Académique Documents

Professionnel Documents

Culture Documents

10

Transféré par

jinny1_0Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

10

Transféré par

jinny1_0Droits d'auteur :

Formats disponibles

The Effect of Chopped

Poly(methyl methacrylate) Fibers

on Some Properties of Acrylic

Resin Denture Base Material

Daryll C. Jagger, BDS, MSc, FDS RCS'

Alan Harrison, TD, BDS, PhD, FDS Res'"

Purpose; The fracture of acrylic resin dentures remains an unresolved prohleni. Over the

years, various approaches to strengthening acrylic resin have been suggested, including

modifying or reinforcing the resin. The aim of this study was to investigate the effect of

chopped pofylmetliyl methacrylate] (PMMA) fibers on some properties of acrylic resin

denture base materidi. Materials and Methods: PMMA in the form of fibers 0,75 mm in

diameter and 5 mm in length was added to acrylic resin denture base material in various

percentages to form a composite material. The influence on doughing and manipulation

times and transverse strength was examined. The results were subjected to statistical

analysis using a one-way analysis of variance and, where appropriate, the Scheff test.

Results: The results showed that the doughing time was decreased by the addition of

fibers, with the manipulation and setting times showing inconsistent changes. There was

a significant difference between the materials in terms of the transverse strength. When

the amount of PMMA fibers in the acrylic resin was increased, there was a decrease in

the modulus of rupture and a decrease in (he modulus of elasticity. The differences were

shown to be statistically significant in some groups. Conclusion: The doughing time was

decreased by the addition of fibers, while the manipulation and setting times showed

inconsistent changes. The incorporation of chopped, randomly oriented PMMA fibers

into acrylic resin had no advantage over the unmodified polymer in terms of strength and

cannot be recommended as a reinforcing agent for acrylic resin denture base material,

IntJ Prosthodont 1999:12:542-546.

Over the years, various approaches to strengthening

acrylic resin have been suggested, including modifying or reinforcing the resin. Strengthening has been approached through chemical modification to produce

graft copolymers of rubber methacrylate, referred to as

high-impact resins,^ or by incorporating various metal

forms" and several types of fibers to provide reinforcement of fiacture-prone areas. Several types of

fibers in varying forms (chopped, woven, and linear),

random or oriented, have been added to acrylic denture resins to improve their physical and mechanical

properties. Reinforcement has been achieved through

the inclusion of polyaramid fibers,^^ sapphire

whiskers,'' and carbon,"'-' In recent years, the inclusion

of glass fibers'""'- and oriented or woven ultrahighmodulus polyethylene fibers'^"'^ has produced encouraging results; however, the extra laboratory

steps'^''" coupled with the additional time required

have limited their use. The incorporation of high-modulus polyethylene beads did not have a significant effect on the mechanical properties of the

he material most commonly used in the construction of dentures is polylmethyl methacrylate)

(PMMA), and although few would dispute that satisfactory esthetics can beachieved with this material, in

terms of mechanical properties it is still far from ideal.

The fracture of acrylic resin dentures remains an unresolved prohlem that may result from impact failure,

for example dropping the denture accidentally, or

fiom fatigue failure caused by repeated flexing under

masticatory forces. Several studies have investigated

the prevalence and types of denture fractures,''^

'Lecturer, Restorative Dentistry, Department of Oral and Dental

Science, Bristol Dental School and Hospital, Bristol, UK.

Professor and Head, Department of Orai and Dentai Science,

Bristol Denial School and Hospital, Bristol, UK.

Reprint requests: Dr D. C. /agger, Department of Oral and Dentai

Science, Division of Restorative Dentistry fProsthodontics), Bristol

Dental School and Hospitai, Lower Maudlin Street, Bristol BSi 2LY,

United Kingdom, e-mail:

D.C.lagger@bris.ac.uk

The tntcrnational lournai ol Prot

542

Volume 1 2, Number &,

laagerflHarrison

Efecl of PMMA Fihers on Acryiic Resin Denture Base Mate

Table 1 Materials Used in the Study

Many attempts to strengthen acrylic resin have failed

because areas of stress concentration occur around embedded materiais, and the overall effect is to weaken

rather than strengthen the denture base. Various suggestions have been made to improve the interface between the denture base material and the reinforcing

material, such as sandblasting,'^ silanization,''' the

use of metal-adhesive resins,^" and plasma treatment,^'

but failure at the interface remains a problem.

