Académique Documents

Professionnel Documents

Culture Documents

General Safety Instruction: English 1.12.2008

Transféré par

leopacuarTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

General Safety Instruction: English 1.12.2008

Transféré par

leopacuarDroits d'auteur :

Formats disponibles

English

1.12.2008

GENERAL SAFETY INSTRUCTION

-

08204

J26492-0.ORD

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

Read the instructions supplied with the product before installation and commissioning.

Keep the instructions in a safe place for future reference.

Table of content

1 Instructions ................................................... 3

1.1 Symbols and abbreviations ........................ 3

2 Safety instructions ....................................... 4

2.1 Safety instructions for preparing to install

the hoist .............................................................. 4

2.2 Safety instructions for installing the hoist ... 4

2.3 Safety instructions for start-up of the hoist . 4

2.4 Safety instructions for operating the hoist ... 5

2.5 Safety instructions for finishing work with the

hoist 9

2.6 Safety instructions for servicing the hoist ... 9

3 Crane inspection points ............................. 10

2/11

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

The instructions needed for the safe and effective installation, operation and maintenance of the hoist

are included in the hoist delivery. The hoist itself is also provided with labels and markings. The

instructions are issued on paper and/or on CD-ROM. The instructions for using digital CD-ROMs are

printed on the packaging.

Read all the instructions supplied with the hoist before starting to install and commission

the hoist.

It is essential for the safety of people and property that the hoist operator, the hoist

serviceman and the personnel in charge of hoist operation and servicing are familiar with

and comply with the safe working principles described in the instructions supplied with the

hoist.

Keep the instructions in a safe place for future reference.

The following symbols are used in the instructions:

Warning!

Caution

3/11

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

The owner of the hoist is responsible for meeting all the requirements described in these

instructions, with the exception of those items for which it has been specifically agreed that

the supplier will carry out the necessary procedures.

Follow these instructions when preparing to install the hoist:

Ensure that installation personnel are professionally competent, professionally qualified and are

provided with adequate instructions for carrying out the installation work.

Check for any dimensional nonconformance in drawings, instructions, parts and structural

measurements.

Beware of other moving machinery in the installation and servicing site, such as machines, other

cranes and automatic doors. The installation area must be arranged so that operation of other

equipment does not endanger installation work (or vice versa).

Ensure that the space reserved for the hoist and crane in the operating location is adequate for all

functions of the crane and hoist.

Prevent unauthorized persons and bystanders from walking on or below the work site.

Follow these instructions if the hoist is to be installed on a track:

Ensure that the runway is designed for the loads caused by the hoist.

Ensure that the installation tolerances for the runway rails meet the set requirements.

Check that the runway has suitable buffer stops for the hoist.

Follow these instructions when installing the hoist:

Use proper safety equipment to prevent objects from falling when working in high places.

Ensure that machinery and equipment cannot start up accidentally and cannot move during

installation and servicing.

Keep installation and servicing locations, and walkways leading to them, clean and tidy.

Prevent tools and parts from falling.

Be prepared for equipment moving in the wrong direction when testing.

Check that the power supply busbars installed are suitable for the hoist.

Check that the supply voltage and frequency are suitable for the hoist.

Ensure that any safety devices bypassed for testing purposes are restored to full operational status.

Follow these instructions when starting up the hoist:

The conditions at the operating site for the hoist must correspond to the operating conditions for

which the hoist is designed (including indoor/outdoor use, ambient temperature/radiance

temperature, wind, dust, splashing, snow, water, handling hazardous materials, fire risk, etc).

Check that there is adequate lighting at the operating site for operating the hoist safely and

efficiently.

4/11

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

If the control position is located on the hoist, check that you can exit from the hoist safely irrespective

of the hoists position on the runway.

Check that there are adequate walkways and service platforms on the hoist and/or adequate

equipment at the operating site for servicing and inspecting the hoist.

Check that the hoist meets the applicable safety requirements.

Check that the hoist meets the applicable operating requirements.

Ensure that the components, electrical connections and steel structures of the hoist have been

inspected and certified as defect-free.

