Académique Documents

Professionnel Documents

Culture Documents

Maintenance of Fire Suppression Systems

Transféré par

Raja Prathap SinghCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Maintenance of Fire Suppression Systems

Transféré par

Raja Prathap SinghDroits d'auteur :

Formats disponibles

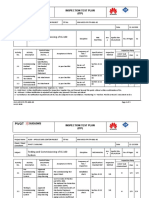

GUIDANCE NOTES

Maintenance of Fire Suppression Systems

Inspection type - British Standards

BS5306: Part 4 : 2001

BS5306: Part 5 : Section 5.1 :1992

BS5306: Part 5 : Section 5.2 :1984

BS7273-1: 2000

BS5839-1: 2002

BS14520: Part 1 : 2006

Carbon Dioxide systems - Fire extinguishing installations and equipment on premises

*Halon Systems - Specification for Halon 1301 total flooding systems

*Halon Systems - Fixed extinguishing installations - Halon 1211 total flooding systems

Electrical actuation of gaseous total flooding extinguishing systems.

Fire Detection and fire alarm systems for buildings

HFC & IG Gaseous fire extinguishing systems - Physical properties & system design

*Note - Under EC Regulation 2037/2000 and Statutory Instrument 528/2002 Halon is to be phased out and Halon fire protection

systems must be decommissioned be 31st December 2003. Should advice be required into the decommissioning procedures and

alternative systems, please contact a member of our Service department on (01282) 717171

BS7273-1/; 2000 (Maintenance - section 10)

Routine testing by the USER

10.1 The user of the installation should ensure that the system is in good working order at all times.

10.2 The user should undertake responsibility for daily and weekly attention in accordance with BS5839-1:2002 section 6 and

BS5306-4:2001 clause 8 as appropriate. Special care should be exercised and training should be given by the service

organisation (Protec fire detection PLC). Should training be required please contact a member of our service department.

10.3 The user of the equipment should carry out weekly visual examination of the fire protection equipment. This should include an

examination of all pressure gauges and a general check that all operating controls are both properly set and accessible and that

all indicators are functioning. It is important that pipework and nozzles are visually checked to ensure that they are not damaged

or obstructed and remain in the designed position.

Inspection & Testing by Protec Fire Detection PLC

10.4 The fire detection system should be inspected and tested in accordance with BS5839-1: 2002 (section 6) 45.2; 45.3 and 45.4

(detailed below). The extinguishing system should be inspected in accordance with BS5306-4: 2001 clause 8 as appropriate.

Records of all inspections and tests, should be maintained (system logbook).

10.5 The extinguishing part of the installation should be inspected at least twice a year by a competent engineer (Protec Fire

detection PLC) and an inspection report made.

10.6 Any extension or alteration to the installation should be carried out by the service organisation.

10.7 A routine maintenance contract for the fire detection system and alarm element of the installation should include during each

visit, the operation of the time delay sounder, the discharge sounder and the operation of the disabled facility in order to test the

system and familiarise the occupier of the protected space.

BS5839-1: 2002 (section 6)

45.2 Recommendation for quarterly inspection of vented batteries

45.3 Recommendation for periodic inspection and test of the system

The period between successive inspection and service visits should be based upon a risk assessment, taking into the type of

system installed, and the environment in which it operates. The period between successive inspection and service visits should

not exceed six months.

45.4 Recommendations for inspection and test of the system over a 12 month period This is in addition to the work recommended in

45.3 During our periodic maintenance visits, the recommendations detailed in section 45.3 will be carried out with a percentage of the

devices tested. Over the periodic maintenance visits, the requirements detailed in section 45.4 will be achieved. Details of the

section tested and percentage of devices will be recorded on this certificate.

The period between successive inspection and service visits will be determined by a risk assessment and the type of system

installed.

BS14520 : Part 1: (2006)

9.2.1

General

9.2.1.1 At least annually, or more frequently as required by the authority, all systems shall be thoroughly inspected and tested for

proper operation by competent personnel.

9.2.1.2 The inspection report with recommendations shall be filed with the owner.

9.2.1.3 At least every 6 months, the container contents shall be checked as follows.

a) Liquefied gases: for halocarbon extinguishants, if a container shows a loss in extinguishant quantity of more than 5% or a loss in

pressure (adjusted for temperature) of more than 10%, it shall be refilled or replaced.

b) Non-liquefied gases: for inert gas extinguishants that are not liquiefied, pressure is an indication of extinguishant quantity.Unless

otherwise specified by the authority, if an inert gas extinguishant container shows a loss in pressure (adjusted for temperature) of more

than 5%, it shall be refilled or replaced. Where container pressure gauges or weight-monitoring devices are used for this purpose, they

shall be compared to a seperate calibrated device at least annually.

