Académique Documents

Professionnel Documents

Culture Documents

Basics of Space Flight - Rocket Propellants

Transféré par

Ernesto D. AguirreTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Basics of Space Flight - Rocket Propellants

Transféré par

Ernesto D. AguirreDroits d'auteur :

Formats disponibles

Basics of Space Flight: Rocket Propellants

1 de 8

http://www.braeunig.us/space/propel.htm#tables

Liquids

Solids

Hybrids

Tables of Properties

Propellant is the chemical mixture burned to produce thrust in rockets and consists of a fuel and an oxidizer. A fuel is a substance that

burns when combined with oxygen producing gas for propulsion. An oxidizer is an agent that releases oxygen for combination with a

fuel. The ratio of oxidizer to fuel is called the mixture ratio. Propellants are classified according to their state - liquid, solid, or hybrid.

The gauge for rating the efficiency of rocket propellants is specific impulse, stated in seconds. Specific impulse indicates how many

pounds (or kilograms) of thrust are obtained by the consumption of one pound (or kilogram) of propellant in one second. Specific

impulse is characteristic of the type of propellant, however, its exact value will vary to some extent with the operating conditions and

design of the rocket engine.

Liquid Propellants

In a liquid propellant rocket, the fuel and oxidizer are stored in separate tanks, and are fed through a system of pipes, valves, and

turbopumps to a combustion chamber where they are combined and burned to produce thrust. Liquid propellant engines are more

complex than their solid propellant counterparts, however, they offer several advantages. By controlling the flow of propellant to the

combustion chamber, the engine can be throttled, stopped, or restarted.

A good liquid propellant is one with a high specific impulse or, stated another way, one with a high speed of exhaust gas ejection. This

implies a high combustion temperature and exhaust gases with small molecular weights. However, there is another important factor

that must be taken into consideration: the density of the propellant. Using low-density propellants means that larger storage tanks will

be required, thus increasing the mass of the launch vehicle. Storage temperature is also important. A propellant with a low storage

temperature, i.e. a cryogenic, will require thermal insulation, thus further increasing the mass of the launcher. The toxicity of the

propellant is likewise important. Safety hazards exist when handling, transporting, and storing highly toxic compounds. Also, some

propellants are very corrosive; however, materials that are resistant to certain propellants have been identified for use in rocket

construction.

21/04/2014 14:03

Basics of Space Flight: Rocket Propellants

2 de 8

http://www.braeunig.us/space/propel.htm#tables

Liquid propellants used in rocketry can be classified into three types: petroleum, cryogens, and hypergols.

Petroleum fuels are those refined from crude oil and are a mixture of complex hydrocarbons, i.e. organic compounds containing only

carbon and hydrogen. The petroleum used as rocket fuel is a type of highly refined kerosene, called RP-1 in the United States.

Petroleum fuels are usually used in combination with liquid oxygen as the oxidizer. Kerosene delivers a specific impulse considerably

less than cryogenic fuels, but it is generally better than hypergolic propellants.

Specifications for RP-1 where first issued in the United States in 1957 when the need for a clean burning petroleum rocket fuel was

recognized. Prior experimentation with jet fuels produced tarry residue in the engine cooling passages and excessive soot, coke and

other deposits in the gas generator. Even with the new specifications, kerosene-burning engines still produce enough residues that

their operational lifetimes are limited.

Liquid oxygen and RP-1 are used as the propellant in the first-stage boosters of the Atlas and Delta II launch vehicles. It also powered

the first-stages of the Saturn 1B and Saturn V rockets.

Cryogenic propellants are liquefied gases stored at very low temperatures, most frequently liquid hydrogen (LH ) as the fuel and

2

liquid oxygen (LO or LOX) as the oxidizer. Hydrogen remains liquid at temperatures of -253 C (-423 F) and oxygen remains in a

2

liquid state at temperatures of -183 C (-297 F).