Ensure that the test loading, test drive and commissioning inspection have been properly carried out

and that the handover log has been properly completed.

Follow these instructions when operating the hoist:

Read all the instructions supplied with the hoist. The hoist operator must be familiar with the

instructions and follow them.

The hoist operator must be competent for the task, must know all the controls of the hoist and must

be able to use them correctly and safely.

The hoist operator must know how to operate the hoist and must be aware of any risk of accident

posed by the operating site.

Learn how to operate the hoist in safe conditions before actually starting to work with the hoist. Learn

how to control the movements of the hook and load. Use the Hoist Owners Manual to familiarize

yourself with the hoist and hoist controls.

Familiarize yourself with the signs and warnings marked on the hoist. The direction symbols for hoist

motions are the same as the symbols marked on the pushbutton controller. Check the direction

symbols in the Hoist Owners Manual.

Learn the hand signals for indicating hoisting motion, trolley traversing and crane travel. The hoist

operator should only accept hand signals from a person authorized to give them.

Ensure that there is adequate lighting as well as proper tools and equipment for the working site, and

that appropriate working procedures are established.

Follow these instructions when preparing to start work:

If the hoist is provided with motion locking devices (eg, rail clamps), open the locking devices before

using the hoist.

Before switching on the main current, ensure that all controls are in the 0-position.

Connect current to the hoist by turning on the safety switches for main current and for control current.

Close the main contactor by pressing the START pushbutton.

If the pushbutton incorporates a selection switch, ensure that the selection switch is in the correct

position before using the control pushbuttons.

Check that all safety switches operate.

Check that the brakes operate.

A hoist that operates outdoors or in cold indoor premises which has been out of service for a longer

than normal period of time should always be first started to move the hook upwards in order to avoid

damage to the roping from freezing of the rope guide.

Follow these instructions when operating the hoist:

5/11

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

The useful lifetime of a hoist depends very much on whether the hoist is correctly used or not. Use of

the hoist for other than the hoist group classification for which it was designed changes its useful

lifetime.

Before hoisting a load, make sure you know a safe and effective path for the load. Ensure that the

load will not collide against objects or people.

Check that no servicemen or unauthorized persons are on the crane and that the rails and power

cables are clear of obstructing objects.

Before hoisting, check that the hoisting devices are securely positioned on the bearing surface of the

hook and that the safety catch on the hook is closed.

Ensure that the load's mass centre is on the centre line of the hook forging so that the load does not

bend the hook neck.

Ensure that the force is applied only to the hook's bearing surface (the lowest point of the hook).

Force applied to other parts of the hook block will cause undesired stresses. Forces on ramshorn

hook have to be equal on both bearing surfaces.

c_hoload1a

Before hoisting, check that the load is balanced and safely fastened at the lifting points.

Before hoisting, ensure that the load cannot slide, slip or detach itself when suspended.

Before hoisting, ensure that the ropes are perpendicular and that the hoist is positioned

perpendicularly above the load to be lifted. A load must not be hoisted or dragged along the ground

in a way that causes side pull on the roping unless the hoist is designed and manufactured for this

purpose.

c_sa1a

When using a lifting accessory (sling, belt etc), always follow the instructions provided by the lifting

accessory manufacturer.

If two cranes are needed to handle a load, a balancing beam must be used to equalize the loading.

Combined hoisting with two cranes must be supervised by a foreman knowledgeable about cranes,

or by a crane specialist, who is then in overall charge of the lifting operation.

6/11

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

Start and stop the travelling motion at low speed to prevent the load from swinging excessively.

Avoid swinging the hook or load during travel motion.

Do not lift people on the hook or load. Lifting people with a hoist is prohibited unless the hoist is

designed and manufactured for that purpose (this must always be agreed with the supplier of the

hoist).

c_sa5a

Do not go under the hook or load. Do not move the hook or load over a person. A load must never be

lifted in a way that can injure a person if the load drops.

c_sa2b

Do not operate the hoist if you know that medication, an illness, injury or other such handicap impairs

your alertness or working ability.

