Académique Documents

Professionnel Documents

Culture Documents

Bus Bar Ampacity Table Ampacities of Copper Bus Bars Alloy Uns C11000

Transféré par

edalzurcTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Bus Bar Ampacity Table Ampacities of Copper Bus Bars Alloy Uns C11000

Transféré par

edalzurcDroits d'auteur :

Formats disponibles

BUS BAR AMPACITY TABLE

AMPACITIES OF COPPER BUS BARS ALLOY UNS C11000

Dimension, In.

Weight Per Ft

in Lb.

Area

Sq. In

MCM

(Thousand

Circ Mils)

1/16 x 1/2

.0312

39.7

.121

1/16 x 3/4

.0469

59.7

.181

1/16 x 1

.0625

79.6

1/16 x 1 1/2

.0938

119

1/16 x 2

.125

1/8 x 1/2

DC Resistance

at 20C,

Microhms/Ft.

30C Rise

50C Rise

65C Rise

Skin Effect

Ratio at

90C

60 Hz

Ampacity

Amp*

Skin Effect

Ratio at

90C

60 Hz

Ampacity

Amp*

Skin Effect

Ratio at

90C

60 Hz

Ampacity

Amp*

264.0

1.00

103

1.00

136

1.00

157

175.0

1.00

145

1.00

193

1.00

225

.241

132

1.00

187

1.00

250

1.00

285

.362

87.7

1.00

270

1.00

355

1.00

410

159

.483

65.8

1.01

345

1.01

460

1.01

530

.0625

79.6

.241

132

1.00

153

1.00

205

1.00

235

1/8 x 3/4

.0938

119

.362

87.7

1.00

215

1.00

285

1.00

325

1/8 x 1

.125

159

.483

65.8

1.01

270

1.01

360

1.01

415

1/8 x 1 1/2

.188

239

.726

43.8

1.01

385

1.01

510

1.01

590

1/8 x 2

.250

318

.966

32.9

1.02

495

1.02

660

1.02

760

1/8 x 2 1/2

.312

397

1.21

26.4

1.02

600

1.02

800

1.02

920

1/8 x 3

.375

477

1.45

21.9

1.03

710

1.03

940

1.03

1100

1/8 x 3 1/2

.438

558

1.69

18.8

1.04

810

1.03

1100

1.03

1250

1/8 x 4

.500

636

1.93

16.5

1.04

900

1.04

1200

1.04

1400

3/16 x 1/2

.0938

119

.362

87.7

1.00

195

1.00

260

1.00

300

3/16 x 3/4

.141

179

.545

58.4

1.01

270

1.01

360

1.01

415

3/16 x 1

.188

239

.726

43.8

1.01

340

1.01

455

1.01

520

3/16 x 1 1/2

.281

358

1.09

29.3

1.02

480

1.02

630

1.02

730

3/16 x 2

.375

477

1.45

21.9

1.03

610

1.03

810

1.03

940

3/16 x 2 1/2

.469

597

1.81

17.5

1.04

740

1.04

980

1.03

1150

3/16 x 3

.562

715

2.17

14.6

1.05

870

1.05

1150

1.04

1350

3/16 x 3 1/2

.656

835

2.53

12.5

1.07

990

1.06

1300

1.06

1500

3/16 x 4

.750

955

2.90

11.0

1.09

1100

1.08

1450

1.07

1700

1/4 x 1/2

.125

159

.483

65.8

1.01

240

1.01

315

