Académique Documents

Professionnel Documents

Culture Documents

Linde Hydrostatic Drive 7 07 PDF

Transféré par

John SimmondsDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Linde Hydrostatic Drive 7 07 PDF

Transféré par

John SimmondsDroits d'auteur :

Formats disponibles

L738 Spotlight On - Linde Hydrostatic Drive.

qxd

13/7/07

10:17

Page 2

Spotlight on.

Linde hydrostatic drive.

Linde Material Handling

Excellence at work.

Printed in United Kingdom. EVC5232/7/07

Linde Material Handling (UK) Ltd

Kingsclere Road, Basingstoke, Hampshire RG21 6XJ

Tel +44(0)1256 342000, Fax +44(0)1256 342923

www.linde-mh.co.uk, enquiries@linde-mh.co.uk

L738 Spotlight On - Linde Hydrostatic Drive.qxd

13/7/07

10:17

Page 4

Hydrostatic drive. Made by Linde.

Leading-edge fork lift truck engineering is inseparably linked to the Linde

hydrostatic drive concept. Not surprisingly, it is acknowledged as the

ultimate drive system superior to any other to achieve maximum lift

truck performance.

Linde has refined hydrostatic drive to match the working conditions of

modern day fork lift trucks perfecting it to meet every requirement for

handling ease, durability, efficiency and ergonomic operation.

It is this technology on which Linde forklifts have built five decades of

continuing success. Users everywhere appreciate the proven fact that Linde

hydrostatic drive moves more in the world of materials handling by

significantly reducing both physical demands and work cycle times.

How does hydrostatic drive work? What is it about hydrostatic drive that

gives Linde trucks their outstanding advantages and Linde truck users a

competitive edge? Read on for the answers.

L738 Spotlight On - Linde Hydrostatic Drive.qxd

13/7/07

10:17

Page 6

Fixed swashplate

Wheel motors

Wheel motors

Piston and slipper

Cylinder block

Accelerator pedals

Accelerator pedals

Engine

Engine

Hydrostatic pump

Tilting swashplate

(forward drive

position)

Hydrostatic pump

Tilting swashplate

(forward drive

position)

Cylinder block joined to shaft

Direction Selection.

F1

Sliding motion produces rotation

by the elementary principle of the

inclined plane

Piston

F2

Resulting rotation

Swashplate

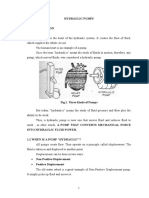

The hydrostatic pump, which basically operates in a similar way to a hydrostatic

motor, differs in one key respect. Because the angle of the swashplate can be

altered, the rate at which oil is delivered by the pump can be controlled

continuously and precisely independently of the speed at which the engine

drives the pump.

When the truck is stationary, the swashplate is in neutral position where the

pistons do not stroke in and out. As a result, no oil is pumped and no power is

transmitted. Pressing the forward accelerator pedal changes the angle of the

swashplate and the pump starts delivering the flow of oil needed to drive the

wheel motors forward. As the swashplate is tilted further, the truck speed

increases.

Changing direction of travel is just as easy and convenient. Pressing the reverse

accelerator pedal tilts the swashplate in the opposite direction, reversing the inlet and

outlet ports so that the oil flow drives the hydraulic motors in the other direction. The

operation is seamless with no adverse effect on the transmission as it transfers

smoothly and safely from maximum speed forward through neutral to maximum speed

in reverse.

L738 Spotlight On - Linde Hydrostatic Drive.qxd

The smooth revolution.

13/7/07

10:17

Page 9

Design advantage.

Durability and efficiency.

Mechanical breakdowns and high servicing expense are a thing of the past.

Durability and efficiency are here to stay with Linde hydrostatic drive.

No differential. Because the flow of oil delivered by the pump is evenly

divided between the two hydraulic motors, no differential is needed for

power transmission.

The H 14 H 35 Linde models are equipped with the unique Linde

hydrostatic direct drive. Two hydraulic wheel motors integrated in

the front drive axle transfer rotation of the output shaft direct to the

wheels, ensuring precise and perfectly controlled transmission of

power.

Oil pressure directly converted to

rotation for forward or reverse travel.

