Académique Documents

Professionnel Documents

Culture Documents

Energia Blok Ya

Transféré par

Junior Miranda0 évaluation0% ont trouvé ce document utile (0 vote)

11 vues5 pagesEnergia Blok Ya

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentEnergia Blok Ya

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

11 vues5 pagesEnergia Blok Ya

Transféré par

Junior MirandaEnergia Blok Ya

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 5

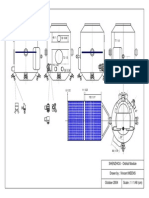

docking unit I

This transition, transit compartment between

the missile and launcher. The birth of this

transitional structure in the total composition

rocket "Energy" is due to several factors, one of

which - the need to create conditions for the

assembly shop detachable connections of

hydraulic and pneumatic lines and electrical

circuits. Direct analogues of such structures in

rocketry enough. For example, combat missiles

of SS-18 and SS-24, placed in transport-launch

containers in its structure are discontinuous and

plug connections of rocket start, collected in an

industrial environment at the stage of final

assembly. Straight joints with a starting

launcher carried out in the open, a rough

version, which allows you to be paired at the

start of weather conditions - wind, rain, snow

and dust. These joints have the necessary

protection and design elements that provide a

guaranteed reliable connections, integrity and

purity of line.

Homepage-docking unit serves as a power

bottom base plate, which is attached to the first

stage unit packet, and in conjunction with the

main circuit of the central block forms a onepiece construction, provides transportation of

1

missiles in the transport-erector and install it in

a vertical position at the start. The unit performs

a safety device that prevents the launch vehicle

from the direct effects and the impact of the

return streams running rocket propulsion

engines at the start of the media. Overall

Homepage-docking unit, the function is part of

the ground complex. The unit is designed for

repeated use to conduct an appropriate volume

of repair and maintenance work after each

start.

Besides Homepage-docking unit as

intermediate devices in the upper belt ties with

rocket launch system used adapter navigation

system and filling-farm drainage mast, which

are mounted on board the missile and the

central unit at the start of the team are

detached, remaining within the launch facility.

The power unit body construction consists of

six compartments stacked together by bolts.

Each section is a welded construction of sheet

steel AK-25.

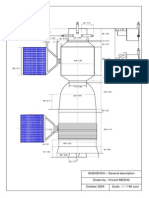

Poster-process unit (block layout I)

After undocking elektroplaty lower part

attributable to the unit, under the action of the

pusher is pulled into the mast, fixed at the same

time opens up, moved to the lower position, the

mechanism of withdrawal of the mast. The mast

tilts torsion mechanism 300 with respect to its

initial position and the stopper spring grips the

support bracket. Cover elektroplaty relieved

when the board neutral position by springs and

covers electrical connectors. This, tilted away

from the rocket, with a closed position

elektroplatoy mast takes power, thermal and

acoustic effects of the gas stream running

rocket engines.

At the command "touch lift" lower part of the

board plug connections of the central unit,

which remains on the launch, docking unit,

under the force of four pushers attracted to the

column and falls on its upper end. To mitigate

the impact in the places where they established

contact spring shock absorbers and PTFE

sleeve. Cover column is closed by the rod

spring. Rasstoporenie locking mechanism

cover in the open position produced a lever

mechanism, one arm of which rests on the

cone of the central rocket unit and discharged

as it moves into the early start.

Cover closing locations plug connections

due to the side of missiles, closed with a spring

drive after the start of the rocket, excluding

collision caps with side blocks. Small Caps

before starting are upright, freely based on the

lateral surface of the tail section of blocks,

moving the rocket slide on the guide pads tail

section and released, the spring force and the

stopper mechanism snaps shut. Larger cap in

its initial position horizontally mounted on the

rocker arm. When the rocket arm slips off the

tail section of the side rocket unit and triggers a

closure cap. Caps which are in an inclined

position, based on the lateral surface of the

roller and closed after when the roller rolls to

the side surface of the side rocket unit.

The original version of Homepage-docking unit

I

The original version of Homepage-connection

block "I". Note the units of the system

maintenance pH at the initial stage of its

movement. If further work on the unit "I" of

using the system refused to support that led to

the lowering of the rocket in the first launch May

15, 1987.

Homepage-docking unit - I unit - simple,

rectangular shape in terms of the outer contour,

with dimensions of 20.25 m by 11.5 m and a

height of a flat portion of the housing of 1.2 m.

