Académique Documents

Professionnel Documents

Culture Documents

Aa Spec 377002

Transféré par

jonodo89Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Aa Spec 377002

Transféré par

jonodo89Droits d'auteur :

Formats disponibles

AA SPECIFICATION

377002

STEEL CORD REINFORCED CONVEYOR

BELTING

ISSUE 0

COPYRIGHT

CONTENTS

PAGE

SCOPE

TECHNICAL REQUIREMENTS TO BE SPECIFIED BY THE ENGINEER

DEFINITIONS

REQUIREMENTS

4.1

4.2

4.3

4.4

4.5

4.6

COVER THICKNESS AND TYPE

CORD SPACING

WIDTH

CLASS

JOINTS IN CORDS

PULLEY DIAMETER

3

3

3

3

4

4

QUALITY ASSURANCE PROVISIONS

5.1

5.2

5.3

COMPLIANCE

SAMPLING

RETENTION OF SAMPLES

4

5

5

TEST AND INSPECTION METHODS

MARKING AND PACKING

7.1

7.2

MARKING

PACKING

5

5

CONTENTS OF DATA PACK

APPENDIX A: RELATED DOCUMENTS

APPENDIX B: RECORD OF AMENDMENTS

APPENDIX C: TECHNICAL REQUIREMENTS TO BE SPECIFIED BY THE ENGINEER

8

APPENDIX D: PULLEY DIAMETERS

AA_SPEC_377002.doc

APPROVED

3 February 2010

Page 1 of 9

Anglo Technical accepts no liability for any damage whatsoever that may result from the use of this material or the information contained

therein, irrespective of the cause and quantum thereof.

AA SPECIFICATION

377002

STEEL CORD REINFORCED CONVEYOR

BELTING

ISSUE 0

COPYRIGHT

This document supersedes AAC Specification 377002, Rev 2

SCOPE

This specification details the additions and exceptions to requirements for steel-cord

reinforced conveyor belting that complies with the requirements of SANS 1366 latest revision.

All belting shall be manufactured strictly in accordance with SANS 1366 and this specification

shall be read in conjunction with SANS 1366.

TECHNICAL REQUIREMENTS TO BE SPECIFIED BY THE ENGINEER

The following requirements shall be specified on every invitation to tender, contract or order:

Title, number, date and issue of this specification.

The class (see SANS 1366 Clause 4.1)

The type (see SANS 1366 Clause 4.2)

The length (see SANS 1366 Clause 4.5.1)

The nominal width of the belting (see Clause 4.5.2)

The troughing angle (see SANS 1366 Clause 4.7.3)

Type of covers (see clause 4.5.3)

The cover thickness (see Clause 4.2)

The name of the independent Quality Assurance Representative (see AA STD 100)

The supplier shall complete Appendix C in consultation with the Engineer to confirm technical

requirements and suitability of the final product.

DEFINITIONS

For the purpose of this specification the definitions contained in SANS 1366 and the following

shall apply:

STD

Anglo American Quality Assurance Procedure

SANS

South African National Standard

A lot

A continuous length of belting greater than 150m submitted at any one

time for inspection testing

Length of belt

A section of belt taken from a lot

The following terms are defined in the General Conditions of Contract:

Anglo American, Approved, Company, Contractor, Engineer

AA_SPEC_377002.doc

APPROVED

3 February 2010

Page 2 of 9

Anglo Technical accepts no liability for any damage whatsoever that may result from the use of this material or the information contained

therein, irrespective of the cause and quantum thereof.

AA SPECIFICATION

377002

STEEL CORD REINFORCED CONVEYOR

BELTING

ISSUE 0

REQUIREMENTS

4.1

COVER THICKNESS AND TYPE

COPYRIGHT

Minimum cover thickness shall be in accordance with SANS 1366, Table 1. Where there are

special requirements for thicker covers, this shall be agreed by the manufacturer and the

Engineer and recorded accordingly.

If ancillary equipment, such as belt tear detection devices are to be installed then the belt

cover thickness shall be adjusted accordingly.

