Académique Documents

Professionnel Documents

Culture Documents

Shear - Torsion - Handout

Transféré par

Dirajen PMTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Shear - Torsion - Handout

Transféré par

Dirajen PMDroits d'auteur :

Formats disponibles

10/15/2012

Shear stress

If two equal and opposite parallel forces Q, not in the

same line, act on parallel faces of a member then it is

said to be loaded in shear.

Shear & Torsion

Shear stress

A shear stress () is defined as a stress which is

applied parallel or tangential to a face of a material.

Shear stress

The formula to calculate average shear stress is:

shear stress ( )

shear load

F

area resisting load A

where

= shear stress;

F

= force applied;

A

= cross sectional area.

The shear stress will always be tangential

to the area on which it acts.

Shear stress

Example I:

In a guillotine, Q is the total force exerted by

the blade. This force is balanced by an equal

and opposite force provided at the edge of the

table.

Shear stress

Example II:

In a punching operation the area of the

resisting shear would be the plate thickness

multiplied

The area resisting shear is measured by the

plate thickness multiplied by the length of the

blade.

by

the

perimeter of

the

hole

punched.

10/15/2012

Riveted Joints

Riveted Joints

The rivet is commonly loaded in shear:

In single-shear the area resisting

shear is the cross-sectional area of

the rivet, d2/4, where d is the

diameter of the rivet.

In double-shear the resisting area

is twice the area of section of the

The single shear takes place on the single plane and the

rivet, and the load which it can be

shear area is the cross - sectional of the rivet, whereas the

carried is theoretically twice that in

double shear takes place in the case of Butt joints of rivets

the single shear.

and the shear area is the twice of the X - sectional area of

Riveted Joints

Clevis

Torque

Power

Torque, also called moment or moment of force, is the

tendency of a force to rotate an object about an axis,

Power

2 * N * T

(kW)

1000

where

fulcrum, or pivot. A torque can be thought of as a twist.

The magnitude of torque depends on three quantities:

First, the force applied; second, the length of the lever

N number of revolutions per second;

T torque (Nm).

arm connecting the axis to the point of force

application; and third, the angle between the two.

Torque, T Force , F x Length, L x sin (angle bet F & L)

10/15/2012

Ultimate shear stress

Allowable working stress-factor of safety

The most suitable strength or stiffness criterion for

The ultimate shear stress or strength is defined

any structural element or component is normally

as:

some maximum stress or deformation which must

not be exceeded. In the case of stresses the value

maximum punch load

area resisting shear

is generally known as the maximum allowable

working stress.

Because of uncertainties of loading conditions, design

procedures, production methods, etc., designers generally

introduce a factor of safety into their designs, defined as

follows:

factor of safety

Factor of Safety

maximum stress

allowable working stress

Factor of Safety

A factor of safety of 3 implies that the design is

Values are normally selected on the basis of a

capable of carrying three times the maximum stress

consideration of the social, human safety and

to which it is expected the structure will be

economic consequences of failure. Typical values

subjected in any normal loading condition.

range from 2.5 (for relatively low consequence,

static load cases) to 10 (for shock load and high

safety risk applications).

Load Factor

Coupling Flanges

In some loading cases, e.g. buckling of struts, neither the

yield stress nor the ultimate strength is a realistic criterion for

failure of components. In such cases it is convenient to

replace the safety factor, based on stresses, with a different

factor based on loads. The load factor is therefore defined

as:

load factor

load at failure

allowable working load

This is particularly useful in applications of the so-called plastic limit

design procedures.

10/15/2012

Shear Strain

Module of Rigidity

The object is rigidly fixed at one face and subject to a stress

The modulus of rigidity, G is given by:

q on the other parallel face. The object deforms sideways.

The shear strain is defined as the angle of deformation, in

radians. Given that the angle is small,

x

l

shear stress,

shear strain,

The shear strain is defined as the

ratio of the distance deformed to

the height.

A shaft is to be fitted with a flanged coupling having 8

bolts on a circle of diameter 150 mm. The shaft may be

subject either to a direct tensile load of 400 kN or to a

Torsion of a Thin Tube

twisting-moment of 18 kNm. If the maximum direct and

shearing stresses permissible in the bolt material are 125

MN/ m2 and 55MN/m2 respectively, find the minimum

diameter of bolt required. Assume each bolt takes an

equal share of the load or torque.