Weight finally subassembly 150 m. On the

upper surface of the block column mounted unit

I pneumohydraulic relations with the board of

the central unit missiles and flip 300 at the start

of the mast cable connections to board the

rocket. The internal configuration of openings

and windows of the unit corresponds to the

contour of the cross section of the aft part of the

rocket with the formation of a power capes

bearing blocks of the first stage. Inner contours

determined by the size nozzle engines with a

view to ensuring non-impact output at the start

of the rocket nozzle. On the outer perimeter

secured a number of power-rigging elements:

pins, brackets and spherical support.

The housing unit is a power base. On the

upper surface of the unit in places of

demountable connections are located covers

closing docking stations and elements from the

effects of a hot flow of the main engines running

at startup. Lower plane accommodates a

docking device pneumohydraulic and electrical

systems on the launch pad.

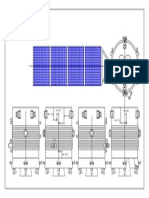

-docking unit rocket "Energy":

In the process of assembling a rocket and

starting-block connection fixed cover all

2

technological devices in a position that does not

prevent the assembly. After assembly the lid are

reset.

The outer surface of the starter housing-unit

connection is protected from the force and

thermal effects of the gas streams running the

main engines panel thermal barrier coating. The

panels are made of heat-resistant and heatresistant composite material ZSP - CFRP

based on silica glass. The panels are fixed to

the body with bolts, the heads of which are

closed thermal protection caps made of

pressed material AG-4V. To eliminate blowjoints between the panels performed their

labyrinth and filled with sealant "Viksint." On the

surface of the column pneumohydraulic

systems and heat-shielding panel mast is

placed on the sub-layer of a material TIM-4 for

the purpose of thermal insulation systems

under long-term temperature conditions daily

and seasonal fluctuations. Protruding elements

such as brackets, supports and pins are closed

tselnopressovannymi heat-shielding caps

removed when hoisting work with blocks and

missiles.

Since the kickoff-docking unit performs the

function of communication with the rocket

launch facilities, the system to be placed in the

block are essentially transit. The main ones are:

the system of filling and draining the fuel

components, circulation system, temperature

control, level control, compressed gases

charging system, the system of control of

pressure, venting and inerting environment

compartments missiles, ensuring temperature

in the compartments, fire and explosion

prevention system and steering gear .

Ventilation systems, ensuring temperature and

fire and explosion prevention are not only

transit, but also perform the same functions

with regard to the start-docking unit. The

system of post-combustion emission of

unreacted hydrogen rocket system undocking

links - front-docking unit is a closed system as a

part of this unit. Reburning of unreacted

hydrogen emissions during start-up and

shutdown of oxygen-hydrogen propulsion

engines of the central unit.

In order to create fire and explosion-proof

environment inside the body cavity sealed unit

is divided by partitions into compartments

"oxygen" and "kerosene". Hydrogen Highway

routed separately through a column

pneumohydraulic systems. Educated

compartments are ventilated through the

collectors and their volumes creates a

protective inert gas - nitrogen.

Pneumohydraulic Transit system located in

the block include the usual elements for them:

lines, knots connections, electro-pneumatic

valves, pyro valve, check valves, valves and

other pylevlagozaschitnye varieties, filters and

interconnect components due to the rocket and

launch launcher.

By the start-docking unit served hydrogen,

oxygen, kerosene, helium, nitrogen gas, freon,

oil for steering drives, compressed air. The unit

installed in 1123 the pipeline with a total length

of about 12 km. Pipelines are made primarily of

steel EP810-VD (about 790 titles), 12X18H10T

(318), and the remaining 15 - steel DI52-VD.

Pipelines for cryogenic components - hydrogen

and oxygen - insulated polyurethane foam

spraying type "Ripor." As bellows expansion

joints movements applied, sharniroobraznye,

loop design. Fittings, valves, actuated by a

command from the control system, that is in

electrical communication and a certain

probability of emission of gases enclosed in

pnevmoschity in which force creates a constant

inert environment.

Plug connection of hydraulic and pneumatic

connections Homepage-docking unit with a

launcher located on the column

pneumohydraulic systems on the outer wall of

the column, a vertical wall of the housing unit

under the column and the lower edge of the

housing. Joining these compounds produced by

means of a starting complex after the

installation launcher to launcher.

Plug connection pneumohydraulic relations

with side blocks launcher located on top of the

Homepage, the docking unit and concentrated

in sets under each block of the first stage. With

the central rocket unit pneumatichydraulic

communication systems, including hydrogen, is

carried through the column pneumatichydraulic

systems.

