Académique Documents

Professionnel Documents

Culture Documents

Tool Box Talk 1

Transféré par

liyaquathaliCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Tool Box Talk 1

Transféré par

liyaquathaliDroits d'auteur :

Formats disponibles

Tool Box

BY

LIYAQUATH ALI CHAPPANGA THOTTATHIL

PREVENTING WELDING FLASHBACK

Every year, hundreds of employees are injured or die as a result of improper use. Knowledge and precautions can prevent

fires and violent explosions.

There are several things you can do to help prevent flashbacks, fires and explosions:

Monitoring the level of hydrogen and shouldnt be low or empty.

Monitoring the partial pressure of oxygen not to be high compared to fuel gas pressure

If using acetylene, keep the pressure below 15 pounds.

Purge your hoses before lighting the torch.

Never light your torch with a mixture of fuel and oxygen. After purging the lines, light the torch with only the fuel gas

valve open.

Check valves should be installed on both torch inlets and operating properly.

Flashback arrestors must be installed on the outlets of both regulators, and/or torch inlets.

Take time to inspect the equipment before.

PROPER REPAIR OF ELECTRICAL CORDS

The first obvious step is often overlooked:

Unplug the cord and take control of both ends.

Cut back the connection only enough of the outer and inner insulation to make the repair.

Color-coded wires on one side need to be connected to the like-colored wires on the other.

Stagger the lengths of the inner wire so that conductors will not come in contact with each other in case of insulation failure.

Make good mechanical connections.

Twist the conductors together and solder, using electrical solder.

Insulate splices using shrink tubing.

Provide outer jacket in order to protects the inner wires from additional damage.

For Plugs Remove outer jacket only as much as is needed to make the repair.

Pay attention to the color coding.

Testing using a simple, inexpensive test light.

EQUIPMENT HAZARDS --REPORT UNSAFE EQUIPMENT

Get in the habit of reporting things that can lead to accidents.

Watch out for the loose or missing machine guard.

Monitor moving part with too much play.

Look for missing nut or bolt,the slipping belt,the loose or cracked shaft housing.

On the electrical side of the picture:

watch for the continually sparking motor,broken switch on a tool.

Locate the damaged extension cord,loose conductors,the burned switch, broken plugs and

receptacles.

Be with a pro-active preventive approach, as safety is everyone's business.

REPORTING AND INVESTIGATING AN ACCIDENT

A good accident investigation tries to answer these questions:

What happened?

When did it happen?

Where did it happen?

Who was involved?

Why did it happen?

How can it be prevented from happening again?

When these questions are answered for all accidents and near misses, patterns often emerge and preventable causes are

often discovered. But the patterns may not be true unless information acquired during the investigation is complete and

accurate. The observations of co-workers, as well as from employees that were directly involved, can be critical. It helps if

everyone will:

Make mental or written notes about the accident before the investigation starts.

Avoid talking to others before talking to the investigator, since this may confuse the facts.

Answer all questions about the incident as accurately as possible.

Take the investigation seriously--give it your best.

REPORTING AND INVESTIGATING AN ACCIDENT (Continued)

When an accident happens, is make sure the worker's injuries are treated.

Near misses should be reported as preventive measure.

Events must be immediately followed by a thorough investigation.

Employees should be constantly alert to potential causes of accidents.

PREVENTING ACCIDENTS IS EVERYONE'S RESPONSIBILITY!

GENERAL SAFETY - SAFE ATTITUDES

Positive attitudes towards safety is important in eliminating unsafe acts and accidents.

Negative attitudes toward safety lead to negative results.

Reminding people about family waiting at home.

Make awareness on adventage of remembering the emergency number.

Enforcing safety rules is part of your supervisor's job

Remind people about safety rules, they are made to protect you.

You are the primary beneficiary.

SAFE USE OF LIQUID PETROLEUM GAS

The primary dangers created by LPG are fire/explosion, carbon monoxide poisoning, asphyxiation, and extreme

cold.

