Académique Documents

Professionnel Documents

Culture Documents

Dekguard Filler

Transféré par

Venkata RaoDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Dekguard Filler

Transféré par

Venkata RaoDroits d'auteur :

Formats disponibles

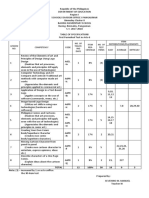

Dekguard Filler*

Acrylic, intercoat pin hole filler

Uses

Instructions for use

Levelling and filling of intercoat pin holes and minor

irregularities prior to the application of pigmented Dekguard

topcoats.

Coating

Advantages

n Single component no mixing required.

n Easy to apply.

n Can be applied to vertical surfaces without slumping.

Description

Dekguard Filler, an external quality filler is based on acrylic

resin and fine fillers.

It has been specially developed for use with the Dekguard

concrete protection system.

If Dekguard Primer* or Nitoprime DG* is to be used it must

be applied prior to applying Dekguard Filler. Dekguard Filler

should be tightly trowelled onto the prepared surface ensuring

that all pin holes and defects are completely filled to produce

a smooth even finish. It is essential that the material is well

worked into the surface in order to ensure maximum adhesion

and minimum thickness. Dekguard Filler can be applied to

existing coatings. The surface of the existing coating has to

be cleaned and abraded. In order to determine if Dekguard

Filler is compatible with the existing coating it may be

necessary to carry out adhesion tests.

Excellent adhesion of the topcoat will be achieved provided

that the Dekguard Filler surface is not contaminated. Where

contamination does occur, e.g. from general dust or cement

debris, then this should be removed prior to overcoating.

Technical support

Cleaning

Fosroc offers a comprehensive technical support service to

specifiers, end users and contractors. It is also able to offer

on-site technical assistance, an AutoCAD facility and

dedicated specification assistance in locations all over the

world.

Tools and equipment should be cleaned with water

immediately after use.

Pack Size

Dekguard Filler

Properties

Form

Bulk density

Application

temperature

Overcoating time

Estimating

:

:

Single component white paste

1500 kg/m3

:

:

5 to 40C

12 hours minimum

18 litre pack

Coverage

Coverage of Dekguard Filler is wholly dependent upon

surface conditions, site trials are therefore recommended to

ascertain actual usage on uneven substrates.

Storage

Shelf life

Dekguard Filler

6 months

Dekguard Filler

Store Dekguard Filler upright in unopened original containers

in cool dry conditions. Storage outside these guidelines will

impair shelf life.

Precautions

Additional Information

Health and safety

Fosroc manufactures a wide range of complementary

products which include :

Wear suitable protective clothing, gloves and eye protection.

The use of barrier creams provide additional skin protection.

In case of contact with eyes, rinse immediately with plenty of

clean water and seek medical attention immediately. If

swallowed seek medical attention immediately - do not induce

vomiting.

Fire

n waterproofing membranes & waterstops

n joint sealants & filler boards

n cementitious & epoxy grouts

n specialised flooring materials

Fosroc additionally offers a comprehensive package of

products specifically designed for the repair and

refurbishment of damaged concrete. Fosrocs Systematic

Approach to concrete repair features the following :

Dekguard Filler is non-flammable

n hand-placed repair mortars

n spray grade repair mortars

n fluid micro-concretes

n chemically resistant epoxy mortars

n anti-carbonation/anti-chloride protective coatings

n chemical and abrasion resistant coatings

For further information on any of the above, please consult

your local Fosroc office - as below.

* Denotes the trademark of Fosroc International Limited

REGIONAL SALES OFFICES IN :

Al Gurg Fosroc LLC

P. O. Box 657

Dubai

United Arab Emirates

TEL : (04) 285 8606

FAX : (04) 285 9649

DUBAI

ABU DHABI

BAHRAIN

KUWAIT

OMAN

QATAR

Al Gurg Fosroc

Al Gurg Fosroc

YBA Kanoo

Boodai

GETCO

Tadmur

TEL : 285 8787

TEL : 673 1779

TEL : 738200

TEL : 481 7618

TEL : 771 5080

TEL : 441 3628

FAX : 285 2023

FAX : 673 1449

FAX : 732828

FAX : 483 2124

FAX : 771 7554

FAX : 444 0812

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard terms and conditions of sale, copies of which

may be obtained on request. Whilst Fosroc endeavours to ensure that the technical information on this data sheet is correct at the time of printing, it is the

customers responsibility to satisfy himself, by checking with the company that this information is still current at the time of use, that the product is suitable for

the intended application, and that the actual conditions of use are in accordance with those recommended. Because Fosroc has no control over the conditions of

use of its products, all recommendations or suggestions regarding the use of these products are made without guarantee.