1.01

360

1/4 x 3/4

.188

239

.726

43.8

1.01

320

1.01

425

1.01

490

1/4 x 1

.250

318

.966

32.9

1.02

400

1.02

530

1.02

620

1/4 x 1 1/2

.375

477

1.45

21.9

1.03

560

1.03

740

1.03

860

1/4 x 2

.500

637

1.93

16.5

1.04

710

1.04

940

1.04

1100

1/4 x 2 1/2

.625

796

2.41

13.2

1.06

850

1.06

1150

1.06

1300

1/4 x 3

.750

955

2.90

11.0

1.08

990

1.08

1300

1.07

1550

1/4 x 3 1/2

.875

1110

3.38

9.40

1.10

1150

1.09

1500

1.09

1750

1/4 x 4

1.00

1270

3.86

8.23

1.12

1250

1.11

1700

1.10

1950

1/4 x 5

1.25

1590

4.83

6.58

1.16

1500

1.15

2000

1.14

2350

1/4 x 6

1.50

1910

5.80

5.49

1.18

1750

1.17

2350

1.17

2700

BUS BAR AMPACITY TABLE

AMPACITIES OF COPPER BUS BARS ALLOY UNS C11000

3/8 x 3/4

.281

358

1.09

29.3

1.02

415

1.02

550

1.02

630

3/8 x 1

.375

477

1.45

21.9

1.03

510

1.03

680

1.03

790

3/8 x 1 1/2

.562

715

2.17

14.6

1.05

710

1.04

940

1.04

1100

3/8 x 2

.750

955

2.90

11.0

1.08

880

1.08

1150

1.07

1350

3/8 x 2 1/2

.938

1190

3.62

8.77

1.12

1050

1.10

1400

1.09

1600

3/8 x 3

1.12

1430

4.35

7.35

1.15

1200

1.14

1600

1.13

1850

3/8 x 3 1/2

1.31

1670

5.06

6.38

1.18

1350

1.16

1800

1.15

2100

3/8 x 4

1.50

1910

5.80

5.49

1.20

1500

1.19

2000

1.18

2350

3/8 x 5

1.88

2390

7.26

4.38

1.24

1800

1.23

2400

1.22

2800

3/8 x 6

2.25

2860

8.69

3.66

1.27

2100

1.26

2800

1.24

3250

1/2 x 1

.500

637

1.93

16.5

1.04

620

1.04

820

1.04

940

1/2 x 1 1/2

.750

955

2.90

11.0

1.08

830

1.08

1100

1.07

1250

1/2 x 2

1.00

1270

3.86

8.23

1.12

1000

1.11

1350

1.10

1550

1/2 x 2 1/2

1.25

1590

4.83

6.58

1.16

1200

1.15

1600

1.14

1850

1/2 x 3

1.50

1910

5.80

5.49

1.20

1400

1.19

1850

1.18

2150

1/2 x 3 1/2

1.75

2230

6.76

4.70

1.24

1550

1.22

2100

1.21

2400

1/2 x 4

2.00

2550

7.73

4.11

1.26

1700

1.25

2300

1.24

2650

1/2 x 5

2.50

3180

9.66

3.29

1.32

2050

1.30

2750

1.29

3150

1/2 x 6

3.00

3820

11.6

2.74

1.36

2400

1.34

3150

1.33

3650

1/2 x 8

4.00

5090

15.5

2.06

1.42

3000

1.40

4000

1.39

4600

* Applicable to typical in-service conditions (indoors, 40C ambient temperature), horizontal run on edge, and free from external

magnetic influences. Furnished by Copper Development Association Inc.