Make sure that the cylinder and relief valves are not damaged in any way.

Damaged cylinders should never be used.

Store cylinders out of the direct sun and away from other heat sources.

A properly filled cylinder will not be full of liquid-some space should remain to accommodate gas.

Inspect your equipment for damages by impact, corrosion over a period of time.

Store LPG cylinders only in a vented areas and away from sources of ignition.

Extinguish all flames and cigarettes in the area on noticing LPG leaking.

Phone from a safe distance away.

Wear gloves to protect yourself when refilling or connecting an LPG cylinder.

Never use LPG appliances indoors without approved ventilation.

SEVEN COMMON ACCIDENT CAUSES

Consider this statistic: 80 out of every 100 accidents are the fault of the person involved in the incident. Unsafe Acts

cause four times as many accidents & injuries as unsafe conditions.

Taking Shortcuts to make the job faster and more efficient but dangerous.

Being Over Confident can lead to improper procedures, tools, or methods in your work leading to an injury.

Starting a Task with Incomplete Instructions.

Poor Housekeeping.

Ignoring Safety Procedures.

Mental Distractions from Work like family matters and interruptions of colleagues.

Failure to Pre-Plan the Work:

"It is better to be careful 100 times than to get killed once." (Mark Twain)

GENERAL SAFETY - SHIFT WORK

In Japan, a study of locomotive operators found that 82% of near accidents occurred between midnight

and 8 a.m.

Prepare and manage yourself for the shift timings.

Establish a bedtime routine.

Guarantee yourself a good seven hours of uninterrupted sleep.

Do not rely on pills..

Avoid caffeine and alcohol within five hours of bedtime.

Eat nutritious foods.

SUNGLASSES VS. SAFETY GLASSES

Use pair of approved safety glasses.

Safety glasses must be shields to reduce the risk of foreign objects from the sides, top or bottom.

Look for "Z87.1,ANSI designation identifying the glasses as approved safety eyewear.

Consider glasses providing IR and UV protection.

Look for glasses that are lightweight and adjustable.

Go for a comfortable one that will fit

THE TEN COMMANDMENTS OF GOOD SAFETY HABITS

Developing everyday safety habits can keep you injury free through the year. Here are ten safety habits to live by:

Set Your Own Standards and practices for safety.

Operate Equipment Only if Qualified..

Respect Machinery..

Use Your Own Initiative for Safety Protection.

Ask Questions. If you are uncertain, ask. Do not accept answers that contain, "I think, I assume, I guess." Be sure.

Use Care and Caution When Lifting.

Practice Good Housekeeping.

Wear Proper and Sensible Work Clothes..

Practice Good Personal Cleanliness.

Be a Positive Part of the Safety Team.

Vous aimerez peut-être aussi

- Fire Extinguisher Training: Instructor: SGT Michael Chism Bco204 Elm ShopDocument37 pagesFire Extinguisher Training: Instructor: SGT Michael Chism Bco204 Elm ShopTimmy CheongPas encore d'évaluation

- Premobilisation Wheel Loader InspectionDocument1 pagePremobilisation Wheel Loader InspectionArjun Satheesan100% (1)

- Safety & Health ProgramDocument2 pagesSafety & Health ProgramD.k. PathakPas encore d'évaluation

- Site Rules Emergency ProceduresDocument2 pagesSite Rules Emergency ProceduresZoranSimjanovskiPas encore d'évaluation

- Schedule For Inspection Nov 19Document1 pageSchedule For Inspection Nov 19Siddharth RanaPas encore d'évaluation

- IGC 2 Slide ReviewDocument83 pagesIGC 2 Slide ReviewaliPas encore d'évaluation

- Index: Cv. Dira Utama SejahteraDocument12 pagesIndex: Cv. Dira Utama SejahteraFreshop SurabayaPas encore d'évaluation

- JSA For Rebar Works Includes Working in ScaffoldingDocument4 pagesJSA For Rebar Works Includes Working in ScaffoldingMohammed Minhaj100% (1)