Because of the low temperatures of cryogenic propellants, they are difficult to store over long periods of time. For this reason, they are

less desirable for use in military rockets that must be kept launch ready for months at a time. Furthermore, liquid hydrogen has a very

low density (0.071 g/ml) and, therefore, requires a storage volume many times greater than other fuels. Despite these drawbacks, the

high efficiency of liquid oxygen/liquid hydrogen makes these problems worth coping with when reaction time and storability are not

too critical. Liquid hydrogen delivers a specific impulse about 30%-40% higher than most other rocket fuels.

Liquid oxygen and liquid hydrogen are used as the propellant in the high efficiency main engines of the Space Shuttle. LOX/LH also

2

powered the upper stages of the Saturn V and Saturn 1B rockets, as well as the Centaur upper stage, the United States' first LOX/LH

rocket (1962).

o

Another cryogenic fuel with desirable properties for space propulsion systems is liquid methane (-162 C). When burned with liquid

oxygen, methane is higher performing than state-of-the-art storable propellants but without the volume increase common with

LOX/LH systems, which results in an overall lower vehicle mass as compared to common hypergolic propellants. LOX/methane is also

2

clean burning and non-toxic. Future missions to Mars will likely use methane fuel because it can be manufactured partly from Martian

in-situ resources. LOX/methane has no flight history and very limited ground-test history.

o

Liquid fluorine (-188 C) burning engines have also been developed and fired successfully. Fluorine is not only extremely toxic; it is a

super-oxidizer that reacts, usually violently, with almost everything except nitrogen, the lighter noble gases, and substances that have

already been fluorinated. Despite these drawbacks, fluorine produces very impressive engine performance. It can also be mixed with

liquid oxygen to improve the performance of LOX-burning engines; the resulting mixture is called FLOX. Because of fluorine's high

toxicity, it has been largely abandoned by most space-faring nations.

Some fluorine containing compounds, such as chlorine pentafluoride, have also been considered for use as an 'oxidizer' in deep-space

21/04/2014 14:03

Basics of Space Flight: Rocket Propellants

3 de 8

http://www.braeunig.us/space/propel.htm#tables

applications.

Hypergolic propellants are fuels and oxidizers that ignite spontaneously on contact with each other and require no ignition source.

The easy start and restart capability of hypergols make them ideal for spacecraft maneuvering systems. Also, since hypergols remain

liquid at normal temperatures, they do not pose the storage problems of cryogenic propellants. Hypergols are highly toxic and must be

handled with extreme care.

Hypergolic fuels commonly include hydrazine, monomethyl hydrazine (MMH) and unsymmetrical dimethyl hydrazine (UDMH).

Hydrazine gives the best performance as a rocket fuel, but it has a high freezing point and is too unstable for use as a coolant. MMH is

more stable and gives the best performance when freezing point is an issue, such as spacecraft propulsion applications. UDMH has the

lowest freezing point and has enough thermal stability to be used in large regeneratively cooled engines. Consequently, UDMH is often

used in launch vehicle applications even though it is the least efficient of the hydrazine derivatives. Also commonly used are blended

fuels, such as Aerozine 50 (or "50-50"), which is a mixture of 50% UDMH and 50% hydrazine. Aerozine 50 is almost as stable as

UDMH and provides better performance.

The oxidizer is usually nitrogen tetroxide (NTO) or nitric acid. In the United States, the nitric acid formulation most commonly used is

type III-A, called inhibited red-fuming nitric acid (IRFNA), which consists of HNO + 14% N O + 1.5-2.5% H O + 0.6% HF (added as

3

a corrosion inhibitor). Nitrogen tetroxide is less corrosive than nitric acid and provides better performance, but it has a higher freezing

point. Consequently, nitrogen tetroxide is usually the oxidizer of choice when freezing point is not an issue, however, the freezing

point can be lowered with the introduction nitric oxide. The resulting oxidizer is called mixed oxides of nitrogen (MON). The number

included in the description, e.g. MON-3 or MON-25, indicates the percentage of nitric oxide by weight. While pure nitrogen tetroxide

o

has a freezing point of about -9 C, the freezing point of MON-3 is -15 C and that of MON-25 is -55 C.

