Académique Documents

Professionnel Documents

Culture Documents

4Z1JHC MTT0001 FLR D 00 HC0000 E01 0019 00 PDF

Transféré par

Deepu ChandranDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

4Z1JHC MTT0001 FLR D 00 HC0000 E01 0019 00 PDF

Transféré par

Deepu ChandranDroits d'auteur :

Formats disponibles

Vendor Document Review Sheet (DECAL)

PROJECT TITLE:

Reliance Pet Coke Gasification Project

VENDOR NAME:

BRIDGE & ROOF COMPANY (INDIA) LIMITED, MUMBAI

DOCUMENT TITLE:

SPLICE CALCULATION FOR PCG - SEZ TANKS

VENDOR DOCUMENT NO:

10017-4Z1JHC-MTT0001-FLR-D-00-HC0000-E01-0019

VENDOR REVISION NO:

00

VENDOR DOCUMENT REVIEW FEEDBACK

Permission to proceed does not constitute acceptance or approval of Design Detail, Calculations, Analysis, Test Methods or Materials developed OR selected by Vendor,

and does NOT relieve Vendor from FULL compliance with Contractual Obligations

Work may proceed.

Revise & Resubmit.Work may proceed,

subject to incorporation of comments

Revise & Resubmit.Work shall not Proceed

For Information Only

By:

Cancelled / Superseded

Final Certified

Date:

MECHANICAL

Discipline:

MT-HCH210-T101/T201/T104/T106/T108, MT-HCH220-T101/T201/T104/T106/T108, MT-HCH230- T101/T201/T104/T106/T108, MT-HUH722T010A/T010B/T011A/T011B, MT-HOH350-T001/T002, MT-HOH355-T001

Equipment No.

MR Number

Z 1 J H C

Project No

10017

M T T 0 0 0 1

F L R

0 0

MRP No.

-

4 Z 1 J H C

M T T 0 0 0 1

Unit No.(Plant WBS)

F L R

0 0

Cat. No.

-

1 - 0

Seq. No.

0

Rev No

9

CLIENT

RIL

CONSULTANT

Project:

FLUOR

Title:

Tag No.

SPLICING DETAIL FOR ROOF

STRUCTURE MEMBERS

REV. NO.

29.05.2014

DATE

BRIDGE & ROOF CO. (I) LTD.

Doc. No. :

MT-HCH210-T101/T201/T104/T106/T108

MT-HCH220-T101/T201/T104/T106/T108

MT-HCH230- T101/T201/T104/T106/T108

MT-HUH722-T010A/T010B/T011A/T011B

MT-HOH350-T001/T002

MT-HOH355-T001

DOCUMENT NO.

ORDER NO. : 70986

RELIANCE PCG

COMPLEX

AT

RIL

JAMNAGAR

Rev

10017-4Z1JHC-MTT0001-FLR-D- .

00-HC0000-E01-0019

0

BR/70986/FLR/SPLICE-2

ISSUED FOR APPROVAL

REVISION

S.R.

BY

S.T.

CHKD.

P.D.

APPD.

CLIENT

RIL

CONSULTANT

Project:

RELIANCE PCG

COMPLEX

AT

RIL

JAMNAGAR

FLUOR

Title:

Tag No.

SPLICING DETAIL FOR ROOF

STRUCTURE MEMBERS

MT-HCH210-T101/T201/T104/T106/T108

MT-HCH220-T101/T201/T104/T106/T108

MT-HCH230- T101/T201/T104/T106/T108

MT-HUH722-T010A/T010B/T011A/T011B

MT-HOH350-T001/T002

MT-HOH355-T001

ORDER NO. : 70986

BRIDGE & ROOF CO. (I) LTD.

Doc. No. :

Rev

10017-4Z1JHC-MTT0001-FLR-D- .