The physical compatibility of fiber and matrix is an

important factor in the success of fiber-reinforced composites. The concept of self-reinforcement of polymers has been discussed,--"-"' although to date not in

the dental literature. PMMA is a thermoplastic material and it is possible to impart molecular orientation into

the polymer by thermomechanical processing. The

highly oriented molecules impart improved strength

characteristics over the randomly oriented and entangled polymer chains. The potential advantage of selfreinforced composite materials is that they should

have improved mechanical properties over the amorphous random polymer. This study investigated the

self-reinforcement of PMMA denture base resin.

The aim of this study was to investigate the eftect

of chopped PMMA fibers on some properties of

acrylic resin denture base material. The properties investigated were the doughing, manipulation, and setting times ofthe material, and its flexural strength. In

this study, the fibers were incorporated into the acrylic

resin polymer powder so that conventional curing

and packing procedures could be used to avoid problems relating to fiber orientation.

Material

Manufacturer

Description

Trevalon Polymer

Dentsply

Trevalon Mcncmer

Dentsply

Heat-cured PMMA

I

powder (93%)

*

BenzoyI peroxide

(0.4%)

tVlMA monomer

Ethylenegl/col

Dimetfiacrylate (6%)

Hydroquinone (0.006%)

Highly drawn PMMA j .

tibers

,;

0.75-mm PMi A fibers

in 5-mm lengths

PMMA = poly(methyl msthacrylate)

7O''Cand 3 hours at lOO^C. The flasks were allowed

to bench cool before opening. The cured plates were

carefully removed from the mold, the excess flash

was removed, and the specimens were finished using

a Kemet polishing machine with wet, self-adhesive,

waterproof silicon carbide paper discs of 203-mm diameter and 320- and 600-A grit size. Each plate was

of sufficient size to be cut into four specimens using

a band saw. The specimens were then returned to the

polishing machine and carefully finished to dimensions of 64 mm X 10 mm x 2.5 mm as specified by

the International Standards Organization (ISO) and

British Standards Institution (BSI) specification for the

testing of denture base resins.-^'^^ Ten specimens

from each group were prepared and stored in a water

bath at 37 2C for 7 days.

The transverse bend test was carried out using a

Lloyd's Instrument Material Testing Machine, model

L2000R using the 3-point method. The test rig is described in BSI specification BS 2487,-^ The test rig

consisted of a loading wedge and a pair of supporting wedges placed 50 mm apart, which represents the

average intermolar distance of a denture. Each test

specimen was centered on the testing rig so that the

loading wedge, set to move at a speed of 5 mm/min,

engaged the center of the upper surface of the specimen until the specimen broke. The specimens were

tested in a water bath at 37 f C . Moduli of rupture

and elasticity were recorded.

Materials and Methods

The materials used in this study are listed in Table 1.

The .75-mm-diameter PMMA fibers were supplied

in precut 5-mm lengths. The short fiber length represented a convenient size for manipulation and inclusion in the acrylic resin dough. The percentages

of fibers used were 0, 5, 15, 20, and 25% by weight.

Transverse Bend Test

Packing Plasticity Test

A series of polymerized blanks was produced by

mixing 24 g of polymer, which included the appropriate percentage of fibers, with 10 mL of methyl

methacrylate monomer. The mixture was left to stand

in a plastic mixing vessel. The mixing procedure

lasted 60 seconds each time and the mix was allowed to reach the dough stage prior to loading into

a gypsum mold in a dental flask. Molds were prepared

by investing master perspex blanks in SYPSLrnFollowing a trial closure, the blanks were cured in

a thermostatical ly control led water bath for 7 hours at

Volume 12, Number 6, 1999

For the evaluation of the flow behavior of the powder/liquid mixtures, a packing plasticity test was performed using samples from each powder mix. Each

sample was made of 24 g of polymer (which includes

the appropriate percentage of fibers) with 10 mL of

monomer. Three samples from each powder mix were

tested and the doughing, manipulation, and setting

times for each group were calculated. The packing

plasticity was performed using a needle penetrometer.

