Académique Documents

Professionnel Documents

Culture Documents

Uso Tektronix Education

Transféré par

chiikachiivasvero90Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Uso Tektronix Education

Transféré par

chiikachiivasvero90Droits d'auteur :

Formats disponibles

IEEE TRANSACTIONS ON EDUCATION, VOL. 49, NO.

3, AUGUST 2006

383

Three-Phase Machines and DrivesEquipment for a

Laboratory-Based Course

S. A. Shirsavar, Member, IEEE, Benjamin A. Potter, Member, IEEE, and Isabel M. L. Ridge

AbstractThe hazards associated with high-voltage three-phase

inverters and high-powered large electrical machines have resulted in most of the engineering courses covering three-phase

machines and drives theoretically. This paper describes a set

of purpose-built, low-voltage, and low-cost teaching equipment

that allows the hands-on instruction of three-phase inverters and

rotating machines. The motivation for moving towards a system

running at low voltages is that the students can safely experiment

freely with the motors and inverter. The students can also access

all of the current and voltage waveforms, which until now could

only be studied in textbooks or observed as part of laboratory

demonstrations. Both the motor and the inverter designs are for

teaching purposes and require minimal effort and cost.

Index TermsBrushless dc motor, course, induction motor, inverter, teaching.

I. INTRODUCTION

TILIZING a mixed variety of pedagogical approaches

to enhance student learning is widely accepted among

educators [1], [2]. By considering adult learning styles, researchers can show that using a variety of stimuli promotes

deep learning [3] and ensures that each adult learner is presented with the material so that it appeals to individual learning

patterns [4].

Laboratory and practical classes play a major role in the education of scientists and engineers [5]. In the field of engineering

education, latest research suggests that the pedagogical learning

objectives of practical sessions generally go much further than

simply supplying an additional stimuli, therefore promoting additional skills and deep learning [6].

The extra skills learned in practical sessions are an integral

part of engineering as a discipline and, from the engineering

educators point of view, the goals for a practical session are

much wider than just the promotion of deep learning. Fry et al.

[6] suggest that these additional aims may include the following:

gaining practical skills and experience of practical pieces

of equipment;

making links between theory and practice;

gathering, manipulating, and interpreting data;

forming and testing hypotheses;

developing problem-solving techniques;

motivating and exciting students.

Manuscript received February 20, 2004; revised April 25, 2006.

S. A. Shirsavar and B. A. Potter are with the Department of Electronic Engineering, School of Systems Engineering, University of Reading, RG6 6AY U.K.

I. M. L. Ridge is with the School of Construction Management and Engineering, University of Reading, RG6 6AY U.K.

Digital Object Identifier 10.1109/TE.2006.879266

The results of two recent surveys of the electronic engineering

students at the University of Reading, Reading, U.K. [7], [8] corroborate many of the above suggestions. Both of these surveys

verified that the engineering students overwhelmingly prefer

an experimental approach to teaching. The vast majority (over

80%) of the students in these surveys felt that experiments enhanced their grasp of the core subject and their understanding of

the theoretical material and made the course more interesting.

However, the study of three-phase rotating machines and their

associated power electronics as part of an undergraduate electronic engineering course seems to lack any significant practical work. This scarcity is indeed understandable because, traditionally, hands-on experiments are not easy to introduce into

such courses. The two main reasons for this difficulty are the

high voltages present in three-phase inverters and the mechanical hazards associated with motors. This problem is particularly acute in departments geared toward electronic engineering,

where the laboratories in general are not equipped for high voltages and rotating machines. Thus, unless explicitly geared toward electrical engineering, many electronic engineering students are only able to follow a mainly theoretical approach.

To solve this problem, the introduction of alternative teaching

methods enhance student learning. Some of these methods use

computers and simulation packages [9], [10], while most of the

work that advocates the use of purpose-built hardware teaches

only dc motors [11], [12]. Indeed, a complete absence of experiment-based teaching material seems to exist for three-phase

inverters driving a three-phase induction motor. This lack of material can be directly attributed to the commercial unavailability

of low-voltage, three-phase induction machines and their associated inverters.