00-HC0000-E01-0019

0

Sheet no. 1 of 9

THE DESIGN OF SPLICES HAVE BEEN DONE BASED ON THE

FOLLOWING CONSIDERATIONS. :1. THE MAIN MEMBER SHOULD BE BUTT WELDED BEFORE SPLICING.

2. ALL EDGES SHALL BE PREPARED BEFORE BUTT WELDING .

3. SPLICES SHALL NOT BE LOCATED AT THE POINT OF MAXIMUM BENDING

MOMENT (i.e. AT MIDSPAN OF THE MEMBER ) AND / OR AT THE POINT OF

MAXIMUM SHEAR FORCE (i.e. AT SUPPORT )

4. SPLICE PLATES ARE DESIGNED FOR 50 % OF FULL STRENGTH OF THE

MEMBER. IT IS CONSIDERED THAT 50% OF THE TOTAL FORCE PASSES

THROUGH THE BUTT WELD.

5.

BUTT WELD SHALL BE SQUARE BUTT WELD FOR THICKNESSES

UPTO 6 mm , SINGLE - V BUTT WELD FOR THICKNESSES UPTO 10 mm

AND DOUBLE - V BUTT WELD FOR THICKNESSES GREATER THAN 10

mm.

CLIENT

CONSULTANT

RIL

Project:

RELIANCE PCG

COMPLEX

AT

RIL

JAMNAGAR

FLUOR

Title:

Tag No.

SPLICING DETAIL FOR ROOF

STRUCTURE MEMBERS

MT-HCH210-T101/T201/T104/T106/T108

MT-HCH220-T101/T201/T104/T106/T108

MT-HCH230- T101/T201/T104/T106/T108

MT-HUH722-T010A/T010B/T011A/T011B

MT-HOH350-T001/T002

MT-HOH355-T001

ORDER NO. : 70986

BRIDGE & ROOF CO. (I) LTD.

Doc. No. :

Rev

10017-4Z1JHC-MTT0001-FLR-D- .

00-HC0000-E01-0019

0

Sheet no. 2 of 9.

DESIGN OF SPLICE FOR DOUBLE ANGLES.

Sample calculation

MAIN MEMBER : 2 ISA 75 X 75 X 8 ( spacing between angles = 12 mm)

C/s area of the main member = 2 x 11.4 = 22.8 cm2

It is considered that 50% of the total force passes through the butt weld.

Flange splice plates are designed for only 50% of the total force.

Area of splice plates required = 22.8 x 0.5 x 1.05 = 11.97 cm2

Provide : 2 nos. ISA 50 x 50 x 6

1 no. PLT. 75 x 12

Splice area provided = 2 x 5.68 + 7.5 x 1.2 = 20.36 cm2 > 11.97 cm2.

Material Specification of roof structure members : IS:2062 Gr. E250 BR

Yield Stress = 250 MPa

Maximum allowable stress in axial tension / compression

= 0.6 x yield stress of material

(Refer IS: 800 )

= 0.6 x 250 MPa = 150 MPa = 1529 kg/cm2

Permissible stress in fillet welds = 1100 kg/cm2

(Refer IS :816 )

Force to be transmitted through splice area = 11.97 x 1529 = 18302.13 kg

Length of 6 mm site fillet weld = 18302.43 /(0.707 x 0.8 x 0.6 x 1100)

= 49.03 mm

Total no. of weld lines = 6

Minm. Length of splicing member on one side of the joint = 8.17 cm

PROVIDE SPLICING MEMBER :

1) 2 nos. ISA 50 X 50 X 6 - 230 mm long.

2) 1 no. PLT.. 75 x 12 - 165 mm long

(Refer Sheet no. 3 of 9 for splice detail.)

CLIENT

RIL

CONSULTANT

Project:

RELIANCE PCG

COMPLEX

AT

RIL

JAMNAGAR

FLUOR

Title:

SPLICING DETAIL FOR ROOF

STRUCTURE MEMBERS

Tag No.

