Académique Documents

Professionnel Documents

Culture Documents

Tablet Everfesent

Transféré par

Adit TaufikCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Tablet Everfesent

Transféré par

Adit TaufikDroits d'auteur :

Formats disponibles

International Journal for Pharmaceutical Research Scholars (IJPRS)

ISSN No: 2277-7873

RESEARCH ARTICLE

V-1, I-2, 2012

Formulation and Evaluation of Effervescent Tablet of Paracetamol and Ibuprofen

Patel HK1*, Chauhan P, Patel KN, Patel BA, Patel PA

1

Shree Swaminarayan Sanskar Pharmacy College, Zundal, Gujarat-382421, India

Manuscript No: IJPRS/V1/I2/00078, Received On: 12/05/2012, Accepted On: 16/05/2012

ABSTRACT

Recently, fast-dissolving drug delivery system have started gaining popularity and acceptance as new

drug delivery system, because they are easy to administer and lead to better compliance. Usually, elderly

people experience difficulty in swallowing the tablet. Paracetamol having analgesic, antipyretic effect,

they inhibit cyclooxygenase enzyme involved in prostaglandin (PG) synthesis but not in peripheral

tissue while Ibuprofen inhibit prostaglandin (PG) synthesis in peripheral tissue so in this study

Paracetamol and Ibuprofen combination used for analgesic, anti-pyretic and anti-inflammatory action

simultaneously. The aim of this study was to formulate effervescent tablet with sufficient mechanical

integrity and to achieve faster disintegration in the water. Effervescent tablets are uncoated tablets that

generally contain acid substances and carbonates or bicarbonates and which react rapidly in the presence

of water by releasing carbon dioxide. They are intended to be dissolved or dispersed in water before use.

Effervescent compositions in the form of tablets are comprising a therapeutic agent, granulating agent,

and an effervescent system which dissolve rapidly in water to yield an effervescent solution containing a

completely dissolved therapeutic agent and a process for their preparation. In this study different ratio of

Citric acid and Sodium bicarbonate was used, superdisintegrant like SSG and cross-providone was used,

compared to cross-providone SSG decreases the Solution time of tablet. Granules prepared by Wet

granulation technique and from the result it was found that the Particle size 355-500 m of granules

show good Solution time and Hardness property.

KEYWORDS

Effervescent tablet, COX-1, COX-2, Paracetamol, Ibuprofen.

INTRODUCTION

The oral dosage forms are the most popular way

of taking medication despite having some

disadvantages like slow absorption and thus

onset of action is prolong. This can be overcome

by administrating the drug in liquid from but,

many APIs have limited level of stability in

liquid form. So, Effervescent tablets acts as an

alternative dosage form. The tablet is added into

a glass of water just before administration and

the drug solution or dispersion is to be drunk

immediately. The tablet is quickly broken apart

by internal liberation of CO2 in water due to

*Address for Correspondence:

Hiren K. Patel

Department of Pharmaceutics,

Shree SwaminarayanSanskar Pharmacy College,

Zundal, Gujarat, India.

E-Mail Id: hkpatel88@yahoo.com

Copyright reserved by IJPRS

interaction between Tartaric acid and Citric acid

with alkali metal carbonates or bicarbonates in

presence of water.1

Effervescent granules are usually prepared from

a combination of Citric acid and Tartaric acid

rather than from a single acid because the use of

either acid alone causes difficulties. When

Tartaric acid is the sole acid, the resulting

granules readily crumble and lack mechanical

strength. Citric acid alone results in a sticky

mixture which is difficult to granulate during

the manufacturing process.

Effervescent salts include the following

ingredients, which actually produce the

effervescence, Sodium bicarbonate, Citric acid

and Tartaric acid. When added to water the acid

509

Formulation and Evaluation of Effervescent Tablet of Paracetamol and Ibuprofen

and base react to liberate carbon dioxide,

resulting in Effervescence. It should be noted

that any acid-base combination which results in

the liberation of carbon dioxide could be used in

place of this combination as long as the

ingredients are suitable for pharmaceutical

use.The reaction between Citric acid and

Sodium bicarbonate and Tartaric acid and

Sodium bicarbonate, which results in liberation

of carbon dioxide, may be shown as follows:2,3

H3C6H5O7.H2O+ 3 NaHCO3

H2O +3 CO2

Na3C6H5O7 +4

Citric acid

Sodium bicarbonate Sodium

citrate Water Carbon dioxide

H2C4H4O6+ 2 NaHCO3

H2O + 2CO2

Na2C4H4O6 +

discs were prepared by compressing the

powders at a pressure of 5 tons for 5 min in a

hydraulic press. Forty scans were obtained at a

resolution of 4 cm-1, from 4000 to 400 cm-1.6,7

Drug-Excipients Compatibility Study by

DSC

The DSC study was carried out using DSC-60

(Shimadzu, Tokyo, Japan). The instrument

comprises of calorimeter, flow controller,

thermal analyzer and operating software. The

samples (drug and excipients) were heated in

sealed aluminum pans under nitrogen flow (30

ml/min) at a scanning rate of 5C/min from 50

to 300C. Empty aluminum pan was used as a

reference. The heat flow as a function of

temperature was measured for the samples.8,9

Tartaric acid Sodium bicarbonate Sodium

tartarate Water Carbon dioxide

PREPARATION OF CORE TABLETS

It should be noted that it requires 3 molecules of

Sodium bicarbonate to neutralize 1 molecule of

Citric acid and 2 molecule of Sodium

bicarbonate to neutralize 1 molecule of Tartaric

acid. The proportion of acids may be varied.

Usually it is desired that ratio of Citric acid to

Tartaric acid equals 1:2 so that the desired ratio

of the ingredients can be calculated as follows,

Wet Granulation: The Wet granulation process

performed into three steps

Citric

acid:

Tartaric

acid:

bicarbonate=1:2:3.44(by weight)4,5

Acid granulation

Sodium

MATERIALS AND METHODS

Paracetmol and Ibuprofen were obtained from

Acron Pharmaceutical Pvt. Ltd.(Ahmedabad,

India). Spray dried lactose was obtained from

Flumost

pharmaceuticals

(USA).

Other

ingredients used were of analytical grade.