Do not lift a load that is fastened to its base or that is heavier than the maximum permissible load for

the hoist or lifting accessories. A jerking or static load can cause an overload. A hoist may only be

used for those loads and load combinations, and at those speeds, for which the hoist has been

designed and manufactured.

Raise the load high enough to prevent it from hitting objects during travel. However, do not raise it

higher than is necessary for the situation. Do not raise the hook to the top safety limit.

During hoisting and travel motion, ensure that the hook, the load, the crane and its moving parts do

not collide with objects or people.

If the hoist is provided with a horn, sound the horn when you move the load in the vicinity of people

who are not paying attention to the moving load.

Do not move the load until you have received a signal from the person attaching the load to the hook

or lifting appliance.

Do not use the overload protection for weighing the load.

Stop all hoisting and travel motions before the safety limit switches.

Do not adjust or bypass the limit switches or warning devices in order to go past motion limits. Do not

use the hoist if the limit switches are inoperative.

7/11

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

If the manually-adjusted backup limit switch in the hoist has triggered, call a serviceman to the hoist

and ask him to determine why the normal safety limit switch did not function.

Do not use the hoisting rope as a lifting lug.

Do not use the hoist if there are visible defects in or damage to the hoist, the hoisting rope, or any

other hoist structure or hoist function. Stop operating the hoist if it operates abnormally (for example,

a high noise level, uneven starting or malfunctions). Using faulty equipment is strictly prohibited.

If defects have been noticed in the hoist, carry out the necessary inspections and servicing. Ensure

that the hoist operates properly before you start to use it again.

Do not use the limit switches to stop the motions of the hoist. Hoist motions must be stopped with the

pushbutton controller or other control device intended for the purpose.

Use the proper pushbuttons intended for controlling the hoist. If you feel you are losing control of the

hoist motions, press the emergency stop button. In a potentially dangerous situation all hoist motions

can be stopped by pressing the emergency stop button, but do not use the emergency stop function

unnecessarily. Ensure that it is safe to re-commence working after the emergency stop button has

been pressed.

Avoid short, jerky motions. Unnecessary short starts cause the hoisting motor to overheat quickly.

The last controller step is for normal drive. The intermediate steps are normally used for short

durations only. Do not switch the controller back and forth unnecessarily because it causes wear.

c_sa6a

Avoid violent collisions into other hoists or against the buffers.

Do not leave a suspended load unattended.

c_sa4a

Do not lower the hook so far that the ropes become slack.

8/11

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

c_sa3a

Do not pull a load from the side. Lower the load with the ropes perpendicular.

Do not use hoist motions to remove the load from the hook.

Do not weld on a hook that is not isolated. Do not fasten a welding electrode to the hoisting rope.

Do not change the size of fuses. A qualified electrician should carry out all electrical work.

Follow these instructions when you finish working with the hoist:

Raise the empty hook or loading device high enough to avoid it causing a hazard to traffic, but not to

the top safety limit.

Leave all controls in the 0-position.

Press the emergency stop button to open the main contactor.

Turn off the safety switches for control current and main current.

Close any mechanical brakes, such as rail clamps, etc.

Inform your foreman of any defects you have noticed.

Inform the next operator of all abnormalities in equipment or operation that you noticed.

Follow these instructions when servicing the hoist:

Carry out regular inspections and preventive maintenance in compliance with the instructions. Keep

a record of inspections and servicing. Regular servicing and inspection procedures are necessary for

the safe and efficient operation of the hoist. In uncertain or unusual cases, contact the supplier of the

hoist.

Pay special attention to the operation of the brake and limit switches, and to the condition of the

hook, rope and pushbutton controller. It is essential that safety devices (overload protectors, limit

switches, etc.) work correctly and are in full operating order because they safeguard against human

error.

Use trained servicing personnel authorized by the manufacturer of the hoist for servicing the hoist.

The person servicing the hoist must be competent for the task and must be familiar with the servicing

and inspection instructions.

Use only genuine spare parts approved by the manufacturer of the hoist.

Any modifications or additions made to the hoists structures or performance values must first be

discussed with the supplier of the hoist.