MT-HCH210-T101/T201/T104/T106/T108

MT-HCH220-T101/T201/T104/T106/T108

MT-HCH230- T101/T201/T104/T106/T108

MT-HUH722-T010A/T010B/T011A/T011B

MT-HOH350-T001/T002

MT-HOH355-T001

ORDER NO. : 70986

BRIDGE & ROOF CO. (I) LTD.

Doc. No. :

Rev

10017-4Z1JHC-MTT0001-FLR-D- .

00-HC0000-E01-0019

0

CLIENT

RIL

CONSULTANT

Project:

RELIANCE PCG

COMPLEX

AT

RIL

JAMNAGAR

FLUOR

Title:

SPLICING DETAIL FOR ROOF

STRUCTURE MEMBERS

Tag No.

MT-HCH210-T101/T201/T104/T106/T108

MT-HCH220-T101/T201/T104/T106/T108

MT-HCH230- T101/T201/T104/T106/T108

MT-HUH722-T010A/T010B/T011A/T011B

MT-HOH350-T001/T002

MT-HOH355-T001

ORDER NO. : 70986

BRIDGE & ROOF CO. (I) LTD.

Doc. No. :

Rev

10017-4Z1JHC-MTT0001-FLR-D- .

00-HC0000-E01-0019

0

Sheet no. 4 of 9

DESIGN OF SPLICE FOR CHANNELS

Sample Calculation.

MAIN MEMBER : ISMC 300 X 90

C/s area of the flange = 9 x 1.36 = 12.24 cm2

It is considered that 50% of the total force passes through the butt weld.

flange splice plates are to be designed for 50% of the total force.

Splice area required = 0.5 x 12.24 x 1.05 = 6.426 cm2

Maximum bending stress = 1682 kg / cm2

Section modulus = 428 cm3

Material Specification of roof structure members : IS:2062 Gr. E250 BR

Yield Stress = 250 MPa

Maximum allowable stress in axial tension / compression

= 0.6 x yield stress of material

(Refer IS: 800 )

= 0.6 x 250 MPa = 150 MPa = 1529 kg/cm2

Maximum allowable stress in bending = 0.66 x yield stress of material

(Refer IS:800 )

= 0.66 x 250 MPa = 165 MPa = 1682 kg/cm2

Permissible stress in fillet welds = 1100 kg/cm2

(Refer IS :816 )

Maximum force due to bending = 1682 x 428 /(30 1.36) = 25136.03 kg

Force to be taken care by flange plates = 0.5 x 25136.03 = 12568.02 kg

Provide flange splice plates :- 1 no.Plt. 80 x 16 thk

C/s area provided = 8.0 x 1.6 = 12.8 cm2 > 6.426 cm2

Maximum axial stress = 1529 kg/cm2.

Force to be transmitted through splice area (max) = 12.8 x 1529 = 19571.2 kg > 12568.02 kg

Length of 10 mm fillet weld on one side of the joint = 19571.2 /(0.707 x 0.8 x 1 x 1100)

= 31.46 cm

Provide 1 no. Plt. 80 x 16 thk x 330 mm long per flange on the inside face.

CLIENT

RIL

CONSULTANT

Project:

RELIANCE PCG

COMPLEX

AT

RIL

JAMNAGAR

FLUOR

Title:

SPLICING DETAIL FOR ROOF

STRUCTURE MEMBERS

Tag No.

MT-HCH210-T101/T201/T104/T106/T108

MT-HCH220-T101/T201/T104/T106/T108

MT-HCH230- T101/T201/T104/T106/T108

MT-HUH722-T010A/T010B/T011A/T011B

MT-HOH350-T001/T002

MT-HOH355-T001

ORDER NO. : 70986

BRIDGE & ROOF CO. (I) LTD.

Doc. No. :

Rev

10017-4Z1JHC-MTT0001-FLR-D- .