USA military specifications for IRFNA were first published in 1954, followed in 1955 with UDMH specifications.

The Titan family of launch vehicles and the second stage of the Delta II rocket use NTO/Aerozine 50 propellant. NTO/MMH is used in

the orbital maneuvering system (OMS) and reaction control system (RCS) of the Space Shuttle orbiter. IRFNA/UDMH is often used in

tactical missiles such as the US Army's Lance (1972-91).

Hydrazine is also frequently used as a monopropellant in catalytic decomposition engines. In these engines, a liquid fuel decomposes

o

into hot gas in the presence of a catalyst. The decomposition of hydrazine produces temperatures up to about 1,100 C (2,000 F) and

a specific impulse of about 230 or 240 seconds. Hydrazine decomposes to either hydrogen and nitrogen, or ammonia and nitrogen.

Other propellants have also been used, a few of which deserve mentioning:

Alcohols were commonly used as fuels during the early years of rocketry. The German V-2 missile, as well as the USA Redstone,

burned LOX and ethyl alcohol (ethanol), diluted with water to reduce combustion chamber temperature. However, as more efficient

fuels where developed, alcohols fell into general disuse.

Hydrogen peroxide once attracted considerable attention as an oxidizer and was used in Britain's Black Arrow rocket. In high

concentrations, hydrogen peroxide is called high-test peroxide (HTP). The performance and density of HTP is close to that of nitric

acid, and it is far less toxic and corrosive; however it has a poor freezing point and is unstable. Although HTP never made it as an

oxidizer in large bi-propellant applications, it has found widespread use as a monopropellant. In the presence of a catalyst, HTP

decomposes into oxygen and superheated steam and produces a specific impulse of about 150 s.

21/04/2014 14:03

Basics of Space Flight: Rocket Propellants

4 de 8

http://www.braeunig.us/space/propel.htm#tables

Nitrous oxide has been used as both an oxidizer and as a monopropellant. It is the oxidizer of choice for many hybrid rocket designs

and has been used frequently in amateur high-powered rocketry. In the presence of a catalyst, nitrous oxide will decompose

exothermically into nitrogen and oxygen and produce a specific impulse of about 170 s.

Solid Propellants

Solid propellant motors are the simplest of all rocket designs. They consist of a casing, usually steel, filled with a mixture of solid

compounds (fuel and oxidizer) that burn at a rapid rate, expelling hot gases from a nozzle to produce thrust. When ignited, a solid

propellant burns from the center out towards the sides of the casing. The shape of the center channel determines the rate and pattern

of the burn, thus providing a means to control thrust. Unlike liquid propellant engines, solid propellant motors cannot be shut down.

Once ignited, they will burn until all the propellant is exhausted.

There are two families of solids propellants: homogeneous and composite. Both types are dense, stable at ordinary temperatures, and

easily storable.

Homogeneous propellants are either simple base or double base. A simple base propellant consists of a single compound, usually

nitrocellulose, which has both an oxidation capacity and a reduction capacity. Double base propellants usually consist of nitrocellulose

and nitroglycerine, to which a plasticiser is added. Homogeneous propellants do not usually have specific impulses greater than about

210 seconds under normal conditions. Their main asset is that they do not produce traceable fumes and are, therefore, commonly

used in tactical weapons. They are also often used to perform subsidiary functions such as jettisoning spent parts or separating one

stage from another.

Modern composite propellants are heterogeneous powders (mixtures) that use a crystallized or finely ground mineral salt as an

oxidizer, often ammonium perchlorate, which constitutes between 60% and 90% of the mass of the propellant. The fuel itself is

generally aluminum. The propellant is held together by a polymeric binder, usually polyurethane or polybutadienes, which is also

consumed as fuel. Additional compounds are sometimes included, such as a catalyst to help increase the burning rate, or other agents

to make the powder easier to manufacture. The final product is rubber like substance with the consistency of a hard rubber eraser.