BS5306 : Part 4 (Clause 8 - Maintenance)

Every installation shall be inspected at least twice a year by a competent person (Protec Fire Detection PLC).

All gas containers shall be periodically maintained, inspected and tested in accordance with BS5430: Part 1.

Protec Fire Detection plc

Issue 0

Commentary and recommendations on clause 8.

It is essential that the system be kept in good working order at all times with this responsibility being in no way diminished by any

periodic or regular servicing carried out. It is recommended that a weekly program of inspection or, more frequent if necessary, is

carried out to ensure that components are free from dust and dirt that might impair the efficiency of the system. This also should

include an inspection of the pipework and nozzles to ensure that they are not obstructed, and remain in the designed position, and to

ensure that all operating controls are properly set and that components have not been damaged.

Cylinder Inspections

In accordance with BS EN 1968:2002 cylinders must be pressure tested every 10 years.These tests are not performed under our

standard service contract agreement, however, these tests can be undertaken by Protec as an addition to the service contract.

Enclosure Integrity Test

System integrity tests are not performed under our standard service contract agreement, however the required integrity test can be

undertaken by Protec Fire Detection Plc as an addition to the service contact.

Additional services - Protec fire detection PLC offer a wide range of maintenance which includes the following systems:

Fire Alarms/Detection

Emergency lighting

CCTV

Voice evacuation systems

Air Sampling

Intruder systems

Fire extinguishers

Public address systems

For a free quotation, please contact our customer services on tel: (01282) 717171

Protec Fire Detection plc

Issue 0

Vous aimerez peut-être aussi

- Emergency Action Plan - Sample PlanDocument12 pagesEmergency Action Plan - Sample Planug201311025100% (1)

- Method Statement - Fire AlarmDocument9 pagesMethod Statement - Fire AlarmiamajumalPas encore d'évaluation

- Hordes - DevastationDocument95 pagesHordes - DevastationMauricio Camacho Dorado100% (8)

- Daniel+madison - Burn PDFDocument44 pagesDaniel+madison - Burn PDFMike Josh67% (3)

- The Wargame by Charles GrantDocument6 pagesThe Wargame by Charles GrantA Jeff Butler100% (3)

- Managing Kuwait Oil Fields Reconstruction Project: Group-02Document5 pagesManaging Kuwait Oil Fields Reconstruction Project: Group-02Tarun TaruPas encore d'évaluation

- Fire Alarm and Detection System ProcedureDocument7 pagesFire Alarm and Detection System ProcedureProjects aissol100% (1)

- Quality Control PlanDocument8 pagesQuality Control PlanBharat jangirPas encore d'évaluation

- Fire Alarm System Record of CompletionDocument4 pagesFire Alarm System Record of CompletionJohn simpsonPas encore d'évaluation

- FDNY High Rise OpsDocument51 pagesFDNY High Rise OpsFlorin Caragea100% (3)

- Fire Drill Audit ChecklistDocument5 pagesFire Drill Audit ChecklistGoh Boon TiongPas encore d'évaluation

- Method of Statement For Bus DuctDocument11 pagesMethod of Statement For Bus DuctTalha AltafPas encore d'évaluation

- Pre-Action Deluge System Test QCDD FormDocument1 pagePre-Action Deluge System Test QCDD FormMahmoud HassanPas encore d'évaluation

- Method of Statement For Bus Duct InstallationDocument11 pagesMethod of Statement For Bus Duct InstallationMohd MuksinPas encore d'évaluation

- Fire Fighting System Inspection ReportDocument6 pagesFire Fighting System Inspection ReportIchsan Bahril100% (1)

- Inspection, Testing and Maintenance of Fire Alarm System ChecklistDocument2 pagesInspection, Testing and Maintenance of Fire Alarm System ChecklistjajakaPas encore d'évaluation

- 12 Fire Protection SystemDocument8 pages12 Fire Protection SystemunnicyriacPas encore d'évaluation

- Preventive Maintenance PlanDocument16 pagesPreventive Maintenance PlanAugust Hari0% (1)