00-HC0000-E01-0019

0

Sheet no. 5 of 9

Permissible average shear stress = 0.4 x yield stress of material

(Refer IS: 800 )

= 0.4 x 250 MPa = 100 MPa = 1019 kg/cm2

C/s area of the web = 30 x 0.78 = 23.4 cm2

It is considered that 50% of the total force passes through the butt weld.

web splice plate is to be designed for 50% of the total force.

Splice area required = 0.5 x 23.4 x 1.05 = 12.285 cm2

Maximum shear = 1019 x 23.4 = 23844.6 kg.

Force through splice area = 0.5 x 23844.6 = 11922.3 kg

Length of 8 mm fillet weld required = 11922.3 /(0.707 x 0.8 x 0.8 x 1100) = 23.95 cm

Provide web splice plate :1 no. Plt. 250 x 8 thk. x 150 mm long

c/s area of splice plate = 25 x 0.8 = 20 cm2 > 12.285 cm2.

(Refer Sheet no. 6 of 9 for splice detail.)

CLIENT

RIL

CONSULTANT

Project:

RELIANCE PCG

COMPLEX

AT

RIL

JAMNAGAR

FLUOR

Title:

SPLICING DETAIL FOR ROOF

STRUCTURE MEMBERS

Tag No.

MT-HCH210-T101/T201/T104/T106/T108

MT-HCH220-T101/T201/T104/T106/T108

MT-HCH230- T101/T201/T104/T106/T108

MT-HUH722-T010A/T010B/T011A/T011B

MT-HOH350-T001/T002

MT-HOH355-T001

ORDER NO. : 70986

BRIDGE & ROOF CO. (I) LTD.

Doc. No. :

Rev

10017-4Z1JHC-MTT0001-FLR-D- .

00-HC0000-E01-0019

0

CLIENT

RIL

CONSULTANT

Project:

RELIANCE PCG

COMPLEX

AT

RIL

JAMNAGAR

FLUOR

Title:

SPLICING DETAIL FOR ROOF

STRUCTURE MEMBERS

Tag No.

MT-HCH210-T101/T201/T104/T106/T108

MT-HCH220-T101/T201/T104/T106/T108

MT-HCH230- T101/T201/T104/T106/T108

MT-HUH722-T010A/T010B/T011A/T011B

MT-HOH350-T001/T002

MT-HOH355-T001

ORDER NO. : 70986

BRIDGE & ROOF CO. (I) LTD.

Doc. No. :

Rev

10017-4Z1JHC-MTT0001-FLR-D- .

00-HC0000-E01-0019

0

Sheet no. 7 of 9

DESIGN OF SPLICE FOR BOX CHANNELS

Sample Calculation.

MAIN MEMBER : 2 ISMC 250X 80

C/s area of the flange = 8 x 1.41x 2 = 22.56 cm2

It is considered that 50% of the total force passes through the butt weld.

flange splice plates are to be designed for 50% of the total force.

Splice area required = 0.5 x 22.56 x 1.05 = 11.844 cm2

Maximum bending stress = 1682 kg / cm2

Section modulus = 2 x 307 = 614 cm3

Material Specification of roof structure members : IS:2062 Gr. E250 BR

Yield Stress = 250 MPa

Maximum allowable stress in axial tension / compression

= 0.6 x yield stress of material

(Refer IS: 800 )

= 0.6 x 250 MPa = 150 MPa = 1529 kg/cm2

Maximum allowable stress in bending = 0.66 x yield stress of material

(Refer IS:800 )

= 0.66 x 250 MPa = 165 MPa = 1682 kg/cm2

Permissible stress in fillet welds = 1100 kg/cm2

(Refer IS :816 )

Maximum force due to bending = 1682 x 614 / 25 = 41309.92 kg

Force to be taken care by flange plates = 0.5 x 41309.92 = 20654.96 kg

Provide flange splice plates :- 1 no.Plt. 130 x 16 thk

C/s area provided = 13 x 1.6 = 20.8 cm2 > 11.844 cm2

Maximum axial stress = 1529 kg/cm2.