543

Tlie International |ou

Efiecl of PMMA Fibers on Acryiic Resin DeiiLure B.ise Material

lagger/iHarrison

Ffg 1 Effect o the addition ot

PMMA fibers (Q.7S-mm diarrieter, 5-mm length) on the (low behavior ot Trevaion i"--ryli<: reSin

denture base rnaieii-si

13121110E

elratio

S.

9-

a7-

\\

\

VV

\ \\

- T

20%

- * -

25%

\\\\

w

6-

V. ^

5-

- . - Controi

- - 5%

-* 15%

V'

4-

3.

2-

^;;:::::^!

0-

1

10

1

20

1

30

Time (min)

ST

40

~T

50

1

60

Fig 2 Etfect of fhe addition of

PMMA fibers (0.75-mm diamefer, 5-mm iength) on fhe doughing, manipulation, and seffing

times of Trevaion acrylic resin

denture base material.

Control

group

i I

6%

group

iDougining lime

15%

group

JManipulation lime

20%

group

|

which has been shown to be an effective method of

measuringdoughing and manipulation times.^''Using

this technique, fhe point at which the penetration decreases sharply (penetration < 10 mm) indicates the beginning of the dough stage ie, doughing time). At a

penetration of < 3 mm the material is not workable and

the setting time is therefore defined as the time from

mixing untii the material becomes rubbery and un-

Tlie Infemalionai Jouniai ol Prostiiodonlics

25%

group

|SeHing time

workable (at the completion of tbe manipulation time).

The manipulation time is the period between doughing (penetration < 10 mm) and setting time (penetration < 3 mm) in which it is possible to manipulate and

pack the dough. The results presented in Figs 1 and 2

and Tables 2 and 3 were subjected to statistical analysis using a one-way analysis of variance (ANOVA)

and, where appropriate, the Scheff test.

544

Tiel2, NumberE.

I agger/Harrison

Etfen of PMMA Fibers on Acrylic Resin Denture 8ase Material

Table 2

Results

The results showed that there was a significant difference between the materials in terms of the transverse strength. Increasing the amount of PMMA fibers

in the acrylic resin decreased the modulus of rupture

from 74.0 MPa (control] to 57.1 (25%) (Table 2) and

decreased tbe modulus of elasticity from 1,831 MPa

(control) to 1,617 MPa 125%] (Table 3). The differences were shown to be statistically significant. The

results showed that the manipulation and setting

times (Fig 2] gradually increased as the percentage of

fibers in the acrylic resin powder increased, with the

exception of the addition of 25% fibers.

T

T + 5% F

T * Z0% F

T + 15%F

T + 25%F

No. ot

specimens

Mean transverse

bend strength MPa)

10

9

10

7

10

74.0

72,7

62.9

60,1

57.1

SD

5.95

3.67

7.0Q :i.

10.39

7.45

"One-way ANOVA indicated thai there was a significant difterence between

thegroLpslPOOOOOl).

Vertical bars indicate values llial were not significantly differeni according to tlie Sctieff tesl,

T = Trevalon acrylic resin demure base maleriak F = PMMA fitters (0.75mm diameter, 5-rnm lengtti); SD = standard deviation.

Table 3

Discussion

Material'

Transverse strength is a measure ofthe stiffness and

resistance to fracture. The ISO 1567-= and BSI2487^''

for denture base resins have specified transverse deformation limits of from 1 to 2.5 mm for a force of 15

to 35 N and from 2 to 5 mm for a force of 15 to 50

N. The mean breaking force of acrylic resin should

not be less than 55 N. In this respect the control material and the moditied specimens containing 5%

fibers satisfied the standard.