Any inspections and repair operations carried out on the hoist after an overload or collision must be

discussed with the supplier of the hoist.

9/11

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

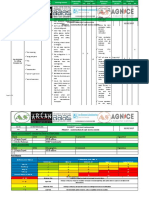

The inspection instructions that are specific to the hoist should primarily be applied when inspecting the

hoist. The table below lists some general crane inspection points and inspection methods. The

inspection interval for a crane in continuous duty is 1 week. Cranes in intermittent duty should be

inspected before being used.

The measurements to be taken at the inspection points are necessary if other methods do not produce

an adequate result. If any defects or abnormalities are observed, they must be investigated and

corrective action must be taken in accordance with the instructions specific to that device.

Structure/

component

Hoist

Bridge travel machinery

Trolley travel machinery

Trolley power supply

Electrical cubicles

Steel structure

Crane runway

Inspection method

Test by

hand/

Visual

Aural

measure

Inspection point

See the separate specification for specific hoist components in the

Hoist Owners Manual.

Fastenings of travel machinery units

Operation of motors

Operation of brakes

Operation of gears

Oil quantities in gearboxes

Condition of rail wheels

Operation of limit switches

Fastenings of travel machinery units

Operation of motors

Operation of brakes

Operation of gears

Oil quantities in gearboxes

Condition of rail wheels

Operation of limit switches

Condition of cables

Condition of cable trolleys

Condition and cleanness of cable support rails

Cleanness of equipment and devices

Condition of wiring in electrical cubicles

Condition of cable seals

Operation of delay relays

Operation of contactors

Adjustment of over-current protectors

Condition of fuses

Cleanness of starting resistors

Fastening of wiring to starting resistors

Operation and condition of main switch

Cleanness and removal of unnecessary objects

Condition of trolley travel rails

Condition of buffers and end stops

Condition and fastening of handrails

Condition of end carriage main girder connection bolts *)

Condition of crane runway

Condition of earthing

Condition of crane current collectors

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

10/11

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

*) Tightening torque for M16 10.9 is 300Nm, M20 8.8 is 390 Nm, M20 10.9 is 580 Nm.

11/11

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

Vous aimerez peut-être aussi

- JOB SAFETY ANALYSIS FOR WATER TREATMENT FACILITIESDocument8 pagesJOB SAFETY ANALYSIS FOR WATER TREATMENT FACILITIESAldrinPas encore d'évaluation

- Safety Shower EyewashDocument18 pagesSafety Shower EyewashKesavanVeeraPas encore d'évaluation

- OHS-PR-09-03-F02 RISK ASSESSMENT For INSTALLATION OF WALL MOUNTED JIB CRANEDocument21 pagesOHS-PR-09-03-F02 RISK ASSESSMENT For INSTALLATION OF WALL MOUNTED JIB CRANEmohammed tofiqPas encore d'évaluation

- Safe Work Practices - CraneDocument22 pagesSafe Work Practices - CranepentianPas encore d'évaluation

- Method Statement Analysis: Basic Job Steps Remarks High Risk Iedntified Mitigation Steps To Reduce/Eliminate The RiskDocument14 pagesMethod Statement Analysis: Basic Job Steps Remarks High Risk Iedntified Mitigation Steps To Reduce/Eliminate The RiskShanavas MuhammedPas encore d'évaluation

- Application of Jet Grouting TechniquesDocument7 pagesApplication of Jet Grouting TechniqueskaistengineerPas encore d'évaluation

- Operation and Maintenance Manual For SubstationDocument16 pagesOperation and Maintenance Manual For Substationprathaban723Pas encore d'évaluation

- RT7017 Signalling and Safety-Related Telecom PDFDocument13 pagesRT7017 Signalling and Safety-Related Telecom PDFCezary P.Pas encore d'évaluation

- Boom Lift PDFDocument2 pagesBoom Lift PDFcityofdarwingisPas encore d'évaluation