DRUG - EXCIPIENTS COMPATIBILITY

STUDY

Drug-Excipients Compatibility Study by FTIR

Fourier-transform infrared (FT-IR) spectra were

obtained using an FT-IR spectrometer. The

Zaltoprofen and Excipients were previously

ground and mixed thoroughly with potassium

bromide, an infrared transparent matrix, at 1:5

(Sample: KBr) ratio, respectively. The KBr

Copyright reserved by IJPRS

First method10,11,12

A) Dry Mixing & Granulation

B) Lubrication of Granules

C) Compression of Lubricated Granules

A) Dry Mixing & Granulation

In first step Weight the Citric acid, Tartaric acid

were blended and passed through Sieve No.40#.

In second step binding agent pvp-k-30 dissolved

in IPA.

The above Organic Solvent was mixed with

Acid portions i.e. Citric acid & Tartaric acid.

The obtained wet mass passed through sieve

no.20# & kept in tray dried at 600C for 1 hr.

Base granulation

In Base granulation firstly the Sodium

bicarbonate, Sodium carbonate were blended

and passed through sieve no.40#In the second

step the Binding agent pvp-k-30 was dissolved

in Organic solvent i.e. IPA. The above organic

solvent was mixed with Base portions i.e.

Sodium bicarbonate & Sodium carbonate. The

510

Formulation and Evaluation of Effervescent Tablet of Paracetamol and Ibuprofen

obtained wet mass passed through sieve no.20#

& kept in tray dried at 600c for 1 hr.

B) Lubrication of acid and base granules

After drying at Room Temperature of both

granules i.e. Acid granules and Base granules

were mixed.After mixing of both granules the

Paracetamol, Ibuprofen, flavour and Lubricating

agent like Sodium benzoate added to the

granules and well mixed.

C) Compression of Lubricated Granules

The Lubricated granules were compressed into

tablet by using rotary tablet punching machine.

(15mm punch)

Second method18

Drug (Paracetamol and Ibuprofen), Sodium

bicarbonate and Potassium carbonate were

blended & passed through sieve no. 40#,

granules prepared by using binding agent (8 ml

Water and 12 ml Ethanol) & dry at 60oC for 1

hr. Citric acid, Sodium bicarbonate, Magnesium

carbonate, spray dried lactose, SSG, PVP-K-30

and Sodium benzoate were blended and pass

through sieve no. 40#, granules prepared by

using binding agent (Ethanol) & dry at 60oC for

30 min. Both granules mix and dry at 60oC for

15 min. Granules were compressed into tablet

by using Single rotary tablet punching machine.

(15 mm punch)

EVALUATION PARAMETER

comprises of calorimeter, flow controller,

thermal analyzer and operating software. The

samples (drug and excipients) were heated in

sealed aluminum pans under air flow (30

ml/min) at a scanning rate of 20C/min from 50

to 300C. Empty aluminum pan was used as a

reference. The heat flow as a function of

temperature was measured for the samples.

POWDER FLOW PROPERTY

Angle of Repose13,14

The angle of repose of the mixture of the drug

and excipients was determined by fixed funnel

method. The values are used in the following

equation to get the angle of repose.

tan = h/r

Where, h, r and are the height, radius and

angle of repose of the powder pile.

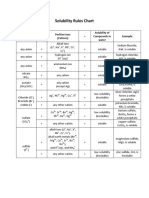

Table 1: Relation of Angle of Repose with

Powder Flow

Angle of repose

Powder flow

< 25

Excellent

25-30

Good

30-40

Passable

40 >

Very Poor

FTIR study

Fourier-transform infrared (FT-IR) spectra were

obtained using an FT-IR spectrometer

(Shimadzu 8400S, Japan). The samples

(Zaltoprofen and Excipients) were previously

ground and mixed thoroughly with potassium

bromide, an infrared transparent matrix, at 1:5

(Sample:KBr) ratio, respectively. The KBr discs

were prepared by compressing the powders at a

pressure of 5 tons for 5 min in a hydraulic press.

Forty scans were obtained at a resolution of 4

cm-1, from 4000 to 400 cm-1.

Bulk Density and Tapped Density15

Accurately weighed of the sample was

transferred to the measuring cylinder of bulk

density apparatus and noted the volume as bulk

volume. The apparatus was adjusted for 100

tapping and noted the final volume as tapped

volume.

DSC study

Bulk density = mass of powder (w) / bulk

volume (Vb)

The DSC study was carried out using DSC-60

(Shimadzu, Tokyo, Japan). The instrument

Tapped density= mass of powder (w) / tapped

volume (V100)

Copyright reserved by IJPRS

511

Formulation and Evaluation of Effervescent Tablet of Paracetamol and Ibuprofen

Table 2: Composition of Batches F1-F9 by using Different Binding Agent

Ingredients

F1*

F2*

F3*

F4*

F5*

F6*

F7*

F8*

F9*

Ibuprofen

200

200

200

200

200

200

200

200

200

Paracetamol

325

325

325

325

325

325

325

325

325

Sodium bicarbonate

500

625

750

500

625

750

500

625

750

Citric acid(anhydrous)

250

250

250

250

250

250

250

250

250

Spray dried lactose

20

20

20

20

20

20

20

20

20

Magnesium carbonate

40

40

40

40

40

40

40

40

40

SSG

40

40

40

40

40

40

40

40

40

Sodium benzoate

20

20

20

20

20

20

Mannitol

Ethanol

2%

-

2%

-

2%

-

2%

2%

2%

PEG-6000

2%

2%

2%

F14*

F15*

F16*

F17*

200

325

525

250

100

20

40

40

20

2%

-

200

325

650

250

100

20

40

40

20

2%

-

200

325

700

400

100

20

40

20

20

2%

2%

200

325

850

400

150

20

40

20

20

2%

2%

*All values are expressed in mg/tablet

Table 3: Composition of Batches F10-F17

Ingredients

F10*

F11*

F12*

F13*

Ibuprofen

200

200

200

200

Paracetamol

325

325

325

325

Sodium bicarbonate

400

525

650

400

Citric acid(anhydrous)

250

250

250

250

Potassium carbonate

100

100

100

100

Spray dried lactose

20

20

20

20

Magnesium carbonate

40

40

40

40

SSG

40

40

40

40

Cross-providone

Sodium benzoate

20

20

20

20

Pvp-k-30

#

Pvp-k-30**& Ethanol

2%

2%

2%

#

Pvp-k-30**& Methanol

2%

#

Ethanol+Water**& Ethanol

#

*All values are expressed in mg/tablet, **Acid portion, Base portion

Copyright reserved by IJPRS

512

Formulation and Evaluation of Effervescent Tablet of Paracetamol and Ibuprofen

Compressibility Index16,17

The Carrs index of the powder was determined

by using formula:

Carrs index (%) = [(TBD LBD) 100]/TBD

Where, TBD is the total bulk density and LBD

is the loose bulk density.

