Académique Documents

Professionnel Documents

Culture Documents

Life Cycle Cost Analysis - EGEE 102 - Energy Conservation and Environmental Protection

Transféré par

gbaludbTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Life Cycle Cost Analysis - EGEE 102 - Energy Conservation and Environmental Protection

Transféré par

gbaludbDroits d'auteur :

Formats disponibles

Life Cycle Cost Analysis

Printer-friendly version

Perform ing a life-cycle cost analysis (LCC) gives the total cost of a lighting system including all expenses incurred over the

life of the system . T his analysis can be applied not only to lighting but for m ost of the appliances, autom obiles, heating

system s, and so on, when two system s are com pared to determ ine the m ost cost effective options.

T here are two reasons to do an LCC analysis:

1. To compare different systems or bulbs in this case

2. To determine the most cost-effective system or a bulb

For som e lighting system s, one of two situations m ay exist:

1. The initial cost may be high but the energy costs will be low over its life time.

2. The initial cost to buy a bulb or a system and the energy or the maintenance costs may be low, but the useful life of such an bulb

or system may be short. (In this case, we may have to replace the appliance several times to get the same useful life as the other

option.)

T herefore, a life-cycle cost (LCC) analysis can be helpful for com paring the total costs incurred over the lifetim e of a lighting

system . It is, in essence, calculating all the costs incurred to buy, m aintain, and run the system over its lifetim e.

Life Cycle Costs = Cost to buy + Cost to maintain it (if any maintenance is

required) + cost of energy to run it for its life + Replacement costs Any salvage value

In the form ula above,

Cost to buy is the purchase price of the bulb or the system.

Cost to maintain is the cost incurred to maintain it in good operating condition. (For example in the case of a car, engine oil

change every 3,000 miles is part of maintenance costs.)

Cost of energy is the energy or the fuel it takes to run the appliance or bulb for its life time.

Replacement cost is the cost to replace the bulb. If bulb A has a life of 1000 hrs and bulb B has a life of 10,000 hours, then

Bulb A needs to be replaced 10 times to get the same useful life period as that of bulb A. Therefore, 10 A bulbs need to be

purchased for each of Bulb B.

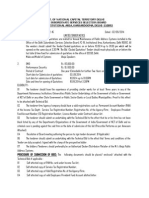

T he table below shows a life cycle cost analysis in com paring an incandescent bulb and a CFL.

Life Cycle Cost Analysis, Incandescent bulb vs CFL bulb

Incandescent

Compact Fluorescent Light

(CFL)

Rating

60 Watts

15 Watts

Lumen output

865 Lumens

900 Lumens

Cost to buy the bulb ($)

$0.60

$5.00

Life of each bulb

1,000 h

10,000 h

Bulbs needed for same life

10 bulbs - $6.00

1 bulb - $5.00

Energy Consumption

60 Watts x 10,000 h

15 Watts x 10,000 h

600,000 Wh = 600 kWh

150,000 Wh = 150 kWh

Price of electricity

$0.085

$0.085

Cost of Electricity needed for

10,000 h

600 kWh X 0.085/kWh =

150 kWh X 0.085/kWh =

$51.00

$12.75

51.00 +6.00

12.75 +5.00

$57.00

$17.75

Total Cost (Life Cycle costs) to

ow n and operate the bulbs for

10,000 h

T his analysis shows clearly that each incandescent bulb replaced with a CFL which would fit

into a regular incandescent bulb fixture would save about $29.25 over 10,000 hours of

operation. Im agine the num ber of bulbs that you have at hom e. Living room , kitchen, bath

room s, bed room s, table lights, floor lam ps, ceiling lights, closets, garage, basem ent, and so

on. T here are energy saving options all over the hom e.

Although they save energy, there are som e disadvantages with CFLs:

They are often physically larger than the incandescent bulbs they replace and simply may not fit the lamp.

The light is generally coolerless yellowthan incandescent light bulbs. This may result in less than pleasing contrast with

ordinary lamps and ceiling fixtures. Newer models have been addressing this issue.

Some types (usually iron ballasts) may produce an annoying flicker.

Ordinary dimmers cannot be used with compact fluorescents.

Like other fluorescents, operation at cold temperatures (under around 5060 degrees F) may result in reduced light output.

There may be an audible buzz from the ballast.