Force to be transmitted through splice area (max) = 20.8 x 1529 = 31803.2 kg > 20654.96 kg

Length of 10 mm fillet weld on one side of the joint = 31803.2 /(0.707 x 0.8 x 1 x 1100)

= 51.12 cm= 511.2 mm

Provide 1 no. Plt. 130 x 16 thk x 525 mm long per flange of the box on the outside face.

CLIENT

RIL

CONSULTANT

Project:

RELIANCE PCG

COMPLEX

AT

RIL

JAMNAGAR

FLUOR

Title:

SPLICING DETAIL FOR ROOF

STRUCTURE MEMBERS

Tag No.

MT-HCH210-T101/T201/T104/T106/T108

MT-HCH220-T101/T201/T104/T106/T108

MT-HCH230- T101/T201/T104/T106/T108

MT-HUH722-T010A/T010B/T011A/T011B

MT-HOH350-T001/T002

MT-HOH355-T001

ORDER NO. : 70986

BRIDGE & ROOF CO. (I) LTD.

Doc. No. :

Rev

10017-4Z1JHC-MTT0001-FLR-D- .

00-HC0000-E01-0019

0

Sheet no. 8 of 9

Permissible average shear stress = 0.4 x yield stress of material

(Refer IS: 800 )

= 0.4 x 250 MPa = 100 MPa = 1019 kg/cm2

C/s area of the web = 25 x 0.72 = 18 cm2

It is considered that 50% of the total force passes through the butt weld.

web splice plate is to be designed for 50% of the total force.

Splice area required = 0.5 x 18 x 1.05 = 9.45 cm2

Maximum shear = 1019 x 18 = 18342 kg.

Force through splice area = 0.5 x 18342 = 9171 kg

Length of 8 mm fillet weld required = 9171 /(0.707 x 0.8 x 0.8 x 1100) = 18.425 cm

Provide web splice plate :1 no. Plt. 190 x 8 thk. x 130 mm long

c/s area of splice plate = 19 x 0.8 = 20 cm2 > 9.45 cm2.

(Refer Sheet no. 6 of 9 for splice detail.)

Provide 1 no. Plt. 190 mm x 8 thk. X 130 mm long on each web of the box channel on the outside face .

CLIENT

RIL

CONSULTANT

Project:

RELIANCE PCG

COMPLEX

AT

RIL

JAMNAGAR

FLUOR

Title:

SPLICING DETAIL FOR ROOF

STRUCTURE MEMBERS

Tag No.

MT-HCH210-T101/T201/T104/T106/T108

MT-HCH220-T101/T201/T104/T106/T108

MT-HCH230- T101/T201/T104/T106/T108

MT-HUH722-T010A/T010B/T011A/T011B

MT-HOH350-T001/T002

MT-HOH355-T001

ORDER NO. : 70986

BRIDGE & ROOF CO. (I) LTD.

Doc. No. :

Rev

10017-4Z1JHC-MTT0001-FLR-D- .

00-HC0000-E01-0019

0

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Mastering Options StrategiesDocument40 pagesMastering Options Strategiesluong847180% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Safety Audit Report SampleDocument24 pagesSafety Audit Report Samplekanakarao187% (15)

- Wps Format Asme Sec - IxDocument2 pagesWps Format Asme Sec - IxDeepu ChandranPas encore d'évaluation

- STA Audit Format-EditableDocument1 pageSTA Audit Format-EditableDeepu ChandranPas encore d'évaluation

- Swilliams Lesson6Document11 pagesSwilliams Lesson6api-276783092Pas encore d'évaluation

- Managerial Accounting and Cost ConceptsDocument67 pagesManagerial Accounting and Cost ConceptsTristan AdrianPas encore d'évaluation