- 1 Introduction Fire Alarm System PDFDocument66 pages1 Introduction Fire Alarm System PDFRaymundus Rizki DomoPas encore d'évaluation

- FACP MethodologyDocument6 pagesFACP MethodologyNobita NobiPas encore d'évaluation

- Fire Alarm Presubmittal Checklist - 201204161022048230Document2 pagesFire Alarm Presubmittal Checklist - 201204161022048230JeffersonPas encore d'évaluation

- Furnace Explosion in CFBC BoilersDocument6 pagesFurnace Explosion in CFBC BoilersHardik Kumar MendparaPas encore d'évaluation

- FDAS Testing & Commissioning MethodologyDocument5 pagesFDAS Testing & Commissioning MethodologyDean Matthew GinsonPas encore d'évaluation

- Seaplus Fire Fighting SystemsDocument24 pagesSeaplus Fire Fighting SystemsYetkin Erdoğan100% (1)

- Fire Pump Routine Checklist NFPA 20Document2 pagesFire Pump Routine Checklist NFPA 20Mouayed ZeadanPas encore d'évaluation

- Fire Safety Log BookDocument21 pagesFire Safety Log Bookjosephselo0% (1)

- Part 23 Fire Fighting & Fire Fighting SystemsDocument23 pagesPart 23 Fire Fighting & Fire Fighting Systemsmuhannad11061975Pas encore d'évaluation

- Fire Supression SystemDocument37 pagesFire Supression SystemStephen Odon Fasto100% (1)

- Keep It Shut SampleDocument17 pagesKeep It Shut SampleZondervan100% (7)

- ANNEXURE For HVW SPRAY SYSTEM - StandardDocument1 pageANNEXURE For HVW SPRAY SYSTEM - StandardVaibhav SawantPas encore d'évaluation

- Preventive Maintenance of FDAS and Sprinkler SystemDocument6 pagesPreventive Maintenance of FDAS and Sprinkler SystemchocostarfishPas encore d'évaluation

- Risk Inspection Report of Shirpur Power PVT LTDDocument15 pagesRisk Inspection Report of Shirpur Power PVT LTDRama Chandra BarikPas encore d'évaluation

- Ammunition Russia 37-40mmDocument5 pagesAmmunition Russia 37-40mmenrico100% (1)

- RT Fire Alarm Systems Care and Maintenance PDFDocument6 pagesRT Fire Alarm Systems Care and Maintenance PDFAndres RamirezPas encore d'évaluation

- Vesdsa System Method StatementDocument39 pagesVesdsa System Method StatementNideesh RobertPas encore d'évaluation

- Inspection Testing and Preventive Maintenance For Fire Protection SystemsDocument14 pagesInspection Testing and Preventive Maintenance For Fire Protection Systemsardhianhk-1100% (1)

- Testing and Commissioning of Water Booster Pump Set Method Statement PDFDocument3 pagesTesting and Commissioning of Water Booster Pump Set Method Statement PDFHumaid ShaikhPas encore d'évaluation

- The Sterling - Fire Protection System Contract 2016 PDFDocument7 pagesThe Sterling - Fire Protection System Contract 2016 PDFEr Dharmadurai RPas encore d'évaluation

- Xtralis TrainingDocument315 pagesXtralis TrainingMelina TreminioPas encore d'évaluation

- SOP16 Testing of Fire Alarm SystemDocument1 pageSOP16 Testing of Fire Alarm Systemanil kumarPas encore d'évaluation

- Advanced Fire Training - 8700055 - REV D - 10/07Document32 pagesAdvanced Fire Training - 8700055 - REV D - 10/07mastersaizPas encore d'évaluation

- Asenware FP100 Addressable Fire Alarm System Installation GuideDocument64 pagesAsenware FP100 Addressable Fire Alarm System Installation Guidefrancky soukPas encore d'évaluation

- Project: Project Name Site No.:: Commissioning Check Sheet For Chilled Water Pump Sheet NoDocument24 pagesProject: Project Name Site No.:: Commissioning Check Sheet For Chilled Water Pump Sheet NoNay Win MaungPas encore d'évaluation

- Contractor'S Material and Test Certificate Fire Sprinkler SystemsDocument4 pagesContractor'S Material and Test Certificate Fire Sprinkler SystemsToufik MedjPas encore d'évaluation

- Check List Test Dan Komisioning - Sistem Pemadam Kebakaran: Equipment Name/Tag No.Document8 pagesCheck List Test Dan Komisioning - Sistem Pemadam Kebakaran: Equipment Name/Tag No.Rudy HarahapPas encore d'évaluation