A solution to the above problem is presented in the excellent work of Undeland and Mohan [13]. In their paper, the authors overcome the unavailability of low-voltage, three-phase

induction machines by designing and constructing their own

three-phase induction motor running off a 42-V dc bus. Although a 42-V dc bus voltage is much lower than in typical

systems, the resulting inverter voltages will still be too high

to allow for hands-on student experimentation, as currently the

maximum voltage permitted for use in undergraduate experimentation in many of the United Kingdoms universities stands

at 30-V dc.

The above discussion shows the existence of a real practical

problem, which has so far prohibited the vast majority of undergraduate students from experimenting with three-phase machines and inverters.

In order to address this problem, this paper describes the

construction of low-voltage (12-V), three-phase induction,

0018-9359/$20.00 2006 IEEE

384

IEEE TRANSACTIONS ON EDUCATION, VOL. 49, NO. 3, AUGUST 2006

Fig. 1. Power stage of the proposed inverter.

brushless dc motors, and an associated three-phase inverter.

The equipment has been designed to be both relatively inexpensive (circa U.S. $25) and easy to construct. Furthermore,

since the inverter runs at only 12 V, the students are able to

experiment freely with the motor and inverter and access the

various waveforms at different points in the circuitry. This

ability to experiment enhances their understanding of the basic

principles of three-phase induction machines and drives.

One must note at this point that the purpose of this paper is

not to prove that experimental work enhances student learning in

engineering courses, as this concept has already been proven by

educationalists [1][6]. The objective of this paper is to inform

colleagues of a novel, easy, and low-cost method of introducing

experimental work into a topic that has suffered from lack of

laboratory work in many educational establishments.

All information required to reproduce these components is

presented, and colleagues who are interested in introducing a

hands-on, practical element to their power electronic courses are

encouraged to make full use of the material presented here. Any

comments or suggestions would be gratefully received. The desire is that the information presented here will assist engineering

educators in improving the instruction of this discipline.

In the following sections, the construction of the inverter and

motor and some experimental results and feedback received

from the students will be described.

II. CONSTRUCTION OF A LOW-VOLTAGE

THREE-PHASE INVERTER

Commercial inverters are not appropriate for undergraduate

teaching. Unavoidable safety issues associated with the high

voltages that these units generate are present, making it difficult, if not impossible, to access the waveforms generated by

such inverters.

In addition, commercially available inverters are far more

complicated than the simple form of a three-phase H-bridge

depicted in most textbooks. Commercial inverters possess circuitry associated with surge protection, electromagnetic inter-

ference suppression, high-side drivers, current limiting, overvoltage protection, and optical isolation. In addition, most new

commercial inverters use all-in-one power modules containing

all the power switches in one package, rendering access to individual switch signals almost impossible.

A simple H-bridge inverter was designed to show the students

clearly how the circuitry relates to classroom material or descriptions found in electronics textbooks. To allow the students

some hands-on experience, a further requirement was for the

operating voltage to be lower than the minimum permitted safe

voltage. In the case of the United Kingdom, this requirement is

50-V ac, equating to a dc bus voltage lower than 30 V.

Since the inverter has been designed as a teaching tool, several features within the design facilitate ease of functional description, ease of construction, and low cost. One notes these

features will, in general, be at the expense of performance.

Fig. 1 depicts the schematic circuit diagram for the power

stage of the inverter, while Fig. 2 depicts the schematic circuit

diagram for the microprocessor control stage of the inverter.

The use of monolithic, integrated circuits (ICs) incorporating

all six switches has been avoided so that the students can have

easy access to all signals within the H-bridge inverter when the

basic operation of the three-phase, H-bridge inverter is taught. In

addition, no isolation is provided in order to simplify the circuit

further.

P-type, metaloxidesemiconductor field-effect transistors

(MOSFETs) have been used on the high-side of the H-Bridge,

i.e., M1, M3, and M5. P-type MOSFETs have the advantage

that they can be switched without the need of expensive and

often delicate high-side drivers, thus reducing circuit complexity and cost. A further simplification has been obtained by

using a MOSFETs parasitic diode for freewheeling purposes

[14]. Furthermore, all six power switches are slightly overrated

to eliminate the need for heatsinking.

The microcontroller stage of the circuit simply consists of

one bottom of the range 8-b microprocessor with its associated

20-MHz clock and voltage regulator. The microcontroller gen-

SHIRSAVAR et al.: THREE-PHASE MACHINES AND DRIVESEQUIPMENT FOR A LABORATORY BASED COURSE

385

Fig. 2. Microcontroller stage of the proposed inverter.