Composite propellants are often identified by the type of polymeric binder used. The two most common binders are polybutadiene

acrylic acid acrylonitrile (PBAN) and hydroxy-terminator polybutadiene (HTPB). PBAN formulations give a slightly higher specific

impulse, density, and burn rate than equivalent formulations using HTPB. However, PBAN propellant is the more difficult to mix and

process and requires an elevated curing temperature. HTPB binder is stronger and more flexible than PBAN binder. Both PBAN and

HTPB formulations result in propellants that deliver excellent performance, have good mechanical properties, and offer potentially long

burn times.

Solid propellant motors have a variety of uses. Small solids often power the final stage of a launch vehicle, or attach to payloads to

boost them to higher orbits. Medium solids such as the Payload Assist Module (PAM) and the Inertial Upper Stage (IUS) provide the

added boost to place satellites into geosynchronous orbit or on planetary trajectories.

The Titan, Delta, and Space Shuttle launch vehicles use strap-on solid propellant rockets to provide added thrust at liftoff. The Space

Shuttle uses the largest solid rocket motors ever built and flown. Each booster contains 500,000 kg (1,100,000 pounds) of propellant

and can produce up to 14,680,000 Newtons (3,300,000 pounds) of thrust.

Hybrid Propellants

21/04/2014 14:03

Basics of Space Flight: Rocket Propellants

5 de 8

http://www.braeunig.us/space/propel.htm#tables

Hybrid propellant engines represent an intermediate group between solid and liquid propellant engines. One of the substances is solid,

usually the fuel, while the other, usually the oxidizer, is liquid. The liquid is injected into the solid, whose fuel reservoir also serves as

the combustion chamber. The main advantage of such engines is that they have high performance, similar to that of solid propellants,

but the combustion can be moderated, stopped, or even restarted. It is difficult to make use of this concept for vary large thrusts, and

thus, hybrid propellant engines are rarely built.

A hybrid engine burning nitrous oxide as the liquid oxidizer and HTPB rubber as the solid fuel powered the vehicle SpaceShipOne,

which won the Ansari X-Prize.

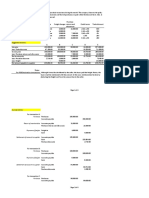

PROPERTIES OF ROCKET PROPELLANTS

Compound

Chemical

Formula

Molecular

Weight

Density

Melting

Point

Liquid Oxygen

32.00

1.14 g/ml

-218.8 C

Liquid Fluorine

38.00

1.50 g/ml

-219.6 C

Nitrogen Tetroxide

N O

92.01

Nitric Acid

HNO

Hydrogen Peroxide

Boiling

Point

-183.0 C

-188.1 C

1.45 g/ml

-9.3 C

21.15 C

63.01

1.55 g/ml

-41.6 C

H O

34.02

1.44 g/ml

-0.4 C

Nitrous Oxide

N O

44.01

1.22 g/ml

-90.8 C

Chlorine Pentafluoride

ClF

130.45

1.9 g/ml

-103 C

Ammonium Perchlorate

ClH NO

117.49

1.95 g/ml

240 C

Liquid Hydrogen

2.016

0.071 g/ml

-259.3 C

Liquid Methane

CH

16.04

0.423 g/ml

-182.5 C

Ethyl Alcohol

C H OH

46.07

0.789 g/ml

-114.1 C

170.34

0.749 g/ml

-9.6 C

216.3 C

175

0.820 g/ml

N/A

177-274 C

32.05

1.004 g/ml

1.4 C

n-Dodecane (Kerosene)