A one-way ANOVA demonstrated a significant difference in the modulus of rupture between the control specimen and tbe modified specimens. The differences, however, were small, with the control

specimen demonstrating the highest value. The addition of a low percentage of fibers |5%l produced

only a 2% decrease. However, with an increase in the

percentage of fibers (25%], tbere was a 23% reduction in the modulus of rupture,

A one-way ANOVA showed a significant difference

in the modulus of elasticity between the groups. The

difference between tbe highest and lowest values

recorded was 12%. The control material exhibited the

highest modulus of elasticity, in this study, the fibers

were incorporated into the acrylic resin polymer

powder so that conventional curing and packing procedures could be used to avoid problems relating to

fiber orientation. Previous studies on the self-reinforcement of PMMA-- used fibers that were aligned

approximately in the tensile stress direction (continuous fiber unidirectional composites], rather than

the discontinuous, randomly orientated fibers used in

this study. The previous study reported an increase in

ihe tensile strength, tensile modulus, and tensile strain

to failure for self-reinforced composite PMMA compared with conventional PMMA. In unidirectional

form the fibers were assumed to carry the bulk of the

transmitted load, but it is likely that for the discontinuous fibers the load is shared between the fiber and

r 6, 199S

Modulus of Rupture

T + 5% F

T + 30% F

T + 15% F

T + 25% F

Modulus of Elasticity

No.ot

pecimens

10

9

10

7

10

Mean elastic

modulus (MPa)

1831

1801

1737

1701

1617

SD

86

108

39 -,

82

1378

'One-way AhJOVA indicated that there was a significant difterence bBtwaen

lhiegroup(P=0.0001).

Vertical bars indcale i/alues ttiat were not significantly different according to the Sclieff lest,

T = Trevalon acrylic resin denture base material; F = PMMA tibers (0.75mm diameter, 5-mm length]; SD = standard deviation.

the matrix. For the continuous fibers, the increased

toughness was attributed to a number of deformation

mechanisms operating in the samples: increased ductility in the self-reinforced composite PMMA fibers

and at tbe fiber interface, diversion of tbe crack out

ofthe original crack plane by fiber splitting, and fiber

matrix interface failure. Because of differences in

fiber orientation, comparison with the results of

Gilbert et al-^ is inappropriate.

The rhologie properties ofthe PMMA dough will

affect its ability fo flow and can influence the accuracy/quality of the molded denture. Mutlu et a l "

stressed the importance of measuring the flow properties during dough formation and the need for a

knowledge ofthe correct doughing and manipulation

times, because it is important that the dough is packed

during the manipulation stage. The results ofthe packing plasticity test in Figs 1 and 2 show that the doughing time was decreased by the addition of the fibers,

although not significantly (control 7 min, 5% fibers 5

min, 15% fibers 5 min, 20% fibers 6 min, and 25%

fibers 3,5 min. There were similarities between all 5

flow curves (Fig 11. There were significant differences

in the setting times with the addition of the fibers to

the polymer powder, although the changes were inconsistent. The manipulation times ranged from 14.5

545

The Intcrnatianai lournal of Prostliudoniics

Effect of PMMA Eibers on Acrylin Resin Denlure Base Material

I agger/Harrison

min (5% fibers) to 25,5 min (25% fibers). There were

significant differences in the manipulation times, although the differences were inconsistent. In practice,

the manipulation time is the most relevant since it reflects the time available to the dental technician to

pack the resin in the mold(s). An extended manipulation time is therefore essential because it allows

several cases to be packed from a single mix. The manipulation time can be extended by refrigerating the

mix; this technique is used in some laboratories.

10,

Solnit CS, The effect of methyl methacrylate reinforcpmeni with

siiane-treated and untreated glass fibers, | Prosthet Deni 1 '191 ;66:

310-314.