BUS BAR AMPACITY TABLE

AMPACITIES OF COPPER BUSBARS ALLOY UNS C11000

Required

Ampacity*

Bus Bar Dimension, Inches**

30C Rise

50C Rise

65C Rise

100-149

1/16 x 1/2

1/16 x 3/4

1/16 x 1/2

150-199

1/16 x 1

1/8 x 1/2

3/16 x 1/2

1/16 x 3/4

1/16 x 1/2

200-249

1/8 x 3/4

1/4 x 1/2

1/8 x 1/2

1/16 x 3/4

1/8 x 1/2

250-299

1/16 x 1 1/2

1/8 x 1

3/16 x 3/4

1/16 x 1

1/8 x 3/4

3/16 x 1/2

1/16 x 1

300-349

1/16 x 2

3/16 x 1

1/4 x 3/4

1/4 x 1/2

1/8 x 3/4

3/16 x 1/2

350-399

1/8 x 1 1/2

1/8 x 1

3/16 x 3/4

1/4 x 1/2

400-449

1/4 x 1

3/8 x 3/4

1/4 x 3/4

1/16 x 1 1/2

1/8 x 1

3/16 x 3/4

450-499

1/8 x 2

3/16 x 1 1/2

1/16 x 2

3/16 x 1

1/4 x 3/4

500-599

1/4 x 1 1/2

3/8 x 1

1/8 x 1 1/2

1/4 x 1

3/8 x 3/4

1/16 x 2

1/8 x 1 1/2

3/16 x 1

600-699

1/8 x 2 1/2

3/16 x 2

1/2 x 1

1/8 x 2

3/16 x 1 1/2

3/8 x 1

1/4 x 1

3/8 x 3/4

700-799

1/8 x 3

3/16 x 2 1/2

1/4 x 2

3/8 1 1/2

1/4 x 1 1/2

1/8 x 2

3/16 x 1 1/2

3/8 x 1

800-899

1/8 x 3 1/2

3/16 x 3

1/4 x 2 1/2

3/8 x 2

1/8 x 2 1/2

3/16 x 2

1/2 x 1

1/4 x 1 1/2

900-999

3/16 x 3 1/2

1/4 x 3

3/16 x 2 1/2

1/4 x 2

3/8 x 1 1/2

3/16 x 2

1/2 x1

BUS BAR AMPACITY TABLE

AMPACITIES OF COPPER BUSBARS ALLOY UNS C11000

1000-1249

3/16 x 4

1/4 x 3 1/2

3/8 x 2 1/2

3/8 x 3

1/2 x 2

1/2 x 2 1/2

1/8 x 4

3/16 x 3

1/4 x 2 1/2

3/8 x 2

1/8 x 3

3/16 x 2 1/2

1/4 x 2

3/8 x 1 1/2

1250-1499

1/4 x 4

3/8 x 3 1/2

1/2 x 3

3/16 x 3 1/2

3/16 x 4

1/4 x 3

3/8 x 2 1/2

1/2 x 2

1/8 x 4

3/16 x 3

1/4 2 1/2

3/8 x 2

1500-1749

1/4 x

3/8 x

1/2 x 3

1/2 x

1/4 x 3 1/2

1/4 x 4

3/8 x 3

1/2 x 2 1/2

3/16 x 3 1/2

3/16 x 4

1/4 x 3

3/8 x 2 1/2

1/2 x 2

3/8 x 3 1/2

1/2 x 3

1/4 x 3

1/4 x

3/8 x

1/2 x 2

5

4

1/2

4

1750-1999

1/4 x 6

3/8 x 5

2000-2499

1/4

3/8

1/2

1/2

2500-2999

1/4 x 10

3/8 x 8

x

x

x

x

8

6

5

6

1/2

4

3

1/2

1/4 x 6

3/8 x 5

1/2 x 4

1/4 x 5

3/8 x 4

1/2 x 3 1/2

3/8 x 6

1/2 x 5

1/4 x 6

3/8 x 5

1/2 x 4

* For 60 Hz current.

** Table gives bus bar cross section which will probably be large enough for ampacities w ithin each range. Knowing required

ampacity, determine possible bus bar dimensions from the table. Then check previous table to verify that size selected has the

necessary ampacity. Example: Assume that required ampacity is 185 amps at 30C rise. Table 2 indicates that 1/16 x 1 in. size

would probably be adequate. This is confirmed by Table 1 which lists the ampacity of 1/6 x 1 in. bus bar as 187 amps.

Furnished by Copper Development Association Inc.

BUS BAR SPECIFICATION

Copper Alloys

C11000, Electrolytic Tough Pitch Copper (ETP): The most common type of copper

used. With a minimum copper content of 99.90%, and an electrical conductivity of 101% IACS, it is

used in such diverse applications as electrical conductors, roofing and flashing, heat exchanger fins

and tanks.

C10100 and C10200, Oxygen Free Coppers: Used where the presence of oxygen in

copper is undesirable, as in certain electronic parts, or metal to be welded. These coppers have

higher purities than ETP and are cast by the refineries in a controlled atmosphere with oxygen

excluded. Cryogenic grades of C10100 copper are also available.

C12200, Phosphorous Deoxidized Copper (DHP): Deoxidized with phosphorous,

making it relatively easy to weld and high temperature braze. However, DHP has a much lower

electrical conductivity - approximately 85% IACS.

C11400 and C14300 Coppers: Used where it is desired to avoid softening in copper that is

soldered at relatively high temperatures, as in automotive heater and radiator fins. The addition of

a small percentage of silver, as in C11400 copper, is effective without a significant change in

thermal and electrical conductivities. The addition of .07% cadmium to C14300 copper has a

similar result, except that the conductivities are reduced by approximately 4%.