- Akon 10.12.18Document1 pageAkon 10.12.18Syed Ali HassanPas encore d'évaluation

- Safe Use of Ladders: Personnel DivisionDocument6 pagesSafe Use of Ladders: Personnel DivisionKheireddine AounallahPas encore d'évaluation

- Breathing Apparatus TrainingDocument5 pagesBreathing Apparatus Traininghello3232Pas encore d'évaluation

- Internal Policy Emergency Response ProcedureDocument16 pagesInternal Policy Emergency Response ProcedureemilPas encore d'évaluation

- Electrical Safety: Unsafe ConditionDocument38 pagesElectrical Safety: Unsafe ConditionYvonne TohPas encore d'évaluation

- Confined Spaces Standard Operating Procedure and Permit CombinedDocument8 pagesConfined Spaces Standard Operating Procedure and Permit CombinedRaza Muhammad SoomroPas encore d'évaluation

- Training Manual - HSE Training Tool BoxDocument44 pagesTraining Manual - HSE Training Tool BoxMoimoi Ty0% (1)

- Fes TBT Housekeeping PDFDocument1 pageFes TBT Housekeeping PDFsalem enwaijiPas encore d'évaluation

- DSE Workstation Checklist Mar 2006Document9 pagesDSE Workstation Checklist Mar 2006shaistaPas encore d'évaluation

- Sop Drill Electric HandDocument2 pagesSop Drill Electric HandLOCAL ExplorerPas encore d'évaluation

- TBT Manual HandlingDocument1 pageTBT Manual HandlingNishadh NishPas encore d'évaluation

- General Safety Inspection ChecklistDocument1 pageGeneral Safety Inspection ChecklistAyşe BalamirPas encore d'évaluation

- Lesson Learned-HIPO Near Miss - Energy IsolationDocument1 pageLesson Learned-HIPO Near Miss - Energy IsolationMukeshPas encore d'évaluation

- Bloodborne and Airborne Pathogens: (Universal Precautions)Document2 pagesBloodborne and Airborne Pathogens: (Universal Precautions)roberto_00643557Pas encore d'évaluation

- Optimise Toolbox Near Miss ReportingDocument2 pagesOptimise Toolbox Near Miss ReportingFatih D. PrasetioPas encore d'évaluation

- Officeriskassess 259943Document2 pagesOfficeriskassess 259943api-332787463Pas encore d'évaluation

- Toolboxtalk2 Housekeeping PDFDocument2 pagesToolboxtalk2 Housekeeping PDFSajid HussainPas encore d'évaluation

- Toolbox Talks - Near Miss ReportingDocument1 pageToolbox Talks - Near Miss ReportinganaPas encore d'évaluation

- Workplace Exposure To Vibration in Europe: An Expert ReviewDocument12 pagesWorkplace Exposure To Vibration in Europe: An Expert Reviewrajesh kumarPas encore d'évaluation

- Identifying and Controlling Hazards: We Lco MeDocument45 pagesIdentifying and Controlling Hazards: We Lco MeAijaz Ahmed ShaikhPas encore d'évaluation

- Appendix B - Driving SafetyDocument5 pagesAppendix B - Driving SafetyMaheshbabu GulakaramPas encore d'évaluation

- Excavation SafetyDocument42 pagesExcavation SafetyajayjanardhankaslePas encore d'évaluation

- 02-Calibration Plan 2016Document5 pages02-Calibration Plan 2016mohamed hamedPas encore d'évaluation

- 12 ES10-10ES Training PPT - 20200303 - 140558Document83 pages12 ES10-10ES Training PPT - 20200303 - 140558Lacatusu MirceaPas encore d'évaluation

- Toolbox Talk: Ladder Safety: Using A Stepladder SafelyDocument2 pagesToolbox Talk: Ladder Safety: Using A Stepladder SafelyAnge JuanPas encore d'évaluation