Table 4: Relation of Carrs Index and Hausners

Ratio with Powder Flow

and analyzed by the use of UV Spectrometer at

340 nm.

Hardness

The hardness of the core tablets and coated

tables were measured using the Pfizer hardness

tester. Six tablets from each formulation were

randomly selected and used. The average

hardness and the standard deviation were

calculated. It is expressed in Kg/cm2.

Thickness

Carrs

Index

Flow

Characteristics

Hausners

Ratio

< 10

Excellent

1.00-1.11

11-15

Good

1.12-1.18

Thickness of the core tablets and coated tablets

were measured by using screw gauge. Ten

tablets from each formulation were randomly

selected and used. Thickness is expressed in

millimeters.

16-20

Fair

1.19-1.25

Friability test20

21-25

Passable

1.26-1.34

26-31

Poor

1.35-1.45

32-37

Very Poor

1.46-1.59

> 38

Extremely Poor

>1.60

Twenty tablets were weight and placed in the

Electrolab friabilator and apparatus was rotated

at 25 rpm for 4 min. After revolution the tablets

were de-dusted and weight. Percentage friability

was calculated from the loss in weight as given

in equation as below. The weight loss should

not be more than 1%.

Hausners Ratio

The Hausners ratio and Carrs index

aremeasures of the flow properties ofpowders.

A Hausners ratio of <1.25indicates a powder

that is free flowingwhereas >1.25 indicates poor

flow ability.

Solution time21,22

Hausners ratio = tapped density / Bulk density

The pH of solution can measured by pH meter,

pH of solution prepared by putting tablets into

water was affected by storage condition due to

liberation of CO2.

EVALUATION OF THE CORE TABLET

Weight Variation Test

Twenty tablets were randomly selected from

each batch and individually weighed. The

average weight and standard deviation of 20

tablets was calculated.

Content Uniformity18,19

Tablets were crushed in mortal and sufficient

amount of ethanol was added to dissolve

properly. Then appropriate dilution was done

Copyright reserved by IJPRS

Time required for 2 tablets to dissolve in 180ml

of water at 17.5 2.5oC.

pH of the solution test23,24

Water content25,26

Titration method used to determine the water

content. In contrast to drying method, this is a

specific method if no side reactions occur only

water will be determined. While using drying

method some problem occurs like apart from

water, other volatile components of the sample

and decomposition products are also

determined. Titration method is rapid (few

513

Formulation and Evaluation of Effervescent Tablet of Paracetamol and Ibuprofen

minutes), can be validated & therefore fully

documented. With the Karlfischer (KF) titration

both free and bound water can be determined

e.g. surface water as crystals or the water

content inside them. The method works over a

wide concentration range from ppm upto 100%

and supplies reproducible and correct result.

Drug content

Formation of two simultaneous equations

were:

Set of two simultaneous equations were:

Cx = (A2 ay1 - A1 ay2)/ (ax2 ay1 - ax1 ay2)

and

Cy = (A1 ax2 - A2ax1)/ (ax2 ay1 - ax1 ay2),

Where

A1 and A2 are the absorbance of sample

solutions at 221.8 nm and 242.2 nm

respectively.

RESULT AND DISCUSSION

Interpretation of FTIR spectra

Compatibility studies were performed using

FTIR spectrophotometer. The characteristic

absorption peaks of pure drug and mixture with

other excipientswere obtained at different wave

numbers.

The peaks obtained in the spectra of pure drug

correlates with the peaks of drug with other

excipients. It does not show any major changes

in peaks which indicate no well-defined

interaction in drug and excipients spectrum.

This indicates that the drug is compatible with

the formulation components. The spectrum for

pure drug and excipients are shown in figure 1

to 4 and interpretations of spectrum are reported

in table no.5.

Cx and Cy are concentration of Ibuprofen and

Paracetamol in mg/mL in sample solution.

By substituting the values of A1 and A2 the

values of Cx and Cy can be calculated by

solving the two equations simultaneously. Here,

ax1 and ax2 are the absorptivity coefficient of

Ibuprofen at 221.8 nm and 242.2 nm

respectively; ay1 and ay2 are the absorptivity

coefficient of Paracetamol at 221.8 nm and

242.2 nm respectively.27,28

Estimation of Paracetamol and Ibuprofen in

Tablet:

Mix content of 20 Tablets and calculate the

average content weight of one tablet. Take

average weight of one tablet and make up the

volume of filtrate with Phosphate buffer

solution 7.2 pH. Filter this solution i.e. it

contains 325mg/100ml of Paracetamol and

200mg/100ml of Ibuprofen, this solution was

appropriately diluted to get approximate

concentration of 10g/ml. The absorbance of

sample solution was measured at 221.8 nm and

242.2 nm against blank. The content of

Paracetamol and Ibuprofen in tablet was

calculated using two framed simultaneous

equations.29,30

Copyright reserved by IJPRS

Figure 1: FT-IR Spectrum of Paracetamol

Figure 2: FT-IR Spectrum of Ibuprofen

514

Formulation and Evaluation of Effervescent Tablet of Paracetamol and Ibuprofen

Drug-Excipients Compatibility Study by

DSC:

Figure 3: FT-IR Spectra of Paracetamol and

Ibuprofen Mixture

The DSC thermograms of pure drug and with

other excipients are depicted in Figure 6.13.

Here, pure drug has the melting point at 174

C&80oC for Paracetamol and Ibuprofen.