The measure by which the electrical conductivity of all materials are compared is known as % IACS

(percent International Annealed Copper Standard). A few comparative conductivity ratings follow:

Type of Metal % IACS

110 Electrolytic Tough-Pitch Copper........................................................................101

102 Oxygen-Free Copper............................................................................................ 101

145 Tellurium Copper.....................................................................................................95

Aluminum EC..................................................................................................................62

Aluminum 6101...............................................................................................................56

505 Phosphor Bronze 1.25%.........................................................................................48

Aluminum 5052...............................................................................................................35

Stainless Steel 302............................................................................................................3

Based on the availability and cost, C11000 Electrolytic Tough Pitch (ETP)

should be specified when suitable.

BUS BAR SPECIFICATION

Temper

The hardness of the copper or copper alloys is obtained by annealing or cold finishing after the

annealing process. Unlike steel and aluminum, copper and most copper alloys are not strengthened

by heat treating in the final stages of processing. During annealing, air is excluded by flooding the

furnaces with protective atmospheres controlled to prevent scaling, staining, or the penetration of

the metal by oxygen or hydrogen. Cold finishing is defined as the permanent deformation or strain

produced in the metal by external forces that are applied while the metals temperature is below its

recrystallization point. It can be achieved by rolling, bending, stretching, or hammering the metal

while it is cold.

Copper Rod and Bar

Annealed Metal (Soft) - Produced by Annealing Hard Metal - Special Soft Tempers are used

for short radius bending, cold heading and cold swaging. Cold worked surfaces are suitable for

most polishing.

1/2 Hard Metal (Cold Worked) - Produced by Cold Drawing or Cold Rolling Soft Metal to

Finish Size. Common Hard Temper Rectangular and Square Bar. Standard Bus Bar Temper. Used

for parts requiring machining, large radius bends, slight cold heading and slight cold swaging.

Full Hard Temper (Cold Worked) - Produced by Cold Drawing or Cold Rolling Soft Metal

to Finish Size. Common Hard Temper for Round Rods. Used for parts requiring machining.

Generally not suitable for bending, cold heading and cold swaging. Hard tempers are favorable to

blanking, shearing and machining.

Sheet, Strip and Roll Copper

Cold Rolled Annealed Temper (Soft Metal) - Produced by Annealing Hard Metal -

Standard Soft Roll Copper is commonly used for deep drawing and spinning. The surface on drawn

parts is suitable for most polishing requirements.

Soft Temper Annealed Metal (Soft Metal) - Produced by Annealing Hard Metal -

Commonly used by sheet metal craftsmen. Used for moderate drawing and cupping. The surface on

drawn parts is suitable for most polishing requirements.

1/4 Hard Metal (Cold Worked) - Produced by Cold Rolling Soft Metal to the Finish

Thickness. Special Hard Temper suitable for shallow forming.

1/2 Hard Metal (Cold Worked) - Produced by Cold Rolling Soft Metal to the Finish

Thickness. Special Hard Temper suitable for 90 deg. bends.

3/4 Hard Metal (Cold Worked) - Produced by cold Rolling Soft Metal to the Finish

Thickness. Suitable for 90 deg. bends. Favorable to blanking, shearing and machining.

Vous aimerez peut-être aussi

- CG 3 Phase MotorDocument76 pagesCG 3 Phase MotorSaravanan Mani100% (1)

- Copper Busbar Rating Table Austral Wright MetalsDocument2 pagesCopper Busbar Rating Table Austral Wright MetalsJonathan AmpisPas encore d'évaluation

- ABB Circuit Breakers For DC ApplicationDocument100 pagesABB Circuit Breakers For DC ApplicationRelief_EngineerPas encore d'évaluation

- ACB MahleDocument40 pagesACB MahlesintarisaPas encore d'évaluation

- Alternator AK6450Document8 pagesAlternator AK6450Cris_eu09Pas encore d'évaluation

- Ieee StandardsDocument176 pagesIeee StandardsVasu IyerPas encore d'évaluation

- Furse Copper Earth RodsDocument3 pagesFurse Copper Earth RodsAlfares KingPas encore d'évaluation

- Marathon Motors BrochureDocument11 pagesMarathon Motors BrochureManjunath AithalPas encore d'évaluation

- 056-006 Introduction To Data Communications PDFDocument2 pages056-006 Introduction To Data Communications PDFahamed jabirPas encore d'évaluation

