Académique Documents

Professionnel Documents

Culture Documents

211 Crete Filler Powder TDS

Transféré par

Syerifaizal Hj. MustaphaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

211 Crete Filler Powder TDS

Transféré par

Syerifaizal Hj. MustaphaDroits d'auteur :

Formats disponibles

211 Crete Filler Powder

DS 11-211-0913

Suitable Substrates

Concrete

Ceramic tile & stone

Concrete masonry

Brick masonry

Cement mortar beds

Drywall boards*

Cement backer board**

Cement plaster

Cement terrazzo

1. PRODUCT NAME

LATICRETE 211 Crete Filler Powder

2. MANUFACTURER/ DISTRIBUTOR

LATICRETE South East Asia Pte Ltd

No. 19 Sungei Kadut, Street 6,

Singapore 728864

Telephone: +65 6515 3028

Fax: +65 6515 3037

Internet: www.laticrete.com.sg

* Consult Laticrete Technical Services for more information.

* *Consult cement backer board manufacturer for specific installation

recommendations and to verify acceptability for exterior use.

3. PRODUCT DESCRIPTION

LATICRETE 211 Crete Filler Powder is a factory prepared

blend of carefully selected raw materials, Portland cement

and graded aggregates. Designed for use with LATICRETE

4237 Thin Set Mortar Additive to produce a high strength

adhesive for ceramic tile and stone that meets and exceeds

the requirements of national and international standards.

Uses

For the installation of ceramic tile and stone over cement

and masonry type surfaces.

Application

Interior and exterior

Wet and dry areas, walls, floors and ceilings

New and remodel construction, residential

commercial applications.

Versatilewet and dry areas, walls, floors and ceilings.

Excellent for use in swimming pools, fountains and

water features.

or

Advantages

Premixedno jobsite blending of powders required.

Safenon-flammable; Safe to store and mix.

Economicalsaves time and money.

Easy to Useno special tools required.

High Strength Formulameets and exceeds National

and International Standards.

Packaging

23kg bag; 80 bags per pallet

Colour

White and grey

Approximate Coverage

23kg of LATICRETE 211 Crete Filler Powder with 5.2 litres

6 litres of LATICRETE Thin Set Mortar Additive will yield

a coverage of 7.48.8 m using a 6 mm x 6 mm square

notch trowel.

Shelf Life

Factory sealed containers of this product are guaranteed to

be of first quality for one (1) year* if stored off the ground in

a dry area.

* High humidity will reduce the shelf life of bagged product.

Limitations

Use LATAPOXY 300 Adhesive for installing green

marble, water sensitive stone and agglomerate and

resin backed tile and stone.

Use a white thin set mortar when installing white or

light-colored stone.

Copyright 2013 Laticrete South East Asia All Rights Reserved

*Datasheets are subject to change without prior notice. For latest revision, please check www.laticrete.com.sg

Adhesives/mastics, mortars and grouts for ceramic tile,

pavers, brick and stone are not replacements for

waterproofing membranes. When a waterproofing

membrane is required, use a LATICRETE

Waterproofing Membrane

Note: Surfaces must be structurally sound, stable and rigid

enough to support ceramic/stone tile, thin brick and similar

finishes. Substrate deflection under all live, dead and

impact loads, including concentrated loads, must not

exceed L/360 for thin bed ceramic tile/brick installations or

L/480 for thin bed stone installations where L = span

length.

Cautions

Consult MSDS for more safety information.

During cold weather, protect finished work from traffic

until fully cured.

Contains portland cement and silica sand. May irritate

eyes and skin. Avoid contact with eyes or prolonged

contact with skin. In case of contact, flush thoroughly

with water.

Wait 14 days after the final grouting period before filing

water features with water at 21C.

Do not take internally. Silica sand may cause cancer or

serious lung problems. Avoid breathing dust. Wear a

respirator in dusty areas.

Keep out of reach of children.

