Académique Documents

Professionnel Documents

Culture Documents

713DD600

Transféré par

betojulioCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

713DD600

Transféré par

betojulioDroits d'auteur :

Formats disponibles

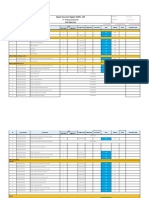

Reference Prcedure EN-P-008

Calculation Face Sheet

Project: CORe FEL3 Study

Client: Vale

Discipline: Mechanical

Calc. Title: Blower Sizing Calculation

Description:

Project No.:

H335456

No. of Sheets:

Revision:

Preliminary

Calc. Doc. No.:

Blower duty calculations for new Rougher/Scavenger and Pyrrhotite Rougher /Scavenger floatation cells

Category of calculation verification required:

Level 5: Review by Lead Engineer (Preliminary Design)

Prepared by:

Date:

Aug 03, 2009

B. Perry

Print Name:

Date:

Preliminary review

by:

Print Name:

Can the calculation now be released for work?

No

To the Client?

No

Date:

Checked by:

Print Name:

Date:

Reviewed by:

Print Name:

Date:

Approved by:

Print Name:

General Notes:

Revision

Date

Superseded by Calculation No.:

Prepared

REVISIONS

Checked

Approved

Description

Date:

Reason voided:

ISO 9001

266953513.xls

Hatch 2009/07

Reference Prcedure EN-P-008

Calculation Face Sheet

Project: CORe FEL3 Study

Client: Vale

Discipline: Mechanical

Project No.:

H335456

No. of Sheets:

Revision:

ISO 9001

266953513.xls

Hatch 2009/07

SHEET NO.

CALCULATION SHEET

__1__

DESCRIPTION

PROJECT NO.

CORe Feasibility Study - Blower Sizing

MADE BY

H335456

B. Perry

DATE

Jul 27. 10

DATE

Assumptions:

1. Blower air will be distributed to the floatation plant via a single header with branches to each bank of cells

2. Nominal pipe sizing based on nominal air velocity of 65 ft/s

3. Pipe sizes based on ANSI B36.10 std wt pipe (final pipe spec will most likely use thinner wall)

4. Pipe absolute roughness coefficient for medium-smooth pipe:

5. Atmosphere assumed as standard air (64 F, 14.7 psi):

Density,

0.0003

ft

0.0753

lbm/ft3

6. Effect of moisture in air is negligible, Gas constant for dry air:

7. Compressibiliy effects on system losses is negligible

8. Temperature effects on system losses is negligible

9. Friction losses and dynamic losses in fittings are factored based on a design factor, df =

Floatation Cell Requirements:

Rougher/scavengers:

10 x Outotec XHD-100

Air required per cell:

883 Aft3/min

Pressure required at top of cell:

5.51 psig

Pyrrhotite rougher/scavengers:

10 x Outotec XHD-100

Air required per cell:

883 Aft3/min

Pressure required at top of cell:

5.51 psig

Assuming T1 = Tstd,

pstd / std.Tstd = p1 / 1.T1 = R

p = RT

Assuming an ideal gas

for

p1 =

1 = 0.10353 lbm/ft3

5.51 psig

For conservation of mass:

std.Qstd = 1.Q1

Standard air required per cell:

Qstd =

1213.9 std ft3/min

24278 std ft3/min

Total standard air requirement:

( 20 cells)

OF

CHECKED BY

1.5

__6__

SHEET NO.

CALCULATION SHEET

__2__

DESCRIPTION

PROJECT NO.

CORe Feasibility Study - Blower Sizing

MADE BY

H335456

B. Perry

DATE

Jul 27. 10

DATE

Main Air Header Size:

Total flow, for 20 cells:

Q=

20

17657 Aft3/min =

883 =

Ideal pipe area for 65 ft/s velocity:

Ap = Q / 65 =

Ideal pipe internal diamater,

Di = ( 4 * Ap / ) 1/2 =

Closest standard pipe size is 30 inch OD,

Aft3/s

294

4.5 ft2

2.40

ft =

28.81 in

Std wt wall thickness = 0.375 inch, Di =

29.25 in

Single Bank Air Header Size:

Flow:

Q = 5 x 883 =

Ideal pipe area for 65 ft/s velocity:

Ap = Q / 65 =

Ideal pipe internal diamater,

Di = ( 4 * Ap / )

Closest standard pipe size is 16 inch OD,

4414

Aft3/min =

73.6

Aft3/s

1.1 ft2

1/2

1.20

ft =

Std wt wall thickness = 0.375 inch, Di =

14.41

in

15.25

in

Single Cell Air Pipe Size:

Flow:

Q = 1 x 883 =

883 Aft3/min =

Ideal pipe area for 65 ft/s velocity:

Ap = Q / 65 =

0.2 ft2

Ideal pipe internal diamater,

Di = ( 4 * Ap / ) 1/2 =

Closest standard pipe size is 6 inch OD,

Std wt wall thickness = 0.280 inch, Di =

Assumed Configuration:

105'

20'

16''

18''

16'

6''

30''

16''

0.48

ft =

OF

CHECKED BY

14.7 Aft3/s

5.81 in

5.44 in

__6__

SHEET NO.