- Aeroplane Flight Training: Lesson Plans for Students & Instructors With Questions - Plus a Lot MoreD'EverandAeroplane Flight Training: Lesson Plans for Students & Instructors With Questions - Plus a Lot MoreÉvaluation : 3 sur 5 étoiles3/5 (2)

- Instron MerlinDocument76 pagesInstron Merlinjsidev100% (4)

- Manual de Operación Telehandler TerexDocument94 pagesManual de Operación Telehandler TerexCesar Augusto Vera Jaimes100% (2)

- The Construction Safety Guide: Injury and Illness Prevention through DesignD'EverandThe Construction Safety Guide: Injury and Illness Prevention through DesignÉvaluation : 4 sur 5 étoiles4/5 (6)

- Method Statement For Power Transformer BIAL STPDocument10 pagesMethod Statement For Power Transformer BIAL STPRUPESH KUMAR100% (2)

- Safe Angle Grinder ProcedureDocument3 pagesSafe Angle Grinder ProcedureKyaw Kyaw Aung50% (2)

- 031 Procedure Rigging Slinging and LiftingDocument18 pages031 Procedure Rigging Slinging and LiftingMohamed Hadjkacem100% (2)

- Hse in Drilling OperationsDocument13 pagesHse in Drilling OperationsSamad Ali Siddiqui100% (2)

- Twin 44Document33 pagesTwin 44Orlando Melipillan100% (2)

- Crane Tiger ManualDocument26 pagesCrane Tiger ManualSurasan ThepsiriPas encore d'évaluation

- Aerial Lifts FactsheetDocument2 pagesAerial Lifts Factsheetomar santosPas encore d'évaluation

- Service Manual ROBBINSDocument0 pageService Manual ROBBINSREDDYGAARI ABBAYI100% (2)

- TrioTIH5162B Screen ManualDocument32 pagesTrioTIH5162B Screen ManualAlejandro CornidePas encore d'évaluation

- Main Switchboard Maintenance PDFDocument17 pagesMain Switchboard Maintenance PDFAzman HanafiahPas encore d'évaluation

- Procedure FireDocument28 pagesProcedure FireRichard D DuPas encore d'évaluation

- Risk Assessment On Combined Cycle Power Plant Mechanical Maintenanance 24 PagesDocument24 pagesRisk Assessment On Combined Cycle Power Plant Mechanical Maintenanance 24 PagesknabpshoPas encore d'évaluation

- Bucket Elevator SafetyDocument18 pagesBucket Elevator SafetyLily VyPas encore d'évaluation

- CT Series 20x36 Jaw CrusherDocument33 pagesCT Series 20x36 Jaw CrusherYimmy MorenoPas encore d'évaluation

- Temporary GeneratorDocument11 pagesTemporary Generatorraju_civilengPas encore d'évaluation

- TRIO CT Series 20x36 Jaw Crusher 1 PDFDocument33 pagesTRIO CT Series 20x36 Jaw Crusher 1 PDFYeco MachineryPas encore d'évaluation

- User Manual - Maintainer Maintenance ExecutionDocument143 pagesUser Manual - Maintainer Maintenance Executionrsanjuan100% (1)

- Screw Conveyor ManualDocument14 pagesScrew Conveyor ManualDavid100% (1)

- Gcrc5510 Iss 2Document50 pagesGcrc5510 Iss 2임동우Pas encore d'évaluation

- Jkr-Osh For ConstructionDocument29 pagesJkr-Osh For ConstructionWan Apai67% (6)

- TF4016 VGF ManualDocument29 pagesTF4016 VGF ManualWaldo Carreño100% (2)

- PM - HSE Plan Session 6Document33 pagesPM - HSE Plan Session 6Mahdi DalyPas encore d'évaluation

- Good Manufacturing Practices (GMPS)Document4 pagesGood Manufacturing Practices (GMPS)Shailesh Gupta100% (1)

- Trio APS 4034F Impact Crusher ManualDocument53 pagesTrio APS 4034F Impact Crusher Manualclaudiu.gheorghe5710Pas encore d'évaluation

- Martin SafetyDocument11 pagesMartin SafetyHayley BurnsPas encore d'évaluation

- Dcon0807965 PDFDocument11 pagesDcon0807965 PDFjorgemegok1860Pas encore d'évaluation