www.fosrocgulf.com

UAE/0097/00/E

Vous aimerez peut-être aussi

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionD'EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionPas encore d'évaluation

- Trafficguard UrDocument2 pagesTrafficguard UrVenkata RaoPas encore d'évaluation

- Powder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsD'EverandPowder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsÉvaluation : 4.5 sur 5 étoiles4.5/5 (17)

- Render CureDocument2 pagesRender CureVenkata RaoPas encore d'évaluation

- Petroleum Refinery Relocation Projects: 5-Phases of Project ManagementD'EverandPetroleum Refinery Relocation Projects: 5-Phases of Project ManagementPas encore d'évaluation

- Nitotile 489Document2 pagesNitotile 489Venkata RaoPas encore d'évaluation

- Proofex GPXDocument2 pagesProofex GPXVenkata RaoPas encore d'évaluation

- Renderoc Plug: Uses SpecificationDocument2 pagesRenderoc Plug: Uses SpecificationVenkata RaoPas encore d'évaluation

- Plasterroc MPRDocument2 pagesPlasterroc MPRVenkata RaoPas encore d'évaluation

- Nitoseal 105: Uses PropertiesDocument2 pagesNitoseal 105: Uses PropertiesVenkata RaoPas encore d'évaluation

- Quality Assurance: Application Guide Jotafloor SealerDocument1 pageQuality Assurance: Application Guide Jotafloor SealerTamerTamerPas encore d'évaluation

- Renderoc BFDocument2 pagesRenderoc BFAdnan Jadoon50% (2)

- Polycoat RbeDocument2 pagesPolycoat RbejovindhaPas encore d'évaluation

- Fosroc Trafficguard UR: Constructive SolutionsDocument2 pagesFosroc Trafficguard UR: Constructive SolutionsSaud PathiranaPas encore d'évaluation

- Renderoc FCXtra SubmittalDocument35 pagesRenderoc FCXtra SubmittalAjit Singh Rathore100% (1)

- TDS 0004 FlexoPrime 202003Document3 pagesTDS 0004 FlexoPrime 202003Mearg NgussePas encore d'évaluation

- POLYCOATDocument2 pagesPOLYCOATGeorge TsiamtsourisPas encore d'évaluation

- Quality Assurance: Application Guide Tankguard 412Document1 pageQuality Assurance: Application Guide Tankguard 412TamerTamerPas encore d'évaluation

- Plasteroc MPRDocument2 pagesPlasteroc MPRTori SmallPas encore d'évaluation

- Rd6appspecDocument2 pagesRd6appspecravi00098Pas encore d'évaluation

- TDS - 0063 CapaFilex - 202003Document3 pagesTDS - 0063 CapaFilex - 202003Mearg NgussePas encore d'évaluation

- Dimetcote 9 PDS AIDocument3 pagesDimetcote 9 PDS AIAmer Y KPas encore d'évaluation

- ProrocplasterofparisdssenDocument2 pagesProrocplasterofparisdssenAdeleye Adedeji PaulPas encore d'évaluation

- ReebolDocument2 pagesReebolVenkata RaoPas encore d'évaluation

- Dekguard WBprimerDocument2 pagesDekguard WBprimerVenkata Raju KalidindiPas encore d'évaluation

- TDS CapaPrimeDocument3 pagesTDS CapaPrimeMearg NgussePas encore d'évaluation

- TDS 0033 FlexoTop 202003Document3 pagesTDS 0033 FlexoTop 202003Mearg NgussePas encore d'évaluation

- Proofex GPDocument2 pagesProofex GPSyed ShahbazPas encore d'évaluation

- Penguard Clear Sealer: Technical Data Sheet Application GuideDocument7 pagesPenguard Clear Sealer: Technical Data Sheet Application GuideAnonymous 4SFfEmcHmDPas encore d'évaluation

- Cicol EtslurryDocument4 pagesCicol EtslurryVenkata RaoPas encore d'évaluation

- Conbextra Ep300Document4 pagesConbextra Ep300Venkata RaoPas encore d'évaluation