- Confined Spaces CardsDocument1 pageConfined Spaces CardsJafar KhanPas encore d'évaluation

- CHAPTER 4 Example-Workplace Hazard in ConcretingDocument2 pagesCHAPTER 4 Example-Workplace Hazard in ConcretingKerol Kerol KerolPas encore d'évaluation

- 01-Ppe Eng PDFDocument17 pages01-Ppe Eng PDFZaki AdamouPas encore d'évaluation

- Heat Stress Essentials: Prevention in ActionDocument38 pagesHeat Stress Essentials: Prevention in ActiongkmlalPas encore d'évaluation

- Ppe Presentation-1Document17 pagesPpe Presentation-1api-273092669Pas encore d'évaluation

- Confined SpacesDocument25 pagesConfined SpaceshemanthPas encore d'évaluation

- Site Induction PresentationDocument16 pagesSite Induction PresentationMewan Naveenda Perera100% (1)

- Health and Safety Self Audit Checklist GeneralDocument8 pagesHealth and Safety Self Audit Checklist Generalوأكثرهم كارهونPas encore d'évaluation

- Safe Working PracticesDocument7 pagesSafe Working PracticesDiana ParkerPas encore d'évaluation

- Under Review: First Aid in The Workplace ProcedureDocument10 pagesUnder Review: First Aid in The Workplace ProcedureLenvinPas encore d'évaluation

- Daily Tool Box MeetingDocument1 pageDaily Tool Box MeetingVipul ShankarPas encore d'évaluation

- Osha (Autosaved)Document33 pagesOsha (Autosaved)Rishindran ParamanathanPas encore d'évaluation

- Hotworks and Welding SafetyDocument21 pagesHotworks and Welding SafetyprokjongPas encore d'évaluation

- Emal Contractor Red BookDocument75 pagesEmal Contractor Red BookVenkadesh PeriathambiPas encore d'évaluation

- Tool Box Training-EnglishDocument8 pagesTool Box Training-Englishraj KumarPas encore d'évaluation

- Guidelines For Storage and Handling Bluescope Steel 'S ProductsDocument20 pagesGuidelines For Storage and Handling Bluescope Steel 'S ProductsElieser Júnio100% (1)

- Stress Training For EmployeesDocument24 pagesStress Training For EmployeesJonasPas encore d'évaluation

- Safety Awareness Print OutsDocument35 pagesSafety Awareness Print OutsStan MacapiliPas encore d'évaluation

- Osha AsbestosDocument12 pagesOsha AsbestosCésar Pacheco RuizPas encore d'évaluation

- Electrical Safety: BY Chris Lacey and Robert JudeDocument16 pagesElectrical Safety: BY Chris Lacey and Robert Juderudejude69Pas encore d'évaluation

- Young Persons Risk Assessment V2.0 October 2021Document2 pagesYoung Persons Risk Assessment V2.0 October 2021Lucas SantosPas encore d'évaluation

- Njqs Core Audit Module - Rev1.6cDocument14 pagesNjqs Core Audit Module - Rev1.6cNene UmohPas encore d'évaluation

- Personal Protective Equipment Policy - FinalDocument6 pagesPersonal Protective Equipment Policy - FinalmarkalvinbonPas encore d'évaluation

- ERT Team Management & Emergency Evacuation ProcedureDocument23 pagesERT Team Management & Emergency Evacuation ProcedureAsif Jamil ChowdhuryPas encore d'évaluation

- DBMS-LM Kavi With MinipjtDocument56 pagesDBMS-LM Kavi With Minipjtkavi_mithuPas encore d'évaluation

- Solution of Tutorial Sheet-3 (Three Phase Networks) : Ans. Given, - Vab - 45kV, ZL (0.5 + j3), Z (4.5 + j9)Document10 pagesSolution of Tutorial Sheet-3 (Three Phase Networks) : Ans. Given, - Vab - 45kV, ZL (0.5 + j3), Z (4.5 + j9)Shroyon100% (2)