Mixture has the melting point at 187 C and 85

o

C. No change in the endotherm peak of the

drug was observed in the mixture of drug with

other excipients. From this, it was inferred that

there was no interaction between the drug and

excipients.23,24

Figure 4: FT-IR Spectra of Paracetamol and

Ibuprofen with all Formulation Excipients

Table 5: Interpretation of FT-IR Spectra21,22

Wave number (cm-1)

Group

Figure 5: Overlay DSC Thermogram of Pure

Paracetamol, Pure Ibuprofen and Physical

mixture

Paracetamol +

Ibuprofen

Physical

mixture

CH3 asymmetrical

stretching

2953.45

2955.38

O-HO stretching

combination

2360.44

2360.44

C=O stretching

1714.41

1714.41

The values obtained for angle of repose all (F1F17) formulations are tabulated in Table 6. All

formulation has value in the range of 25.37 to

39.17.This indicates good flow property of the

powder blends.

Amide II band

1509.03

1509.03

Density

CH-CO

deformation

1420.32

1428.99

OH in plane

deformation

1326.79

1326.79

C.C stretching

1227.47

1230.36

C-N-H group

1070.3

1070.3

Para-disubstituted

aromatic ring

1009.55

1011.48

Copyright reserved by IJPRS

Angle of Repose()

a) Loose bulk Density(LBD)

The values obtained for loose bulk density of

(F1-F17) formulations are given in Table 6. The

maximum value of LBD was found to be 0.66

and minimum value was found to be 0.50 which

indicates good flow property. LBD value of all

(F1-F17) formulations ranges between 0.500.66.

515

Formulation and Evaluation of Effervescent Tablet of Paracetamol and Ibuprofen

b) Tapped density

The values obtained for tapped bulk density of

all (F1-F17) formulations are in Table 6. TBD

value of all (F1-F17) formulations ranges

between 0.59-0.79.

Hausners Ratio

The values obtained for Hausners ratio for all

(F1-F17) formulations are in Table. Hausners

ratio value of all (F1-F17) formulations ranges

between 1.12 - 1.26 indicating that the powder

blends have good flow property.

Carrs compressibility index

The values obtained for compressibility index

for all (F1-F17) formulations are tabulated in

Table. Compressibility index of all formulations

(F1-F17) was found between 10.81% - 20.77%

indicating that the powder blends have good

flow property.

Table 6: Evaluation of Powder blend (Batches F1-F17)

Formulations

Angle of

repose

()

Loose bulk

density

(LBD)

Tapped bulk

density (TBD)

Hausners

Ratio

Carrs

Compressibility

Index

(%)

F1

25.67

0.62

0.70

1.12

11.42

F2

27.06

0.64

0.72

1.13

11.11

F3

36.88

0.60

0.74

1.23

18.91

F4

29.74

0.54

0.62

1.15

12.90

F5

32.23

0.52

0.60

1.15

13.33

F6

29.82

0.55

0.63

1.14

12.69

F7

39.17

0.58

0.72

1.24

19.44

F8

39.53

0.61

0.77

1.26

20.77

F9

38.71

0.63

0.78

1.24

19.23

F10

26.82

0.61

0.69

1.13

11.59

F11

25.57

0.63

0.71

1.13

11.27

F12

28.31

0.58

0.66

1.14

12.12

F13

29.14

0.52

0.60

1.16

13.33

F14

26.87

0.55

0.62

1.13

11.30

F15

31.28

0.53

0.65

1.22

18.47

F16

25.37

0.62

0.70

1.13

11.42

F17

29.81

0.54

0.63

1.17

14.28

Copyright reserved by IJPRS

516

Formulation and Evaluation of Effervescent Tablet of Paracetamol and Ibuprofen

Table 7: Evaluation of Tablet (Batches F1-F9)

Formulations

Hardness

(kg/cm2)

Solution

time(second)

Friability

(%)

Content

uniformity(%)

pH of solution

F1

3.5

175

0.71

103*&105#

6.32

F2

4.0

155

0.60

91*&93#

6.11

F3

3.5

142

0.62

91*&97#

6.27

F4

3.0

117

0.85

94*&101#

6.35

F5

2.5

115

0.90

102*&92#

6.12

F6

2.0

117

0.80

99*&107#

6.93

F7

2.5

132

Fail

91*&97#

5.33

F8

2.5

135

Fail

104*&92#

5.47

F9

2.0

128

Fail

94*&101#

5.40

*Paracetamol, #Ibuprofen

Table 9: Evaluation of Tablet (Batches F10-F17)

Formulations

Hardness

(kg/cm2)

Solution

time

(second)

Friability

(%)

Content

uniformity (%)

pH of

solution

F10

3.1

130

0.80

98*&93#

7.00

F11

3.5

125

0.75

97*&98#

6.95

F12

3.2

127

0.81

97*&100#

7.10

F13

3.5

215

0.73

100*&107#

6.80

F14

4.0

187

0.65

104*&92#

7.05

F15

3.2

174

0.72

92*&92#

7.10

F16

4.5

133

0.30

98*&98#

7.18

F17

5.0

128

0.34

99*&97#

7.15

Water

Content

(%)

1.4

1

1.8

1

1

*Paracetamol, #Ibuprofen

Copyright reserved by IJPRS

517

Formulation and Evaluation of Effervescent Tablet of Paracetamol and Ibuprofen

CONCLUSION

a) In present work we are used different acids

and bases in different concentration from that

we conclude 1:2.5 ratio was excellent for this

formulation.

b) The total nine placebo tablets were prepared

and evaluated for hardness, disintegration

time, weight variation and solubility. All the

formulation shows hardness and weight

variation with in limit but the combination of

citric

acid

(20.00%),

sodium

bicarbonate(42.5%),

potassium

carbonate(5.0%),

magnesium

carbonate(5.0%) for thefinal formulation, and

the binding agent PVP-K-30(2%) and sodium

benzoate (1%).because these ingredients

shows the good effervescent reaction and has

no problem in capping and sticking like other

formulation.

c) These formulations evaluated for hardness,

friability, and weight variation, solution time

etc. Formulation having acid base ratio 1:2

solution time found 125 to 135 second, ratio

1:2.5 solution time found 115 to 125 second

and ratio 1:3 solution time found 105 to 115

second, ratio 1:3 shows good solution time

but they hardness was found to be 2 to

3kg/cm2, while ratio 1:2.5 having harness 4

to 5kg/cm2 so acid base ratio 1:2.5 having

good Solution time, Hardness and other

parameters.

d) The effervescent tablets of Paracetamol and

Ibuprofen can be formulated for quick

analgesic, anti-pyretic action and antiinflammatory action by effervescence

reaction using citric acid (20%), sodium

bicarbonate (42.5%) and magnesium

carbonate (5.0%), potassium carbonate

(5.0%), pvp-k-30 (2%) gives the better

effervescence. The Ethanol used as the

binding agent. Sodium benzoate (1%) used as

lubricating agent.

e) Water content can be measured by Karl

Fischer titration method. Its values reveal that

content of moisture in tablet.