Using this bolt diameter and assuming only one bolt to

carry the full torque what would then be the shearing

stress in the bolt?

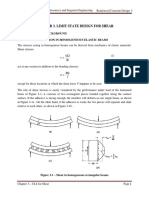

Torsion of a thin tube

Torsion of a thin tube

If it is assumed that the displacement BB' is small

Consider the thin tube of mean radius r, having a wall

compared with the length of tube AB, then AB' will be

thickness (t is very small compared with r).

approximately straight.

Then angle < BOB' is the angle of twist of the length

If a torque T is applied to both ends of the tube, one end

will twist relative to the other. A strip AB parallel to the

tube axis will distort to AB'.

AB. The shear strain is:

Shear strain,

BB' r

rad

AB l

since BB' = r , and AB = length of tube l.

10/15/2012

Torsion of a thin tube

The shear force on the cross-section of the tube is:

Shear force, F

torque T

radius r

Also since / G, the modulus of rigidity, and r/ l , then

G

r/ l

This force acts on area 2rt, since the tube is thin.

Therefore

Shear stress,

shear force

F

area

2rt

T/r

T

2rt 2r 2 t

Hence,

r

l

Notes:

For a given torque the angle of twist varies directly with the length;

In these formulae, the twist must be in radians.

Assumptions:

1. The shaft is composed of a succession of thin

concentric tubes;

Torsion of Solid Shafts

2. Each thin tube carries shear force

independent of, and without interfering with,

its neighbours.

3. Lines which are radial before twisting are

assumed to remain radial after twisting;

4. The shaft is not stressed beyond the elastic

limit.

Area, dA

= 2r x dr

Torque carried by tube 2 r 2 x

If is the shear stress at radius r, then

Shear force on tube

= 2r x dr x

Torque carried by tube

= 2r x dr x x r

= 2r2 dr

G

r x dr

l

G 3

r dr

l

The whole torque T carried by the solid shaft is the sum of

all the elementary torques, ie

We know that

r

l

G

r

l

G 3

r dr

l

10/15/2012

Since radial lines before twisting remain radial after

T G

Ip

l

Rearranging

twisting, is the same for all the thin tubes making up the

shaft. Also G and l are constant, therefore

G

T

l

G

Ip

2 r dr

l

Since

r

l

A useful re-arrangement

Ip is the polar second moment of area of a shaft

T G

Ip

l

r

of circular section.

Ip

2 r 3 dr

Another useful re-arrangement

Important points:

The angle of twist varies directly with length l ;

Tl

GIp

Since

Tr

Ip

for a given torque T, the shear stress q is

proportional to the radius r.

Thus the

maximum shear stress occurs at the outside

surface where r=d/2, and the shear stress at

the centre of the shaft is zero.

A thin steel tube 90 mm inside diameter is subjected to

a torque of 500Nm.

A thin tube 1.5 mm thick, 80 mm mean diameter is

a) If the shear stress is not to exceed 28 MN/m2,

calculate the tube thickness.

subjected to a torque of 350 Nm. Calculate (a) the

shear stress in the tube, (b) the twist on a 1 m length.

b) If the twist is not to exceed 2.5mm of arc on a

600mm length what would be the thickness

required?

G = 84 GN/m2.

G = 84 GN/m2.

10/15/2012

Twisting of Hollow shafts

Twisting of Hollow shafts

If d2 and d1 are the outside and inside diameters of

a hollow shaft subject to a twisting moment T then

the equation

G

l

2 r 3 dr

Ip

Ip

d2 / 2

2 r 3 dr

d1 / 2

(d 2 4 - d 1 4 )

32

may be rewritten as:

G

l

d2 / 2

2 r 3 dr

d1 / 2

Comparison of shear stress distributions in a solid

and a hollow shaft

Since

Ip r

then

T

.r

Ip

The maximum shear stress for a given torque is again

at the outside fibres of the shaft, where r = d2/2.

Stiffness and Strength

Stiffness and Strength

The stiffness or torsional rigidity of a shaft is the

The strength of a shaft is measured by the torque it

torque to produce unit angle of twist. Thus if a

can transmit for a given permissible value of the

torque T produces a twist then

maximum shear stress.

stiffness

T G Ip

For a given shear stress the strengths of two shafts

are the ratio of the corresponding torques.