- TDS - Masterflow 524Document2 pagesTDS - Masterflow 524Venkata RaoPas encore d'évaluation

- Nitobond Ep..Document4 pagesNitobond Ep..budhikurniawanPas encore d'évaluation

- Intercrete 4802 - AG - Rev1 - EngDocument5 pagesIntercrete 4802 - AG - Rev1 - EngLinnie McleodPas encore d'évaluation

- DC786 TechnicalDocument3 pagesDC786 TechnicalfanofphonicsPas encore d'évaluation

- Intergard 986Document4 pagesIntergard 986Ashta VakrPas encore d'évaluation

- Pilot II: Technical Data Sheet Application GuideDocument6 pagesPilot II: Technical Data Sheet Application Guidendt stanleyPas encore d'évaluation

- Intergard 475HS: Primed SurfacesDocument3 pagesIntergard 475HS: Primed SurfaceskareemPas encore d'évaluation

- Nitobond ARDocument2 pagesNitobond ARSantos Rex100% (1)

- AG 494 Jotafloor Sealer Euk GBDocument6 pagesAG 494 Jotafloor Sealer Euk GBAhmed SalahPas encore d'évaluation

- Hardtop CA Technical Data Sheet JotunDocument5 pagesHardtop CA Technical Data Sheet JotunSam JosePas encore d'évaluation

- AG 45382 Pilot QD Topcoat Euk GBDocument6 pagesAG 45382 Pilot QD Topcoat Euk GBFatih GökbuaPas encore d'évaluation

- Renderoc SPxtraDocument2 pagesRenderoc SPxtraBalasubramanian AnanthPas encore d'évaluation

- Polyguard PEDocument2 pagesPolyguard PEabcd1860100% (1)

- Protective Coating-3Document0 pageProtective Coating-3Sivaratnam NavatharanPas encore d'évaluation

- Renderoc BFDocument2 pagesRenderoc BFmilanbrasinaPas encore d'évaluation

- 188 NanoGrout GPDocument4 pages188 NanoGrout GPAlden Cayaga100% (1)

- Interchar 1260 Application Guidelines UkDocument18 pagesInterchar 1260 Application Guidelines UkMarkCanicula100% (1)

- TDS 10740 Gardex Primer Euk IDDocument4 pagesTDS 10740 Gardex Primer Euk IDIchsan BahrilPas encore d'évaluation

- Amercoat 471 Application May 08Document2 pagesAmercoat 471 Application May 08Biju_PottayilPas encore d'évaluation

- Proglaze IIDocument3 pagesProglaze IIMohammad ALTAKIPas encore d'évaluation

- Fosroc Renderoc CS PuneDocument2 pagesFosroc Renderoc CS Punealdred_chezkaPas encore d'évaluation

- Interzone 101Document0 pageInterzone 101hennawijayaPas encore d'évaluation

- Penguard Express Datasheet " AzadJotun"Document5 pagesPenguard Express Datasheet " AzadJotun"AzadAhmadPas encore d'évaluation

- Nitoproof 10Document2 pagesNitoproof 10Venkata RaoPas encore d'évaluation

- PlastisealDocument4 pagesPlastisealVenkata RaoPas encore d'évaluation

- Penguard HB 2005 PDFDocument4 pagesPenguard HB 2005 PDFMuthuKumarPas encore d'évaluation

- Carboguard 703 GFDocument2 pagesCarboguard 703 GFlhanx2100% (2)

- ResiGard SL2Document4 pagesResiGard SL2fhsn84Pas encore d'évaluation

- Brush BondDocument4 pagesBrush BondVenkata RaoPas encore d'évaluation

- TDS - Mastertile 540 - WjgroutDocument2 pagesTDS - Mastertile 540 - WjgroutVenkata RaoPas encore d'évaluation

- Tds - Waboflex SRDocument3 pagesTds - Waboflex SRVenkata RaoPas encore d'évaluation

- TDS - Mastertile 40Document2 pagesTDS - Mastertile 40Venkata RaoPas encore d'évaluation

- TDS - Mastertile 30 - WPMDocument2 pagesTDS - Mastertile 30 - WPMVenkata RaoPas encore d'évaluation

- TDS - Mastertile 530 - RbgroutDocument1 pageTDS - Mastertile 530 - RbgroutVenkata RaoPas encore d'évaluation

- TDS - Mastertile 550 - DgroutDocument3 pagesTDS - Mastertile 550 - DgroutVenkata RaoPas encore d'évaluation