The belting shall be of the following types:

4.2

a) Type F

Belting with a rubber cover that has both fire-retardant and antistatic

properties when tested in accordance with 4.7.4, 4.7.5 and 4.7.6.

Physical properties of rubber covers are given in Table 2.

b) Type A

A belt with rubber covers formulated specifically for abrasion resistance

and with physical properties stipulated in Table 2.

c) Type C

A belt with a rubber cover that is suitable for the conveyance of abrasive

materials under average working conditions.

d) Type N & M

Non-fire retardant belting with covers of varying degrees of cut and

gouge resistance as defined by tensile strength and elongation at break

properties stipulated in Table 2.

CORD SPACING

The cord spacing and diameter recommended in SANS 1366, Table 1 shall be mandatory for

all belts. Variation from this table will only be by concession request.

Cords for belting supplied for a specific conveyor belt installation shall be the same diameter

and shall be sourced from one supply.

4.3

WIDTH

The nominal width of the belting shall be specified by the Engineer (see Clause 2.0) and shall

be one of the following widths, in millimetres: 750, 900, 1050, 1200, 1350, 1500, 1650, 1800,

2100 and 2400.

4.4

CLASS

The class of belting shall be indicated by the letters St, followed by the breaking strength of

the belting, in kilonewtons per metre of width and shall comply with the construction as in

Table 1 unless otherwise agreed by the manufacturer and purchaser.

AA_SPEC_377002.doc

APPROVED

3 February 2010

Page 3 of 9

Anglo Technical accepts no liability for any damage whatsoever that may result from the use of this material or the information contained

therein, irrespective of the cause and quantum thereof.

AA SPECIFICATION

377002

STEEL CORD REINFORCED CONVEYOR

BELTING

ISSUE 0

COPYRIGHT

TABLE 1: CLASSES AND CONSTRUCTION

4.5

Class

Thickness of

Cover

mm, min

Nominal distance between centres (cord pitch)

mm

Cord diameter

mm, max

Steel Cords

St

500

20.0

3.6

St

630

16.0

3.6

St

800

17.0

3.6

St

1 000

14.5

4.4

St

1 250

12.0

4.4

St

1 400

19.0

6.3

St

1 600

16.0

6.3

St

2 000

13.5

6.3

St

2 500

15.0

7.4

St

3 150

16.0

8.6

St

4 000

15.0

9.3

St

5 000

17.0

11.5

St

6 000

10

17.0

13.0

JOINTS IN CORDS

There shall be no join in any cord or in any one length of belt supplied unless agreed by

concession.

4.6

PULLEY DIAMETER

The Contractor shall advise the Company of the minimum pulley diameters which may be

used with the conveyor belt (see Appendix D).

QUALITY ASSURANCE PROVISIONS

The requirements of AA STD 100 shall apply.

5.1

COMPLIANCE

Compliance with the agreed quality assurance plan will be monitored in the suppliers works

by a client representative and/or independent third party.

AA_SPEC_377002.doc

APPROVED

3 February 2010

Page 4 of 9

Anglo Technical accepts no liability for any damage whatsoever that may result from the use of this material or the information contained

therein, irrespective of the cause and quantum thereof.

AA SPECIFICATION

377002

STEEL CORD REINFORCED CONVEYOR

BELTING

ISSUE 0

COPYRIGHT

5.2

SAMPLING

5.2.1

One sample for testing in accordance with SANS 1366 to be provided representing each

length of belt; the first sample shall be at the beginning of the first length and the last sample

shall be at the end of the last length.

5.2.2

Fire retardant tests and trough ability test may be done per lot only.

5.2.3

Each batch of cord received by the manufacturer shall be subjected to a cord breaking

strength test to verify the cord supplier certificate. The test is to be conducted in accordance

with SANS 1366 section 6.6

5.3

RETENTION OF SAMPLES

Samples for dimensional testing as specified in SANS 1366 shall be retained until the belt

has been delivered to the client. In the case of belting for man-riding conveyors, two

additional strips of 500mm long belting must be retained indefinitely by the manufacturer for

possible future testing.