CALCULATION SHEET

__3__

DESCRIPTION

PROJECT NO.

CORe Feasibility Study - Blower Sizing

MADE BY

H335456

OF

__6__

CHECKED BY

B. Perry

DATE

Jul 27. 10

DATE

Approximate System Losses:

Formulae:

ref. ASHRAE Handbook 2009 ed.

Blower to Header:

Nominal pipe size = 18"

Pipe internal diameter = hydraulic diameter:

Pipe Area:

Ap = * (Dh / 2)

Flow:

Velocity:

V = Q / Ap

Approximate Pipe Length:

Dh =

17.25 in

Ap =

233.7 in2

Q =

4414 Aft3/min

V =

2720 Aft/min

L =

Approximate Reynolds number:

Re =

Friction factor:

pf =

Estimated total losses:

Header:

20 ft

3.99E+05

0.0200

Friction pressure loss:

1.62 ft2

Err:522

0.177 inch WG

0.00639 psi

0.266 inch WG

0.00959 psi

Nominal pipe size = 30"

Pipe internal diameter = hydraulic diameter:

Pipe Area:

Ap = * (Dh / 2)

Flow:

Velocity:

V = Q / Ap

Approximate Pipe Length:

Approximate Reynolds number:

Dh =

29.25 in

Ap =

672.0 in2

Q =

17657 Aft3/min

V =

3784 Aft/min

L =

Re =

Friction factor:

Friction pressure loss:

50 ft

9.41E+05

0.0200

pf =

4.67 ft2

0.505 inch WG

Err:522

=

0.01824 psi

pf . df =

Estimated total losses:

0.758 inch WG

0.02736 psi

SHEET NO.

CALCULATION SHEET

__4__

DESCRIPTION

PROJECT NO.

CORe Feasibility Study - Blower Sizing

MADE BY

H335456

Jul 27. 10

DATE

Nominal pipe size = 16"

Pipe internal diameter = hydraulic diameter:

Pipe Area:

Ap = * (Dh / 2) 2

Flow:

Velocity:

V = Q / Ap

Approximate Pipe Length:

Dh =

15.25 in

Ap =

182.7 in2

Q =

4414 Aft3/min

V =

3480 Aft/min

L =

Approximate Reynolds number:

Re =

4.51E+05

0.0200

pf =

Friction pressure loss:

pf . df =

Estimated total losses:

1.27 ft2

141 ft

Friction factor:

Cell Feed Line:

__6__

B. Perry

DATE

Header To Last Cell:

OF

CHECKED BY

Err:522

2.312 inch WG

0.08345 psi

3.468 inch WG

0.12517 psi

Nominal pipe size = 6"

Pipe internal diameter = hydraulic diameter:

Pipe Area:

Ap = * (Dh / 2)

Flow:

Velocity:

V = Q / Ap

Dh =

5.44 in

Ap =

23.2 in2

Q =

883 Aft3/min

V =

Approximate Pipe Length:

5470 Aft/min

L =

Approximate Reynolds number:

15 ft

Re =

2.53E+05

Friction factor:

0.0200

pf =

Friction pressure loss:

pf . df =

Estimated total losses:

Summation of System Losses =

7.05 inch WG

0.25

0.06148 psi

2.555 inch WG

0.09221 psi

psi

= pressure required at cell + system losses

=

5.51

5.77

psig

0.25

=

159.8

Err:522

1.703 inch WG

Blower Discharge Pressure

Estimated blower discharge pressure:

0.16 ft2

inch WG

SHEET NO.

CALCULATION SHEET

__5__

DESCRIPTION

PROJECT NO.

CORe Feasibility Study - Blower Sizing

MADE BY

H335456

B. Perry

DATE

Jul 27. 10

DATE

Blower Power

Blower power,

HP =

f =

Assuming total fan efficiency,

0.7

HPtotal =

Total blower power,

p in inch WG

Q.p / 6356.f

872

Estimated from curve

HP

HPea =

For four duty blowers, power for each,

217.9

HP

Recommend 250 HP drive motor.

Spencer Power Mizer Blower Size Selection

Total blower capacity, Qtotal =

For four duty blowers, Qea

Approximate blower total pressure,

24278 std ft3/min

6069.38 std ft3/min

pt =

159.8 inch WG

5.8 psig

OF

CHECKED BY

__6__

SHEET NO.