4. TECHNICAL DATA

Applicable Standards

BS EN 1348; 1346; 1308; 12002, ANSI 118.1

Performance Properties

LATICRETE 211 Crete Filler powder mixed with

LATICRETE 4237 Latex Additive

Test

Test

Method

Tensile Adhesion

Bond Strength

(28 days)

Tensile Adhesion

after Water

Immersion

(28 days)

Tensile Adhesion

after Heat Ageing

(28 days)

Open time

(30mins)

Transverse

Deformation

Slip Resistance

Shear Bond

Strength

Specification

Results

EN 1348

1N/mm

>2.5N/mm

EN 1348

1N/mm

>1.3N/mm

EN 1348

1N/mm

>2.3N/mm

EN1346

0.5N/mm

>1.3N/mm

EN 12002

2.5mm

> 2.5mm

EN 1308

0.5mm

<0.5mm

ANSI 118.1

>1.03N/mm

>2.3N/mm

Working Properties

LATICRETE 211 Crete Filler powder

LATICRETE 4237 Thin Set Mortar Additive

0

Open Time (25 C)

0

Pot Life (25 C)

Time to Light Traffic

Wet Density

mixed

with

30 minutes

2 hours

24 hours

~1500 kg/m

Specifications subject to change without notification. Results shown are

typical but reflect test procedures used. Actual field performance will

depend on installation methods and site conditions.

5. INSTALLATION

Surface Preparation

All surfaces should be between 40F (4C) and 90F (32C)

and structurally sound, clean and free from all dirt, oil,

grease, loose peeling paint, laitance, concrete sealers or

curing compounds. Rough or uneven concrete surfaces

should be made smooth with LATICRETE Latex Portland

Cement Underlayment to provide a wood float (or better)

finish. Dry, dusty concrete slabs or masonry should be

dampened and excess water swept off. Installation may be

made on a damp surface.

Note: Latex portland cement mortars do not require a

minimum cure time for concrete slabs. All slabs must be

plumb and true to within 6 mm in 3 m. Expansion joints shall

be provided through the tile work from all construction or

expansion joints in the substrate. Follow ANSI specification

A108.01-3.7

Requirements

for

Movement

Joints:

Preparations by Other Trades or TCNA detail EJ171

Movement JointsVertical & Horizontal. Do not cover

expansion joints with mortar.

Mixing

Stir LATICRETE 211 Crete Filler Powder thoroughly before

use. Use approximately 5.2l- 6l of LATICRETE 4237 Thin

Set Mortar Additive to 23kg of LATICRETE 211 Crete Filler

Powder and place LATICRETE 4237 Thin Set Mortar

Additive in a clean plastic pail. Do not dilute.

Add LATICRETE 211 Crete Filler Powder to LATICRETE

4237 Thin Set Mortar Additive and mix to a smooth,

trowelable consistency. Allow mortar to slake 510 minutes.

Adjust consistency if necessary. Remix and apply with the

proper sized notched trowel.

Application

Apply mortar to the substrate with the flat side of the trowel,

pressing firmly to work into surface. Comb on additional

mortar with the notched side.

Copyright 2013 Laticrete South East Asia All Rights Reserved

*Datasheets are subject to change without prior notice. For latest revision, please check www.laticrete.com.sg

Note: Use the proper sized notched trowel to ensure full

bedding of the tile. It is essential that enough mortar is used

to completely cover the back of the tile with a minimum 2

mm to 3 mm uniform thickness. Spread as much mortar as

can be covered with tile in 1520 minutes. Back butter

large tiles >200 mm x 200 mm to provide full bedding and

firm support. Place tiles into wet, sticky mortar and beat in

using a beating block and rubber mallet to embed tile and

adjust level. Check mortar for complete coverage by

periodically removing a tile and inspecting bedding mortar

transfer onto back of tile.

8. MAINTENANCE

LATICRETE and LATAPOXY grouts require routine

cleaning with a neutral pH soap and water. All other

LATICRETE and LATAPOXY materials require no

maintenance but installation performance and durability

may depend on properly maintaining products supplied by

other manufacturers.