TEST AND INSPECTION METHODS

Tests and inspection methods shall comply with the requirements of SANS 1366.

MARKING AND PACKING

7.1

MARKING

Marking shall comply with the requirements of SANS 1366 with the exception that belting is to

be marked on the non-carrying surface where possible. Every 50m of belting shall have a

unique mark. The tenderer is required to make some suggestions in this regard

The letters AA shall follow the marking for the class e.g. St 2500 AA.

7.2

PACKING

Packing shall comply with the requirements of SANS 1366. The tenderer should also advise

on suitable procedures for sea and road freight, as applicable. The supplier shall advise on

the correct long-term storage of spare conveyor belting of the selected type.

CONTENTS OF DATA PACK

The data pack shall be issued with each belt upon delivery and shall contain the following

information:

A copy of the original order

A copy of the factory job-card, containing information relating to the raw material details

such as steel cords, bonder rubber and cover rubber.

A copy of the certificate supplied by the steel cord manufacturer and a copy of the

results of the cord strength verification test conducted by the manufacturer.

AA_SPEC_377002.doc

APPROVED

3 February 2010

Page 5 of 9

Anglo Technical accepts no liability for any damage whatsoever that may result from the use of this material or the information contained

therein, irrespective of the cause and quantum thereof.

AA SPECIFICATION

377002

STEEL CORD REINFORCED CONVEYOR

BELTING

ISSUE 0

COPYRIGHT

A manufacturing plan indicating the amount of rolls and final lengths.

A copy of the belt design, relating to cord diameters used and cord spacing.

Process control checks.

Finished belt measurements, taken at 50m intervals.

Laboratory test results for tests conducted in accordance with SANS 1366, for all belt

samples.

Repair report sheet.

Final inspection report and signed delivery release from factory.

Approved concession requests (where applicable).

Verification by the supplier that the final product is in accordance with client

requirements and specifications.

In the event of new belting being spliced to existing belting, a splice design approved by

the supplier of the new belting.

In the event of a new installation, a splice design supplied by the manufacturer as well

as a splice plan should more than 2 rolls of belting be supplied. The plan should

indicate the order of installation of the rolls.

A copy of the complete data pack demonstrating compliance with the requirements of

SANS 1366 shall be delivered with the belt. The master copy shall be kept at the offices of

the supplier for a minimum period of 10 years. Three hard copies of the data pack to be

supplied as well as a copy on CD in a recognisable format.

AA_SPEC_377002.doc

APPROVED

3 February 2010

Page 6 of 9

Anglo Technical accepts no liability for any damage whatsoever that may result from the use of this material or the information contained

therein, irrespective of the cause and quantum thereof.

AA SPECIFICATION

377002

STEEL CORD REINFORCED CONVEYOR

BELTING

ISSUE 0

COPYRIGHT

APPENDIX A: RELATED DOCUMENTS

AA SPEC 377002: Steel Cord Reinforced Conveyor Belting

The latest issue of the following documents shall form part of this specification.

AA STD 100

Quality Requirements for Suppliers of Critical and Major Equipment

SANS 1366

Steel cord reinforced conveyor belting

APPENDIX B: RECORD OF AMENDMENTS

Issue 0

AA_SPEC_377002.doc

New document based on AAC 377002 Rev 2; reviewed and updated

(Paul Nel, January 2010)

APPROVED

3 February 2010

Page 7 of 9

Anglo Technical accepts no liability for any damage whatsoever that may result from the use of this material or the information contained

therein, irrespective of the cause and quantum thereof.