Fig. 4. Low-voltage, three-phase, PCB-mounted induction motor.

Fig. 3. Fully constructed inverter.

erates all six pulsewidth-modulated (PWM) outputs, incorporating within them the necessary dead time. The switching frequency is set to 3 kHz, while the base speed is fixed at 100 Hz.

This specification allows the six PWM signals to be generated

by a lookup table and permits the use of an inexpensive, low-performance processor. The microprocessor code, written in the C

programming language, is straightforward and has not been included in this paper. However, if required, the code can be obtained by contacting the corresponding author.

The entire circuit is routed on a single-sided board to allow

easy, in-house construction. The complete printed circuit board

(PCB) layout, its silkscreen, and the component lists are included in the Appendix.

Fig. 3 depicts the fully constructed inverter. The most expensive component in the circuit is the microprocessor at U.S.

$3.80, and hence educational establishments will be able to

make their own inverters with minimal cost and effort.

III. CONSTRUCTION OF LOW-VOLTAGE THREE-PHASE MOTORS

The three-phase induction motor and the three-phase brushless dc motor that will be described in this section share the same

simple stator assembly. Therefore, it is only necessary to exchange the rotors in order to switch between the different motor

types.

A. Miniature Three-Phase Induction Motor

Winding the electromagnets is a major problem when constructing any kind of motor by hand. In the case of induction

and brushless dc machines, construction is easier because no

rotor windings are present; only the stator needs to be wound.

However, even the smallest motors require thousands of turns of

very fine wire for each phase to produce enough magnetomotive

force at a reasonable current.

The easiest means of producing suitable windings was to remove the solenoids from simple, proprietary relays. Although

not the cheapest solution, relay solenoids provided compact,

uniformly wound coils with sufficient electromagnetic force at

reasonable current. The relays, from which the solenoids used

in the motor shown in Fig. 4 were taken, cost around U.S. $3

each. Of course, the winding distribution of the above motor is

different from a commercial machine and will not be able to produce any usable torque. However, for understanding the basic

principles, this arrangement will suffice, especially for courses

geared towards electronic engineering where the main emphasis

will be on the power electronic inverter.

386

IEEE TRANSACTIONS ON EDUCATION, VOL. 49, NO. 3, AUGUST 2006

Fig. 5. Interchangeable rotors used in the motors.

Fig. 6. Stator PWM voltage and sinusoidal current.

The rotor was made from a piece of copper pipe with end caps

fitted top and bottom and is shown in Fig. 5 (bottom left). The

rotor shaft was taken from a miniature dc motor.

Having chosen the coils and rotor, the stator assembly was

simply mounted on a PCB that provided the electrical connections for the coils. The stator circuit was designed so that the

stator configuration could be changed between star and delta

with the use of a switch. If desired for further simplicity, the

switch could be removed and the coils permanently connected

in one configuration. The delta configuration is preferable to

give the greatest start-up torque and, hence, the lowest operating

voltage.

B. Miniature Three-Phase Brushless dc Motor

The stator of the brushless dc motor is identical to the induction motor assembly described above. However, the rotor

for this type of motor is made of permanent magnets. Manufacture of magnets, specifically for the rotor, would be prohibitively expensive and unnecessary. A permanent-magnet rotor

can be made by removing the stator magnets of the miniature

U.S. $1 dc motor and attaching them to the rotor as is shown

in Fig. 5. By removing the windings from the rotor shown in

Fig. 5 (center) and attaching the two semicircular magnets that

were used to make the stator of the dc motor, the finished rotor

shown in Fig. 5 (right) can be constructed. The rotor of the induction and brushless dc motors are fully interchangeable in the

stator assembly.

IV. RESULTS

Both motors, with both stator assemblies, were found to operate smoothly with dc bus voltages as low as 12 V when connected to the inverter described earlier in this paper. The overall

system is well within safe voltage limits and presents no significant electrical risk to the user. In addition, since the kinetic energy in the rotor is very low because of its small size, no significant mechanical risks are present. Students can now have full,

safe access to all the voltages and currents, which would normally be impossible with commercial motors and inverters.

As an example, the statement Fig. 6 depicts the stator voltage

and the stator currents for a delta-connected induction motor. As

can be seen from Fig. 6, although the stator voltage is clearly a

Fig. 7. Dead time between the gate drive signals.