10/15/2012

Power and Torque

Power

2 * N * T

(kW)

1000

Compare the torsional stiffness of a solid

where

shaft 50 mm diameter, 300 mm long, with

that of a hollow shaft of the same

N number of revolutions per second;

material having diameters 75 mm, 50 mm

T torque (Nm).

and length 200 mm.

Angle of Twist in Elastic Range

The propeller shaft of an aircraft engine

is steel tubing of 75 mm external and 60

mm internal diameter.

The shaft is to

transmit 150 kW at 1650 rev/min.

The

failing stress in shear for this shaft is 140

MN/m2. What is the safety factor?

TL

I pG

7.87

Angle of Twist in Elastic Range

Angle of Twist in Elastic Range

Ti L i

p iG i

I

i

T(x) dx

I p (x) G

10/15/2012

Angle of Twist in Elastic Range

Sign Convention

T(x) dx

I p (x) G

J(x) I p (x)

Sign Convention

Sign Convention

A shaft is made of a steel alloy having an allowable shear

The solid shaft of radius r is subjected to a torque T.

stress of allow = 120 N/mm2. If the diameter of the shaft is 15

Determine the radius r of the inner core of the shaft that

mm, determine the maximum torque T that can be

resists one-quarter of the applied torque (T/4). Solve the

transmitted.

problem by using the torsion formula.

What would be the maximum torque T if a 10-mm-diameter

hole is bored through the shaft? Sketch the shear-stress

distribution along a radial line in each case.

10/15/2012

The shaft has an outer diameter of 25 mm and an inner diameter

of 20 mm. If it is subjected to the applied torques as shown,

determine the absolute maximum shear stress developed in the

shaft. The smooth bearings at A and B do not resist torque.

The steel shaft is subjected to the torsional loading shown.

Determine the absolute maximum shear stress in the shaft and

sketch the shear-stress distribution along a radial line where it is

maximum.

Torsion of Noncircular Members

Torsion of Noncircular Members

Previous torsion formulas are valid

for axisymmetric or circular shafts

Planar cross-sections of noncircular

shafts do not remain planar and

stress and strain distribution do not

vary linearly

For uniform rectangular crosssections, T

TL

max

c1ab 2

c2ab3G

At large values of a/b, the maximum

shear stress and angle of twist for

other open sections are the same as

a rectangular bar.

3 - 58

10

Vous aimerez peut-être aussi

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985D'EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Pas encore d'évaluation

- Machine Design: Stress Concentration FactorsDocument30 pagesMachine Design: Stress Concentration FactorsM.HPas encore d'évaluation

- Torsion, Unsymmetric Bending and Shear CenterDocument24 pagesTorsion, Unsymmetric Bending and Shear CenterpetronashscribdidPas encore d'évaluation

- Torsion of Opened Cross Sections. Loads On Frame Due To Fuselage BendingDocument17 pagesTorsion of Opened Cross Sections. Loads On Frame Due To Fuselage BendingLUIS ISAAC LEON PAROPas encore d'évaluation

- Chapter Five: BendingDocument14 pagesChapter Five: BendingDexterneohhongweiPas encore d'évaluation

- REVIEW 1 - Bending Open and Closed SectioDocument28 pagesREVIEW 1 - Bending Open and Closed SectioRobin JamesPas encore d'évaluation

- Shear Stress in BeamsDocument8 pagesShear Stress in BeamsDaniel NaughtonPas encore d'évaluation

- Lec4 - Shear of Thin Walled BeamsDocument52 pagesLec4 - Shear of Thin Walled Beamsamber batoolPas encore d'évaluation

- Reinforced Concrete Shear Design PrinciplesDocument27 pagesReinforced Concrete Shear Design PrinciplesFekadu DebelaPas encore d'évaluation

- Bending of Open & Closed Cross Section BeamsDocument57 pagesBending of Open & Closed Cross Section BeamsSebastian Carter100% (1)

- Chapter 5 Lamina Failure TheoriesDocument15 pagesChapter 5 Lamina Failure TheoriesyousefPas encore d'évaluation