Types of Lighting: Low-pressure sodium

up

Efficacy of Light Bulbs

Vous aimerez peut-être aussi

- M Tender 514Document5 pagesM Tender 514gbaludbPas encore d'évaluation

- Tender 767Document2 pagesTender 767gbaludbPas encore d'évaluation

- Fire Tender 2014Document37 pagesFire Tender 2014gbaludbPas encore d'évaluation

- Supply, Installation & Testing and Commissioning of P.A. System, Tower AC & Water Cooler Cum Purifier For IHM & Different Panthanivas of OTDC LTDDocument9 pagesSupply, Installation & Testing and Commissioning of P.A. System, Tower AC & Water Cooler Cum Purifier For IHM & Different Panthanivas of OTDC LTDgbaludbPas encore d'évaluation

- Tender For CCTV New - Copy 1Document12 pagesTender For CCTV New - Copy 1gbaludbPas encore d'évaluation

- Tender For Sitc of Pa Systems - Nabard MproDocument30 pagesTender For Sitc of Pa Systems - Nabard MprogbaludbPas encore d'évaluation

- National Institute of Fashion Technology, KolkataDocument9 pagesNational Institute of Fashion Technology, KolkatagbaludbPas encore d'évaluation

- AMCPASDocument3 pagesAMCPASgbaludbPas encore d'évaluation

- Govt. of National Capital Territory Delhi Delhi Subordinate Services Selection Board Fc-18, Institutional Area, Karkardooma, Delhi-110092Document7 pagesGovt. of National Capital Territory Delhi Delhi Subordinate Services Selection Board Fc-18, Institutional Area, Karkardooma, Delhi-110092gbaludbPas encore d'évaluation

- For The Works of Near: Unit QTY Rate AmountDocument3 pagesFor The Works of Near: Unit QTY Rate AmountgbaludbPas encore d'évaluation

- Chennai Port Trust: TENDER No. MEE/15/2013/ DCME (EC/OS)Document56 pagesChennai Port Trust: TENDER No. MEE/15/2013/ DCME (EC/OS)gbaludbPas encore d'évaluation

- Pa System Analogue SpecificationDocument2 pagesPa System Analogue SpecificationgbaludbPas encore d'évaluation

- Tender Form Pa SystemsDocument3 pagesTender Form Pa SystemsgbaludbPas encore d'évaluation

- Tender For Sound System For Class RoomsDocument5 pagesTender For Sound System For Class RoomsgbaludbPas encore d'évaluation

- 05 WiproDocument26 pages05 WiprogbaludbPas encore d'évaluation

- Cissca v2 Catalog en W o MarkDocument2 pagesCissca v2 Catalog en W o MarkgbaludbPas encore d'évaluation

- WVP 25118 - 218 - 126 - 226 NSDocument1 pageWVP 25118 - 218 - 126 - 226 NSgbaludbPas encore d'évaluation

- PAS TenderDocument8 pagesPAS TendergbaludbPas encore d'évaluation

- Datashe T E: Input Interface UnitDocument1 pageDatashe T E: Input Interface UnitgbaludbPas encore d'évaluation

- WP155002EN Optimizing Rack LRDocument4 pagesWP155002EN Optimizing Rack LRgbaludbPas encore d'évaluation

- Guide To Commercial InstallationsDocument42 pagesGuide To Commercial InstallationsgbaludbPas encore d'évaluation

- Wireless Address Able Smoke DetectorDocument1 pageWireless Address Able Smoke DetectorgbaludbPas encore d'évaluation

- 225 Ongoing Projects CompletedDocument4 pages225 Ongoing Projects CompletedgbaludbPas encore d'évaluation

- 7Hfkqlfdo8Qlyhuvlw/ $VDFKL, Dvl%Oyg'0Dqjhurqqrwhoyyduydud#UgvolqnurDocument4 pages7Hfkqlfdo8Qlyhuvlw/ $VDFKL, Dvl%Oyg'0Dqjhurqqrwhoyyduydud#UgvolqnurgbaludbPas encore d'évaluation

- Intellivox DS180 Data 011614Document12 pagesIntellivox DS180 Data 011614gbaludbPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- ASME Code Section 8 ContentDocument6 pagesASME Code Section 8 ContenttasingenieriaPas encore d'évaluation