- ASNT NDT Level III Certification GuideDocument8 pagesASNT NDT Level III Certification GuideIndigo Wave0% (2)

- MS For The Access Control System Installation and TerminationDocument21 pagesMS For The Access Control System Installation and Terminationwaaji snapPas encore d'évaluation

- Production of Activated CarbonDocument11 pagesProduction of Activated CarbonShii Bautista100% (1)

- SSTMCV Retail PowerDocument5 pagesSSTMCV Retail Powervipin.yadavPas encore d'évaluation

- Company Name Email Id Contact Location: 3 Praj Industries Limited Yogesh960488815Pune-Nagar Road, SanaswadiDocument65 pagesCompany Name Email Id Contact Location: 3 Praj Industries Limited Yogesh960488815Pune-Nagar Road, SanaswadiDhruv Parekh100% (1)

- SyllogismDocument7 pagesSyllogismDeepu ChandranPas encore d'évaluation

- RT OfferDocument12 pagesRT OfferDeepu ChandranPas encore d'évaluation

- Time and Work 30 QuestionsDocument5 pagesTime and Work 30 QuestionsDeepu ChandranPas encore d'évaluation

- 300 Copy Gas Cutting Daily Check ListDocument3 pages300 Copy Gas Cutting Daily Check ListDeepu ChandranPas encore d'évaluation

- Petal DevelopmentDocument2 pagesPetal DevelopmentDeepu ChandranPas encore d'évaluation

- Mobile Crane, Hydra Planning & Risk Assessment Checklist: Plant/AreaDocument1 pageMobile Crane, Hydra Planning & Risk Assessment Checklist: Plant/AreaDeepu ChandranPas encore d'évaluation

- Tools & Tackles Monthly InspectionDocument4 pagesTools & Tackles Monthly InspectionDeepu ChandranPas encore d'évaluation

- RT Summary Report for DWG NO MED-711Document130 pagesRT Summary Report for DWG NO MED-711Deepu ChandranPas encore d'évaluation

- Sharp Tanks & Structurals (P) LTD Drinking Water Tank - : J3 Project - ZRTFDocument3 pagesSharp Tanks & Structurals (P) LTD Drinking Water Tank - : J3 Project - ZRTFDeepu ChandranPas encore d'évaluation

- Ladder Inspection Check ListDocument4 pagesLadder Inspection Check ListDeepu ChandranPas encore d'évaluation

- Fabrication Yard LayoutDocument1 pageFabrication Yard LayoutDeepu ChandranPas encore d'évaluation

- 100 Copy Scaffolding Erection Check ListDocument4 pages100 Copy Scaffolding Erection Check ListDeepu Chandran100% (1)

- Imir 3156Document38 pagesImir 3156Deepu ChandranPas encore d'évaluation

- SiteDocument9 pagesSiteDeepu ChandranPas encore d'évaluation

- Wled LengthDocument1 pageWled LengthDeepu ChandranPas encore d'évaluation

- Paint Type and DFT Requirements for TanksDocument2 pagesPaint Type and DFT Requirements for TanksDeepu ChandranPas encore d'évaluation

- 56 Requist Validation MTTDocument3 pages56 Requist Validation MTTDeepu ChandranPas encore d'évaluation

- Sharptank - PF ECR September-16Document11 pagesSharptank - PF ECR September-16Deepu ChandranPas encore d'évaluation

- QC StickerDocument44 pagesQC StickerDeepu ChandranPas encore d'évaluation

- Pneumatic Test ProcedureDocument7 pagesPneumatic Test ProcedureDeepu ChandranPas encore d'évaluation

- STS Ril 002Document1 127 pagesSTS Ril 002Deepu ChandranPas encore d'évaluation

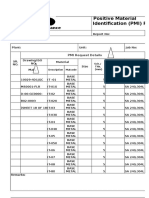

- Reliance: Positive Material Identification (PMI) ReportDocument16 pagesReliance: Positive Material Identification (PMI) ReportDeepu ChandranPas encore d'évaluation