PWM square wave, the stator current is a sine wave with slight

harmonics.

By expanding the time base of the voltage waveform, the students can for the first time observe the dead time generated by

the inverter under safe low-voltage conditions. A typical waveform is depicted in Fig. 7.

In addition, since most modern oscilloscopes provide a

Fourier Transform function, students can now also study the

switching harmonics experimentally. The frequency spectrum,

displayed using a digital oscilloscope, is depicted in Fig. 8;

harmonic analysis is a prime example of one of the many

important topics that so far could only be studied theoretically.

By way of summary, the inverter and motors presented in this

paper allow students to carry out hands-on, practical investigations into, but not limited to, the following topics:

the generation and use of PWM waveforms;

inverters, gate drive signals, and the use of dead time;

harmonic content of the inverter voltage outputs;

running three-phase machines and start-up characteristics;

differences and similarities between dc brushless motors

and ac induction motors;

currents and voltages in the motors stator windings;

differences between star and delta stator configurations;

harmonic content of the stator currents and the low-pass

filtering effect of the coils.

SHIRSAVAR et al.: THREE-PHASE MACHINES AND DRIVESEQUIPMENT FOR A LABORATORY BASED COURSE

387

Fig. 8. Switching harmonics on the current waveform.

Fig. 10. Silkscreen for the inverter.

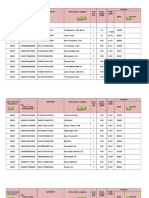

TABLE I

BILL OF MATERIALS FOR THE INVERTER

Fig. 9. PCB layout for the inverter.

V. STUDENT FEEDBACK

As stated in the Introduction of this paper, the objective of this

paper is not to prove that experimental work enhances student

understanding. This concept has already been proven and has

been referenced in this paper. Nevertheless, the students in the

School of Systems Engineering at the University of Reading

who used this equipment as part of their course were surveyed.

The vast majority of students in this survey (over 80%) expressed that experimentation with the inverter and motor, including the ability to carry out hands-on tests, made the subject of electrical machines and power electronics much easier

to understand and far more interesting. In addition, the students

wanted to see a similar approach adopted in their other subjects.

VI. CONCLUSION

The hazards, both electrical and mechanical, associated with

typical three-phase inverters and machines have meant that

the vast majority of related course material is theoretical. This

paper describes a miniature, low-voltage three-phase inverter

and motor that avoids these hazards and allows the student

direct and full access to all signals and motor elements.

The stator design allows for the study of both a three-phase induction machine and a three-phase brushless dc motor by simply

changing the rotor. The designs of all parts of the system have

been carefully considered to produce a system which is simple

to manufacture and has a low overall cost (circa U.S. $25).

Typical oscilloscope readings covering voltages, currents, and

Fourier transforms of both voltages and currents have been included and show the wealth and range of practical investigations

that could be made by the student.

The feedback received from the students who have used the

presented teaching material was very positive. The feedback

showed that enabling students to have hands-on ready access to

such equipment not only rekindles interest in the subject, but

also significantly improves their understanding and promotes

deep learning.

APPENDIX

The complete printed circuit board layout for the inverter is

shown in Fig. 9, and the corresponding silkscreen is shown in

Fig. 10. The bill of materials for the inverter is shown in Table I.

388

IEEE TRANSACTIONS ON EDUCATION, VOL. 49, NO. 3, AUGUST 2006

REFERENCES

[1] N. Entwistle and S. Waterson, Approaches to studying and levels of

processing in university students, Br. J. Educ. Psychol., vol. 58, pp.

258265, 1988.

[2] J. Biggs, Student Approaches to Learning and Studying. Melbourne,

Australia: Australian Council for Educational Research, 1987.

[3] N. Ford, Recent approaches to the study and teaching of effective

learning in higher education, Rev. Educ. Res., vol. 51, pp. 345377,

1981.

[4] P. Honey and A. Mumford, Using Your Learning Styles, 3rd ed.

Maidenhead, U.K.: Peter Honey, 1995.

[5] D. Boud, J. Dunn, and E. Hegarty-Hazel, Teaching in Laboratories.

Guildford, U.K.: Society for Research into Higher Education, 1986.