The revolutionary feature of this innovative technology is that the

pistons of the wheel motors are fitted in a rotating cylinder block

and ride on a fixed swashplate. Oil pressure from the pump acting

on the motor pistons results in rotary motion, almost entirely

without friction, which is transmitted to the cylinder block. Wear is

minimised by an oil film between the piston and swashplate of the

axial-piston pump that prevents metal to metal contact.

Speed and direction of travel are controlled by the hydrostatic

pump driven by the trucks engine.

3 Pressure of oil flow controls the output torque.

3 Rate of oil flow controls the truck speed.

3 Direction of oil flow controls the travel direction.

No conventional service brake. Hydrostatic drive brakes the truck by halting

the flow of oil. As the accelerator pedal is released, the truck progressively

and smoothly decelerates to a stop.

No gearbox. Infinitely variable control of oil flow rate and seamless change

of travel direction made possible by Linde hydrostatic drive eliminates the

need for a mechanical gearbox.

No clutch. The hydraulic pump is set to neutral position, with the accelerator

pedals eliminating the need for a clutch.

Linde forklift

Conventional forklift

Diesel/LPG engine

Diesel/LPG engine

Hydraulic pump

Clutch

Hydraulic motors

Powershift

Reduction gearing

Gearbox

Wheels

Gearshift

Reduction gearing

3 Fewer components,

loss-free

power transmission

Differential

Brakes

Wheels

Page 12

No inching pedal.

No conventional brakes.

Hands and feet normally have a lot to do when operating a fork lift truck.

Much of it has to be done more or less simultaneously. Training and

experience can reduce the physical input and Linde hydrostatic drive has

an even more significant impact in this area.

Simplicity.

The hands also have simpler tasks. The left hand operates the compact

steering wheel while the right hand actuates fingertip controls for all mast

and fork functions. Complete separation of the travelling and load handling

functions drastically reduces the number of feet and

hand movements required for each load

handling cycle and enables the operator to

concentrate fully on the immediate task,

manoeuvre more accurately and lift or

lower with greater precision.

Picking up a load, transporting it,

putting it down and making the return

run requires 58 actions from the

operator on a forklift equipped with

conventional gearbox, but only 28 on a

Linde forklift!

steer

Travelling forward and in reverse is controlled by two separate accelerator

pedals. The operator of a Linde forklift is able to keep both feet on the

accelerator pedals. The brake pedal is only actuated in an emergency

situation, as Linde hydrostatic drive automatically applies the brakes as the

accelerator pedal is released. Handling of the truck itself is responsive and

precise. The operator always feels in full control with minimum physical

input required.

drive reverse

10:17

lift/lower

13/7/07

drive forward

L738 Spotlight On - Linde Hydrostatic Drive.qxd

L738 Spotlight On - Linde Hydrostatic Drive.qxd

13/7/07

10:17

Page 14

No slipping.

No spinning.

Without Linde hydrostatic drive the operator must go through many unnecessary

lifting and manoeuvring operations, which costs time; and time is money! Linde

hydrostatic drive keeps a Linde forklift squarely on track, accelerates quicker and

gets road transport vehicles unloaded much more efficiently. This is achieved

without working faster; its just that the Linde truck does exactly what the operator

wants it to do.

With Linde hydrostatic drive the forklift remains securely on track and

manoeuvres with utmost precision. Absence of a gearbox results in maximum

efficiency of every truck movement. That adds up to greater reliability in load

handling with distinctly better productivity.

Benefits all around.

Fuel economy is improved by as much as 30 per cent depending on the

application because of the engine running within the optimum range of rpm at

all times and its output being converted fully into travel motion.

Oil change intervals are only every 6,000 operating hours as a result of the

almost wear-free working characteristics of Linde hydrostatic drive. The oil

lasts six times longer than with hydrodynamic drive.

Long life and low maintenance costs are achieved owing to the elimination of

conventional mechanical consumable parts from the hydrostatic drive train.

Linde forklifts load/unload more delivery vehicles in less time,

using less fuel and with less maintenance requirements.

Because it takes up to 20 per cent less time to do the same job with the twin

accelerator pedals on a Linde hydrostatic drive forklift, there is less strain on

both the operator and machine.