Grouting

Grout installation can occur after a minimum of 24 hours

curing time at 21C. Grout with LATICRETE 1500 Tri-Poly

Fortified Sanded Grout or LATICRETE 1600 Tri-Poly

Fortified Unsanded Grout mixed with LATICRETE 1776

Grout Enhancer. For maximum stain resistance use

LATICRETE SpectraLOCK PRO Grout.

LATICRETE South East Asia Pte Ltd

No. 19 Sungei Kadut, Street 6,

Singapore 728864

Telephone: (65) 6515-3028

Fax: (65) 6515-3037

Email: sales@laticrete.com.sg

United States Invention Patent No.: 6881768 (and other Patents)

Cold Weather Note: The setting of Portland cement

mortars and grouts are retarded by low temperatures.

Protect finished work for an extended period when installing

in cold weather. Do not set tile when surface temperature is

below freezing or when substrate is frozen.

9. TECHNICAL SERVICES/ CONTACT

Technical Assistance

Information is available by calling:

Technical and safety literature

To acquire technical and safety literature, please visit our

website at www.laticrete.com.sg

Hot Weather Note: The evaporation of moisture in

Portland cement mortars is accelerated by hot, dry

conditions. Apply to dampened surfaces and protect freshly

spread mortar and finished work when installing in

temperatures over 35C.

Cleaning

Clean tools and tile work with water while mortar is fresh.

6. AVAILABILITY AND COST

Availability

LATICRETE and LATAPOXY materials are available

worldwide. For Distributor information, call:

Telephone: +65 6515 3028

Fax: +65 6515 3037

For on-line Distributor Information, visit LATICRETE at

www.laticrete.com.sg

6. WARRANTY

LATICRETE South East Asia Pte Ltd warrants that

LATICRETE 211 Crete Filler Powder is free from

manufacturing defects and will not break down, deteriorate

or disintegrate under normal usage for a period of one (1)

year from date of purchase subject to terms and conditions

stated.

Copyright 2013 Laticrete South East Asia All Rights Reserved

*Datasheets are subject to change without prior notice. For latest revision, please check www.laticrete.com.sg

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Construction Quality ManagementDocument85 pagesConstruction Quality Managementconstruction managment91% (23)

- 2020 Global Finance Business Management Analyst Program - IIMDocument4 pages2020 Global Finance Business Management Analyst Program - IIMrishabhaaaPas encore d'évaluation

- Audio - Questions: Safety Equipment Reliability Handbook (SERH) 4th EditionDocument29 pagesAudio - Questions: Safety Equipment Reliability Handbook (SERH) 4th EditionLuc SchramPas encore d'évaluation

- Filing Labeling - Sample RoomDocument1 pageFiling Labeling - Sample RoomSyerifaizal Hj. MustaphaPas encore d'évaluation

- Issue No - 4 - Cream E-MagDocument34 pagesIssue No - 4 - Cream E-MagSyerifaizal Hj. MustaphaPas encore d'évaluation

- Guide To Performance Management - 2023Document43 pagesGuide To Performance Management - 2023Syerifaizal Hj. MustaphaPas encore d'évaluation

- Master List of Construction DrawingsDocument94 pagesMaster List of Construction DrawingsSyerifaizal Hj. MustaphaPas encore d'évaluation

- CREAM E-Magazine - Issue 1, January 2023Document24 pagesCREAM E-Magazine - Issue 1, January 2023Syerifaizal Hj. MustaphaPas encore d'évaluation

- BC Bitumen CoatingDocument3 pagesBC Bitumen CoatingSyerifaizal Hj. MustaphaPas encore d'évaluation

- Notes - The Most Common Irregular VerbsDocument1 pageNotes - The Most Common Irregular VerbsSyerifaizal Hj. MustaphaPas encore d'évaluation

- CREAM E-Magazine - Issue 1, January 2023Document24 pagesCREAM E-Magazine - Issue 1, January 2023Syerifaizal Hj. MustaphaPas encore d'évaluation