RP-1

C H

12

26

n 1.953n

N/A

-252.9 C

-161.6 C

78.2 C

46.07

0.866 g/ml

-52.4 C

Dimethyl Hydrazine

(CH ) NNH

60.10

0.791 g/ml

-58 C

2

2

150.2 C

-13.1 C

CH NHNH

3 2

83 C

Methyl Hydrazine

-88.5 C

N H

Hydrazine

o

o

113.5 C

o

87.5 C

o

63.9 C

21/04/2014 14:03

Basics of Space Flight: Rocket Propellants

6 de 8

http://www.braeunig.us/space/propel.htm#tables

Aluminum

Al

Polybutadiene

(C H )

4

6 n

26.98

2.70 g/ml

660.4 C

2467 C

3000

0.93 g/ml

N/A

N/A

NOTES:

Chemically, kerosene is a mixture of hydrocarbons; the chemical composition depends on its source, but it usually consists

of about ten different hydrocarbons, each containing from 10 to 16 carbon atoms per molecule; the constituents include

n-dodecane, alkyl benzenes, and naphthalene and its derivatives. Kerosene is usually represented by the single compound

n-dodecane.

RP-1 is a special type of kerosene covered by Military Specification MIL-R-25576. In Russia, similar specifications were

developed under specifications T-1 and RG-1.

Nitrogen tetroxide and nitric acid are hypergolic with hydrazine, MMH and UDMH. Oxygen is not hypergolic with any

commonly used fuel.

o

Ammonium perchlorate decomposes, rather than melts, at a temperature of about 240 C.

ROCKET PROPELLANT PERFORMANCE

Combustion chamber pressure, P = 68 atm (1000 PSI) ... Nozzle exit pressure, P = 1 atm

c

Oxidizer

Liquid Oxygen

Liquid Fluorine

FLOX-70

Nitrogen Tetroxide

Fuel

Hypergolic

Mixture Ratio

Specific Impulse

(s, sea level)

Density Impulse

(kg-s/l, S.L.)

Liquid Hydrogen

No

5.00

381

124

Liquid Methane

No

2.77

299

235

Ethanol + 25% water

No

1.29

269

264

Kerosene

No

2.29

289

294

Hydrazine

No

0.74

303

321

MMH

No

1.15

300

298

UDMH

No

1.38

297

286

50-50

No

1.06

300

300

Liquid Hydrogen

Yes

6.00

400

155

Hydrazine

Yes

1.82

338

432

Kerosene

Yes

3.80

320

385

Kerosene

No

3.53

267

330

Hydrazine

Yes

1.08

286

342

MMH

Yes

1.73

280

325

UDMH

Yes

2.10

277

316

21/04/2014 14:03

Basics of Space Flight: Rocket Propellants

7 de 8

http://www.braeunig.us/space/propel.htm#tables

50-50

Red-Fuming Nitric Acid

(14% N O )

2

Yes

1.59

280

326

Kerosene

No

4.42

256

335

Hydrazine

Yes

1.28

276

341

MMH

Yes

2.13

269

328

UDMH

Yes

2.60

266

321

50-50

Yes

1.94

270

329

Hydrogen Peroxide

(85% concentration)

Kerosene

No

7.84

258

324

Hydrazine

Yes

2.15

269

328

Nitrous Oxide

HTPB (solid)

No

6.48

248

290

Chlorine Pentafluoride

Hydrazine

Yes

2.12

297

439

Ammonium Perchlorate

(solid)

Aluminum + HTPB (a)

No

2.12

277

474

Aluminum + PBAN (b)

No

2.33

277

476

NOTES:

Specific impulses are theoretical maximum assuming 100% efficiency; actual performance will be less.

All mixture ratios are optimum for the operating pressures indicated, unless otherwise noted.

LO /LH and LF /LH mixture ratios are higher than optimum to improve density impulse.

2

FLOX-70 is a mixture of 70% liquid fluorine and 30% liquid oxygen.

Where kerosene is indicated, the calculations are based on n-dodecane.

Solid propellant formulation (a): 68% AP + 18% Al + 14% HTPB.