Copyright reserved by IJPRS

f) The effervescent tablets were prepared by

wet granulation by using different binding

agent like pvp-k-30, mannitol, ethanol, peg6000 (also act as lubricant).

g) The prepared tablets were evaluated for

content uniformity and physical parameters,

while using peg-6000 and mannitol as

binding agent the solution time was low

compared to pvp-k-30 and ethanol.

h) When acid granulation and base granulation

performed separately hardness problem

occurs and Ibuprofen not soluble in a glass of

water at the time of taking medicines. To

overcome Ibuprofen solubility problem base

part granulate with drug i.e Paracetamol and

Ibuprofen using binding agent ethanol and

water, remaining part like acid, base,

lubricant granulate with ethanol in this part

pvp-k-30(2%) added in dry form, developing

formula by above method having good

evaluations parameters.

REFERENCES

1. Srinath KR, Chowdary P, Palanisamy P,

Vamsy K, Aparna S and Ali S, Formulation

and Evaluation of Effervescent Tablets of

Paracetamol. International Journal of

Pharmaceutical Research and Development,

2011, 2(12), 76-104.

2. Liberman H., Lachman L., Pharmaceutical

Dosage Forms: Tablets; Marcel Dekker Inc

New York, 1993, 85.

3. Liberman H., Lachman L., Pharmaceutical

Dosage Forms: Tablets; Marcel Dekker Inc

New York, 2005, 286-292.

4. Bolt I, Merrifield D and Carter P.

Pharmaceutical

Formulation

with

Effervescent

Couple.

U.S.

Patent

005962022, Oct. 5, 1999.

5. Pearlswig

D.M,

Masters

Thesis,

Simulation Modeling Applied to the Single

Pot Processing of Effervescent Tablets.

North Carolina State University, 1995.

6. Ali K, Effervescent Granules and Methods

for Their Preparation, May 2005,

518

Formulation and Evaluation of Effervescent Tablet of Paracetamol and Ibuprofen

www.pharmainfo.net/reviews/reviewpatents-effervescent-granules.pdf

7. Parikh D., Handbook of Pharmaceutical

Granulation Marcel Dekker Inc. New York,

1997, 339.

8. Stahl H, Drying of Pharmaceutical

Granules in Single Pot Systems. Indian

Journal of Pharmaceutical Science. 1999,

7(61), 656-661.

9. Roscheisena G and Schmidt P, Preparation

and Optimisation of Leucine as Lubricant

for Effervescent Tablet Formulations.

Pharmaceutical Acta Helvetiae. 1995, 2(70),

133-139.

10. Rotthauser B, Kraus G and Schmidt P,

Optimization of Effervescent Tablet

Formulation Containing Spray Dried Lleucine and Polyethylene Glycol 6000 as

Lubricants using a Central Composite

Design. European Journal of Pharmaceutics

and Biopharmaceutics. 1998, 6(46), 85-94.

11. Van der Goten W, A Special Requirement

for Tablet Presses to be Used in

Effervescent Production. Technical Paper,

Halle, 2001.

12. Robert E, Lee M, Packaging of

Effervescent

Material,

2005,

www.amerilabtech.com/packaging/effervesc

entmaterial.

13. Ancel H., Popovich N. And Allen L.,

Pharmaceutical Dosage Forms and Drug

Delivery Systems; B. L. Waverly Private

Ltd, 1999, 469-471.

14. Howard L., Martin J., Harrisons Principles

of Internal Medicines; 16th Edn; McGrawhill Medical Publishing Division, 2005, 7175.

15. Lipsky P., Harrisons Principles of Internal

Medicines; 16th Edn; McGraw-hill Medical

Publishing Division, 2005, 1968-1970.

16. Arnett F, The American Rheumatism

Association 1987 Revised Criteria for the

Classification of Rheumatoid Arthritis.

Arthritis Rheum. 1988, 31, 315.

Copyright reserved by IJPRS

17. Choi H, Methotrexate and Mortality in

Patients with Rheumatoid Arthritis.

Clinical Therapeutics, 2002, 35, 160-173.

18. Gruber

P.

Effervescent

Ibuprofen

Preparation and Process for the Production.

U.S. Patent 0172981, Jul. 8, 2010.

19. Krishna S and Supanaranond W, Fever in

Uncompticated Plasmodium Falciparum

Malaria:

Randomized

Double-blind

Comparison of Ibuprofen and Paracetamol

Treatment. The Royal Society of Tropical

Medicine and Hygiene. 1995, 89, 507-509.

20. Livshits A, Machtinger R, David LB and

Spira M, Ibuprofen and Paracetamol for

Pain Relief During Medical Abortion: a

Double-blind

Randomized

Controlled

Study. Fertility and Sterility. 2009, 5(91),

1877-1880.

21. Kanabar D, Dale S and Rawat M,

Ibuprofen and Paracetamol Use in Febrile

Children and the Occurrence of AsthmaRelated Symptoms. Clinical Therapeutics.

2007, 12(29), 2716-2723.

22. Paul I, Sarah A, Yang C and Watts H,

Efficacy of Standard Doses of Ibuprofen

Alone, Alternating, and Combined with

Acetaminophen for the Treatment of Febrile

Children. Clinical Therapeutics. 2010,

14(32), 2433-2440.

23. Moore R, Straube S, Paine J, Derry S and

McQuay H, Minimum Efficacy Criteria for

Comparisons between Treatments Using

Individual Patient Meta-analysis of Acute

Pain Trials: Examples of Etoricoxib,

Paracetamol,

Ibuprofen,

and

Ibuprofen/Paracetamol Combinations after

Third Molar Extraction. International

Association for the Study of Pain. 2011,

152, 982989.

24. Helmy A, Kady S and Khames A,

Preparation, Characterization, and Invitro/vivo Evaluation of Indion-based

Chewable Tablets of Paracetamol and

Ibuprofen for Pediatric Use.Journal of

American Science. 2011, 7(12), 831-844.