- Energy Resources Availability Management and Environmental Impacts ContentsDocument11 pagesEnergy Resources Availability Management and Environmental Impacts ContentsRangaswamy VittalaPas encore d'évaluation

- PhotoVoltaic General CatalogDocument20 pagesPhotoVoltaic General CatalogCourtney HernandezPas encore d'évaluation

- PHD Thesis 2Document108 pagesPHD Thesis 2ahmedkhalidhussain100% (1)

- 300Q PDFDocument2 pages300Q PDFAlex CastañedaPas encore d'évaluation

- Hydro Consultancy: Delivering Renewable Energy SolutionsDocument4 pagesHydro Consultancy: Delivering Renewable Energy SolutionsEdzwan RedzaPas encore d'évaluation

- SGS Group Profile enDocument8 pagesSGS Group Profile enchienPas encore d'évaluation

- Conducted Electromagnetic Emissions Analysis in Grid-Tied PV SystemDocument4 pagesConducted Electromagnetic Emissions Analysis in Grid-Tied PV SystemskrtamilPas encore d'évaluation

- Access and EgressDocument13 pagesAccess and EgressVan LianPas encore d'évaluation

- Attachment REPORTDocument39 pagesAttachment REPORTsemPas encore d'évaluation

- Technical Description of An Electric Tooth BrushDocument4 pagesTechnical Description of An Electric Tooth BrushAre LeyPas encore d'évaluation

- Reflections On Energy Sustainability in Latin America: Biomass and Circular EconomyDocument7 pagesReflections On Energy Sustainability in Latin America: Biomass and Circular EconomyIjahss JournalPas encore d'évaluation

- V Series Breakers (Including MDU Type) CatalogDocument70 pagesV Series Breakers (Including MDU Type) CatalogAndrew MaverickPas encore d'évaluation

- FSC ModelingDocument5 pagesFSC Modelings_banerjeePas encore d'évaluation

- Design of Re Inforc 00 BurkDocument90 pagesDesign of Re Inforc 00 BurkdeniPas encore d'évaluation

- EnergyConversion CarbonTrustDocument4 pagesEnergyConversion CarbonTrustReynaldo GrantPas encore d'évaluation

- CLL-Allingua DE1AExamParticipantDocument8 pagesCLL-Allingua DE1AExamParticipantKarel FrisbyPas encore d'évaluation

- KSIBbrochureDocument4 pagesKSIBbrochureJack AboutboulPas encore d'évaluation

- CFB Boiler Erection Persentation Rev-2Document33 pagesCFB Boiler Erection Persentation Rev-2juarsa r100% (2)

- Iso-Tc255 n0016 Iso TC 255 Business Plan-30Document10 pagesIso-Tc255 n0016 Iso TC 255 Business Plan-30Hiron NurulPas encore d'évaluation

- File Chinh Thuc HSG Tháng 3 2021Document14 pagesFile Chinh Thuc HSG Tháng 3 2021NhiPas encore d'évaluation

- Siemens Company PresentationDocument35 pagesSiemens Company PresentationOleksandr Ivanov100% (1)

- Project Inception Report - High Capacity Power Transmission Corridor - Main ReportDocument59 pagesProject Inception Report - High Capacity Power Transmission Corridor - Main ReportMin100% (1)

- Briquette Moulding MachineDocument29 pagesBriquette Moulding MachineLife of kalyanPas encore d'évaluation

- Bosch SHV65P03UCDocument2 pagesBosch SHV65P03UCPurcellMurrayPas encore d'évaluation

- Black and Green Bold Illustrative Environmental Sustainability Infographics - 20240405 - 200448 - 0000Document1 pageBlack and Green Bold Illustrative Environmental Sustainability Infographics - 20240405 - 200448 - 0000sandbox.ply22Pas encore d'évaluation

- Standards and Norms in PVDocument23 pagesStandards and Norms in PVbehroozPas encore d'évaluation

- Biomass Boiler - Buyers GuideDocument7 pagesBiomass Boiler - Buyers GuideMathias LeonPas encore d'évaluation

- Power Technology BookDocument245 pagesPower Technology BookMuhammad rizkiPas encore d'évaluation

- Gas - Liquid Mixing Impeller of New GenerationDocument8 pagesGas - Liquid Mixing Impeller of New GenerationscranderiPas encore d'évaluation