- Issue No - 4 - Cream E-MagDocument34 pagesIssue No - 4 - Cream E-MagSyerifaizal Hj. MustaphaPas encore d'évaluation

- Control of RC WorksDocument52 pagesControl of RC WorksSyerifaizal Hj. MustaphaPas encore d'évaluation

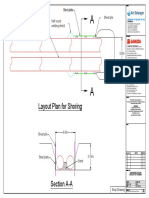

- ShoringDocument1 pageShoringSyerifaizal Hj. MustaphaPas encore d'évaluation

- Guide To Performance Management - 2023Document43 pagesGuide To Performance Management - 2023Syerifaizal Hj. MustaphaPas encore d'évaluation

- SH - Shop Drawings Tracking ListDocument6 pagesSH - Shop Drawings Tracking ListSyerifaizal Hj. MustaphaPas encore d'évaluation

- RWTP-GB-AMS-L-000263-2023 - Proposal of Test Frequency For Site ImplementationDocument3 pagesRWTP-GB-AMS-L-000263-2023 - Proposal of Test Frequency For Site ImplementationSyerifaizal Hj. MustaphaPas encore d'évaluation

- Davco Grout 280 Eco Sds en MyDocument9 pagesDavco Grout 280 Eco Sds en MySyerifaizal Hj. MustaphaPas encore d'évaluation

- MOS UnloadingDocument3 pagesMOS UnloadingSyerifaizal Hj. MustaphaPas encore d'évaluation

- BC Bitumen Coating SDS en MYDocument8 pagesBC Bitumen Coating SDS en MYSyerifaizal Hj. MustaphaPas encore d'évaluation

- Green Building Index Malaysia Assessment CriteriaDocument22 pagesGreen Building Index Malaysia Assessment CriteriaGholai KhocezkhoPas encore d'évaluation

- Jadual Minggu Orientasi SRIAZA 2023 Tahap 1Document1 pageJadual Minggu Orientasi SRIAZA 2023 Tahap 1Syerifaizal Hj. MustaphaPas encore d'évaluation

- EMS Audit ChecklistDocument4 pagesEMS Audit ChecklistSyerifaizal Hj. MustaphaPas encore d'évaluation

- QMS Audit ChecklistDocument4 pagesQMS Audit ChecklistSyerifaizal Hj. MustaphaPas encore d'évaluation

- Two Component Semi-Rigid Foam: NCL Pu Flex-2Document2 pagesTwo Component Semi-Rigid Foam: NCL Pu Flex-2Syerifaizal Hj. MustaphaPas encore d'évaluation

- SH Audit ChecklistDocument5 pagesSH Audit ChecklistSyerifaizal Hj. MustaphaPas encore d'évaluation

- Take Stocks QSHE Monthly Dashboard GBU - KPI July 2022.rev.00Document43 pagesTake Stocks QSHE Monthly Dashboard GBU - KPI July 2022.rev.00Syerifaizal Hj. MustaphaPas encore d'évaluation

- PARVIS - Lodgement Plan PDFDocument1 pagePARVIS - Lodgement Plan PDFSyerifaizal Hj. MustaphaPas encore d'évaluation

- PMP Audit ChecklistDocument6 pagesPMP Audit ChecklistSyerifaizal Hj. MustaphaPas encore d'évaluation

- ESG ScreenshotDocument1 pageESG ScreenshotSyerifaizal Hj. MustaphaPas encore d'évaluation

- Mos - P.U InjectionDocument1 pageMos - P.U InjectionSyerifaizal Hj. MustaphaPas encore d'évaluation

- Evaluation On Training EffectivenessDocument3 pagesEvaluation On Training EffectivenessSyerifaizal Hj. MustaphaPas encore d'évaluation

- Developing the cycle of maslahah based performance management system implementationDocument27 pagesDeveloping the cycle of maslahah based performance management system implementationM Audito AlfansyahPas encore d'évaluation

- Desana Texts and ContextsDocument601 pagesDesana Texts and ContextsdavidizanagiPas encore d'évaluation