- Form 72-Fire Hydrant and Sprinkler System Periodic Testing and MaintenanceDocument3 pagesForm 72-Fire Hydrant and Sprinkler System Periodic Testing and MaintenanceSatrio Budi Prakosa RachmanPas encore d'évaluation

- Fire Alarm MaintenanceDocument2 pagesFire Alarm Maintenancesamantha1966Pas encore d'évaluation

- Form 70 Fire Hydrant and SprinklersDocument2 pagesForm 70 Fire Hydrant and SprinklersmkdholkiyaPas encore d'évaluation

- Testing & Commissioning of Fire Alarm SystemDocument3 pagesTesting & Commissioning of Fire Alarm Systemhaytham65Pas encore d'évaluation

- Fire Alarm SystemsDocument10 pagesFire Alarm SystemsQuyet Thang TranPas encore d'évaluation

- DBR of Luminous HosurDocument81 pagesDBR of Luminous HosurrajaPas encore d'évaluation

- Site Acceptance Test (Sat) For EhouseDocument1 pageSite Acceptance Test (Sat) For EhouseAngel AmpuPas encore d'évaluation

- Testing Procedure SprinklerDocument2 pagesTesting Procedure SprinklerBea RullanPas encore d'évaluation

- Fire Alarm System Maintenance 3Document1 pageFire Alarm System Maintenance 3renvPas encore d'évaluation

- Aerosol System Functional Test QCDD FormDocument3 pagesAerosol System Functional Test QCDD FormMahmoud HassanPas encore d'évaluation

- CERTIFICATE This Is To Certify That The Project Was Done byDocument7 pagesCERTIFICATE This Is To Certify That The Project Was Done byJagadish SahuPas encore d'évaluation

- Testing and Commissioning of IG 100 System: Inspection Test Plan (ITP)Document3 pagesTesting and Commissioning of IG 100 System: Inspection Test Plan (ITP)Samboy DionisioPas encore d'évaluation

- MSN 057 Solas II 2 Maintenance and Inspection of Fire Protection Systems and AppliancesDocument14 pagesMSN 057 Solas II 2 Maintenance and Inspection of Fire Protection Systems and AppliancesJothimanikkam SomasundaramPas encore d'évaluation

- Basic Framework For Submission of Performance-Based SolutionsDocument83 pagesBasic Framework For Submission of Performance-Based Solutionsahmed abdohPas encore d'évaluation

- Schedule Plan For Fire Alarm SystemsDocument3 pagesSchedule Plan For Fire Alarm SystemscajaroPas encore d'évaluation

- Sprinkler and SystmesDocument4 pagesSprinkler and SystmesridwanPas encore d'évaluation

- Precommision Cleaning of Piping SystemsDocument10 pagesPrecommision Cleaning of Piping SystemsElias EliasPas encore d'évaluation

- Fire Alarm Requirement Comparison: Assembly: QCD Guidelines NFPA 101 2018 - CHAPTER 12 QCD AnnexDocument63 pagesFire Alarm Requirement Comparison: Assembly: QCD Guidelines NFPA 101 2018 - CHAPTER 12 QCD AnnexNATHANPas encore d'évaluation

- Air Handling Unit PDFDocument16 pagesAir Handling Unit PDFizani_idrisPas encore d'évaluation

- Sofco Nfpa 25 FormDocument5 pagesSofco Nfpa 25 FormVin BdsPas encore d'évaluation

- Statement HDPE PDFDocument1 pageStatement HDPE PDFshameemPas encore d'évaluation

- NCA 2 ManualDocument112 pagesNCA 2 ManualatnatcPas encore d'évaluation

- Preventative Maintenance Task Sheet: Plant/Equipment: Job IDDocument29 pagesPreventative Maintenance Task Sheet: Plant/Equipment: Job IDJaveria KhanPas encore d'évaluation

- VESDA Troubleshooting Guide - Rev05Document26 pagesVESDA Troubleshooting Guide - Rev05Eduardo Diaz PichardoPas encore d'évaluation

- Fire Alarm Routine Checklist NFPA 72Document2 pagesFire Alarm Routine Checklist NFPA 72QasimPas encore d'évaluation

- Cooling Tower TNCDocument6 pagesCooling Tower TNCAarol Hatta100% (1)