- FLEXURAL 12 (Autosaved)Document42 pagesFLEXURAL 12 (Autosaved)Ezen ChiPas encore d'évaluation

- Mechanics of Solids CE 1201Document12 pagesMechanics of Solids CE 1201G Sri SoumyaPas encore d'évaluation

- Chapter 22 - FuselagesDocument25 pagesChapter 22 - FuselagesLUIS ISAAC LEON PAROPas encore d'évaluation

- Prestressed Concrete: Load Balancing and DeflectionsDocument20 pagesPrestressed Concrete: Load Balancing and Deflections16052169Pas encore d'évaluation

- Sandwich Structures 1Document17 pagesSandwich Structures 1Srikanth StarkPas encore d'évaluation

- Bending of Open Section BeamsDocument35 pagesBending of Open Section BeamsRavishanker BaligaPas encore d'évaluation

- Pure Bending PDFDocument8 pagesPure Bending PDFAlvin SmithPas encore d'évaluation

- Mechanics and Materials: Chapter 6: BendingDocument37 pagesMechanics and Materials: Chapter 6: BendingMuhammad Mumtaz Ahmad100% (1)

- Bending Stresses in BeamDocument29 pagesBending Stresses in BeamilhammkaPas encore d'évaluation

- MoM Summary PointsDocument39 pagesMoM Summary PointsAmmarPas encore d'évaluation

- Gravity Dam Design and Analysis: - Dam/reservoir Site Selection - Reservoir CapacityDocument22 pagesGravity Dam Design and Analysis: - Dam/reservoir Site Selection - Reservoir CapacityHabtamu HailuPas encore d'évaluation

- Design and Linear Static Analysis of Transport Aircraft Vertical Tail For Different Rudder Deflection (Rotation)Document13 pagesDesign and Linear Static Analysis of Transport Aircraft Vertical Tail For Different Rudder Deflection (Rotation)Alaek Nu'manPas encore d'évaluation

- Important RCC Questions-Short and LongDocument15 pagesImportant RCC Questions-Short and LongmailjoelsamuelPas encore d'évaluation

- Cec 101 TestDocument1 pageCec 101 TestOlowo Ayobami MichaelPas encore d'évaluation

- Strength of MaterialsDocument17 pagesStrength of MaterialskalpanaPas encore d'évaluation

- Chapter 1 - Stress and StrainDocument49 pagesChapter 1 - Stress and StrainLuke Nate SarmientoPas encore d'évaluation

- Poisson'S Ratio Biaxial and Triaxial DeformationDocument8 pagesPoisson'S Ratio Biaxial and Triaxial DeformationRyan Jhay YangPas encore d'évaluation

- Bending and Buckling of General Laminated Curved Beams UsingDocument14 pagesBending and Buckling of General Laminated Curved Beams UsingMohammed ElmahjoubiPas encore d'évaluation

- Limit State Design TheoryDocument3 pagesLimit State Design TheoryEvans KishPas encore d'évaluation

- Som PDFDocument105 pagesSom PDFanon_10845568100% (1)

- Chapter 3 Plane TrussDocument15 pagesChapter 3 Plane TrussKishan PurohitPas encore d'évaluation

- Stresses in Machine ElementsDocument18 pagesStresses in Machine ElementsthirumalaikumaranPas encore d'évaluation

- Eccentricconnectionsinsteelstructure 151210011806Document33 pagesEccentricconnectionsinsteelstructure 151210011806Manjunath TontanalPas encore d'évaluation

- Simple Bending TheoryDocument8 pagesSimple Bending Theorybryan9422100% (2)

- Particle Equilibrium Part 1: Free Body Diagrams and Force AnalysisDocument18 pagesParticle Equilibrium Part 1: Free Body Diagrams and Force AnalysisCasalta KennethPas encore d'évaluation

- Struc Analysis Chapter 2Document19 pagesStruc Analysis Chapter 2Kerol Kerol KerolPas encore d'évaluation

- Aircraft Structures Course OverviewDocument42 pagesAircraft Structures Course OverviewShwetha BhatPas encore d'évaluation

- Strain Gage-WhatDocument16 pagesStrain Gage-WhatAshok JoshiPas encore d'évaluation