- Rheofinish 202: Solvent Based Chemical Release AgentDocument2 pagesRheofinish 202: Solvent Based Chemical Release AgentVenkata RaoPas encore d'évaluation

- TDS - Masterkure 161Document2 pagesTDS - Masterkure 161Venkata Rao0% (1)

- TDS - Wabocrete IIDocument2 pagesTDS - Wabocrete IIKingshuk SarkarPas encore d'évaluation

- TDS - Masterkure 106Document2 pagesTDS - Masterkure 106Venkata RaoPas encore d'évaluation

- TDS - Rheomix 141Document4 pagesTDS - Rheomix 141Venkata RaoPas encore d'évaluation

- Reebol WBDocument2 pagesReebol WBVenkata RaoPas encore d'évaluation

- TDS Rheomix 121Document3 pagesTDS Rheomix 121Tanzeel Liaqat100% (1)

- 3696 2Document7 pages3696 2Venkata RaoPas encore d'évaluation

- TDS - Masterkure 107Document2 pagesTDS - Masterkure 107Venkata Rao100% (1)

- Fosroc Acid EtchDocument2 pagesFosroc Acid EtchVenkata RaoPas encore d'évaluation

- PlastisealDocument4 pagesPlastisealVenkata RaoPas encore d'évaluation

- Conbextra Ep300Document4 pagesConbextra Ep300Venkata RaoPas encore d'évaluation

- Conbextra Cable GroutDocument4 pagesConbextra Cable GroutVenkata RaoPas encore d'évaluation

- Brush BondDocument4 pagesBrush BondVenkata RaoPas encore d'évaluation

- ReebolDocument2 pagesReebolVenkata RaoPas encore d'évaluation

- Nitomortar SDocument4 pagesNitomortar SVenkata RaoPas encore d'évaluation

- Nitoprime ZincrichDocument4 pagesNitoprime ZincrichVenkata RaoPas encore d'évaluation

- Sacrament of ConfirmationDocument41 pagesSacrament of ConfirmationPablo CuadraPas encore d'évaluation

- Solo Leveling Ch.201-270 (Completed) PDFDocument1 030 pagesSolo Leveling Ch.201-270 (Completed) PDFDuta Ananda100% (3)

- Daniel Ricardo Montoya Trabajo Present Simple.Document6 pagesDaniel Ricardo Montoya Trabajo Present Simple.Carlos Orlando Pinto0% (1)

- Bibliography of JazzDocument171 pagesBibliography of Jazzpendakigunung100% (1)

- Introduction To Advertising: D RajendrababuDocument25 pagesIntroduction To Advertising: D RajendrababuRajendra Babu DaraPas encore d'évaluation

- First Periodical Test in Arts.6Document6 pagesFirst Periodical Test in Arts.6Cathlyn Joy GanadenPas encore d'évaluation

- ConclusionDocument8 pagesConclusionPablo PiquerasPas encore d'évaluation

- Representation of Women in HorrorDocument2 pagesRepresentation of Women in HorrorGooner42100% (1)

- The Art of Octave Playing, Fifty Progressive Studies For The Piano, Compiled, Classified and Edited by Signund Herzog and Andor Pintér PDFDocument154 pagesThe Art of Octave Playing, Fifty Progressive Studies For The Piano, Compiled, Classified and Edited by Signund Herzog and Andor Pintér PDFAntonio Hernandez100% (3)

- Recorder Flute Sheet MusicDocument61 pagesRecorder Flute Sheet MusicDavid Martinez100% (2)

- Character and Songs Requested With Links Provided: Mark La Vie BohemeDocument2 pagesCharacter and Songs Requested With Links Provided: Mark La Vie BohemejohnisaPas encore d'évaluation

- GE1121 Reading AssignmentDocument1 pageGE1121 Reading AssignmentNaomi WongPas encore d'évaluation

- Chalkokondyles The HistoriesDocument28 pagesChalkokondyles The HistoriesBozo SeljakotPas encore d'évaluation

- Herbie Hancock Solo Analysis On PinocchiDocument11 pagesHerbie Hancock Solo Analysis On PinocchiMarco Macci100% (3)

- Daniella Ignacio First DraftDocument7 pagesDaniella Ignacio First DraftDaniella IgnacioPas encore d'évaluation

- Final Final ScriptDocument4 pagesFinal Final Scriptapi-187936779Pas encore d'évaluation

