication Corporation (NTC)Faheem Sajid100% (1)

- Compre Queation PaperDocument6 pagesCompre Queation PaperGanesh DharmireddyPas encore d'évaluation

- Evaluation of Yogurt Production Line Simulation Using Arena SoftwareDocument8 pagesEvaluation of Yogurt Production Line Simulation Using Arena Softwareg defPas encore d'évaluation

- Design and Implementation of Audio Transceiver Using Infrared Laser For Audio Signal DetectionDocument4 pagesDesign and Implementation of Audio Transceiver Using Infrared Laser For Audio Signal DetectionGoitom HailePas encore d'évaluation

- Water Level Sensor (Submersible)Document4 pagesWater Level Sensor (Submersible)anon_975837510Pas encore d'évaluation

- 2015-NBLUCK LK260 Engine Part ListDocument16 pages2015-NBLUCK LK260 Engine Part ListPedroPas encore d'évaluation

- SAP QM Calibration MethodDocument3 pagesSAP QM Calibration MethodvrkattulaPas encore d'évaluation

- Oral Histology & Embryology-FikreDocument240 pagesOral Histology & Embryology-FikreHeran A AlhadiPas encore d'évaluation