- IPCR Part 2 2017Document4 pagesIPCR Part 2 2017RommelPas encore d'évaluation

- CRCCDocument13 pagesCRCCGalih SantanaPas encore d'évaluation

- EmpanelHospList HelpFAQDocument13 pagesEmpanelHospList HelpFAQaditi001Pas encore d'évaluation

- LEGRAND Main Price List April 2012Document124 pagesLEGRAND Main Price List April 2012Ajay SinghPas encore d'évaluation

- Rescue Boat Lsa 5.1Document4 pagesRescue Boat Lsa 5.1Celal BozdoganPas encore d'évaluation

- CAM Charges Working For The Month of May 2023Document1 pageCAM Charges Working For The Month of May 2023adnandani2882Pas encore d'évaluation

- Dilg-Mbcrpp Isf Q2 2023Document2 pagesDilg-Mbcrpp Isf Q2 2023Mallari GabrielPas encore d'évaluation

- Emmeskay MIL-SIL TutorialDocument52 pagesEmmeskay MIL-SIL TutorialNeacsu EugenPas encore d'évaluation

- TIA Workshop ITBDocument48 pagesTIA Workshop ITBFirman Suhendra100% (1)

- Image AnalysisDocument404 pagesImage Analysisholyfreeman34Pas encore d'évaluation

- 08L76 HR3 A21Document6 pages08L76 HR3 A21liebofreakPas encore d'évaluation

- C/C++ Programming Language NotesDocument68 pagesC/C++ Programming Language Notesctf challengePas encore d'évaluation

- 5 Blasting Limit GuidelinesDocument7 pages5 Blasting Limit GuidelinesTry Oka Afandy SinagaPas encore d'évaluation

- MARTA: 2012 KPMG Phase II Final DraftDocument114 pagesMARTA: 2012 KPMG Phase II Final DraftthomaswheatleyPas encore d'évaluation

- Catalogo de Oleohidraulica AGVDocument73 pagesCatalogo de Oleohidraulica AGVadjime3Pas encore d'évaluation

- Nvidia CompanyDocument4 pagesNvidia CompanyaaaPas encore d'évaluation

- 6.hydraulic Pressure SpesificationDocument3 pages6.hydraulic Pressure SpesificationTLK ChannelPas encore d'évaluation

- VirtualHost Examples - Apache HTTP ServerDocument9 pagesVirtualHost Examples - Apache HTTP ServerSaitejaTallapellyPas encore d'évaluation

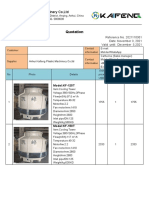

- KAIFENG Quotation For 150T Cooling TowerDocument13 pagesKAIFENG Quotation For 150T Cooling TowerEslam A. FahmyPas encore d'évaluation

- Cs9152 DBT Unit IV NotesDocument61 pagesCs9152 DBT Unit IV NotesNivithaPas encore d'évaluation

- 990 Vibration Transmitter Datasheet-141612mDocument14 pages990 Vibration Transmitter Datasheet-141612mloopkkPas encore d'évaluation

- Module Tes Answer Key: Student B Student ADocument2 pagesModule Tes Answer Key: Student B Student AKremena KoevaPas encore d'évaluation

- Canvera Photobook GuideDocument16 pagesCanvera Photobook GuideAnupam KumarPas encore d'évaluation

- GRT655 GRT655L Product Guide ImperialDocument20 pagesGRT655 GRT655L Product Guide ImperialDanilo UrruchurtoPas encore d'évaluation

- 1743 LKWActrosXXXXXX 954frDocument4 pages1743 LKWActrosXXXXXX 954frgeothermal3102100% (1)

- Ef3602 9Document2 pagesEf3602 9AwanPas encore d'évaluation

- BPQ REV. 0 Interactive FormDocument2 pagesBPQ REV. 0 Interactive FormcosmicbunnyPas encore d'évaluation