519

Formulation and Evaluation of Effervescent Tablet of Paracetamol and Ibuprofen

25. Perioli L, Ambrogi V, Angelici F, Ricci M

and Giovagnoli S, Development of

Mucoadhesive

Patches

for

Buccal

Administration of Ibuprofen. Journal of

Control Release. 2004, 99, 73-82.

26. Pather L. Effervescent Drug Delivery

System for Oral Administration. U.S. Patent

6509036, Jan 21, 2003.

27. Gondalia R, Mashru R, Savaliya P,

Development

and

Validation

of

Spectrophotometric

Methods

for

Simultaneous Estimation of Ibuprofen and

Paracetamol in Soft Gelatin Capsule by

Simultaneous

Equation

Method.

International

Journal

of

ChemTech

Research. 2010, 2(4), 1881-1885.

Copyright reserved by IJPRS

28. Bolt J., Merrifield D. Pharmaceutical

Formulation with Effervescent Couple. U.S.

Patent 5962022, Oct 5, 1999.

29. Khoshayand M, Abdollahi H, Shariatpanahi

M and Saadatfard A, Simultaneous

Spectrophotometric

Determination

of

Paracetamol, Ibuprofen and Caffeine in

Pharmaceuticals by Chemometric Methods,

Spectrochimica Acta Part A. 2008, 70, 491

499.

30. Joshi R, Pawar N, Katiyar S and Devendra

B, Development and Validation of UV

Spectrophotometric

Methods

for

Simultaneous Estimation of Paracetamol and

Ibuprofen in Pure and Tablet Dosage Form.

Der Pharmacia Sinica. 2011, 2 (3), 164-171.

520

Vous aimerez peut-être aussi

- UV-Visible Spectrophotometric Method of Paracetamol Tablet FormulationDocument5 pagesUV-Visible Spectrophotometric Method of Paracetamol Tablet FormulationEditor IJTSRDPas encore d'évaluation

- 10 11648 J SJC 20180602 11 PDFDocument7 pages10 11648 J SJC 20180602 11 PDFAnonymous XDKzvvpFzzPas encore d'évaluation

- Analytical Methods for Major and Modified Nucleosides - HPLC, GC, MS, NMR, UV and FT-IRD'EverandAnalytical Methods for Major and Modified Nucleosides - HPLC, GC, MS, NMR, UV and FT-IRPas encore d'évaluation

- Sulfur Precipitated MSDS: Section 1: Chemical Product and Company IdentificationDocument6 pagesSulfur Precipitated MSDS: Section 1: Chemical Product and Company IdentificationImma OlayanPas encore d'évaluation

- Ionic Liquids in Lipid Processing and Analysis: Opportunities and ChallengesD'EverandIonic Liquids in Lipid Processing and Analysis: Opportunities and ChallengesXuebing XuPas encore d'évaluation

- Kinetics of Ester HydrolysisDocument24 pagesKinetics of Ester HydrolysisNick OnuskaPas encore d'évaluation

- Calcium Gluconate 10 Injection B.P DR 1433675212243Document2 pagesCalcium Gluconate 10 Injection B.P DR 1433675212243Ayash Kant HotaPas encore d'évaluation

- Preparation of 4-Nitrophenylacetonitrile and 4-Nitrophenylacetic AcidDocument9 pagesPreparation of 4-Nitrophenylacetonitrile and 4-Nitrophenylacetic AcidNdumiso Manyathi0% (1)

- ASEAN TMHS GMP Training - Chapter 8 - Contract Manufacturing and Analysis GMP Seminar Dec 2018 MLB PDFDocument18 pagesASEAN TMHS GMP Training - Chapter 8 - Contract Manufacturing and Analysis GMP Seminar Dec 2018 MLB PDFbuena100% (1)

- High-Performance Liquid ChromatographyDocument5 pagesHigh-Performance Liquid ChromatographyYulia PrimasariPas encore d'évaluation

- FTS CP SyrupDocument14 pagesFTS CP SyrupWara RizkyPas encore d'évaluation

- USP1225Document10 pagesUSP1225jljimenez1969Pas encore d'évaluation

- CH 17 PDFDocument15 pagesCH 17 PDFkrishnaPas encore d'évaluation

- Metformin+Glibenclamide Thesis PDFDocument114 pagesMetformin+Glibenclamide Thesis PDFnari9Pas encore d'évaluation

- Amperometric TitrationsDocument5 pagesAmperometric Titrationsarun231187100% (1)

- Paracetamol PDFDocument23 pagesParacetamol PDFJinav GhataliaPas encore d'évaluation

- Altering Product StrengthDocument44 pagesAltering Product StrengthAngelica Salvatierra0% (2)

- Experiment T2: Chromatographic Purity Profiling of A Sample of Paracetamol Pure Substance Aims and ObjectivesDocument3 pagesExperiment T2: Chromatographic Purity Profiling of A Sample of Paracetamol Pure Substance Aims and Objectivesjontusiire67% (3)

- Drug Receptor and PharmacodynamicsDocument45 pagesDrug Receptor and PharmacodynamicsFebrianaMPas encore d'évaluation

- Method Development and Validation of Paracetamol Drug by RP-HPLC 1Document7 pagesMethod Development and Validation of Paracetamol Drug by RP-HPLC 1Anonymous ncDgoMOPas encore d'évaluation

- Comparison of The Solubilization Effect of Micronized PoloxamersDocument1 pageComparison of The Solubilization Effect of Micronized Poloxamerssaeedazadi1352Pas encore d'évaluation

- A Review On Derivative Uv-Spectrophotometry Analysis of Drugs-Jcchems-63!03!4126Document9 pagesA Review On Derivative Uv-Spectrophotometry Analysis of Drugs-Jcchems-63!03!4126Gustavo100% (1)

- Chimie An II Chemestry Essay About Paracetamol (Acetaminophen)Document6 pagesChimie An II Chemestry Essay About Paracetamol (Acetaminophen)Anca-Alina BujenitaPas encore d'évaluation

- Advanced Pharmaceutical AnalysisDocument4 pagesAdvanced Pharmaceutical AnalysisRezaul RazibPas encore d'évaluation

- Paracetamol StabilityDocument5 pagesParacetamol StabilityElia LindraPas encore d'évaluation

- StabilitystudiesDocument99 pagesStabilitystudiesromita duttaPas encore d'évaluation