Solid propellant formulation (b): 70% AP + 16% Al + 12% PBAN + 2% epoxy curing agent.

SELECTED ROCKETS AND THEIR PROPELLANTS

Rocket

Stage

Engines

Propellant

Specific Impulse

Atlas/Centaur (1962)

0

1

2

Rocketdyne YLR89-NA7 (x2)

Rocketdyne YLR105-NA7

P&W RL-10A-3-3 (x2)

LOX/RP-1

LOX/RP-1

LOX/LH2

259s sl / 292s vac

220s sl / 309s vac

444s vacuum

Titan II (1964)

1

2

Aerojet LR-87-AJ-5 (x2)

Aerojet LR-91-AJ-5

NTO/Aerozine 50

NTO/Aerozine 50

259s sl / 285s vac

312s vacuum

Saturn V (1967)

1

2

3

Rocketdyne F-1 (x5)

Rocketdyne J-2 (x5)

Rocketdyne J-2

LOX/RP-1

LOX/LH2

LOX/LH2

265s sl / 304s vac

424s vacuum

424s vacuum

Space Shuttle (1981)

0

1

OMS

Thiokol SRB (x2)

Rocketdyne SSME (x3)

Aerojet OMS (x2)

PBAN Solid

LOX/LH2

NTO/MMH

242s sl / 268s vac

363s sl / 453s vac

313s vacuum

21/04/2014 14:03

Basics of Space Flight: Rocket Propellants

8 de 8

Delta II (1989)

http://www.braeunig.us/space/propel.htm#tables

RCS

Kaiser Marquardt R-40 & R-1E

NTO/MMH

280s vacuum

0

1

2

Castor 4A (x9)

Rocketdyne RS-27

Aerojet AJ10-118K

HTPB Solid

LOX/RP-1

NTO/Aerozine 50

238s sl / 266s vac

264s sl / 295s vac

320s vacuum

Compiled, edited and written in part by Robert A. Braeunig, 1996, 2005, 2006, 2008.

Bibliography

Back Home Next

21/04/2014 14:03

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Nastran Error ListDocument599 pagesNastran Error ListMvkr Bhargav0% (2)

- Dynamic Modeling and Simulation of Basic Oxygen FuDocument23 pagesDynamic Modeling and Simulation of Basic Oxygen FuErnesto D. AguirrePas encore d'évaluation

- Dynamic Modeling and Optimization of Basic Oxygen Furnace BOF OperationDocument139 pagesDynamic Modeling and Optimization of Basic Oxygen Furnace BOF OperationErnesto D. AguirrePas encore d'évaluation

- An Extension of The Method of Trefftz For Finding Local Bounds On The Solutions and Their Derivatives of Boundary Value... (Cooperman, Philip)Document74 pagesAn Extension of The Method of Trefftz For Finding Local Bounds On The Solutions and Their Derivatives of Boundary Value... (Cooperman, Philip)Ernesto D. AguirrePas encore d'évaluation

- An Extension of The Method of Trefftz For Finding Local Bounds On The Solutions and Their Derivatives of Boundary Value... (Cooperman, Philip)Document74 pagesAn Extension of The Method of Trefftz For Finding Local Bounds On The Solutions and Their Derivatives of Boundary Value... (Cooperman, Philip)Ernesto D. AguirrePas encore d'évaluation

- Applsci 10 05101 v2Document18 pagesApplsci 10 05101 v2Ernesto D. AguirrePas encore d'évaluation

- Pde 18 ADocument140 pagesPde 18 AErnesto D. AguirrePas encore d'évaluation

- Basic ConstantsDocument3 pagesBasic ConstantsErnesto D. AguirrePas encore d'évaluation

- New Theory FlightDocument18 pagesNew Theory FlightErnesto D. AguirrePas encore d'évaluation

- Scilab Text Books PDFDocument286 pagesScilab Text Books PDFwiyatmiPas encore d'évaluation