- Motor ProtectionDocument61 pagesMotor ProtectionWynn ChoPas encore d'évaluation

- DM-10 IECO Diode Monitor User's ManualDocument5 pagesDM-10 IECO Diode Monitor User's ManualsivakaranPas encore d'évaluation

- BCM 3A, 5A & 10A Battery ChargerDocument4 pagesBCM 3A, 5A & 10A Battery Chargerbbpncb100% (1)

- 280kw Cummins GeneratorDocument3 pages280kw Cummins GeneratorChen CarolinePas encore d'évaluation

- gc2000 ManualDocument269 pagesgc2000 ManualthuanPas encore d'évaluation

- Transtech Surge Handout Rev2Document44 pagesTranstech Surge Handout Rev2Anonymous 0iYfWI6fPas encore d'évaluation

- HV Switch Gear - PPT-Rev01Document11 pagesHV Switch Gear - PPT-Rev01Lalit Kumar JainPas encore d'évaluation

- Guide To Low Voltage Circuit-Breakers Standards: in Accordance With BS EN 60898-1, BS EN 60898-2 and BS EN 60947-2Document36 pagesGuide To Low Voltage Circuit-Breakers Standards: in Accordance With BS EN 60898-1, BS EN 60898-2 and BS EN 60947-2knsb0% (1)

- Part-B Sub-Section - Iiib-08 TransformerDocument24 pagesPart-B Sub-Section - Iiib-08 TransformerPhanidev Kumar50% (2)

- DNV Earthing Rule Pag.36Document1 pageDNV Earthing Rule Pag.36CHOCAMAN1Pas encore d'évaluation

- 1986-0040-EL-SPE01-0001 RA Specification For Induction MotorsDocument14 pages1986-0040-EL-SPE01-0001 RA Specification For Induction MotorsjmohammadrezaPas encore d'évaluation

- 4016 SeriesDocument20 pages4016 SeriesOGPas encore d'évaluation

- Phoenix Contact 2 PDFDocument49 pagesPhoenix Contact 2 PDFraj sekharPas encore d'évaluation

- ReportDocument2 pagesReportArka EnergyPas encore d'évaluation

- PV-user-manual V2.4 20180523Document60 pagesPV-user-manual V2.4 20180523RICHARDPas encore d'évaluation

- Technical Data Sheet For Avk-Alternators: Unsaturated Saturated Unsaturated SaturatedDocument9 pagesTechnical Data Sheet For Avk-Alternators: Unsaturated Saturated Unsaturated SaturatedTariqMaqsoodPas encore d'évaluation

- Sivacon 8PT-Busbar Rear-Technical CatalogueDocument69 pagesSivacon 8PT-Busbar Rear-Technical CatalogueLaurentiu CatalinPas encore d'évaluation

- Schneider Case StudyDocument5 pagesSchneider Case StudyAnonymous CO7aaHrPas encore d'évaluation

- VHP5904LTDocument2 pagesVHP5904LTm.a.hadiPas encore d'évaluation

- Contactors: Controls Protection Connection AutomationDocument25 pagesContactors: Controls Protection Connection Automationidforemon6898Pas encore d'évaluation

- Understanding Masterpact NW - NTDocument64 pagesUnderstanding Masterpact NW - NTBilal AshrafPas encore d'évaluation

- Full Paper P-031Document9 pagesFull Paper P-031SUBRATA BISWASPas encore d'évaluation

- Dokumen - Tips - Numerical Rho 3 Motor Protection Relay Easun R Current TransformerDocument4 pagesDokumen - Tips - Numerical Rho 3 Motor Protection Relay Easun R Current TransformerPAWAN RAJPUTPas encore d'évaluation

- Operator Training: Panel Kontrol Diesel Engine & Gas Engine Di Fasilitas Produksi Akasia BagusDocument22 pagesOperator Training: Panel Kontrol Diesel Engine & Gas Engine Di Fasilitas Produksi Akasia BagusVERY SYAYIDINAPas encore d'évaluation

- Instalare Si Service PDFDocument8 pagesInstalare Si Service PDFmicon75_tlPas encore d'évaluation

- REF Fuse Application GuideDocument17 pagesREF Fuse Application GuidemuskanumeedPas encore d'évaluation