- Static Forces On Surfaces Buoyancy: Dr. Khalil Mahmoud ALASTAL &Document79 pagesStatic Forces On Surfaces Buoyancy: Dr. Khalil Mahmoud ALASTAL &Silas Sailas Endjala0% (1)

- Material PropertiesDocument42 pagesMaterial PropertiesDr_M_Soliman100% (2)

- Lecture 9 - Struct Idealization - BoomsDocument40 pagesLecture 9 - Struct Idealization - BoomstmkhoyanPas encore d'évaluation

- Materials Engineering: Pangasinan State University Urdaneta Campus Mechanical Engineering DepartmentDocument7 pagesMaterials Engineering: Pangasinan State University Urdaneta Campus Mechanical Engineering DepartmentiamjemahPas encore d'évaluation

- 84 TOP MOST Strength of Materials - Mechanical Engineering Multiple Choice Questions and Answers Mechanical Engineering Multiple Choice QuestionsDocument24 pages84 TOP MOST Strength of Materials - Mechanical Engineering Multiple Choice Questions and Answers Mechanical Engineering Multiple Choice QuestionsJagadish MekaPas encore d'évaluation

- Logarithmic DecrementDocument7 pagesLogarithmic DecrementammarPas encore d'évaluation

- Unit - Iv Plastic Analysis of StructuresDocument32 pagesUnit - Iv Plastic Analysis of StructuresOraib AljaafrehPas encore d'évaluation

- Triaxial Testing ExplainedDocument4 pagesTriaxial Testing ExplainedKamal K AlwanPas encore d'évaluation

- Continuous Beam: FIG. 11a Simply Supported BeamDocument55 pagesContinuous Beam: FIG. 11a Simply Supported BeamNeven Ahmed HassanPas encore d'évaluation

- Shear CenterDocument24 pagesShear Centerhbuyhbuy100% (1)

- Reynolds Transport TheoremDocument14 pagesReynolds Transport TheoremJayant SisodiaPas encore d'évaluation

- DRC Two MarksDocument26 pagesDRC Two MarksVenkatesh GRmPas encore d'évaluation

- Chapter 7Document69 pagesChapter 7m_alodat6144Pas encore d'évaluation

- Deformable - Chapter 5Document21 pagesDeformable - Chapter 5Charlotte FerriolPas encore d'évaluation

- Jj310-Strength of Material: TorsionDocument42 pagesJj310-Strength of Material: TorsionHafiezul HassanPas encore d'évaluation

- STR ModuleDocument10 pagesSTR ModuleViamae Avellana CabutajePas encore d'évaluation

- Torsion - Notes PDFDocument20 pagesTorsion - Notes PDFRichy Rahul AdithyaPas encore d'évaluation

- To RsionDocument16 pagesTo Rsionpriodeep chowdhuryPas encore d'évaluation

- Torsion TestDocument7 pagesTorsion TestmohanadymtPas encore d'évaluation

- FCE 231: Torsion of Circular Shafts and Thin-Walled TubesDocument6 pagesFCE 231: Torsion of Circular Shafts and Thin-Walled TubesRonald obasiePas encore d'évaluation

- 1244am5.dr. M. Dhanabhakyam & F. Naveen Sulthana PDFDocument8 pages1244am5.dr. M. Dhanabhakyam & F. Naveen Sulthana PDFDirajen PMPas encore d'évaluation

- Work Motivation and Job SatisfactionDocument8 pagesWork Motivation and Job SatisfactionDirajen PMPas encore d'évaluation

- The Mediating Role of Job Burnout in The Relationship Between Role Conflict and Job PerformanceDocument8 pagesThe Mediating Role of Job Burnout in The Relationship Between Role Conflict and Job PerformanceDirajen PMPas encore d'évaluation

- BurnoutDocument9 pagesBurnoutDirajen PMPas encore d'évaluation

- Work Motivation and Job SatisfactionDocument8 pagesWork Motivation and Job SatisfactionDirajen PMPas encore d'évaluation

- Effects of Burnout On Employees' Satisfaction A Research at 3, 4 and 5 Star HotelsDocument12 pagesEffects of Burnout On Employees' Satisfaction A Research at 3, 4 and 5 Star HotelsDirajen PMPas encore d'évaluation