11, Vallittu PK, Comparison of in vitro fatigue resislantf of acrylic

resin partial denture reinforced with continuous L;ISS fibres or

metal wire. I Prosthodont 1996;S:115-121,

12, Valiittu PK. Some aspects of ihe tensile strengths inidirectional

glass fibre poly (methyl methacrylate) composm used in den.

lures, ) Oral Rehabil 1998;25:100-105,

13, Ciarke DA, Ladizesky NH, Chow TW, Acrylic resins reinforced

with highiy drawn linear polyethylene woven fibres. Construction

of upper denture bases, Aust Dent) 1992;37:394-399,

14, Ladizesky NH, Chow TW, Cheng VV. Denture base reinforcement

using woven polyethyiene liber. Inl | Prosthodont 1994;7:

307-314,

15, Gutteridge DL, Reinforcement of poly (methyl methacryiate) with

ultra-high-modulus polyethylene fibre, i Dent 1992;2O:5O-54,

16, CariosB, Harrison A, The effect of untreated UHMWPE beads

on some properties of acrylic resin denture base materiai, J Dent

1997;25:59-64,

1 7. Harrison A, Constan tin id is V, Vowles R, The effect of surface

treated UHMWPE beads on some properties of acrylic denture

basemaieriai, Eur J Prosthodont Restorative Dent 1997;5:39^2,

Conclusions

The incorporation of chopped, randomly oriented

poly(methyl methacrylate) fibers to acrylic resin

had no advantage over the unmodified polymer

in terms of strength, and it cannot be recommended as a reinforcing agent for acrylic resin

denture base material in its present form,

The doughing time was decreased relative to the

control by the addition of fibers, while the manipulation and setting times showed inconsistent

changes.

References

1,

2,

3,

4,

5,

18.

Vailittu PK, Lassila VP, Effect of metal strengt h ener's surface

roughness on fracture resistance of acrylic denture base material, J Oral Rehabil 1992; 19:385-391.

19.

Valiittu PK, Comparison of two different silane compounds used

for Improving adhesion between fibres and acrylic denlure base

malerial. | Oral Rehabil 1993;2O:533-539,

Tanai<a T, Nagata K, Takeyama M, Asuta M, Nakabayashi N,

Masuhara E, 4 Meta opaque resin. A new resin strongly adhesive lo nickel c h r o m i u m alloy, | Dent Res 198l;fcO'

1,697-1,706.

20,

Hargreaves AS, The prevalence of fractured dentures. A survey,

Br DentJ 1969;126:451^5S.

Darbar R, Huggett R, Harrison A, Denture fracture. A survey,

BrDenlJ 1994;17fc342-345.

Rodford RA, Further development and evaluation of higii-impactstfengthdenturebase materiais. I Dent 199O;18:151-15?.

PolyzoisGL, Reinforcementof denture acrylic resin. The effect

of metal inserts and denture resin type on fracture res i stance, Eur

; Prosthodont Restorative Dent 1995;3:275-278.

Grave AMH, Cliandler HD, Wolfaardt |F, Denture base acrylic

reinforced with high modulus fibre, Dem Mater 19aS;1 :TS5-187.

21,

Ramos V, Runyan DA, Christensen LC, The effect of plasma

treated polyethyiene fiber on the fracture strength of poly methylmcthacryiate, I Prosthet Dent 1996;76:94-96.

23.

Gilbert |L, Ney DS, Lautenschlager EP, Self reinforced composite poly (methyl methacrylate): Static and fatigue properties,

Biomaterials 1995;16:1,043-1,055,

Wright DD, Lau ten sch lager EP, Gilbert |L, Bending and fracture

roughness of woven self reinforced composite poly [methylmethacryiatel, J Biomed Mater Res 1997;36:441^53,

23,

6,

Berrong IM, Weed RM, Voung )M. Eracture resistance of Kevlarreinforced polyimethyl methacrylate) resin: A preliminary study,

IntJ Prosthodont l990;3:391-395,

24,

Wright D D , Lautenschlager EP, Gilben |L. Interfacial properties

ofselfreinforcedcompositepoly(methyl methacrylate). J Biomed

Mater Resl99S;43:153-1&1.