Vous aimerez peut-être aussi

- Trans Filter Guide PDFDocument2 pagesTrans Filter Guide PDFJohn SimmondsPas encore d'évaluation

- Weber3236adjust PDFDocument1 pageWeber3236adjust PDFJohn SimmondsPas encore d'évaluation

- 4a FeDocument16 pages4a FeJohn Simmonds78% (18)

- 2002 System Wiring Diagrams Toyota CorollaDocument41 pages2002 System Wiring Diagrams Toyota Corollakabanek75% (4)

- Komatsu PC128UU-2 Shop Manual PDFDocument623 pagesKomatsu PC128UU-2 Shop Manual PDFJohn Simmonds93% (46)

- HY30 8200 Truck Pumps Uk 112 WebDocument76 pagesHY30 8200 Truck Pumps Uk 112 WebDhamotharan ManoharanPas encore d'évaluation

- Adjust pneumatic truck pedal heightDocument6 pagesAdjust pneumatic truck pedal heightAndrey TsymbalovPas encore d'évaluation

- Jrc-Jcy-1800 VDR Instruction ManualDocument90 pagesJrc-Jcy-1800 VDR Instruction ManualJude Jerry Pereira100% (3)

- Electro-Hydraulic Actuator Type PVEP / PVEP-F TechDocument16 pagesElectro-Hydraulic Actuator Type PVEP / PVEP-F TechHYDRAULICGURUPas encore d'évaluation

- Form Commisioning SANY - SKT 90S 2 LBRDocument1 pageForm Commisioning SANY - SKT 90S 2 LBRj.andry. dprPas encore d'évaluation

- 5 IQANdesign Introduction System Layout and Basic FunctionDocument24 pages5 IQANdesign Introduction System Layout and Basic FunctionDinh SangPas encore d'évaluation

- 118-7126-Brokk-Katalog 2018 19 En14Document72 pages118-7126-Brokk-Katalog 2018 19 En14Luis Martín Torres MuhechPas encore d'évaluation

- Disassembly and AssemblyDocument46 pagesDisassembly and AssemblyTransportation MaintanancePas encore d'évaluation

- TH 417d en (19b) PDFDocument4 pagesTH 417d en (19b) PDFArsène TIA MANPas encore d'évaluation

- I-Flex System Error Code Data Error Code Error Possible Cause Elimination E01Document10 pagesI-Flex System Error Code Data Error Code Error Possible Cause Elimination E01vitor santosPas encore d'évaluation

- Huolto-Ohje Haulotte Star 8-10 Eng (Osa 1) PDFDocument197 pagesHuolto-Ohje Haulotte Star 8-10 Eng (Osa 1) PDFBaciu NicolaePas encore d'évaluation

- Maintenance and Lubrication EN PDFDocument38 pagesMaintenance and Lubrication EN PDFDaniel Castillo PeñaPas encore d'évaluation

- ht26rt oDocument280 pagesht26rt oمحمد مباركPas encore d'évaluation

- JCPT0808 JCPT1612DCB Operatots ManualDocument99 pagesJCPT0808 JCPT1612DCB Operatots ManualJames GamingPas encore d'évaluation

- Toyota Trouble Code Info: 96 & Later Are OBD2 Systems and Require A ScantoolDocument8 pagesToyota Trouble Code Info: 96 & Later Are OBD2 Systems and Require A ScantoolCesar Vega100% (1)

- Operating and Maintenance Instructions: Self-Propelled Access Platforms Ha15D - Ha15DxDocument50 pagesOperating and Maintenance Instructions: Self-Propelled Access Platforms Ha15D - Ha15DxStelian CrisanPas encore d'évaluation

- Liebherr R 924 Excavator RadiatorDocument12 pagesLiebherr R 924 Excavator RadiatorLiebherr0% (1)

- Dokumen - Tips - Hiab 071 Operators Manual Tervensbullsten 071 Operators Manual Hiab 140 PartsDocument3 pagesDokumen - Tips - Hiab 071 Operators Manual Tervensbullsten 071 Operators Manual Hiab 140 PartsOctavio50% (2)

- Hettich Rotanta 460 - Repair ManualDocument92 pagesHettich Rotanta 460 - Repair ManualService Medisal100% (1)

- Lidos Lwe Webservice: LTM 1120-1-015 Z23358 Z23358 2970 913948608Document5 pagesLidos Lwe Webservice: LTM 1120-1-015 Z23358 Z23358 2970 913948608mohamedPas encore d'évaluation