AA SPECIFICATION

377002

STEEL CORD REINFORCED CONVEYOR

BELTING

ISSUE 0

COPYRIGHT

APPENDIX C: TECHNICAL REQUIREMENTS TO BE SPECIFIED BY THE ENGINEER

The following requirements shall be specified on every invitation to tender, contract or order:

Title, number, date and issue of this specification

The nominal width of the belt (see Clause 4.5.2)

750

900

1050

1200

1350

1500

1650

1800

2100

St 500

St 1400

St 4000

St 630

St 1600

St 5000

St 800

St 2000

St 6300

St 1000

St 2500

St 1250

St 3150

N-SB

2400

Belt class (see SANS 1366 Clause 4.1)

The type of covers

The cover thickness (see Clause 4.5.3)

Top:

The Contractor shall advise the Company of the minimum

pulley diameter which may be used with the conveyor belt

mm

Bottom

High tension

mm

Drive

mm

Low tension

mm

The length required (see SANS 1366 Clause 4.5.1)

mm

The troughing angle (see SANS 1366 Clause 4.7.3)

The name of the independent Quality Assurance

Representative (see AA STD 100)

AA stock code number (if available)

Engineer

AA_SPEC_377002.doc

For the supplier

APPROVED

3 February 2010

Page 8 of 9

Anglo Technical accepts no liability for any damage whatsoever that may result from the use of this material or the information contained

therein, irrespective of the cause and quantum thereof.

AA SPECIFICATION

377002

STEEL CORD REINFORCED CONVEYOR

BELTING

ISSUE 0

COPYRIGHT

APPENDIX D: PULLEY DIAMETERS

Recommended minimum pulley diameters for use with the classes of belting covered by the standard

are in the table below. The use of flat faced (non-crowned) pulleys is recommended.

1

Pulley Diameter

mm, min

Class

Type A(a)

Type B(b)

Type C(c)

St

500

500

400

315

St

630

500

400

315

St

800

500

400

315

St 1 000

800

630

500

St 1 250

800

630

500

St 1 400

1 000

800

630

St 1 600

1 000

800

630

St 2 000

1 000

800

630

St 2 500

1 250

1 000

800

St 3 500

1 250

1 000

800

St 4 000

1 400

1 250

1 000

St 5 000

1 600

1 400

1 250

St 6 300

2 000

1 600

1 400

(a) Pulley

Type A

High tension type driving pulleys e.g. tandem drive, single drive, head drive and

tripper pulleys; high tension type non-driving pulleys

(b) Pulley

Type B

Low tension type non-driving pulleys e.g. tail, take-up or high tension snub/bend

pulleys that have a wrap angle 30.

(c)

Pulley Type C

Low tension type non-driving pulleys e.g. bend, low tension snub that have a wrap

angle 30.

AA_SPEC_377002.doc

APPROVED

3 February 2010

Page 9 of 9

Anglo Technical accepts no liability for any damage whatsoever that may result from the use of this material or the information contained

therein, irrespective of the cause and quantum thereof.

Vous aimerez peut-être aussi

- Belt Selection Procedure-FENNERDocument12 pagesBelt Selection Procedure-FENNERkmambiPas encore d'évaluation

- Fenner Conveyor Belting Steel CordDocument8 pagesFenner Conveyor Belting Steel CordDavidP04Pas encore d'évaluation

- Technical Data Sheet - Steel Cord FR GradeDocument2 pagesTechnical Data Sheet - Steel Cord FR Gradeamol1321Pas encore d'évaluation

- Maxx Steelflex Steel Cord BeltsDocument12 pagesMaxx Steelflex Steel Cord BeltsVicky ImmanuelPas encore d'évaluation

- SolidwovendatasheetDocument1 pageSolidwovendatasheetjonodo89Pas encore d'évaluation

- Formula calculates conveyor belt transition distanceDocument8 pagesFormula calculates conveyor belt transition distanceRajaram JayaramanPas encore d'évaluation

- NTN 6368 2 Bro Aggrgts FinalDocument8 pagesNTN 6368 2 Bro Aggrgts Finaldeni jakaPas encore d'évaluation

- Is 8531 1986Document6 pagesIs 8531 1986Srini KumarPas encore d'évaluation

- Aac Spec 373001 PDFDocument13 pagesAac Spec 373001 PDFJakesPas encore d'évaluation