[6] H. Fry, S. Ketteridge, and S. Marshall, A Handbook for Teaching &

Learning in Higher Education: Enhancing Academic Practice, 2nd

ed. London, U.K.: Kogan Page, 2003.

[7] B. A. Potter, S. A. Shirsavar, and I. Ridge, Purpose built teaching

equipment for a laboratory based course in three phase machines

and drives, presented at the IEEE Int. Conf. Mechatronics, Istanbul,

Turkey, 2004.

[8] S. A. Shirsavar, Teaching practical design of switch-mode power supplies, IEEE Trans. Educ., vol. 47, no. 4, pp. 467473, Nov. 2004.

[9] T.-F. Chan, Analysis of electrical machines using Symphony, IEEE

Trans. Educ., vol. 35, no. 1, pp. 7682, Feb. 1992.

[10] M. H. Nehrir, F. Fatehi, and V. Gerez, Computer modeling for enhancing instruction of electric machinery, IEEE Trans. Educ., vol. 38,

no. 2, pp. 166170, May 1995.

[11] M. H. Nehrir, A. J. Odermann, and B. D. Bowen, A microcomputer-microprocessor-based dc motor speed controller for undergraduate electric machinery laboratory, IEEE Trans. Educ., vol. 33, no. 4,

pp. 341345, Nov. 1990.

[12] M. Mazo, J. Urena, F. J. Rodriguez, J. J. Garcia, J. L. Lazaro, E. Santiso, F. Espinosa, R. Garcia, P. Revenga, J. C. Garcia, E. Bueno, and R.

Mateos, Teaching equipment for training in the control of dc, brushless, and stepper servomotors, IEEE Trans. Educ., vol. 41, no. 2, pp.

146158, May 1998.

[13] T. Undeland and N. Mohan, Meeting the challenge: Revitalizing

courses in power electronics and electric drives, presented at the

Nordic Workshop Power Industrial Electronics (Norpie 2002), Stockholm, Sweden, 2002.

[14] E. Rogers, AN-940: How P-Channel HEXFET power MOSFETs can

simplify your circuit, in IR Application Notes. El Segundo, CA: International Rectifier Inc.

S. A. Shirsavar (M94) received the B.Eng. (Hons.) degree in electronic engineering and the Ph.D. degree from the University of Reading, Reading, U.K., in

1992 and 1998, respectively.

After a period of working in the industry designing embedded controller

hardware, switch-mode power supplies, and high-performance three-phase inverters, he returned to the University of Reading as a Lecturer, where he has

been teaching courses at all levels. His main research interests are in power electronics and renewable energy resources, in particular high-efficiency grid-connected inverters for use with solar panels.

Benjamin A. Potter (M04) received the M.Eng. (Hons.) degree in engineering

science from the University of Oxford, Oxford, U.K., in 2001. He is currently

working towards the Ph.D. degree at the University of Reading, U.K., and is

actively involved in lecturing and laboratory-based teaching.

His main research interests include electric machines and drives and power

electronics, in particular the modeling of the high-frequency behavior of induction machines.

Mr. Potter is a member of the Institution of Electrical Engineers (IEE) in the

United Kingdom.

Isabel M. L. Ridge was awarded the B.Sc. degree in mechanical engineering

(with mathematics) and the Ph.D. degree from the University of Reading,

Reading, U.K., in 1988 and 1992, respectively. Her Ph.D. research focused on

the Bending-tension fatigue of wire rope.

Currently, she is a Principal Research Fellow in the School of Construction

Management and Engineering at the University of Reading, where she manages

the Rope Research Programme. Her main field of interest is in the behavior and

condition assessment of offshore mooring lines for oil platforms, which she has

studied for over 15 years. She is a member of the Organisation Internationale

Pour lEtude de lEndurance des Cbles (OIPEEC) Management Committee

and President of the OIPEEC Scientific Committee and is currently editor of

their bulletin.

Dr. Ridge is a member of the following professional societies: a Member

of the Institute of Mechanical Engineers (CEng, MIMechE); Registered with

FEANI (Eur. Ing.); a Member of the British Institute of Non-Destructive Testing

(MInstNDT); and a Fellow of the Royal Society for the Encouragement of Arts,

Manufacturers and Commerce (FRSA). In addition, she has received the following awards and prizes in recognition of her work: the Institution of Mechanical Engineers project prize (1988), the OIPEEC Award (1993), and the Worshipful Company of Turners design prize Silver Medal (1994).