- 6 PDFDocument4 pages6 PDFHernan LopezPas encore d'évaluation

- Suzuki Swift - Vacuum - Diagrams PDFDocument5 pagesSuzuki Swift - Vacuum - Diagrams PDFJohn SimmondsPas encore d'évaluation

- Electric Motors 198 Semptember 2012Document184 pagesElectric Motors 198 Semptember 2012Aleksandar KerekeshPas encore d'évaluation

- Narrow AisleDocument6 pagesNarrow AislealejandroquiodettisPas encore d'évaluation

- Article - Screw Threads DesignDocument16 pagesArticle - Screw Threads DesignPRADEEPPas encore d'évaluation

- Engineering Specification For MV SwitchgearDocument21 pagesEngineering Specification For MV SwitchgearSundaresan SabanayagamPas encore d'évaluation

- 1 984-EkskavatoraDocument225 pages1 984-EkskavatoraericPas encore d'évaluation

- H2 Power Bank ManualDocument19 pagesH2 Power Bank ManualMarcantonio Infascelli100% (1)

- Solid Rivets ComparisonDocument3 pagesSolid Rivets ComparisonManoj ManoharanPas encore d'évaluation

- Wheel Loader L 586: Product InformationDocument16 pagesWheel Loader L 586: Product InformationcraigPas encore d'évaluation

- Diesel Counterbalance TrucksDocument9 pagesDiesel Counterbalance Truckshocine gherbiPas encore d'évaluation

- Essential Forklift Servicing and Maintenance GuideDocument2 pagesEssential Forklift Servicing and Maintenance GuideYe Min HtikePas encore d'évaluation

- BHP Puller Sets Instruction and Repair Parts SheetDocument40 pagesBHP Puller Sets Instruction and Repair Parts SheetAnonymous tFhBRs0% (1)

- Руководство по ремонту дизельного двигателя D 934 A6-D939 A6 (Workshop manual)Document197 pagesРуководство по ремонту дизельного двигателя D 934 A6-D939 A6 (Workshop manual)МаксимPas encore d'évaluation

- HPV 02 VariablePump enDocument36 pagesHPV 02 VariablePump enSorinPas encore d'évaluation

- New Holland TC29DA, TC33DA Service Repair ManualDocument21 pagesNew Holland TC29DA, TC33DA Service Repair ManualggjjjjotonesPas encore d'évaluation

- Maxiforce 2009 CatalogDocument228 pagesMaxiforce 2009 CatalogMotokoy Sprekitik Takoykoy100% (1)

- Poclain Hydraulics Selection GuideDocument44 pagesPoclain Hydraulics Selection GuideM S GokulPas encore d'évaluation

- Powerful Demag CC 1500 CraneDocument42 pagesPowerful Demag CC 1500 Cranemartin_jaitmanPas encore d'évaluation

- Welcome To Our Specification Guide: Crane/Lifting Equipment IndexDocument305 pagesWelcome To Our Specification Guide: Crane/Lifting Equipment Indexsabah8800Pas encore d'évaluation

- Tecnord JHM DatasheetDocument10 pagesTecnord JHM Datasheetfrancisco santiago gallardoPas encore d'évaluation

- E 314C SpecalogDocument16 pagesE 314C SpecalogArmando Muñoz100% (1)

- Orwak 5030Document8 pagesOrwak 5030Enrique MurgiaPas encore d'évaluation

- PK24001 High Performance Cost-Efficient All-Rounder Knuckle-Boom CraneDocument2 pagesPK24001 High Performance Cost-Efficient All-Rounder Knuckle-Boom CraneHeiner JaimesPas encore d'évaluation

- LT 1055 SuperestruturaDocument132 pagesLT 1055 SuperestruturaHernan Reyes CarbonellPas encore d'évaluation

- LP 02 KTPK Outline RodadoDocument2 pagesLP 02 KTPK Outline RodadoMARIO DEL PINO MUÑOZPas encore d'évaluation

- Eaton Series 10 Char Lynn Power Steering Wide Angle Control Catalog C Stcu Ts008 e en UsDocument20 pagesEaton Series 10 Char Lynn Power Steering Wide Angle Control Catalog C Stcu Ts008 e en UsRicardo ArzolaPas encore d'évaluation