- Steel Cord Conveyor BeltingDocument10 pagesSteel Cord Conveyor BeltingnicolasPas encore d'évaluation

- Conveyor BeltsDocument22 pagesConveyor BeltsFavorSea Industrial Channel LimitedPas encore d'évaluation

- E1102m PDFDocument283 pagesE1102m PDFBhawani Singh RajawatPas encore d'évaluation

- IE Catalogue 2007Document38 pagesIE Catalogue 2007Вадим НикитенкоPas encore d'évaluation

- Conveyor Belt Glossary TermsDocument27 pagesConveyor Belt Glossary TermsLuis FloresPas encore d'évaluation

- Boundary Dimensions and Bearing Number CodesDocument4 pagesBoundary Dimensions and Bearing Number CodesPutra Kanjeng Romo RomoPas encore d'évaluation

- Almex Institute - Transitions (1!28!11)Document5 pagesAlmex Institute - Transitions (1!28!11)Luis FloresPas encore d'évaluation

- Gundlach Roll Crushers BrochureDocument2 pagesGundlach Roll Crushers Brochurerajeevup2004Pas encore d'évaluation

- Phoenix Conveyor Belt Technical DataDocument1 pagePhoenix Conveyor Belt Technical DataVenkatesha HebbarPas encore d'évaluation

- Heavy Duty Apron Feeder PDFDocument2 pagesHeavy Duty Apron Feeder PDFNova HeriPas encore d'évaluation

- VibratingEquipmentBrochure PDFDocument10 pagesVibratingEquipmentBrochure PDFWilliam VillamizarPas encore d'évaluation

- Conveyor Transitions: Michael Cremeens, VP Business Development Member, NIBA Education/Technical Committee MemberDocument7 pagesConveyor Transitions: Michael Cremeens, VP Business Development Member, NIBA Education/Technical Committee MemberPanchoMiyamotoPas encore d'évaluation

- Drum & Pulley Lagging - All State Conveyors - Innovative Solutions ProviderDocument7 pagesDrum & Pulley Lagging - All State Conveyors - Innovative Solutions ProviderJosue21SPas encore d'évaluation

- Sole PlatesDocument12 pagesSole Platesjonodo89Pas encore d'évaluation

- en SKF BeltsDocument168 pagesen SKF BeltsYair CorredorPas encore d'évaluation

- Banda Conveyor PDFDocument38 pagesBanda Conveyor PDFJorge Rios RPas encore d'évaluation

- Grooved Drum ArticleDocument2 pagesGrooved Drum ArticleLizardladPas encore d'évaluation

- Production of Conveyor BeltsDocument2 pagesProduction of Conveyor Beltssuraia100% (1)

- Renold Chain CatalogueDocument24 pagesRenold Chain CatalogueThang NguyenPas encore d'évaluation

- Heavy Duty Conveyor Pulley Catalog PDFDocument84 pagesHeavy Duty Conveyor Pulley Catalog PDFJoel MoorePas encore d'évaluation

- I Feeder Application Design CalculationsDocument2 pagesI Feeder Application Design Calculationsarsaniose100% (1)

- Aa Spec 331001Document13 pagesAa Spec 331001Mardi RahardjoPas encore d'évaluation

- BearingDocument4 pagesBearingFidatul Ain HalidPas encore d'évaluation

- WCB External Gear Slewing Bearing-Single Row Ball Slewing RingDocument7 pagesWCB External Gear Slewing Bearing-Single Row Ball Slewing RingWCB BEARINGPas encore d'évaluation

- Conveyor Chain CatalogueDocument51 pagesConveyor Chain CatalogueRay RojasPas encore d'évaluation

- Ramsey Conveyor Protection SwitchesDocument6 pagesRamsey Conveyor Protection SwitchesArif AmirPas encore d'évaluation

- Pans PDFDocument8 pagesPans PDFJorge Prado DiazPas encore d'évaluation

- 06 Kuenzel Elevators GB 10 07Document2 pages06 Kuenzel Elevators GB 10 07Mauricio MpintoPas encore d'évaluation