CALCULATION SHEET

__6__

DESCRIPTION

CORe Feasibility Study - Blower Sizing

PROJECT NO.

MADE BY

H335456

B. Perry

DATE

Spencer Power Mizer Series 6000 Blower Recommended

Jul 27. 10

OF

CHECKED BY

DATE

__6__

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Fuel Tank Buying Guide PDFDocument4 pagesFuel Tank Buying Guide PDFlutfi_ismailPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- DE I790117301 0240MEC0301 - R0 Layout1Document1 pageDE I790117301 0240MEC0301 - R0 Layout1betojulioPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Project Initialization: Minesight 100-Series Programs Program SummariesDocument64 pagesProject Initialization: Minesight 100-Series Programs Program SummariesJuan Alvarado ZegarraPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- G LIT Fire-Hopper PDFDocument2 pagesG LIT Fire-Hopper PDFbetojulioPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Thord Wennberg Lic2010Document112 pagesThord Wennberg Lic2010Sergio Manuel Ovando ChaconPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Solids and Slurries - Definition of TermsDocument12 pagesSolids and Slurries - Definition of TermsAndresPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Manual For Printing8Document401 pagesManual For Printing8betojulio100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- General Notes: Concrete Notes: Abbreviations: Reinforcement Clearance DetailDocument53 pagesGeneral Notes: Concrete Notes: Abbreviations: Reinforcement Clearance DetailbetojulioPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- 606 SaniTite HP To Dissimiliar Pipe ConnectionDocument1 page606 SaniTite HP To Dissimiliar Pipe ConnectionbetojulioPas encore d'évaluation

- Anexo ADocument3 pagesAnexo AbetojulioPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Feeder or Conveyor: What's The Difference and Why Does It Matter?Document4 pagesFeeder or Conveyor: What's The Difference and Why Does It Matter?Neeraj AgrawalPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Roberts - Feeder Design PDFDocument31 pagesRoberts - Feeder Design PDFLuis Alonso Hoyos AvalosPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Horizontal Pump 760 MCRDocument7 pagesHorizontal Pump 760 MCRbetojulioPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- PUCAM-00-B-001 - 100-Simbología P&ID PDFDocument1 pagePUCAM-00-B-001 - 100-Simbología P&ID PDFbetojulioPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Feeder or Conveyor: What's The Difference and Why Does It Matter?Document4 pagesFeeder or Conveyor: What's The Difference and Why Does It Matter?Neeraj AgrawalPas encore d'évaluation

- 606 SaniTite HP To Dissimiliar Pipe Connection PDFDocument1 page606 SaniTite HP To Dissimiliar Pipe Connection PDFbetojulioPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- HDPE Installation ManualDocument37 pagesHDPE Installation ManualKunnilath Satish100% (1)

- Pipe Pocket Guide1 PDFDocument37 pagesPipe Pocket Guide1 PDFbetojulioPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- ADS SpecificationsDocument24 pagesADS Specificationsbeto061684Pas encore d'évaluation

- A5 20 Post Installation Testing of HP StormDocument4 pagesA5 20 Post Installation Testing of HP StormbetojulioPas encore d'évaluation

- ADS Specifications PDFDocument24 pagesADS Specifications PDFbetojulioPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- ADH5-Installation August 2016Document33 pagesADH5-Installation August 2016betojulioPas encore d'évaluation

- 608 HDPE To HDPE Connection (MarMac)Document1 page608 HDPE To HDPE Connection (MarMac)betojulioPas encore d'évaluation

- Valvula Bola 1500 PsiDocument8 pagesValvula Bola 1500 PsibetojulioPas encore d'évaluation

- The Basic Principle of Dresser Couplings PDFDocument1 pageThe Basic Principle of Dresser Couplings PDFbetojulioPas encore d'évaluation

- Model 3d AnilloDocument1 pageModel 3d AnillobetojulioPas encore d'évaluation

- Angus MonitorsDocument16 pagesAngus Monitorsmuhammadtayyab_87Pas encore d'évaluation

- Akron Monitors CatalogDocument22 pagesAkron Monitors CatalogbetojulioPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Valvula Bola 1500 PsiDocument8 pagesValvula Bola 1500 PsibetojulioPas encore d'évaluation

- Drawing Weak Acid CoolerDocument1 pageDrawing Weak Acid CoolerbetojulioPas encore d'évaluation

- Chapter-3 PPTDocument109 pagesChapter-3 PPTnunuPas encore d'évaluation

- Technical Proposal For Cryogenic Nitrogen GeneratorDocument28 pagesTechnical Proposal For Cryogenic Nitrogen Generatora.faramarziPas encore d'évaluation