- Dijagram Nosivosti Liebherr 1040.1Document4 pagesDijagram Nosivosti Liebherr 1040.1Slobodan NocajPas encore d'évaluation

- 03 Final Hydraulic Pumps (Module-III)Document19 pages03 Final Hydraulic Pumps (Module-III)Pyae Phyoe AungPas encore d'évaluation

- Teagle Tomahawk Common Backplate 404 404m 4040 505 505m 5050 Issue 1111Document44 pagesTeagle Tomahawk Common Backplate 404 404m 4040 505 505m 5050 Issue 1111regivaldojrPas encore d'évaluation

- Hiab XS377CLX Loadchart CWDocument2 pagesHiab XS377CLX Loadchart CWJuan Diego ArizabalPas encore d'évaluation

- Information Bulletin - MAC 25 Allowable Wind SpeedDocument1 pageInformation Bulletin - MAC 25 Allowable Wind SpeedStuart EdwardsPas encore d'évaluation

- Linde Ex H20-30Document2 pagesLinde Ex H20-30victorg107270Pas encore d'évaluation

- Stage V XF Series 1.5t-X5.5t Operation Manual 2020-06 ENDocument110 pagesStage V XF Series 1.5t-X5.5t Operation Manual 2020-06 ENmirko coppiniPas encore d'évaluation

- Maintenance ManualDocument78 pagesMaintenance ManualbannetPas encore d'évaluation

- Manitou MHT 1490 (EN)Document4 pagesManitou MHT 1490 (EN)ManitouPas encore d'évaluation

- LIEBHERR (2007 2008) BaumamagazinDocument60 pagesLIEBHERR (2007 2008) BaumamagazinJanko JankovicPas encore d'évaluation

- r914b Us NTB - 7376 0Document24 pagesr914b Us NTB - 7376 0FranciscoOliveira100% (1)

- 700609EN A 0616 Diesel Platforms Range-BDDocument40 pages700609EN A 0616 Diesel Platforms Range-BDManitou100% (1)

- Haulotte HA 260PX PDFDocument66 pagesHaulotte HA 260PX PDFromaldoagurtoPas encore d'évaluation

- Atlas Copco XATS 156 Dd Air CompressorDocument4 pagesAtlas Copco XATS 156 Dd Air Compressorusman zafarPas encore d'évaluation

- Special ToolsDocument24 pagesSpecial ToolsSuka MuttAstroPas encore d'évaluation

- Madill 800Document3 pagesMadill 800Skyler Franklin0% (1)

- 6614 SKF Agri Hub For Tillage DisksDocument8 pages6614 SKF Agri Hub For Tillage DisksAlvaro MunozPas encore d'évaluation

- Mini-Crawler Crane: Operation & Maintenance ManualDocument191 pagesMini-Crawler Crane: Operation & Maintenance ManualAli KuliPas encore d'évaluation

- Subject: Recommended Oils List: Lift Truck Series All Trucks - See Chart April 1, 2006 CODE 7500Document6 pagesSubject: Recommended Oils List: Lift Truck Series All Trucks - See Chart April 1, 2006 CODE 7500murshed audatallaPas encore d'évaluation

- Serie 391 H16-20 BROCHUREDocument8 pagesSerie 391 H16-20 BROCHUREOlvil MovilPas encore d'évaluation

- Mau Cham Cong NV 5679Document1 pageMau Cham Cong NV 5679Thien NguyenPas encore d'évaluation

- Tecbrake Installation Guide For Caterpillar 3406, 3406B and 3406CDocument18 pagesTecbrake Installation Guide For Caterpillar 3406, 3406B and 3406CdimitriapPas encore d'évaluation

- Noregon JPRO Catalog PDFDocument8 pagesNoregon JPRO Catalog PDFJohn SimmondsPas encore d'évaluation

- Suspension and Axle PDFDocument57 pagesSuspension and Axle PDFJohn SimmondsPas encore d'évaluation

- Section : Operation of Instruments and ControlsDocument10 pagesSection : Operation of Instruments and ControlsJohn SimmondsPas encore d'évaluation

- Section : Operation of Instruments and ControlsDocument10 pagesSection : Operation of Instruments and ControlsJohn SimmondsPas encore d'évaluation