- Conveying and StoringDocument28 pagesConveying and StoringTin Nguyen100% (1)

- Technical Manual Conveyor Belting GuideDocument39 pagesTechnical Manual Conveyor Belting Guideraja020Pas encore d'évaluation

- Pneumatic Ship and Barge UnloadersDocument6 pagesPneumatic Ship and Barge Unloadersomni_partsPas encore d'évaluation

- Feeder BreakerDocument10 pagesFeeder BreakerAmit BhaduriPas encore d'évaluation

- Conveyor Chain Design GuideDocument64 pagesConveyor Chain Design GuideAtacomaPas encore d'évaluation

- Shrink Disc MAVDocument36 pagesShrink Disc MAVTim kuPas encore d'évaluation

- Understanding The Vulcanizing Cycle As Used in Splicing (3!28!11)Document7 pagesUnderstanding The Vulcanizing Cycle As Used in Splicing (3!28!11)Luis FloresPas encore d'évaluation

- Solutions Guide: Standards I Members I ProductsDocument75 pagesSolutions Guide: Standards I Members I ProductsZul ZulhilmiPas encore d'évaluation

- AA SPEC 371001 - Conveyor Pulleys and ShaftsDocument14 pagesAA SPEC 371001 - Conveyor Pulleys and Shaftsjonodo89Pas encore d'évaluation

- Renold Wheels SprocketsDocument36 pagesRenold Wheels Sprocketssumanthkulkarni07Pas encore d'évaluation

- 2010 - Telescopic ChuteDocument29 pages2010 - Telescopic ChutesteelagePas encore d'évaluation

- Chaplin 1995Document13 pagesChaplin 1995Rodrigo Alejandro Flores ZuñigaPas encore d'évaluation

- CBG8144 en Solution Cement IndustryDocument12 pagesCBG8144 en Solution Cement IndustryJavier TorresPas encore d'évaluation

- Bucket elevator chains and components guideDocument45 pagesBucket elevator chains and components guideMuhammad Irvan FPas encore d'évaluation

- Conveyor Belt Cover GradesDocument1 pageConveyor Belt Cover GradessuraiaPas encore d'évaluation

- ED261d01 Alta VelocidadDocument48 pagesED261d01 Alta Velocidadoctavio lugoPas encore d'évaluation

- Specification Adrde 210212Document87 pagesSpecification Adrde 210212HEMANTKHERAPas encore d'évaluation

- CB Continental CatalogueDocument69 pagesCB Continental CatalogueAina LikuntatiPas encore d'évaluation

- PUBLIC POWER CORPORATION SPECIFICATION FOR STOCKBRIDGE VIBRATION DAMPERSDocument10 pagesPUBLIC POWER CORPORATION SPECIFICATION FOR STOCKBRIDGE VIBRATION DAMPERSgiorgis072Pas encore d'évaluation

- Aa Spec 371002Document5 pagesAa Spec 371002JDPas encore d'évaluation

- FS4005 Cable TraysDocument8 pagesFS4005 Cable TraysRamesh AnanthanarayananPas encore d'évaluation

- Aashto M-180 PDFDocument11 pagesAashto M-180 PDF48181Pas encore d'évaluation

- Astm A82-79Document5 pagesAstm A82-79jameyconnorPas encore d'évaluation

- L100 (0a)Document1 pageL100 (0a)jonodo89Pas encore d'évaluation

- ENG ECI ELC SPC 004 Electrical InstallationDocument68 pagesENG ECI ELC SPC 004 Electrical Installationjonodo89Pas encore d'évaluation

- Sole PlatesDocument12 pagesSole Platesjonodo89Pas encore d'évaluation

- K0001 A430 M SPC 0011 Rev02 Metallic Wear LiningDocument15 pagesK0001 A430 M SPC 0011 Rev02 Metallic Wear Liningjonodo89Pas encore d'évaluation

- Fire Protection Standard For Electrical Equipment and InstallationsDocument27 pagesFire Protection Standard For Electrical Equipment and Installationsjonodo89100% (1)