- Too1 B LHSDocument347 pagesToo1 B LHSDeepu ChandranPas encore d'évaluation

- Sts-Sez HC Ra 2Document17 pagesSts-Sez HC Ra 2Deepu ChandranPas encore d'évaluation

- Gas Purging Optimises Root WeldsDocument4 pagesGas Purging Optimises Root WeldsDeepu ChandranPas encore d'évaluation

- March 2017Document11 pagesMarch 2017Anonymous NolO9drW7MPas encore d'évaluation

- Grate Inlet Skimmer Box ™ (GISB™ ) Suntree Technologies Service ManualDocument4 pagesGrate Inlet Skimmer Box ™ (GISB™ ) Suntree Technologies Service ManualOmar Rodriguez OrtizPas encore d'évaluation

- Aesculap Qatar UniversityDocument3 pagesAesculap Qatar UniversityAl Quran AcademyPas encore d'évaluation

- VVIP Circuit House achieves 5-star GRIHA ratingDocument1 pageVVIP Circuit House achieves 5-star GRIHA ratingmallikaPas encore d'évaluation

- Mid Semester ExaminationDocument2 pagesMid Semester ExaminationMOHAMMED RIHANPas encore d'évaluation

- 1 s2.0 S0313592622001369 MainDocument14 pages1 s2.0 S0313592622001369 MainNGOC VO LE THANHPas encore d'évaluation

- Piroxicam (Wikipedia)Document4 pagesPiroxicam (Wikipedia)Adrian ArnasaputraPas encore d'évaluation

- GSR Azure High Level ArchitectureDocument4 pagesGSR Azure High Level ArchitectureCSKPas encore d'évaluation

- Routine E-Mail Messages and Memos-Ch 8Document43 pagesRoutine E-Mail Messages and Memos-Ch 8Faryal ArifPas encore d'évaluation

- Notes and Questions On-Op AmpDocument11 pagesNotes and Questions On-Op AmpjitenPas encore d'évaluation

- Lfa Sop 00067Document6 pagesLfa Sop 00067Ahmed IsmaillPas encore d'évaluation

- Deploy A REST API Using Serverless, Express and Node - JsDocument13 pagesDeploy A REST API Using Serverless, Express and Node - JszaninnPas encore d'évaluation

- Siemens ProjectDocument17 pagesSiemens ProjectMayisha Alamgir100% (1)

- Project 863 EvidenceDocument5 pagesProject 863 EvidenceMilan TolhuisenPas encore d'évaluation

- Javacore 20100918 202221 6164 0003Document44 pagesJavacore 20100918 202221 6164 0003actmon123Pas encore d'évaluation

- Chapter 7 - Trade and Investment EnvironmentDocument7 pagesChapter 7 - Trade and Investment EnvironmentMa. Cristel Rovi RibucanPas encore d'évaluation

- Research Paper About Cebu PacificDocument8 pagesResearch Paper About Cebu Pacificwqbdxbvkg100% (1)

- 2022 Semester 2 Letter To Parents - FinalDocument7 pages2022 Semester 2 Letter To Parents - FinalRomanceforpianoPas encore d'évaluation

- ADVOCACY AND LOBBYING NDocument7 pagesADVOCACY AND LOBBYING NMwanza MaliiPas encore d'évaluation

- Seaflo Outdoor - New Pedal Kayak Recommendation July 2022Document8 pagesSeaflo Outdoor - New Pedal Kayak Recommendation July 2022wgcvPas encore d'évaluation

- OspndDocument97 pagesOspndhoangdo11122002Pas encore d'évaluation

- Introduction Electrical MotorDocument36 pagesIntroduction Electrical MotorYajidPas encore d'évaluation

- Portfolio Management Banking SectorDocument133 pagesPortfolio Management Banking SectorNitinAgnihotri100% (1)