- 2000kva Power ModuleDocument8 pages2000kva Power ModuleIrfan SaeedPas encore d'évaluation

- ABB ACS550 Drives CatalogueDocument16 pagesABB ACS550 Drives CatalogueAnonymous hXUhpe7S100% (1)

- KUVAG Indicating System CPI VI-3P R (10-52kV)Document3 pagesKUVAG Indicating System CPI VI-3P R (10-52kV)registracijus100% (1)

- Generator Capability CurveDocument37 pagesGenerator Capability CurveJeya KannanPas encore d'évaluation

- Record PlusDocument250 pagesRecord PlusDixie VictoriaPas encore d'évaluation

- 13 SVC Systems Power Quality D 2008-03-12Document10 pages13 SVC Systems Power Quality D 2008-03-12satelite54100% (1)

- 6120+aisikai AtsDocument1 page6120+aisikai AtsАлександр ЩеблыкинPas encore d'évaluation

- Electrical Protective EquipmentDocument17 pagesElectrical Protective EquipmentKhageswar SamalPas encore d'évaluation

- Minilec (India) PVT - LTD.: Price ListDocument13 pagesMinilec (India) PVT - LTD.: Price Listarindam mallickPas encore d'évaluation

- Calculate Transformer Size and MotorDocument2 pagesCalculate Transformer Size and MotorThirumalPas encore d'évaluation

- FNX SDF PDFDocument24 pagesFNX SDF PDFAnonymous SDeSP1Pas encore d'évaluation

- ComAP Powermanagement Load Reserve Calculation V3Document8 pagesComAP Powermanagement Load Reserve Calculation V3pdealersPas encore d'évaluation

- Procom Cop Advance PDFDocument36 pagesProcom Cop Advance PDFBALAJI UPas encore d'évaluation

- PVB Outdoor Vacuum Circuit Breaker (Catalogue)Document27 pagesPVB Outdoor Vacuum Circuit Breaker (Catalogue)Prashanth Chandrashekar100% (1)

- Dry Type Cast Resin TransformersDocument24 pagesDry Type Cast Resin TransformersNguyễn Nhật ÁnhPas encore d'évaluation

- Manual Do Operador IL NT 12-2008Document9 pagesManual Do Operador IL NT 12-2008albertooliveira100% (1)

- Siemens Sge 2mwDocument2 pagesSiemens Sge 2mwmohsen_cumminsPas encore d'évaluation

- Variable Speed Drive Triol АК06Document40 pagesVariable Speed Drive Triol АК06Николай СурминPas encore d'évaluation

- Off-Grid Storage SystemDocument9 pagesOff-Grid Storage SystempennacchiettiPas encore d'évaluation

- Ka Ratings - Copper OnlyDocument10 pagesKa Ratings - Copper OnlySanjeewa HemaratnePas encore d'évaluation

- Det 375Document10 pagesDet 375nicesreekanthPas encore d'évaluation

- Ampacity Chart For Copper Bus Bar DesignDocument2 pagesAmpacity Chart For Copper Bus Bar DesignfaberromeroPas encore d'évaluation

- Ampacity Chart For Copper Bus Bar DesignDocument2 pagesAmpacity Chart For Copper Bus Bar DesignfaberromeroPas encore d'évaluation

- DC KaapelitaulukkoDocument1 pageDC KaapelitaulukkoJuotosKolviPas encore d'évaluation

- Learning To Love VBA PDFDocument108 pagesLearning To Love VBA PDFedalzurc0% (1)

- Gases For Plasma Cutting PDFDocument1 pageGases For Plasma Cutting PDFedalzurcPas encore d'évaluation

- Run Your Diesel Vehicle On Biofuels PDFDocument250 pagesRun Your Diesel Vehicle On Biofuels PDFedalzurcPas encore d'évaluation

- Python Intro To Computer Science PDFDocument261 pagesPython Intro To Computer Science PDFedalzurcPas encore d'évaluation

- MFAC14 Application GuidanceDocument22 pagesMFAC14 Application GuidanceleedodsonPas encore d'évaluation

- Cable Termination - BS5372 - DormanDocument1 pageCable Termination - BS5372 - DormanedalzurcPas encore d'évaluation

- Gases For Plasma CuttingDocument1 pageGases For Plasma CuttingedalzurcPas encore d'évaluation