- Product Data Sheet For CP 680-P and CP 680-M Cast-In Firestop Devices Technical Information ASSET DOC LOC 1540966Document1 pageProduct Data Sheet For CP 680-P and CP 680-M Cast-In Firestop Devices Technical Information ASSET DOC LOC 1540966shama093Pas encore d'évaluation

- Service Manual: Precision SeriesDocument32 pagesService Manual: Precision SeriesMoises ShentePas encore d'évaluation

- Why Choose Medicine As A CareerDocument25 pagesWhy Choose Medicine As A CareerVinod KumarPas encore d'évaluation

- Key Fact Sheet (HBL FreedomAccount) - July 2019 PDFDocument1 pageKey Fact Sheet (HBL FreedomAccount) - July 2019 PDFBaD cHaUhDrYPas encore d'évaluation

- EA Linear RegressionDocument3 pagesEA Linear RegressionJosh RamosPas encore d'évaluation

- KPUPDocument38 pagesKPUPRoda ES Jimbert50% (2)

- Embryology-Nervous System DevelopmentDocument157 pagesEmbryology-Nervous System DevelopmentGheavita Chandra DewiPas encore d'évaluation

- Master SEODocument8 pagesMaster SEOOkane MochiPas encore d'évaluation

- Lab StoryDocument21 pagesLab StoryAbdul QadirPas encore d'évaluation

- C4 ISRchapterDocument16 pagesC4 ISRchapterSerkan KalaycıPas encore d'évaluation

- Google Earth Learning Activity Cuban Missile CrisisDocument2 pagesGoogle Earth Learning Activity Cuban Missile CrisisseankassPas encore d'évaluation

- Vector 4114NS Sis TDSDocument2 pagesVector 4114NS Sis TDSCaio OliveiraPas encore d'évaluation

- Unit 14 Ergonomics Design: AND ProductDocument24 pagesUnit 14 Ergonomics Design: AND ProductRämêşh KątúřiPas encore d'évaluation

- STS Prelim ExamDocument2 pagesSTS Prelim ExamMychie Lynne MayugaPas encore d'évaluation

- ALXSignature0230 0178aDocument3 pagesALXSignature0230 0178aAlex MocanuPas encore d'évaluation

- Mutual Fund PDFDocument22 pagesMutual Fund PDFRajPas encore d'évaluation

- Extrajudicial Settlement of Estate Rule 74, Section 1 ChecklistDocument8 pagesExtrajudicial Settlement of Estate Rule 74, Section 1 ChecklistMsyang Ann Corbo DiazPas encore d'évaluation

- Hydraulics Engineering Course OverviewDocument35 pagesHydraulics Engineering Course Overviewahmad akramPas encore d'évaluation

- Critical Methodology Analysis: 360' Degree Feedback: Its Role in Employee DevelopmentDocument3 pagesCritical Methodology Analysis: 360' Degree Feedback: Its Role in Employee DevelopmentJatin KaushikPas encore d'évaluation

- Link Ratio MethodDocument18 pagesLink Ratio MethodLuis ChioPas encore d'évaluation

- (123doc) - Chapter-24Document6 pages(123doc) - Chapter-24Pháp NguyễnPas encore d'évaluation

- 7 Aleksandar VladimirovDocument6 pages7 Aleksandar VladimirovDante FilhoPas encore d'évaluation

- I Will Be Here TABSDocument7 pagesI Will Be Here TABSEric JaoPas encore d'évaluation

- Ovr IbDocument27 pagesOvr IbAriel CaresPas encore d'évaluation

- Draft SemestralWorK Aircraft2Document7 pagesDraft SemestralWorK Aircraft2Filip SkultetyPas encore d'évaluation

- PNBONE_mPassbook_134611_6-4-2024_13-4-2024_0053XXXXXXXX00 (1) (1)Document3 pagesPNBONE_mPassbook_134611_6-4-2024_13-4-2024_0053XXXXXXXX00 (1) (1)imtiyaz726492Pas encore d'évaluation