- EXX-EME-STD-0008 - Wear Liners For Plate Work and ChutesDocument22 pagesEXX-EME-STD-0008 - Wear Liners For Plate Work and Chutesjonodo89100% (1)

- Cable Racking Oline Catalogue - 2011 Pages 84 86Document3 pagesCable Racking Oline Catalogue - 2011 Pages 84 86jonodo89Pas encore d'évaluation

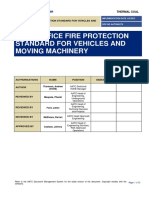

- Fire Protection Standard For Vehicles and Moving MachineryDocument39 pagesFire Protection Standard For Vehicles and Moving Machineryjonodo89100% (1)

- Fire Protection Standard For Use of Plastic PipesDocument6 pagesFire Protection Standard For Use of Plastic Pipesjonodo89Pas encore d'évaluation

- Static Shaft Pulleys With Internal BearingsDocument14 pagesStatic Shaft Pulleys With Internal Bearingsjonodo89100% (1)

- Surface Preparation and Paint SpecificationDocument63 pagesSurface Preparation and Paint Specificationjonodo89Pas encore d'évaluation

- Generic Geared ReducersDocument12 pagesGeneric Geared Reducersjonodo89Pas encore d'évaluation

- Belt Conveyor Idlers and RollsDocument14 pagesBelt Conveyor Idlers and Rollsjonodo89Pas encore d'évaluation

- K0001 A430 M SPC 0011 Rev02 Metallic Wear LiningDocument15 pagesK0001 A430 M SPC 0011 Rev02 Metallic Wear Liningjonodo89Pas encore d'évaluation

- Equipment SafeguardingDocument40 pagesEquipment Safeguardingjonodo89Pas encore d'évaluation

- Mechanical StandardsDocument10 pagesMechanical Standardsjonodo890% (1)

- Conveyor Equipment SpecificationDocument20 pagesConveyor Equipment Specificationjonodo89Pas encore d'évaluation

- The Design of Troughed Belt ConveyorsDocument44 pagesThe Design of Troughed Belt Conveyorsjonodo89Pas encore d'évaluation

- Conveyor Belt Protection SystemsDocument12 pagesConveyor Belt Protection Systemsjonodo89Pas encore d'évaluation

- Screw Take UpsDocument7 pagesScrew Take Upsjonodo89Pas encore d'évaluation

- 2RVRETURNS25Document1 page2RVRETURNS25jonodo89Pas encore d'évaluation

- Single ClampDocument1 pageSingle Clampjonodo89Pas encore d'évaluation

- New Doc 2018-04-24Document6 pagesNew Doc 2018-04-24jonodo89Pas encore d'évaluation

- AATC000859 - AATC Design Criteria and Guidelines For Surface Infrastructure - Mechanical & StructuralDocument68 pagesAATC000859 - AATC Design Criteria and Guidelines For Surface Infrastructure - Mechanical & Structuraljonodo89Pas encore d'évaluation

- 2RVRETURNS25Document1 page2RVRETURNS25jonodo89Pas encore d'évaluation

- New Doc 2018-04-24Document6 pagesNew Doc 2018-04-24jonodo89Pas encore d'évaluation

- M&T Risk & AssuranceDocument39 pagesM&T Risk & Assurancejonodo89Pas encore d'évaluation

- BB Design ReportDocument79 pagesBB Design Reportjonodo89Pas encore d'évaluation

- Aa Spec 114005Document45 pagesAa Spec 114005jonodo8950% (2)

- ERP in Apparel IndustryDocument17 pagesERP in Apparel IndustrySuman KumarPas encore d'évaluation

- The Crucible Summary and Analysis of Act TwoDocument4 pagesThe Crucible Summary and Analysis of Act TwoXhéhzÂda saleem zehriPas encore d'évaluation

- Demonetisation IndiaDocument71 pagesDemonetisation IndiaVinay GuptaPas encore d'évaluation