- Ancient Astronauts: ParanormalDocument20 pagesAncient Astronauts: ParanormalDirajen PMPas encore d'évaluation

- Stimulating Forces of Employees Satisfaction A Study of Pakisan Textile Sector PDFDocument9 pagesStimulating Forces of Employees Satisfaction A Study of Pakisan Textile Sector PDFDirajen PMPas encore d'évaluation

- Thesis Tran LamDocument40 pagesThesis Tran Lamrama0001Pas encore d'évaluation

- The Effects of Flattening Hierarchies On Employee Performance in Organizations: A Study of A South African Retail GroupDocument6 pagesThe Effects of Flattening Hierarchies On Employee Performance in Organizations: A Study of A South African Retail GroupDirajen PMPas encore d'évaluation

- Burnout Syndrome in Male and Female Gestalt and Cognitive-Behavioral PsychotherapistsDocument7 pagesBurnout Syndrome in Male and Female Gestalt and Cognitive-Behavioral PsychotherapistsDirajen PMPas encore d'évaluation

- MegalodonDocument11 pagesMegalodonDirajen PMPas encore d'évaluation

- Linking Marketing and Corporate Strategies: Chapter TwoDocument30 pagesLinking Marketing and Corporate Strategies: Chapter TwoDirajen PMPas encore d'évaluation

- 715 Mauritius 8 PDFDocument210 pages715 Mauritius 8 PDFDirajen PMPas encore d'évaluation

- A Night of ToilsDocument1 pageA Night of ToilsDirajen PM100% (1)

- Occupational Standards for Textile Sector Knitting Machine OperatorDocument51 pagesOccupational Standards for Textile Sector Knitting Machine OperatorDirajen PMPas encore d'évaluation

- PPPDocument5 pagesPPPDirajen PMPas encore d'évaluation

- Very PoorDocument1 pageVery PoorDirajen PMPas encore d'évaluation

- WikiforceDocument5 pagesWikiforceDirajen PMPas encore d'évaluation

- WikiforceDocument5 pagesWikiforceDirajen PMPas encore d'évaluation

- StakeholdersDocument1 pageStakeholdersDirajen PMPas encore d'évaluation

- WikiforceDocument5 pagesWikiforceDirajen PMPas encore d'évaluation

- Professional Development For Strategic Managers (134Document21 pagesProfessional Development For Strategic Managers (134Shamim Ahmed Mozumder Shakil100% (3)

- Set Up ReductionDocument5 pagesSet Up ReductionDirajen PMPas encore d'évaluation

- PBEIIDocument6 pagesPBEIIDirajen PMPas encore d'évaluation

- Programming For VDocument1 pageProgramming For VDirajen PMPas encore d'évaluation

- Set Up ReductionDocument5 pagesSet Up ReductionDirajen PMPas encore d'évaluation

- Ball Bearing Size Chart: Inner, Outer Diameters & WidthsDocument4 pagesBall Bearing Size Chart: Inner, Outer Diameters & WidthsDirajen PMPas encore d'évaluation

- ABC SampleDocument29 pagesABC SampleDirajen PMPas encore d'évaluation

- BTEC Prof L7 StratManLd Iss2Document212 pagesBTEC Prof L7 StratManLd Iss2Girish NuckchadyPas encore d'évaluation

- 39CQ Iom 06302014Document20 pages39CQ Iom 06302014Non Etabas GadnatamPas encore d'évaluation

- Short and Open Circuit Test On TransformerDocument1 pageShort and Open Circuit Test On TransformerRyan DagsilPas encore d'évaluation

- Mechatronics Handbook - 02 - Mechatronic Design Approach PDFDocument16 pagesMechatronics Handbook - 02 - Mechatronic Design Approach PDFJosé Fernando TerronesPas encore d'évaluation

- JP For RadiographyDocument7 pagesJP For Radiographytaparia_piyushPas encore d'évaluation

- Introduction To The OpenDSSDocument4 pagesIntroduction To The OpenDSSanoopeluvathingal100Pas encore d'évaluation

- Checklist Water Audit v1Document19 pagesChecklist Water Audit v1hammad.phistreamPas encore d'évaluation

- B23 B24 User Manual PDFDocument168 pagesB23 B24 User Manual PDFAurel BodenmannPas encore d'évaluation