- Propeller Design For Con Ceptual TurboprDocument123 pagesPropeller Design For Con Ceptual TurboprMario RossiPas encore d'évaluation

- 1045 - High Altitude (HA) Functionality in OneSAF UC09 - MorashDocument26 pages1045 - High Altitude (HA) Functionality in OneSAF UC09 - MorashErnesto D. AguirrePas encore d'évaluation

- Front MatterDocument10 pagesFront MatterErnesto D. AguirrePas encore d'évaluation

- Manual Scilab CodeDocument25 pagesManual Scilab CodeErnesto D. AguirrePas encore d'évaluation

- Cbo-Airship 001 PDFDocument28 pagesCbo-Airship 001 PDFErnesto D. Aguirre100% (1)

- Rocket Thrust Example ProblemsDocument33 pagesRocket Thrust Example ProblemsErnesto D. AguirrePas encore d'évaluation

- Properties of Standard AtmosphereDocument6 pagesProperties of Standard AtmosphereErnesto D. AguirrePas encore d'évaluation

- Flight Stability & Control - D.V. CaugheyDocument153 pagesFlight Stability & Control - D.V. CaugheyKhairul Nizam100% (1)

- Liquid Oxygen & Kerosene - ChartsDocument3 pagesLiquid Oxygen & Kerosene - ChartsErnesto D. AguirrePas encore d'évaluation

- DVP 8.06 PaperDocument14 pagesDVP 8.06 PaperErnesto D. AguirrePas encore d'évaluation

- Abi5 YongDocument18 pagesAbi5 YongErnesto D. AguirrePas encore d'évaluation

- 88238main - H-1731-Modeling Simulation and Flight Characteristics of An Aircraft Designed To Fly at 10000 Feet PDFDocument44 pages88238main - H-1731-Modeling Simulation and Flight Characteristics of An Aircraft Designed To Fly at 10000 Feet PDFErnesto D. AguirrePas encore d'évaluation

- Computational Foundation of ThermodynamicsDocument18 pagesComputational Foundation of ThermodynamicsErnesto D. AguirrePas encore d'évaluation

- Rolls-Royce Outlook 2020Document16 pagesRolls-Royce Outlook 2020Ernesto D. AguirrePas encore d'évaluation

- Construction of A Test Rig and Scaled Aircraft Wing For Validation Final ReportDocument161 pagesConstruction of A Test Rig and Scaled Aircraft Wing For Validation Final ReportErnesto D. AguirrePas encore d'évaluation

- Book ProDocument281 pagesBook ProErnesto D. AguirrePas encore d'évaluation

- A Nonhydrostatic Finite-Element Model For Three-Dimensional Stratified OceanicDocument16 pagesA Nonhydrostatic Finite-Element Model For Three-Dimensional Stratified OceanicErnesto D. AguirrePas encore d'évaluation

- Point Out of Flight EnvelopeDocument18 pagesPoint Out of Flight EnvelopeOdair ProphetaPas encore d'évaluation

- Vision 2020Document26 pagesVision 2020Borja CedielPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- K. Subramanya - Engineering Hy-Hill Education (India) (2009) 76Document1 pageK. Subramanya - Engineering Hy-Hill Education (India) (2009) 76ramsinghmahatPas encore d'évaluation

- Buzan, Barry - Security, The State, The 'New World Order' & BeyondDocument15 pagesBuzan, Barry - Security, The State, The 'New World Order' & Beyondyossara26100% (3)

- Sap Business Objects Edge Series 3.1 Install Windows enDocument104 pagesSap Business Objects Edge Series 3.1 Install Windows enGerardoPas encore d'évaluation

- 1.4 BG00381946 - ADocument1 page1.4 BG00381946 - AAnand KesarkarPas encore d'évaluation

- 2010 DOE FEMP Exterior Lighting GuideDocument38 pages2010 DOE FEMP Exterior Lighting GuideMoideen Thashreef100% (1)