- Multimodal Transport Bill of Lading PDFDocument3 pagesMultimodal Transport Bill of Lading PDFJulia TombakPas encore d'évaluation

- Action Plan for Integrated Waste Management in SaharanpurDocument5 pagesAction Plan for Integrated Waste Management in SaharanpuramitPas encore d'évaluation

- Cost of DebtDocument3 pagesCost of DebtGonzalo De CorralPas encore d'évaluation

- Pharma: Conclave 2018Document4 pagesPharma: Conclave 2018Abhinav SahaniPas encore d'évaluation

- How K P Pinpoint Events Prasna PDFDocument129 pagesHow K P Pinpoint Events Prasna PDFRavindra ChandelPas encore d'évaluation

- Construct Basic Sentence in TagalogDocument7 pagesConstruct Basic Sentence in TagalogXamm4275 SamPas encore d'évaluation

- The Princess AhmadeeDocument6 pagesThe Princess AhmadeeAnnette EdwardsPas encore d'évaluation

- Demand To Vacate - Januario MendozaDocument1 pageDemand To Vacate - Januario Mendozaclaudenson18Pas encore d'évaluation

- Chaitanya Candra KaumudiDocument768 pagesChaitanya Candra KaumudiGiriraja Gopal DasaPas encore d'évaluation

- List of Universities in Tamil Nadu1Document7 pagesList of Universities in Tamil Nadu1RCAS IICPas encore d'évaluation

- Disaster Drilling Land RigsDocument21 pagesDisaster Drilling Land Rigsmohanned salahPas encore d'évaluation

- F1 English PT3 Formatted Exam PaperDocument10 pagesF1 English PT3 Formatted Exam PaperCmot Qkf Sia-zPas encore d'évaluation

- Student Majoriti Planing After GrdaduationDocument13 pagesStudent Majoriti Planing After GrdaduationShafizahNurPas encore d'évaluation

- CPAR and UCSP classes inspire passion for healthcareDocument2 pagesCPAR and UCSP classes inspire passion for healthcareMARIAPATRICIA MENDOZAPas encore d'évaluation

- Vitiating Factors in ContractsDocument20 pagesVitiating Factors in ContractsDiana Wangamati100% (6)

- WordAds - High Quality Ads For WordPress Generate IncomeDocument1 pageWordAds - High Quality Ads For WordPress Generate IncomeSulemanPas encore d'évaluation

- IEC 60050-151-2001 Amd2-2014Document8 pagesIEC 60050-151-2001 Amd2-2014mameri malekPas encore d'évaluation

- CEI KAH OCT v1Document1 pageCEI KAH OCT v1Francis Ho HoPas encore d'évaluation

- Dorfman v. UCSD Ruling - California Court of Appeal, Fourth Appellate DivisionDocument20 pagesDorfman v. UCSD Ruling - California Court of Appeal, Fourth Appellate DivisionThe College FixPas encore d'évaluation

- The Genesis of The Five Aggregate TeachingDocument26 pagesThe Genesis of The Five Aggregate Teachingcrizna1Pas encore d'évaluation

- The Witch of Kings CrossDocument11 pagesThe Witch of Kings CrossMarguerite and Leni Johnson100% (1)

- Madhuri Economics of Banking Semester 1 ProjectDocument35 pagesMadhuri Economics of Banking Semester 1 ProjectAnaniya TiwariPas encore d'évaluation

- Capital Fixed & Working - New SyllabusDocument6 pagesCapital Fixed & Working - New SyllabusNaaz AliPas encore d'évaluation

- Court rules on nullification of title in ejectment caseDocument1 pageCourt rules on nullification of title in ejectment caseNapolyn FernandezPas encore d'évaluation

- Hwa Tai AR2015 (Bursa)Document104 pagesHwa Tai AR2015 (Bursa)Muhammad AzmanPas encore d'évaluation

- Indian Accounting StandardsDocument4 pagesIndian Accounting StandardsManjunatha B KumarappaPas encore d'évaluation

- IMRANADocument4 pagesIMRANAAji MohammedPas encore d'évaluation