- Cable Temperature RatingsDocument2 pagesCable Temperature RatingsedalzurcPas encore d'évaluation

- Natural PH IndicatorsDocument3 pagesNatural PH IndicatorsedalzurcPas encore d'évaluation

- Cable 2 ToroidDocument1 pageCable 2 ToroidedalzurcPas encore d'évaluation

- Natural pH-Indicators PDFDocument3 pagesNatural pH-Indicators PDFedalzurcPas encore d'évaluation

- Al-Fanar Derating FactorsDocument1 pageAl-Fanar Derating FactorsedalzurcPas encore d'évaluation

- Fat Fiction - How Do You Get GallstonesDocument12 pagesFat Fiction - How Do You Get GallstonesedalzurcPas encore d'évaluation

- Estimating With Microsoft ExcelDocument9 pagesEstimating With Microsoft ExcelBert EngPas encore d'évaluation

- Naturally Treating GallstonesDocument4 pagesNaturally Treating GallstonesedalzurcPas encore d'évaluation

- Power Amplifier SizingDocument6 pagesPower Amplifier SizingedalzurcPas encore d'évaluation

- B01LX6GEVLDocument155 pagesB01LX6GEVLrphmi100% (2)

- Fat Fiction - How Do You Get GallstonesDocument12 pagesFat Fiction - How Do You Get GallstonesedalzurcPas encore d'évaluation

- Baking Soda A Natural Remedy - Ulcer PainDocument4 pagesBaking Soda A Natural Remedy - Ulcer PainedalzurcPas encore d'évaluation

- Current Transformer Design GuideDocument3 pagesCurrent Transformer Design Guidedeepthik27Pas encore d'évaluation

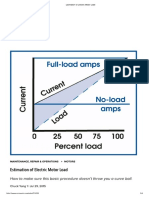

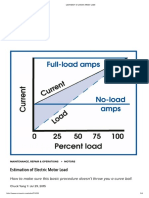

- Estimation of Electric Motor Load PDFDocument4 pagesEstimation of Electric Motor Load PDFedalzurcPas encore d'évaluation

- Hydrogen Gas Cutting System PDFDocument5 pagesHydrogen Gas Cutting System PDFedalzurcPas encore d'évaluation

- Estimation of Electric Motor LoadDocument4 pagesEstimation of Electric Motor LoadedalzurcPas encore d'évaluation

- Red Cabbage PH IndicatorDocument4 pagesRed Cabbage PH IndicatoredalzurcPas encore d'évaluation

- BIOS Password Backdoors in LaptopsDocument4 pagesBIOS Password Backdoors in LaptopsedalzurcPas encore d'évaluation

- Naturally Treating GallstonesDocument4 pagesNaturally Treating GallstonesedalzurcPas encore d'évaluation

- Baking Soda A Natural Remedy - Ulcer PainDocument4 pagesBaking Soda A Natural Remedy - Ulcer PainedalzurcPas encore d'évaluation

- Drive and Folder Sharing Win7Document4 pagesDrive and Folder Sharing Win7edalzurcPas encore d'évaluation

- Aerogen 15piesDocument18 pagesAerogen 15piesJuan Marcelo Rodriguez PereyraPas encore d'évaluation

- Lab 1 1. Determination of Catchment Area Using Topographic MapDocument43 pagesLab 1 1. Determination of Catchment Area Using Topographic MapAashutosh KashyapPas encore d'évaluation

- M-Tech Admission Brochure: 2-Years and 3-Years Programs Session: July, 2019Document6 pagesM-Tech Admission Brochure: 2-Years and 3-Years Programs Session: July, 2019sindhuPas encore d'évaluation

- MCO2 SP300 8011 SP2 8007 Operationmanual enDocument49 pagesMCO2 SP300 8011 SP2 8007 Operationmanual encengiz gunesPas encore d'évaluation

- Mod. SSP-1/EV: Programmable Systems SimulatorDocument2 pagesMod. SSP-1/EV: Programmable Systems Simulatorlusoegyi 1919Pas encore d'évaluation

- ControlLogix For SIL 2 PDFDocument4 pagesControlLogix For SIL 2 PDFveerendraPas encore d'évaluation