Plug connection connections interconnect

pneumohydraulic mainly undocks portsionerami

force team "contact recovery" and only some of

them - the course of a rocket.

The so-called decoupling "progress" is

essentially a rocket undocking the fluid

connection of the moving force at the start of

the rocket. Such releasable connections may

be designed as a complete valve assembly,

which is normally arranged sealing the junction

with a calibrated spring force - such a

separation joint occurs without compromising

the integrity of the valve. Or the compound can

be in the form of a valve device, which

3

tightness is achieved not only seal gaskets and

solid one-piece construction compound. In that

case, a weak section in which force when

moving the rocket this design breaks when

driving course missile. The weak link is

sometimes made of less resistant materials,

including plastics.

The peculiarity and attractiveness of such a

releasable connection is its reliability and

timeliness of undocking. Reliability due to

simplicity of design. In this circuit, with proper

design it, - the minimum number of elements

involved in the work, including no need to

depend on the reliability of the operation

command. Timeliness of separation - a quality

which makes it possible to be sure that the pipe

is not broken during the failed rocket motion.

Undocking line occurs only when started an

irreversible process - movement, and only at

the beginning of the movement. In fact, if you

sever ties before lifting when the failed missile

launch remains of fluid management. In this

case, there is a dangerous situation is

unplanned.

It would, no doubt - needed only

communication undocks course of a rocket. So

dividing joints are made of virtually all combat

missiles. However, given that the number of

connections is large enough spread and

asymmetry, the force on the undocking

progress rocket takes significant level,

especially when placing the bonds on the

periphery of the cross section of the rocket - a

problem of stability of the rocket. For large

perturbations of the control system can not

cope with the stabilization of the rocket and to

give, at best, off-nominal mode of flight, if not

an accident.

Undocking pneumohydraulic and electrical

connections on the team before the start of the

movement creates almost ideal conditions for

the beginning of a missile. However, this

scheme requires a very high degree of

processing and system design excellence

division. The design of the rocket "Energy" was

the vast majority of detachable joints, undocks

team. Part of the connectors in the basic control

pressure undocks course of a rocket. This

design decision was not unanimous. A staunch

opponent of the scheme was adopted

VPBarmin. Already in 1982 at the Council of

Chief Designers, he demanded to revise the

scheme. It was established a group of experts

tasked to re-evaluate the correctness of the

decision. Group entrusted me to lead - a

supporter of the gap connectors swing. But the

state of development of the project and the

prevailing situation at the time made it

impossible to radically alter the design. The

Group has reported (in case of disagreement

designers ground-based) that the scheme

should be retained in the form in which it was

designed. I supported the opinion of the group

and we have directed our attention to the

careful development of the division.

But before starting May 15, 1987 battle was

between academics and VPBarmin Glushko,

who filmed their guarantees on the reliability of

the launch, exposing once again criticized the

system. The Commission adopted the General

Designer VP Glushko. Barmin addressed me as

Chief Designer, which, he said, has sufficient

experience in the development of military

missiles, to cancel the launch and alter the

design. It was unreal. Knowing him, I still could

not support it. But the system itself has shown.

At the second start-up, 29 October 1988 not

undock hinged sighting unit. This site lurked just

a mistake.

To control pyro aid of valves and other

devices located in block number of devices

which are included in the housing to create a

temperature control and a neutral medium. To

measure the temperature and pressure of the

gas medium inside the applied temperature

sensors such as TP and gauge pressure

transmitters type DD.

Electrical connection Homepage-docking

unit through discontinuous elektroplaty. Each

side rocket unit has about 1,500

telecommunication circuits, central - 2000. On

the side blocks are used explosive type

connectors PC-50, the central unit - such as 9P.

Contact launcher carried three elektroplaty

placed on the underside of the starting-anddocking unit. Each board has eighteen type

connectors "Bhutan", allows automatic docking

of the carrier rocket through the starting block

with a launcher.

The power connection is carried out with a

missile unit in sixteen points - four on each side

of the unit. Each power unit has two

pnevmozamka, axial loads, and two guide pins

- for transverse loads. To ensure the

compensation of errors in the assembly and

manufacture of rocket units nodes have the

ability to adjust the axial direction up to fifty

millimeters in the transverse and angular

directions - within two degrees. Replacing

pneumatic locks provided through a special

hatch and does not cause difficulties.