7,

GrantAA, Greener EH, Whisker reinforcement of poly [methyl

metha cry I atel denture base resins. Aust Dent] 1967:12:29-33,

Bowman A|, Manley TR The eiimination of breakages in upper

dentures by reinforcement with carbon fibre. Br Dent J 19E4;

1 56:87-89,

Ekslrand K, Ruyter IE, Wellendorf H, Carbon/graphite fibre reinforced polylmethylmelhacrylate): Properties under dry and

wetconditions. I Biomed Mater Res 987;21:l,065-1,080,

25,

I n t e r n a t i o n a l Standard O r g a n i z a t i o n . ISO 1 5 6 7 : 1 9 8 8 ,

Specifications for Denture Base Polymers, Geneva: ISO, 1998,

26,

British Standards institution. Specification for Denture Base

Polymers. BS 2487:1989. London: BSl, 1989,

MutluG, HuggetiR, Harrison A, Determination of doughing and

manipulation times of acrylic resin denture base material anda

proposal for a specification for a packing plasticity test, I Dent

1992;2O:3l 1-317,

8,

9,

The intemaiional Journai ol Prosthdnlics

27,

546

Volume 12, Number 6,

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- 440T4 4T60 4t60e 4t65eDocument24 pages440T4 4T60 4t60e 4t65eFTompkins73100% (4)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Etap - Relay CoordinationDocument311 pagesEtap - Relay CoordinationManohar Potnuru100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- PR-1078 - Hydrogen Sulphide Management ProcedureDocument22 pagesPR-1078 - Hydrogen Sulphide Management Procedureromedic360% (1)

- BOQ For Interior WorkDocument2 pagesBOQ For Interior WorkSudhanshu MandlikPas encore d'évaluation

- Lexus Brand BrochureDocument40 pagesLexus Brand Brochurejammypops100% (1)

- Sampling Procedure and Tables For InspectionDocument43 pagesSampling Procedure and Tables For InspectionAnonymous AoTZuNvxPas encore d'évaluation

- BPQ REV. 0 Interactive FormDocument2 pagesBPQ REV. 0 Interactive FormcosmicbunnyPas encore d'évaluation

- G3508 - 600kvaDocument7 pagesG3508 - 600kvaJim Patrick ChombaPas encore d'évaluation

- Occupational Health and Safety of Hydrogen Sulphide (H2S)Document20 pagesOccupational Health and Safety of Hydrogen Sulphide (H2S)hitm357100% (1)

- Sample Detailed Estimates PDFDocument9 pagesSample Detailed Estimates PDFJj Salazar Dela CruzPas encore d'évaluation

- Stress Fatigue PrinciplesDocument12 pagesStress Fatigue Principlesjinny1_0Pas encore d'évaluation

- Groper's ApplianceDocument4 pagesGroper's Appliancejinny1_0Pas encore d'évaluation

- Pulp Therapy-Guideline AapdDocument8 pagesPulp Therapy-Guideline Aapdjinny1_0Pas encore d'évaluation

- AAPD Policy On - FluorideUseDocument2 pagesAAPD Policy On - FluorideUsejinny1_0Pas encore d'évaluation

- Patient-Assessed Security Changes When Replacing Mandibular Complete DenturesDocument7 pagesPatient-Assessed Security Changes When Replacing Mandibular Complete Denturesjinny1_0Pas encore d'évaluation

- KurthDocument18 pagesKurthjinny1_0Pas encore d'évaluation

- Spacer Design Jips 2005 PDFDocument5 pagesSpacer Design Jips 2005 PDFjinny1_0Pas encore d'évaluation

- Assessing The Quality of Clinical Procedures and Technical Standards of Dental Laboratories in Fixed Partial Denture TherapyDocument7 pagesAssessing The Quality of Clinical Procedures and Technical Standards of Dental Laboratories in Fixed Partial Denture Therapyjinny1_0Pas encore d'évaluation

- Mandibular Overdentures Stabilized by Astra Tech Implants With Either Ball Attachments or Magnets: 5-Year ResultsDocument9 pagesMandibular Overdentures Stabilized by Astra Tech Implants With Either Ball Attachments or Magnets: 5-Year Resultsjinny1_0Pas encore d'évaluation

- Long-Term Cytotoxicity of Dental Casting AlloysDocument8 pagesLong-Term Cytotoxicity of Dental Casting Alloysjinny1_0Pas encore d'évaluation