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Electronics Mini Dictionary by GadgetronicxDocument49 pagesElectronics Mini Dictionary by GadgetronicxObby JhonPas encore d'évaluation

- Electronic DevicesDocument36 pagesElectronic DevicessurajPas encore d'évaluation

- Features Applications: Sbvs022B - September 2000 - Revised June 2009Document17 pagesFeatures Applications: Sbvs022B - September 2000 - Revised June 2009demononesPas encore d'évaluation

- 1.5ke540a 1383094Document4 pages1.5ke540a 1383094dnn38hdPas encore d'évaluation

- MT174 Polyphase MeterDocument2 pagesMT174 Polyphase MeterYigit SarıkayaPas encore d'évaluation

- 50 TOP TRANSISTORS Questions and Answers PDFDocument8 pages50 TOP TRANSISTORS Questions and Answers PDFamadullah janPas encore d'évaluation

- 1N5819 SMDDocument2 pages1N5819 SMDHla Swe OoPas encore d'évaluation

- Mechanical Engineering ItineraryDocument10 pagesMechanical Engineering ItineraryMarcos AquinoPas encore d'évaluation

- Zheludev 2007 LTLDocument4 pagesZheludev 2007 LTLNaeem KhanPas encore d'évaluation

- EH Liquipoint FTW31 FTW32 DatasheetDocument24 pagesEH Liquipoint FTW31 FTW32 DatasheetRoomel UrbinaPas encore d'évaluation

- Unit 4Document76 pagesUnit 4raghuram67Pas encore d'évaluation

- MVAJ 05 Trip RelayDocument9 pagesMVAJ 05 Trip RelayKT MENON100% (1)

- Flyback ConverterDocument21 pagesFlyback Converterleechulmiu0% (1)

- Anna University - Bio Medical Engineering Syllabus Reg - 2017Document11 pagesAnna University - Bio Medical Engineering Syllabus Reg - 2017Haem Nahth50% (2)

- Power Semiconductor DevicesDocument73 pagesPower Semiconductor DevicesRajesh BhaskarlaPas encore d'évaluation

- AKL User ManualDocument678 pagesAKL User Manualmaia.df11Pas encore d'évaluation

- LVDTDocument6 pagesLVDTSobia JamilPas encore d'évaluation

- Infrared Plastic Solar CellDocument4 pagesInfrared Plastic Solar CellAjesh.V.RPas encore d'évaluation

- Logic Lab 1 - Digital Abstraction (5 Gates)Document16 pagesLogic Lab 1 - Digital Abstraction (5 Gates)ram010Pas encore d'évaluation

- Slua 963 BDocument37 pagesSlua 963 BSean ShugarPas encore d'évaluation

- Door-Open Alarm PDFDocument2 pagesDoor-Open Alarm PDFjoseph_kachappilly80% (5)

- Acs Error CodesDocument3 pagesAcs Error CodesMalik udinPas encore d'évaluation

- Fundamentals of Electrical EngineeringDocument31 pagesFundamentals of Electrical EngineeringErick BuksonPas encore d'évaluation

- AGN071 - Load Sharing With Quadrature LoopDocument5 pagesAGN071 - Load Sharing With Quadrature LoopQuang PhamPas encore d'évaluation

- Lampiran A1 SD A5Document466 pagesLampiran A1 SD A5Irfansyah MaladiPas encore d'évaluation

- To Study The Characteristics of A Common Emitter NPN (Or PNP) Transistor & To Find Out The Values of Current & Voltage GainsDocument11 pagesTo Study The Characteristics of A Common Emitter NPN (Or PNP) Transistor & To Find Out The Values of Current & Voltage GainsAman AhamadPas encore d'évaluation

- Aop 1 1 107 PDFDocument55 pagesAop 1 1 107 PDFkhaled loteesPas encore d'évaluation

- Chandar An 2010Document4 pagesChandar An 2010Alvaro Balvin VelasquezPas encore d'évaluation

- Mastering Electronics DesignDocument14 pagesMastering Electronics DesignArunabh BhattacharyaPas encore d'évaluation

- Nnsn968b Con InverterDocument33 pagesNnsn968b Con InverterNeida MorenoPas encore d'évaluation