Opening and closing pnevmozamkov

4

conducted by a control air pressure up to two

hundred atmospheres. When the pressure

pnevmozamok retains its original position open or closed. The resource allows reuse of

castles. In preparing the rocket for launch team

made the disclosure after refueling propellants -

in advance of irreversible processes to increase

the reliability of operation of the locks on the

opening provided by the duplication of their

discovery using the Unified pyrotechnic device.

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Air Force HistoryDocument170 pagesAir Force HistoryCAP History Library100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- NASA Astronauts On Soyuz Experience and Lessons For The FutureDocument42 pagesNASA Astronauts On Soyuz Experience and Lessons For The FutureBob AndrepontPas encore d'évaluation

- Gemini Program Mission Report Gemini ViiiDocument560 pagesGemini Program Mission Report Gemini ViiiBob AndrepontPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Scrib RamjetDocument34 pagesScrib RamjetNafis Zahran Ed100% (1)

- Solar SystemDocument21 pagesSolar Systemmystie100% (1)

- This Is The First of The Big ShotsDocument12 pagesThis Is The First of The Big ShotsBob AndrepontPas encore d'évaluation

- Air Tractor At-802u BrochureDocument8 pagesAir Tractor At-802u BrochureTraction Marketing Group100% (3)

- (Dover Books On Aeronautical Engineering) Angelo Miele - Flight Mechanics - Theory of Flight Paths-Dover Publications (2016) PDFDocument450 pages(Dover Books On Aeronautical Engineering) Angelo Miele - Flight Mechanics - Theory of Flight Paths-Dover Publications (2016) PDFJK Noksi100% (1)

- Messerschmitt Me 262 SchwalbeDocument39 pagesMesserschmitt Me 262 SchwalbeIgnacio Moratinos Castañeda100% (4)

- Checklist A330Document7 pagesChecklist A330librepescadorPas encore d'évaluation

- FM 100-63 Infantry-Based Opposing ForceDocument399 pagesFM 100-63 Infantry-Based Opposing ForceJared A. Lang100% (1)

- Vs-40 Sounding RocketDocument5 pagesVs-40 Sounding RocketJunior MirandaPas encore d'évaluation

- SHENZHOU - Shroud ConfigurationDocument1 pageSHENZHOU - Shroud ConfigurationJunior MirandaPas encore d'évaluation

- Spaceflight101 Com Spacerockets Long March 7Document30 pagesSpaceflight101 Com Spacerockets Long March 7Junior MirandaPas encore d'évaluation

- Shenzhou 3Document1 pageShenzhou 3Junior MirandaPas encore d'évaluation

- Ballistic Missiles and Missile Defense in AsiaDocument84 pagesBallistic Missiles and Missile Defense in AsiaJunior MirandaPas encore d'évaluation

- SHENZHOU - General DescriptionDocument1 pageSHENZHOU - General DescriptionJunior MirandaPas encore d'évaluation

- Shenzhou 2Document1 pageShenzhou 2Junior MirandaPas encore d'évaluation

- A Better Focus On ShenzhouDocument4 pagesA Better Focus On ShenzhouJunior MirandaPas encore d'évaluation

- Shenzhou 4Document1 pageShenzhou 4Junior MirandaPas encore d'évaluation

- Expedition 14 Press KitDocument118 pagesExpedition 14 Press KitUhrin ImrePas encore d'évaluation

- Ambitious Goal of Sergei KorolevDocument5 pagesAmbitious Goal of Sergei KorolevJunior MirandaPas encore d'évaluation

- Turbo 2Document1 pageTurbo 2Junior MirandaPas encore d'évaluation

- ColunaDocument1 pageColunaJunior MirandaPas encore d'évaluation

- 2.8isometric ViewDocument9 pages2.8isometric ViewSiva KumarPas encore d'évaluation

- "Kurs" Radio Engineering SystemDocument2 pages"Kurs" Radio Engineering SystemJunior MirandaPas encore d'évaluation

- Angara A5Document16 pagesAngara A5Junior MirandaPas encore d'évaluation

- Isometric Drawings Guide in <40 CharactersDocument6 pagesIsometric Drawings Guide in <40 CharactersSiva KumarPas encore d'évaluation

- Buran 2Document4 pagesBuran 2Junior MirandaPas encore d'évaluation

- SaluytbakDocument1 pageSaluytbakJunior MirandaPas encore d'évaluation

- Energia Blok YaDocument5 pagesEnergia Blok YaJunior MirandaPas encore d'évaluation