- ACS 2000 4 KV: Motor Temperature Supervision InformationDocument6 pagesACS 2000 4 KV: Motor Temperature Supervision InformationJean Carlos da SilvaPas encore d'évaluation

- @achyarnurandi - Simple Configuration TDM Emulation Service On Your Nokia 7705-SAR8 and 7705-SARFDocument10 pages@achyarnurandi - Simple Configuration TDM Emulation Service On Your Nokia 7705-SAR8 and 7705-SARFJesus Rosales100% (1)

- Electrical Safety Form Formula Bharat 2019: Car # Team Name Institution NameDocument30 pagesElectrical Safety Form Formula Bharat 2019: Car # Team Name Institution NameGamin' with skelebonePas encore d'évaluation

- Alternating CurrentDocument17 pagesAlternating CurrentShinjiPas encore d'évaluation

- IEO Syllabus Third Year-Electronics and Communications EngineeringDocument2 pagesIEO Syllabus Third Year-Electronics and Communications EngineeringAkhil AaronPas encore d'évaluation

- EX600 Profibus DPDocument87 pagesEX600 Profibus DPalberto240174Pas encore d'évaluation

- Stock Statement AUG-18.Document38 pagesStock Statement AUG-18.Atul TiwariPas encore d'évaluation

- LPB1 Circuit Analysis PDFDocument1 pageLPB1 Circuit Analysis PDF大石 真義Pas encore d'évaluation

- Canafusion - CA-2000 Specification - 1Document1 pageCanafusion - CA-2000 Specification - 1Anggaran RSUD.M.Natsir SolokPas encore d'évaluation

- Simulation Paper 8Document8 pagesSimulation Paper 8Sandip KumarPas encore d'évaluation

- Manual Gerador FY6900Document49 pagesManual Gerador FY6900Claudio RodriguesPas encore d'évaluation

- Fifth Generation (5G) : by - Shaik Mohammed ShabazDocument16 pagesFifth Generation (5G) : by - Shaik Mohammed Shabazshabaz AmanPas encore d'évaluation

- Reliability 2022 FinalDocument30 pagesReliability 2022 FinalMohamed ElzabalawyPas encore d'évaluation

- Aoc TV LCD L42H831-L47H831-D47H831-D42H831 Jandui PDFDocument101 pagesAoc TV LCD L42H831-L47H831-D47H831-D42H831 Jandui PDFFernando SilvaPas encore d'évaluation

- Pierlite Led PanelsDocument4 pagesPierlite Led PanelsAzeemPas encore d'évaluation

- Air Flow SensorDocument23 pagesAir Flow SensorRinus ZoetebierPas encore d'évaluation

- Product End of Life Instructions: Mixed I/O Module, With Mixed Technologies (Analog, Digital and Hart)Document3 pagesProduct End of Life Instructions: Mixed I/O Module, With Mixed Technologies (Analog, Digital and Hart)Mohd JannahPas encore d'évaluation

- Automatic Rain Detector SynopsisDocument4 pagesAutomatic Rain Detector SynopsisAnkush KhannaPas encore d'évaluation

- (TUTORIAL) Unlock Sim Network On Samsung Galaxy Mini S5570, Ace S5830, Gio S5660, Pop I559, Fit S5670Document30 pages(TUTORIAL) Unlock Sim Network On Samsung Galaxy Mini S5570, Ace S5830, Gio S5660, Pop I559, Fit S5670edwartcano50% (2)

- Spec Sheet - 3306 250 KVA PrimeDocument4 pagesSpec Sheet - 3306 250 KVA PrimeAsantony Raj100% (1)

- LG LTV Pricelist (March 2019)Document3 pagesLG LTV Pricelist (March 2019)galura gizeldaPas encore d'évaluation

- GC Troubleshooting - GC Troubleshooting - Hints and Tips - Chromatography - ChromservisDocument6 pagesGC Troubleshooting - GC Troubleshooting - Hints and Tips - Chromatography - Chromservisசிவஸ்ரீஹரிPas encore d'évaluation

- VTT10000 Manual PDFDocument6 pagesVTT10000 Manual PDFalekyaPas encore d'évaluation

- TDQM 609016 172718DEI 65FT2v02 - 7 16Document1 pageTDQM 609016 172718DEI 65FT2v02 - 7 16Сергей МирошниченкоPas encore d'évaluation