- 1YEPMSC2520E001 RevA SafeGearMCC2.5 IOMMDocument48 pages1YEPMSC2520E001 RevA SafeGearMCC2.5 IOMMnyala chisolaPas encore d'évaluation

- Rotary Airlock Feeders: Installation, Operation & Maintenance InstructionsDocument16 pagesRotary Airlock Feeders: Installation, Operation & Maintenance InstructionsMKPashaPashaPas encore d'évaluation

- Solar PV Methodology - BRIDocument20 pagesSolar PV Methodology - BRI2020dlb121685Pas encore d'évaluation

- METHOD STATEMENT FOR INSTALLION OF SOFT STATER COHDocument5 pagesMETHOD STATEMENT FOR INSTALLION OF SOFT STATER COHAldrige Tatenda VengesaiPas encore d'évaluation

- OSHA Fact Sheet - AMLDocument4 pagesOSHA Fact Sheet - AMLd. donlonPas encore d'évaluation

- R&M EZ Lift Manual Products ManualDocument81 pagesR&M EZ Lift Manual Products ManualisendPas encore d'évaluation

- Construction Method of Statement: Submitted By: Mega Air EnterprisesDocument12 pagesConstruction Method of Statement: Submitted By: Mega Air Enterprisesallen bernabePas encore d'évaluation

- Rotary Airlock Feeders: Installation, Operation & Maintenance InstructionsDocument16 pagesRotary Airlock Feeders: Installation, Operation & Maintenance InstructionsrheriPas encore d'évaluation

- Instructions For The Safe Use Of: Beam ClampsDocument2 pagesInstructions For The Safe Use Of: Beam ClampsRonny AndalasPas encore d'évaluation

- Aerial Lifts Safety GuideDocument2 pagesAerial Lifts Safety GuideJafar KhanPas encore d'évaluation

- Sop AntennaDocument27 pagesSop AntennaAltezza AtehPas encore d'évaluation

- Installation and maintenance manual for air handling equipmentDocument24 pagesInstallation and maintenance manual for air handling equipmentAdnan AttishPas encore d'évaluation

- Top Drive Drilling Equipment HSE ManualDocument16 pagesTop Drive Drilling Equipment HSE ManualHayLenLeePas encore d'évaluation

- Hand Operated Chain Lever HoistsDocument2 pagesHand Operated Chain Lever HoistsegyinspectoryahooPas encore d'évaluation

- Unloading of EWPs From ContainersDocument10 pagesUnloading of EWPs From ContainersPirashanth SathananthanPas encore d'évaluation

- Rotary Airlock FeenderDocument14 pagesRotary Airlock Feenderpipit agusPas encore d'évaluation

- VWR Water Jacketed Co2 Incubators With Microprocessor ControlDocument33 pagesVWR Water Jacketed Co2 Incubators With Microprocessor Controlshupc100% (2)

- TLS 14K Open Front Four Post Installation Operation Manual Part List TLS414ALORR1 TLS414ALOXR1Document34 pagesTLS 14K Open Front Four Post Installation Operation Manual Part List TLS414ALORR1 TLS414ALOXR1Esteban MéndezPas encore d'évaluation

- Instructions For The Safe Use Of: Travelling Girder TrolleysDocument2 pagesInstructions For The Safe Use Of: Travelling Girder TrolleysMuhammad Umair RasheedPas encore d'évaluation

- 59 Acop For Mobile GantriesDocument2 pages59 Acop For Mobile Gantriesdsn_sarmaPas encore d'évaluation

- AgempDocument7 pagesAgemppavan kumarPas encore d'évaluation

- DOC0142874Document10 pagesDOC0142874DeivisPas encore d'évaluation

- Heavy Duty AssignmentDocument15 pagesHeavy Duty AssignmentSurafel MesfinPas encore d'évaluation