- Search USP29: HQ Copper SulphateDocument3 pagesSearch USP29: HQ Copper SulphateAntony GamalPas encore d'évaluation

- HPMC Pittcon 2008Document1 pageHPMC Pittcon 2008Sonet SahaPas encore d'évaluation

- Development & Validation of HPLC Analytical Assay For Mefenamic Acid.Document11 pagesDevelopment & Validation of HPLC Analytical Assay For Mefenamic Acid.Anonymous SDUIPeqXPas encore d'évaluation

- Effect of System Parameters On Controlled ReleaseDocument49 pagesEffect of System Parameters On Controlled ReleaseSindhur Sreedharan MPas encore d'évaluation

- ICPMS Reading MaterialDocument40 pagesICPMS Reading MaterialHimanshiPas encore d'évaluation

- Expression Vectors PDFDocument2 pagesExpression Vectors PDFJennifer33% (3)

- Assay of Aspirin: 1-Spectrophotometric MethodsDocument11 pagesAssay of Aspirin: 1-Spectrophotometric MethodsMasamkele Mdondolo33% (3)

- Magnesium Stearate: Magnesii StearasDocument3 pagesMagnesium Stearate: Magnesii StearaswilPas encore d'évaluation

- Sigma Aldrich Grading ChartDocument2 pagesSigma Aldrich Grading Chartjm06100% (1)

- Glimepiride TabletDocument48 pagesGlimepiride Tabletrabd samPas encore d'évaluation

- Acid Ascorbic StabilityDocument29 pagesAcid Ascorbic StabilityJaime PerezPas encore d'évaluation

- BCS Class of DrugsDocument45 pagesBCS Class of DrugsLionO50% (2)

- European Journal of Biomedical AND Pharmaceutical SciencesDocument14 pagesEuropean Journal of Biomedical AND Pharmaceutical SciencesSACHIN BHASKAR NARKHEDEPas encore d'évaluation

- Procedure For Penicillin ContaminationDocument43 pagesProcedure For Penicillin Contaminationsarikayas100% (4)

- Food MicrobiologyDocument2 pagesFood MicrobiologyEditor IJTSRDPas encore d'évaluation

- Scientific Approach For RP-HPLC Method Development Complete ReviewDocument11 pagesScientific Approach For RP-HPLC Method Development Complete ReviewijsidonlineinfoPas encore d'évaluation

- Pharmaceutical EngineringDocument24 pagesPharmaceutical EngineringKedai Kado UnikPas encore d'évaluation

- Analysis of Paracetamol Tablets Using A Calibration CurveDocument4 pagesAnalysis of Paracetamol Tablets Using A Calibration CurveRicky RafinaldiPas encore d'évaluation

- PolymorphismDocument14 pagesPolymorphismPrem SinghPas encore d'évaluation

- Practical Titration PDFDocument164 pagesPractical Titration PDFCojocaru George0% (1)

- IPC-IP Addendum - 2019 Salient - FeaturesDocument2 pagesIPC-IP Addendum - 2019 Salient - FeaturespawnammalPas encore d'évaluation

- TBOC FMOC Protocols in Peptide SynthesisDocument30 pagesTBOC FMOC Protocols in Peptide Synthesissantosh kumar sahoo100% (1)

- Atomic Absorption Spectroscopy:A Special Emphasis On Pharmaceutical and Other ApplicationsDocument6 pagesAtomic Absorption Spectroscopy:A Special Emphasis On Pharmaceutical and Other ApplicationsdewiPas encore d'évaluation

- Development and Evaluation of Fast Dissolving Tablets of FlurbiprofenDocument11 pagesDevelopment and Evaluation of Fast Dissolving Tablets of FlurbiprofenJOURNAL CLUB FOR PHARMACEUTICAL SCIENCES (JCPS)Pas encore d'évaluation

- Ibuprofen (Pharmacopoea)Document3 pagesIbuprofen (Pharmacopoea)Titis Adisti HapsariPas encore d'évaluation

- 1228 5 PDFDocument5 pages1228 5 PDFdeepanmb007Pas encore d'évaluation

- Experiment 3Document14 pagesExperiment 3HanyszShalPas encore d'évaluation

- Stability Indicating RP-HPLC Method For The Determination of Terbutaline Sulphate, Guaifenesin, Ambroxol Hydrochloride and Preservatives Content in Liquid FormulationsDocument6 pagesStability Indicating RP-HPLC Method For The Determination of Terbutaline Sulphate, Guaifenesin, Ambroxol Hydrochloride and Preservatives Content in Liquid FormulationsHanimi ReddyPas encore d'évaluation

- Karl Fischer Water DeterminationDocument3 pagesKarl Fischer Water DeterminationEmad AliPas encore d'évaluation

- Pharmaceutical ExcipientsDocument5 pagesPharmaceutical Excipientsmads56091Pas encore d'évaluation

- Dealing With Post Approval Changes-Supac: Wasim Raja.S Sri Venkateswara College of PharmacyDocument52 pagesDealing With Post Approval Changes-Supac: Wasim Raja.S Sri Venkateswara College of PharmacyProf_WasimPas encore d'évaluation

- Classroom IntructionsDocument1 pageClassroom IntructionsAdit TaufikPas encore d'évaluation

- Classroom IntructionsDocument1 pageClassroom IntructionsAdit TaufikPas encore d'évaluation

- AritmiaDocument28 pagesAritmiaAdit TaufikPas encore d'évaluation

- McfarlandDocument2 pagesMcfarlandAdit TaufikPas encore d'évaluation

- GuptaDocument7 pagesGuptaAdit TaufikPas encore d'évaluation

- DPPH Oleh MolyneuxDocument9 pagesDPPH Oleh MolyneuxReski AmaliaPas encore d'évaluation

- Coconut Health StudyDocument9 pagesCoconut Health StudyAdit TaufikPas encore d'évaluation

- Antioxidant TCWDocument12 pagesAntioxidant TCWAdit TaufikPas encore d'évaluation

- Minuman Probiotik PengujianDocument7 pagesMinuman Probiotik PengujianAdit TaufikPas encore d'évaluation

- Organic Syntheses Collective Volume 5Document1 162 pagesOrganic Syntheses Collective Volume 5caltexas100% (4)

- Experiment 7 - Batch ReactorDocument5 pagesExperiment 7 - Batch Reactormythili83% (6)