- Annex 1: Homeroom Guidance Monitoring Tool (School Level) Homeroom Guidance Monitoring ToolDocument2 pagesAnnex 1: Homeroom Guidance Monitoring Tool (School Level) Homeroom Guidance Monitoring ToolMariel Gregore0% (1)

- Defining The Christian Faith PaperDocument8 pagesDefining The Christian Faith Paperlin tongPas encore d'évaluation

- Irjet V3i7146 PDFDocument6 pagesIrjet V3i7146 PDFatulnarkhede2002Pas encore d'évaluation

- University of Dar Es Salaam: Faculty of Commerce and ManagementDocument37 pagesUniversity of Dar Es Salaam: Faculty of Commerce and ManagementEric MitegoPas encore d'évaluation

- Assignment 2 Management Perspective Son Leadership MotivationDocument14 pagesAssignment 2 Management Perspective Son Leadership MotivationHoneyVasudevPas encore d'évaluation

- Somanabolic+Muscle+Maximizer+PDF+ +eBook+Free+Download+Kyle+LeonDocument34 pagesSomanabolic+Muscle+Maximizer+PDF+ +eBook+Free+Download+Kyle+LeonAaron BarclayPas encore d'évaluation

- IGCSE Religious Studies (Edexcel - 2009 - Be Careful Not To Choose The New' IGCSE)Document8 pagesIGCSE Religious Studies (Edexcel - 2009 - Be Careful Not To Choose The New' IGCSE)Robbie TurnerPas encore d'évaluation

- Register A Custom Table in Apps SchemaDocument5 pagesRegister A Custom Table in Apps SchemaIapps ErpSolutionsPas encore d'évaluation

- AH Business-Management All 2011Document11 pagesAH Business-Management All 2011Sanam PuriPas encore d'évaluation

- Network Models For Seat Allocation On Flights: Moshe Dror,?Document12 pagesNetwork Models For Seat Allocation On Flights: Moshe Dror,?Isabel VillaPas encore d'évaluation

- 8 - Packed Tower Design-1Document65 pages8 - Packed Tower Design-1M.H vafaeiPas encore d'évaluation

- CE 2812-Permeability Test PDFDocument3 pagesCE 2812-Permeability Test PDFShiham BadhurPas encore d'évaluation

- Cel2106 SCL Worksheet 6Document3 pagesCel2106 SCL Worksheet 6HarryJoy JackPas encore d'évaluation

- Content and Context Analysis of Selected Primary SourccesDocument3 pagesContent and Context Analysis of Selected Primary SourccesToshi CodmPas encore d'évaluation

- Concept MapDocument1 pageConcept Mapapi-402935758Pas encore d'évaluation

- Theoretical & Conceptual Framework (RESEARCH)Document3 pagesTheoretical & Conceptual Framework (RESEARCH)Rizza Manabat PacheoPas encore d'évaluation

- Power Factor Improvement SystemDocument25 pagesPower Factor Improvement SystemBijoy SahaPas encore d'évaluation

- LP Addition of PolynomialsDocument5 pagesLP Addition of PolynomialsJolina Bagwisa LptPas encore d'évaluation

- Handout No. 03 - Purchase TransactionsDocument4 pagesHandout No. 03 - Purchase TransactionsApril SasamPas encore d'évaluation

- Theater InstallationDocument7 pagesTheater InstallationtemamPas encore d'évaluation

- Technical EnglishDocument7 pagesTechnical EnglishGul HaiderPas encore d'évaluation

- Recovering The Snorra Edda On Playing Gods, Loki, and The Importance of HistoryDocument17 pagesRecovering The Snorra Edda On Playing Gods, Loki, and The Importance of HistoryM SPas encore d'évaluation

- UntitledDocument45 pagesUntitledjemPas encore d'évaluation

- Three Moment Equation For BeamsDocument12 pagesThree Moment Equation For BeamsRico EstevaPas encore d'évaluation

- ScriptDocument12 pagesScriptWaleed Nadeem50% (2)