- The Design of A Slotted Vertical Screen Breakwater PDFDocument13 pagesThe Design of A Slotted Vertical Screen Breakwater PDFscrane@Pas encore d'évaluation

- Using Breakover Devices in Triac and SCR Gate Control CircuitsDocument37 pagesUsing Breakover Devices in Triac and SCR Gate Control CircuitsAnnalyn Duculan SoriaPas encore d'évaluation

- Rectificador A Diodos Siemens-Sitras-Rec-Pi-EnDocument6 pagesRectificador A Diodos Siemens-Sitras-Rec-Pi-EnVictor Manuel BonettoPas encore d'évaluation

- Graviner MK6 Oil Mist DetectorDocument4 pagesGraviner MK6 Oil Mist DetectorDhanielPas encore d'évaluation

- 03 MAN D2Z2IM ACT350xx ENDocument24 pages03 MAN D2Z2IM ACT350xx ENAlfonso Lopez toroPas encore d'évaluation

- محطات الطاقةDocument22 pagesمحطات الطاقةJoe LewisPas encore d'évaluation

- Current Transformer - Electrical Notes & ArticlesDocument47 pagesCurrent Transformer - Electrical Notes & Articlesnomy158100% (1)

- XR77CX: Installing and Operating InstructionsDocument5 pagesXR77CX: Installing and Operating InstructionsVũ Hằng PhươngPas encore d'évaluation

- Liebhaber NESC 2017 ChangesDocument80 pagesLiebhaber NESC 2017 ChangesEdgar ZapanaPas encore d'évaluation

- SHD30 and SHD30-45 Models: (Standard)Document2 pagesSHD30 and SHD30-45 Models: (Standard)Roger TorrejonPas encore d'évaluation

- 3/27/2016 Portable AC On Rent Pune - Portable AC Rentals Pune - AC Rentals Pune On SulekhaDocument3 pages3/27/2016 Portable AC On Rent Pune - Portable AC Rentals Pune - AC Rentals Pune On SulekhadcoolsamPas encore d'évaluation

- Voith Thyricon Excitation SystemDocument8 pagesVoith Thyricon Excitation SystemKeshab ShresthaPas encore d'évaluation

- V. Ganapathy On Calculation of Flue Gas DensityDocument2 pagesV. Ganapathy On Calculation of Flue Gas DensityRi KoPas encore d'évaluation

- ST Series Servo Motor: Beijing KND CNC Technique Co.,Ltd. 01.2012Document21 pagesST Series Servo Motor: Beijing KND CNC Technique Co.,Ltd. 01.2012Dinos ArhPas encore d'évaluation

- EXPANSION VALVES SERIES DOCUMENT (THERMOSTATIC & CONSTANT PRESSUREDocument44 pagesEXPANSION VALVES SERIES DOCUMENT (THERMOSTATIC & CONSTANT PRESSURESite EngineeringtiaPas encore d'évaluation

- 001 NemDocument4 pages001 NemNg Han PeiPas encore d'évaluation

- Mayo College: Dining Hall at AjmerDocument79 pagesMayo College: Dining Hall at AjmerFaquruddinPas encore d'évaluation

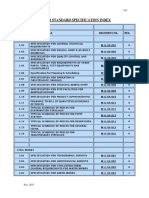

- Water Standard Specification Index As On Dec 2015Document10 pagesWater Standard Specification Index As On Dec 2015afp15060% (1)

- Method of Lighting CalculationsDocument3 pagesMethod of Lighting CalculationsSpencer Josh RegedorPas encore d'évaluation

- Cylinder Cutout Cylinder CutoutDocument12 pagesCylinder Cutout Cylinder CutoutIsrael Miranda ZamarcaPas encore d'évaluation

- GROUP 1 - PetE 3306 - Final Requirement in Engineering EconomicsDocument12 pagesGROUP 1 - PetE 3306 - Final Requirement in Engineering Economicskevin alidoPas encore d'évaluation

- TERAO Presentation August 2022Document48 pagesTERAO Presentation August 2022LuatNguyenPas encore d'évaluation

- High Efficiency Battery Charger Using DC-DC ConverterDocument4 pagesHigh Efficiency Battery Charger Using DC-DC ConvertersanilPas encore d'évaluation