- DGSEngineering Circular 1 of 2022Document12 pagesDGSEngineering Circular 1 of 2022Audumbar BhoiPas encore d'évaluation

- BKWSU HIndi-English Murli GlossaryDocument66 pagesBKWSU HIndi-English Murli GlossaryRaja Prathap SinghPas encore d'évaluation

- I P e - H C L I R T Q TDocument7 pagesI P e - H C L I R T Q TRaja Prathap SinghPas encore d'évaluation

- 8in1 110512Document5 pages8in1 110512Raja Prathap SinghPas encore d'évaluation

- Ch. 6-7 - Routing Theory - Part 3 CCNA Semester 2Document47 pagesCh. 6-7 - Routing Theory - Part 3 CCNA Semester 2Raja Prathap SinghPas encore d'évaluation

- Parking Planning ProcessDocument19 pagesParking Planning ProcessRaja Prathap SinghPas encore d'évaluation

- Simplex Installation 4100 6048 VESDA Interface CardDocument20 pagesSimplex Installation 4100 6048 VESDA Interface CardRaja Prathap SinghPas encore d'évaluation

- Simplex Installation Instructions 4100 6062 TFX Interface ModuleDocument22 pagesSimplex Installation Instructions 4100 6062 TFX Interface ModuleRaja Prathap SinghPas encore d'évaluation

- XLG 1Document9 pagesXLG 1Raja Prathap SinghPas encore d'évaluation

- Simplex Installation Instructions IDNet+ ModuleDocument16 pagesSimplex Installation Instructions IDNet+ ModuleRaja Prathap SinghPas encore d'évaluation

- MISERY WPN Appendix Vers1Document92 pagesMISERY WPN Appendix Vers1Sam WhitemanPas encore d'évaluation

- Halothane-: Tel: 514-956-7503 Fax: 514-956-7504 Internet: WWW - Megs.ca Email: Support@megs - CaDocument8 pagesHalothane-: Tel: 514-956-7503 Fax: 514-956-7504 Internet: WWW - Megs.ca Email: Support@megs - CaNiluh Komang Putri PurnamantiPas encore d'évaluation

- Requirements For Use of Quick-Response Fire SprinklersDocument4 pagesRequirements For Use of Quick-Response Fire Sprinklersaneesh100Pas encore d'évaluation

- Fire Hilton 1 PDFDocument7 pagesFire Hilton 1 PDFJayanath FernandoPas encore d'évaluation

- Chapter 14Document31 pagesChapter 14bobPas encore d'évaluation

- BlazeMaster Sample Specification - CanadaDocument4 pagesBlazeMaster Sample Specification - CanadaHugo Mario Ariza PalacioPas encore d'évaluation

- Roles and Functions of The Fire ServiceDocument7 pagesRoles and Functions of The Fire ServiceJamieGillumPas encore d'évaluation

- Rules For Fire Safety in HotelsDocument13 pagesRules For Fire Safety in HotelsTomPas encore d'évaluation

- LE6940 Colt Advanced Law Enforcement Carbine ManualDocument61 pagesLE6940 Colt Advanced Law Enforcement Carbine ManualDouble Chocolate Ice Cream100% (2)

- The Judge - Rabindranath TagoreDocument7 pagesThe Judge - Rabindranath TagoreYêu Văn HọcPas encore d'évaluation

- Military History Map of 1854-1890 - Atlas of The Sioux Wars, Part 2Document51 pagesMilitary History Map of 1854-1890 - Atlas of The Sioux Wars, Part 2HistoricalMapsPas encore d'évaluation

- Sapphire Manual PN570590Document101 pagesSapphire Manual PN570590FitflowPeruPas encore d'évaluation

- Msds SC 4000Document9 pagesMsds SC 4000Cristián RojasPas encore d'évaluation

- Evidence-Based Practices PowerPointDocument53 pagesEvidence-Based Practices PowerPointAbdul hayeePas encore d'évaluation

- Technical ProposalDocument2 pagesTechnical Proposalmoonis muhammedPas encore d'évaluation

- MSDS MeltDown Beneath ZeroDocument2 pagesMSDS MeltDown Beneath ZeroMarymaryBrucePas encore d'évaluation

- Fire Drill ScenarioDocument1 pageFire Drill ScenarioAlta Tierra FssPas encore d'évaluation

- Instruction: Department of DefenseDocument35 pagesInstruction: Department of Defensebena omerPas encore d'évaluation