- Aerial LiftDocument1 pageAerial LiftasknishanPas encore d'évaluation

- Упутство за инсталацију и одржавање електричних једноструких зрака - englishDocument24 pagesУпутство за инсталацију и одржавање електричних једноструких зрака - englishMiljana Dule CvetkovićPas encore d'évaluation

- General Series Overhead Crane: User ManualDocument31 pagesGeneral Series Overhead Crane: User ManualjokoPas encore d'évaluation

- BL-1500 Combination Brake Lathe Operator's ManualDocument33 pagesBL-1500 Combination Brake Lathe Operator's ManualCelso J. Cruz CaamalPas encore d'évaluation

- Bradco 625 Trencher ManualDocument107 pagesBradco 625 Trencher ManualAnonymous zSpR5jUdPas encore d'évaluation

- Mobile (Truck) Cranes: Primary HazardsDocument6 pagesMobile (Truck) Cranes: Primary HazardsfiarPas encore d'évaluation

- Wner S Anual: M Ehlt (1-4K) & PST (1-3K)Document20 pagesWner S Anual: M Ehlt (1-4K) & PST (1-3K)tintuc_inPas encore d'évaluation

- Alcohol Cetoestearilico MsdsDocument6 pagesAlcohol Cetoestearilico MsdsJoha Darwin ChPas encore d'évaluation

- Msds SKF Bearing GreaseDocument8 pagesMsds SKF Bearing Greaselucone123Pas encore d'évaluation

- CHAPTER 6 Workplace Environment and ErgonomicsDocument30 pagesCHAPTER 6 Workplace Environment and Ergonomicsadlirazin24Pas encore d'évaluation

- Nebosh Igc 200 Question and Answers Part 1Document4 pagesNebosh Igc 200 Question and Answers Part 1khanPas encore d'évaluation

- Trenching SafetyDocument1 pageTrenching SafetyAldrien CabintePas encore d'évaluation

- Baicapil MSDS 1013 PDFDocument3 pagesBaicapil MSDS 1013 PDFJFREDYPINOPas encore d'évaluation

- High-Voltage Safety Improvement Design For ElectriDocument15 pagesHigh-Voltage Safety Improvement Design For ElectriVăn BảoPas encore d'évaluation

- SDS - Therminol 66 - ENDocument10 pagesSDS - Therminol 66 - ENMarianny BritoPas encore d'évaluation

- Industrial Hygiene CSTDocument93 pagesIndustrial Hygiene CSTClaude De GuzmanPas encore d'évaluation

- Centre For Quality Surveillance Nepal Pvt. LTD.: About UsDocument7 pagesCentre For Quality Surveillance Nepal Pvt. LTD.: About UsbpharmbaPas encore d'évaluation

- Chapter 10 - Special HazardsDocument28 pagesChapter 10 - Special Hazardssqamar68Pas encore d'évaluation

- Health, Safety and Environmental Impact Assessment (HSEIA) : The Applus+ SolutionDocument2 pagesHealth, Safety and Environmental Impact Assessment (HSEIA) : The Applus+ SolutionPradeep Martha FPas encore d'évaluation

- RA For Hvac Duct InstallationDocument2 pagesRA For Hvac Duct Installationfairoos aliPas encore d'évaluation

- Manual Julabo HE4Document78 pagesManual Julabo HE4Gavril VengescuPas encore d'évaluation

- Fire Hilton 1 PDFDocument7 pagesFire Hilton 1 PDFJayanath FernandoPas encore d'évaluation

- Safety Data Sheet: Section 1. Chemical Product and Company IdentificationDocument13 pagesSafety Data Sheet: Section 1. Chemical Product and Company Identificationharlendri STPas encore d'évaluation

- DM 5th-B (Group-10)Document15 pagesDM 5th-B (Group-10)Kur28Pas encore d'évaluation

- Primary Animal Production Checklist Edition 9Document104 pagesPrimary Animal Production Checklist Edition 9elflaquito80Pas encore d'évaluation

- HIDC HSE 006 Lock Out Tag Out (LOTO) AwarenessDocument16 pagesHIDC HSE 006 Lock Out Tag Out (LOTO) AwarenessMuhammad SaqibPas encore d'évaluation