- Orion's 8 Key EFT-1 Test Flight Events ExplainedDocument6 pagesOrion's 8 Key EFT-1 Test Flight Events ExplainedJunior MirandaPas encore d'évaluation

- Delta IV Launch Services UserDocument1 pageDelta IV Launch Services UserJunior MirandaPas encore d'évaluation

- Shenzhou - SinoDefenceDocument10 pagesShenzhou - SinoDefenceJunior MirandaPas encore d'évaluation

- Orion's 8 Key EFT-1 Test Flight Events ExplainedDocument6 pagesOrion's 8 Key EFT-1 Test Flight Events ExplainedJunior MirandaPas encore d'évaluation

- All International Space Station Missions: Spacecraft Launch Landing/ Deorbit Mission Mission Crew 1998Document10 pagesAll International Space Station Missions: Spacecraft Launch Landing/ Deorbit Mission Mission Crew 1998Junior MirandaPas encore d'évaluation

- F-1 EngineDocument11 pagesF-1 EnginentschkePas encore d'évaluation

- Solar ProbesDocument27 pagesSolar ProbesJunior MirandaPas encore d'évaluation

- Shenzhou - SinoDefenceDocument10 pagesShenzhou - SinoDefenceJunior MirandaPas encore d'évaluation

- Analysis of A Water-Propelled RocketDocument15 pagesAnalysis of A Water-Propelled Rockethecaicedo77Pas encore d'évaluation

- Energy-Maneuverability MethodsDocument5 pagesEnergy-Maneuverability Methodsaleemsalman55Pas encore d'évaluation

- Solevrcs. Smart OlevDocument11 pagesSolevrcs. Smart Olevrrg_abraxPas encore d'évaluation

- 20 REASONS WHY PLUTO SHOULD STILL BE A PLANETDocument2 pages20 REASONS WHY PLUTO SHOULD STILL BE A PLANETStevenPas encore d'évaluation

- Ae 430 3 PDFDocument14 pagesAe 430 3 PDFcrimelife6100% (1)

- NTSB Preliminary ReportDocument2 pagesNTSB Preliminary ReportRobertPas encore d'évaluation

- Angle of AttackDocument1 pageAngle of AttackSefa DoğanPas encore d'évaluation

- F 35Document4 pagesF 35Ιωάννης Γεωργίου ΜάντηςPas encore d'évaluation

- Stem Lesson Ld04 Aerodynamics SarradetDocument19 pagesStem Lesson Ld04 Aerodynamics SarradetYadana1Pas encore d'évaluation

- Isa PDFDocument7 pagesIsa PDFairsorPas encore d'évaluation

- 1 2 5 A AerodynamicforcesDocument23 pages1 2 5 A Aerodynamicforcesapi-325609547Pas encore d'évaluation

- 5 Whys: Jon Woolfrey Faculty of Engineering & Information Technology, University of Technology SydneyDocument10 pages5 Whys: Jon Woolfrey Faculty of Engineering & Information Technology, University of Technology Sydneyoscar147Pas encore d'évaluation

- Class10 English1 Unit03 NCERT TextBook EnglishEditionDocument16 pagesClass10 English1 Unit03 NCERT TextBook EnglishEditionPiklooBearPas encore d'évaluation

- NASA Space Shuttle STS-91 Press KitDocument68 pagesNASA Space Shuttle STS-91 Press KitOrion2015Pas encore d'évaluation

- ASTRID Rocket Flight TestDocument7 pagesASTRID Rocket Flight TestKhoa VũPas encore d'évaluation

- Bonanza A36 Emergency Procedures Q N ADocument2 pagesBonanza A36 Emergency Procedures Q N AalbucurPas encore d'évaluation

- Combustion Engineering-2000-Minimum Recirculation Flame Control (MRFC) Pulverized Solid Fuel Nozzle Tip PDFDocument22 pagesCombustion Engineering-2000-Minimum Recirculation Flame Control (MRFC) Pulverized Solid Fuel Nozzle Tip PDFKrozePas encore d'évaluation

- UCS Satellite Database Officialname 12-1-2018Document854 pagesUCS Satellite Database Officialname 12-1-2018Dzikrina Nailil AzkiyaPas encore d'évaluation

- Did We Land on the MoonDocument2 pagesDid We Land on the MoonKPas encore d'évaluation

- ISRO MissionDocument3 pagesISRO Missionakansha rawatPas encore d'évaluation