- Precision of CNC-Milled Titanium Frameworks For Implant Treatment in The Edentulous JawDocument8 pagesPrecision of CNC-Milled Titanium Frameworks For Implant Treatment in The Edentulous Jawjinny1_0Pas encore d'évaluation

- Effects of Thermocycling On The Tensile Bond Strength Between Resin Cement and Dentin Surfaces After Temporary Cement ApplicationDocument7 pagesEffects of Thermocycling On The Tensile Bond Strength Between Resin Cement and Dentin Surfaces After Temporary Cement Applicationjinny1_0Pas encore d'évaluation

- The Mandibuiar Speech Envelope in Subjects With and Without Incisai Tooth WearDocument6 pagesThe Mandibuiar Speech Envelope in Subjects With and Without Incisai Tooth Wearjinny1_0Pas encore d'évaluation

- 100124119Document175 pages100124119mkeiwuaPas encore d'évaluation

- Waste Management in Selected Hotels in GoaDocument11 pagesWaste Management in Selected Hotels in GoaSyna SoaresPas encore d'évaluation

- Emmeskay MIL-SIL TutorialDocument52 pagesEmmeskay MIL-SIL TutorialNeacsu EugenPas encore d'évaluation

- Dilg-Mbcrpp Isf Q2 2023Document2 pagesDilg-Mbcrpp Isf Q2 2023Mallari GabrielPas encore d'évaluation

- 4 - 5.1 - Fluid Action On Surfaces (Plane Surface)Document16 pages4 - 5.1 - Fluid Action On Surfaces (Plane Surface)Jacky CagampanPas encore d'évaluation

- Product Presentation PPT NeerajDocument8 pagesProduct Presentation PPT NeerajNeeraj UdiniyaPas encore d'évaluation

- Fdot Precast Bent Cap Development and Implementation: AbstractDocument10 pagesFdot Precast Bent Cap Development and Implementation: AbstractCongOanh PHANPas encore d'évaluation

- 990 Vibration Transmitter Datasheet-141612mDocument14 pages990 Vibration Transmitter Datasheet-141612mloopkkPas encore d'évaluation

- Communication With Energy Meter and Field Devices Using PLCDocument3 pagesCommunication With Energy Meter and Field Devices Using PLCIJRASETPublicationsPas encore d'évaluation

- Chapter 2 A Guide To Using UnixDocument53 pagesChapter 2 A Guide To Using UnixAntwon KellyPas encore d'évaluation

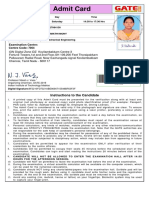

- Admit Card: Examination Centre: Centre CodeDocument1 pageAdmit Card: Examination Centre: Centre CodekrishnaPas encore d'évaluation

- Individual: DR Winnie Louis LeeDocument27 pagesIndividual: DR Winnie Louis Leeedn_mj1645Pas encore d'évaluation

- Agroforestry: A Sustainable Land-Use System For Food and WoodDocument72 pagesAgroforestry: A Sustainable Land-Use System For Food and WoodAlok PatraPas encore d'évaluation

- Aes MatlabDocument32 pagesAes MatlabbalajithrillerPas encore d'évaluation

- Guide To Apparel/Textile Care Symbols: Machine Wash CyclesDocument1 pageGuide To Apparel/Textile Care Symbols: Machine Wash Cyclesnilhan1Pas encore d'évaluation

- 690 2004Document19 pages690 2004RahilaHammadPas encore d'évaluation

- Solution of Tutorial Sheet-3 (Three Phase Networks) : Ans. Given, - Vab - 45kV, ZL (0.5 + j3), Z (4.5 + j9)Document10 pagesSolution of Tutorial Sheet-3 (Three Phase Networks) : Ans. Given, - Vab - 45kV, ZL (0.5 + j3), Z (4.5 + j9)Shroyon100% (2)

- Thesis Report Vishal Part 1Document9 pagesThesis Report Vishal Part 1vishal infantrajPas encore d'évaluation

- Dutypoint BrochureDocument24 pagesDutypoint Brochuremh wPas encore d'évaluation

- MclogitDocument19 pagesMclogitkyotopinheiroPas encore d'évaluation