- Topic 01 Stiochiometry and Mole AsDocument6 pagesTopic 01 Stiochiometry and Mole AszafarchemPas encore d'évaluation

- w328 Concentration Worksheet PDFDocument2 pagesw328 Concentration Worksheet PDFtheresia gallaPas encore d'évaluation

- 4.CPP S BlockDocument6 pages4.CPP S BlockRuchira SahaPas encore d'évaluation

- Is 12681 1989Document15 pagesIs 12681 1989dipen royPas encore d'évaluation

- Reactivity Series & Corrosion of MetalsDocument9 pagesReactivity Series & Corrosion of MetalsabdulrehmanPas encore d'évaluation

- Plasguard 7122 PDFDocument18 pagesPlasguard 7122 PDFNageswara Rao BavisettyPas encore d'évaluation

- Chapter 3 BPSDocument21 pagesChapter 3 BPSAngel FaithPas encore d'évaluation

- Further Evidence For Gaseous CO2 Transport in Relation To Root Uptake of CO2 in Rice PlantDocument13 pagesFurther Evidence For Gaseous CO2 Transport in Relation To Root Uptake of CO2 in Rice Plantjonathen jaganPas encore d'évaluation

- Chemical Eq and ReactionsDocument35 pagesChemical Eq and ReactionsskandhaPas encore d'évaluation

- B405 00Document25 pagesB405 00Ahmed HussienPas encore d'évaluation

- 1.1 & 1.2 - Chemistry and Its Importance & Scientific MethodDocument24 pages1.1 & 1.2 - Chemistry and Its Importance & Scientific MethodsivagurusasPas encore d'évaluation

- General Chemistry NotesDocument24 pagesGeneral Chemistry NotesGary MuhwatiPas encore d'évaluation

- MCQs in Fluid and Electrolyte Balance With AnswersDocument50 pagesMCQs in Fluid and Electrolyte Balance With AnswersAbdulkadir Waliyy Musa100% (2)

- Expt 6 PresentationDocument27 pagesExpt 6 PresentationTj DacalanioPas encore d'évaluation

- SaltDocument5 pagesSaltElvera MarlianiPas encore d'évaluation

- 0620 w08 QP 03Document25 pages0620 w08 QP 03Hubbak KhanPas encore d'évaluation

- Calcium PDFDocument3 pagesCalcium PDFJakir AhmedPas encore d'évaluation

- Chapter 10. Sulphuric Acid: Short QuestionsDocument14 pagesChapter 10. Sulphuric Acid: Short QuestionsAbhay VishwakarmaPas encore d'évaluation

- North Vista 2015 Prelim Paper 1Document20 pagesNorth Vista 2015 Prelim Paper 1GM MonsterEtaPas encore d'évaluation

- Effect of Denture Cleansers On Cobalt-Chromium Alloy Surface: A Simulated Period of 5 Years' UseDocument9 pagesEffect of Denture Cleansers On Cobalt-Chromium Alloy Surface: A Simulated Period of 5 Years' UseAmina Sakly BoussaidPas encore d'évaluation

- Mini Project Potassium ClorideDocument6 pagesMini Project Potassium ClorideAbdul QayyumPas encore d'évaluation

- Solubility Rules ChartDocument2 pagesSolubility Rules ChartLumwanga MukadiPas encore d'évaluation

- List of Analytical ReagentsDocument7 pagesList of Analytical ReagentskishormamunPas encore d'évaluation

- GEG #1 Mobil Pegasus 805Document2 pagesGEG #1 Mobil Pegasus 805dhavit wijayantoPas encore d'évaluation

- SBHS Preliminary Chemistry Yearly ExDocument19 pagesSBHS Preliminary Chemistry Yearly ExGary ZhangPas encore d'évaluation

- 8 SaltsDocument13 pages8 SaltswanyanaPas encore d'évaluation

- Chapter 1: Introduction: 1.1 Definition, Necessity and Scope of IrrigationDocument15 pagesChapter 1: Introduction: 1.1 Definition, Necessity and Scope of IrrigationKubaPas encore d'évaluation

- Test Review Topic 13:3 AK PDFDocument10 pagesTest Review Topic 13:3 AK PDFKeyerria HowardPas encore d'évaluation

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincD'EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincÉvaluation : 3.5 sur 5 étoiles3.5/5 (137)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeD'EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeÉvaluation : 4 sur 5 étoiles4/5 (1)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeD'EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeÉvaluation : 5 sur 5 étoiles5/5 (4)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsD'EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsÉvaluation : 4 sur 5 étoiles4/5 (146)

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsD'EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsÉvaluation : 5 sur 5 étoiles5/5 (3)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeD'EverandChemistry for Breakfast: The Amazing Science of Everyday LifeÉvaluation : 4.5 sur 5 étoiles4.5/5 (90)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolD'EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolPas encore d'évaluation

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableD'EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- Meltdown: Nuclear disaster and the human cost of going criticalD'EverandMeltdown: Nuclear disaster and the human cost of going criticalÉvaluation : 5 sur 5 étoiles5/5 (5)

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilD'EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilÉvaluation : 5 sur 5 étoiles5/5 (1)

- Chemistry: a QuickStudy Laminated Reference GuideD'EverandChemistry: a QuickStudy Laminated Reference GuideÉvaluation : 5 sur 5 étoiles5/5 (1)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookD'EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookPas encore d'évaluation

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideD'EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuidePas encore d'évaluation

- Taste: Surprising Stories and Science About Why Food Tastes GoodD'EverandTaste: Surprising Stories and Science About Why Food Tastes GoodÉvaluation : 3 sur 5 étoiles3/5 (20)

- Bioplastics: A Home Inventors HandbookD'EverandBioplastics: A Home Inventors HandbookÉvaluation : 4 sur 5 étoiles4/5 (2)

- A Perfect Red: Empire, Espionage, and the Quest for the Color of DesireD'EverandA Perfect Red: Empire, Espionage, and the Quest for the Color of DesireÉvaluation : 4 sur 5 étoiles4/5 (129)

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsD'EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsPas encore d'évaluation

- Tribology: Friction and Wear of Engineering MaterialsD'EverandTribology: Friction and Wear of Engineering MaterialsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeD'EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeÉvaluation : 5 sur 5 étoiles5/5 (1)

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookD'EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookPas encore d'évaluation