- PNE00001Document23 pagesPNE00001Максим ХилоPas encore d'évaluation

- Surge CalcsDocument29 pagesSurge CalcsThamotharanPas encore d'évaluation

- WafercheckDocument4 pagesWafercheckjuan serranoPas encore d'évaluation

- Test Method For Determination of Valve Flow CoefficientDocument14 pagesTest Method For Determination of Valve Flow CoefficientCharan KumarPas encore d'évaluation

- BVM Series Catalog Section-FinalDocument5 pagesBVM Series Catalog Section-FinalsaulomonPas encore d'évaluation

- Content Dam LMC New-PDF LMC Flanges - Product RangeDocument11 pagesContent Dam LMC New-PDF LMC Flanges - Product RangebenePas encore d'évaluation

- GA 132 - 125psig (8.6bar) - Air CooledDocument1 pageGA 132 - 125psig (8.6bar) - Air CooledGleidson AnteroPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- User Manual Capillary Tube 06-03-18Document5 pagesUser Manual Capillary Tube 06-03-18Anonymous uEOZ7raPkzPas encore d'évaluation

- 072 90 00 EngineAcessoryDocument30 pages072 90 00 EngineAcessoryblackhawkPas encore d'évaluation

- Domestik KAP.400M : Dosing Pump ExistingDocument1 pageDomestik KAP.400M : Dosing Pump ExistingHanum PravitasariPas encore d'évaluation

- PSV Price LESER 2018Document204 pagesPSV Price LESER 2018WG GZ100% (2)

- 35 82 Suction Guides IandODocument6 pages35 82 Suction Guides IandOKhalifa Mohammed RiswanPas encore d'évaluation

- Lecture #2 Hydraulic Reservoirs & PumpsDocument27 pagesLecture #2 Hydraulic Reservoirs & PumpsWei ChingPas encore d'évaluation

- Master Document Register (MDR) - SOP: PT. PP (Persero) - Divisi EPC QHSE Department Up To Date: 15 Juli 2017Document8 pagesMaster Document Register (MDR) - SOP: PT. PP (Persero) - Divisi EPC QHSE Department Up To Date: 15 Juli 2017NazirussalimPas encore d'évaluation

- NPT, Nps & - ThreadsDocument3 pagesNPT, Nps & - ThreadsklashincoviskyPas encore d'évaluation

- HDS01Document3 pagesHDS01Sylvain AguedaPas encore d'évaluation

- Catálogo Bombas KSB PDFDocument142 pagesCatálogo Bombas KSB PDFYerco David Marin Quidequeo0% (1)

- B 350 Forced Air Vortex Flare System 1976Document6 pagesB 350 Forced Air Vortex Flare System 1976Hassan GDOURAPas encore d'évaluation

- FogBuster InstallDocument5 pagesFogBuster Installth.wilbersPas encore d'évaluation

- Haskel Pump SelectionDocument3 pagesHaskel Pump Selectionsondk2100% (1)

- Thickness Monitoring (TM) EquipmentDocument236 pagesThickness Monitoring (TM) EquipmentTommyPas encore d'évaluation

- MECTR Question Paper BankDocument10 pagesMECTR Question Paper BankDept. Of Mechanical Engg.Pas encore d'évaluation

- NEMO - MultiphasenpumpeDocument9 pagesNEMO - MultiphasenpumpeCesar MerchanPas encore d'évaluation

- Diagram Alir Neraca Massa Over AllDocument1 pageDiagram Alir Neraca Massa Over AllTeknik Kimia PLS1 Kelas B 2018Pas encore d'évaluation

- Aerodynamics For Engineering Students 6th Edition Houghton Solutions Manual DownloadDocument16 pagesAerodynamics For Engineering Students 6th Edition Houghton Solutions Manual DownloadKimberly Leavins100% (24)

- Catalogo K 20 en PDFDocument118 pagesCatalogo K 20 en PDFsanthoshkrishnaPas encore d'évaluation

- HS372221 26 Pip Iso 0168 0000 1 - Rm01aDocument1 pageHS372221 26 Pip Iso 0168 0000 1 - Rm01aibrahim qasimovPas encore d'évaluation

- Fan HistoryDocument6 pagesFan HistoryAsadPas encore d'évaluation

- University of Chicago Press Fall 2009 Distributed TitlesD'EverandUniversity of Chicago Press Fall 2009 Distributed TitlesÉvaluation : 1 sur 5 étoiles1/5 (1)

- University of Chicago Press Fall 2009 CatalogueD'EverandUniversity of Chicago Press Fall 2009 CatalogueÉvaluation : 5 sur 5 étoiles5/5 (1)