- How The World Was Created (Panayan)Document25 pagesHow The World Was Created (Panayan)Mary Kris De AsisPas encore d'évaluation

- Visayas (Cebu, Oriental Negros)Document13 pagesVisayas (Cebu, Oriental Negros)Ana Daniela VillarosaPas encore d'évaluation

- SQ Arioso PartsDocument4 pagesSQ Arioso PartsjavoliveiraPas encore d'évaluation

- Theragatha (Pali English) BhanteSujato 2col A4Document126 pagesTheragatha (Pali English) BhanteSujato 2col A4Christopher Brown100% (1)

- Features List Zapfino Extra PDFDocument4 pagesFeatures List Zapfino Extra PDFJose Luis Valencia CastilloPas encore d'évaluation

- Is There A Bank Near Here?Document13 pagesIs There A Bank Near Here?Camilo BanquethPas encore d'évaluation

- Padma Puranam Volume 2 (Anandaashrama, 1894) PDFDocument392 pagesPadma Puranam Volume 2 (Anandaashrama, 1894) PDFUpadhyayula Surya Raghavender100% (1)

- Our Toy ShopDocument5 pagesOur Toy ShopMafe MuñozPas encore d'évaluation

- Porgy and BessDocument75 pagesPorgy and BessRiccardo BasiPas encore d'évaluation

- Soal Mid Test Semester 1Document2 pagesSoal Mid Test Semester 1Riri SeptianiPas encore d'évaluation

- University of Sargodha MA English SyllabusDocument2 pagesUniversity of Sargodha MA English SyllabusRazwan Shahad100% (1)

- Let The Good Times Roll by Mark HankinsDocument182 pagesLet The Good Times Roll by Mark Hankinssteve100% (4)

- PH Exporters ListDocument77 pagesPH Exporters ListHerbert Bactong100% (1)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionD'EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionÉvaluation : 3 sur 5 étoiles3/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretD'EverandWaste: One Woman’s Fight Against America’s Dirty SecretÉvaluation : 5 sur 5 étoiles5/5 (1)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontD'EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontÉvaluation : 4.5 sur 5 étoiles4.5/5 (18)

- The Cyanide Canary: A True Story of InjusticeD'EverandThe Cyanide Canary: A True Story of InjusticeÉvaluation : 4 sur 5 étoiles4/5 (52)

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksD'EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksPas encore d'évaluation

- Introduction to Ecology and Environmental Laws in IndiaD'EverandIntroduction to Ecology and Environmental Laws in IndiaPas encore d'évaluation

- Slow Violence and the Environmentalism of the PoorD'EverandSlow Violence and the Environmentalism of the PoorÉvaluation : 4 sur 5 étoiles4/5 (5)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionD'Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionPas encore d'évaluation

- Busted!: Drug War Survival Skills and True Dope DD'EverandBusted!: Drug War Survival Skills and True Dope DÉvaluation : 3.5 sur 5 étoiles3.5/5 (7)

- The Rights of Nature: A Legal Revolution That Could Save the WorldD'EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldÉvaluation : 5 sur 5 étoiles5/5 (1)

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaD'EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaÉvaluation : 4 sur 5 étoiles4/5 (1)

- Down to the Wire: Confronting Climate CollapseD'EverandDown to the Wire: Confronting Climate CollapseÉvaluation : 4.5 sur 5 étoiles4.5/5 (8)

- Environmental Education in Practice: Concepts and ApplicationsD'EverandEnvironmental Education in Practice: Concepts and ApplicationsPas encore d'évaluation

- Introduction to Ecology and Environmental Laws in IndiaD'EverandIntroduction to Ecology and Environmental Laws in IndiaPas encore d'évaluation

- Principles of direct and superior responsibility in international humanitarian lawD'EverandPrinciples of direct and superior responsibility in international humanitarian lawPas encore d'évaluation

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933D'EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933Pas encore d'évaluation

- A Guide to the Climate Apocalypse: Our Journey from the Age of Prosperity to the Era of Environmental GriefD'EverandA Guide to the Climate Apocalypse: Our Journey from the Age of Prosperity to the Era of Environmental GriefPas encore d'évaluation

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksD'EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksPas encore d'évaluation

- Obstacles to Environmental Progress: A U.S. perspectiveD'EverandObstacles to Environmental Progress: A U.S. perspectivePas encore d'évaluation