- AKO-14012 AKO-14023, AKO-14123,: 1411H210 Thermometers and Thermostats With 1 Probe and 1 Relay: AKO-140XX, AKO-141XXDocument2 pagesAKO-14012 AKO-14023, AKO-14123,: 1411H210 Thermometers and Thermostats With 1 Probe and 1 Relay: AKO-140XX, AKO-141XXmartinPas encore d'évaluation

- Eetarp IPS E900 Series Datasheet PDFDocument11 pagesEetarp IPS E900 Series Datasheet PDFWasleyPas encore d'évaluation

- 2021 Multi Split Catalogue Final MayDocument24 pages2021 Multi Split Catalogue Final MayMinh Phát Điều HoàPas encore d'évaluation

- Valve Clearance PDFDocument10 pagesValve Clearance PDFspammed Scribd userPas encore d'évaluation

- Spa 308 220VDocument15 pagesSpa 308 220VMarius BalicaPas encore d'évaluation

- Data Sheet 3KC9000-8CL10: ModelDocument5 pagesData Sheet 3KC9000-8CL10: ModelMARIAMPas encore d'évaluation

- Hfo Heating System P&idDocument1 pageHfo Heating System P&idAbdur RehmanPas encore d'évaluation

- RobotsDocument8 pagesRobotsRicardo Miranda Jr.0% (1)

- Suntan: Metallized Polypropylene Film Capacitor - X2Document2 pagesSuntan: Metallized Polypropylene Film Capacitor - X2MAgnoNogueiraPas encore d'évaluation

- Frenic Lift Lm2a Instruction Manual Inr Si471894f e 3ph 230v IncludedDocument75 pagesFrenic Lift Lm2a Instruction Manual Inr Si471894f e 3ph 230v IncludedBienvenido Cascales RodríguezPas encore d'évaluation

- TCEW: Guide to Electrical Wiring Types and Termination MethodsDocument17 pagesTCEW: Guide to Electrical Wiring Types and Termination MethodsnpfhPas encore d'évaluation

- X15 - Humo AzulDocument9 pagesX15 - Humo AzulmttoguboPas encore d'évaluation

- Service 3121249 11-30-10 Global EnglishDocument268 pagesService 3121249 11-30-10 Global EnglishLuis Villafuerte LeandroPas encore d'évaluation

- Rectifier Diodes SKN 20 SKR 20 Skna 20 SKN 26 SKR 26: RSM Frms RRMDocument4 pagesRectifier Diodes SKN 20 SKR 20 Skna 20 SKN 26 SKR 26: RSM Frms RRMMalco BaldovinoPas encore d'évaluation

- Camera Accessories - Quick Selection GuideDocument39 pagesCamera Accessories - Quick Selection GuidecarlosPas encore d'évaluation

- M 1Document59 pagesM 1KEEP CALM studiosPas encore d'évaluation

- M.V Arabian Sea Electrical Repairs For Lay Up 2017: RS No. Work Specification QTY RemarksDocument3 pagesM.V Arabian Sea Electrical Repairs For Lay Up 2017: RS No. Work Specification QTY RemarksMariyath Muraleedharan KiranPas encore d'évaluation

- Cat 336FL ExcavatorDocument36 pagesCat 336FL ExcavatorKeron TrotzPas encore d'évaluation

- Motores Auxiliares Marinos Cat Mma c18 Lehm8147 00Document4 pagesMotores Auxiliares Marinos Cat Mma c18 Lehm8147 00Manuel Armando Salazar BravoPas encore d'évaluation

- Micropump 380manualDocument20 pagesMicropump 380manualمحمود سلحشورPas encore d'évaluation

- Explore Our 2018 Motorcycle CollectionDocument8 pagesExplore Our 2018 Motorcycle CollectionToni Kuzmanić100% (1)

- Battery Operated Grease GunDocument2 pagesBattery Operated Grease GunMamobaPas encore d'évaluation

- Gas Lift Válvula PilotoDocument2 pagesGas Lift Válvula PilotoFabio ParceroPas encore d'évaluation

- 4K Security Camera Kits and AccessoriesDocument6 pages4K Security Camera Kits and AccessoriesGlenn KapzPas encore d'évaluation

- AT400T41T M.Y. 2013 Cursor 13 Euro ViDocument16 pagesAT400T41T M.Y. 2013 Cursor 13 Euro ViCesar MartinezPas encore d'évaluation