Académique Documents

Professionnel Documents

Culture Documents

An-Claisse Coal Ash and Flyash

Transféré par

Dhandapani ManoharanCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

An-Claisse Coal Ash and Flyash

Transféré par

Dhandapani ManoharanDroits d'auteur :

Formats disponibles

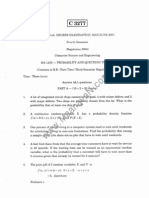

ICP-OES APPLICATION

Characterization of Coal, Coal Ash and Coal Fly Ash Using Borate Fusion for ICP Analysis

Authors: Mlanie BDARD, Janice PITRE and Philippe DAIGLE | Claisse

INTRODUCTION

Global Sample Preparation Method

Coal is the most abundant fossil fuel in the world[1]. It has been used by

humans for centuries and is still widely used today to produce electricity, steel

and industry materials such as cement[2].

Before being submitted to the fusion process, each sample was ashed in a Pt/Au crucible in

the muffle furnace according to this following ashing method:

It is essential for industries to characterize coal to fully understand its use as

well as to manage the recovery of its derivative products in order to reduce

the environmental impact. Characterization also prevents damages on industrial

equipment caused by mineral deposit in furnaces and kettles[3].

The purpose of this project is to demonstrate that precision and accuracy

criteria in standard methods such as ASTM D6357, ASTM D6349 and

AS 1038.14 1-2003 can be met by using borate fusion as a dissolution method

for ICP-OES analysis. This preparation step will be facilitated by using

LeNeo fusion instrument.

Ramp up to 500C for 1 hour

Ramp up to 750C for 2 hours

Hold at 750C for 2 hours

The ashes were then fused following the procedure of mixing 0.150 g of lithium nitrate

(LiNO3) and 1.000 g of lithium metaborate/1.5% lithium bromide (LiM/LiBr) flux in Pt/Au

crucibles. A fully automatic LeNeo instrument was used to fuse the samples.

The complete process of fusion and dissolution took less than 15 minutes. The resulting

solutions were then diluted up to 200 mL in 10% nitric acid for subsequent analyses on

a Perkin Elmer Optima 7300 DV ICP-OES.

RESULTS

METHOD

High lithium matrix can cause signal suppression or signal increase for some elements.

In order to counteract this effect, matrix matching and internal standards were used. The

dilution of sample prevented any clogging caused by a high salt matrix. The calibration

solutions of each element were done in a LiM/LiBr 1.5% matrix, just like the sample. Calibration curves were done using a concentration range close to the sample concentrations.

Sample concentrations are within the calibration range. Five points including the blank were

used for each element. The correlation of each curve was higher than 0.999.

Apparatus and Instrumental Conditions

An automatic LeNeo fusion

instrument designed by

Claisse was used to

generate borate solutions.

Its resistance-based electric

system, excellent insulation

properties and preset fusion

programs allow a uniform

heating, thus providing

repeatable and reproducible fusion conditions and a

perfect retention of volatile

elements.

Method Detection Limits

Method detection limits (MDLs) were based on 10 replicate measurements of a series of

low diluted sample solutions. The MDL was calculated by multiplying the standard deviation

of the 10 replicate measurements by three.

MDL= 3 x S10

A Fisher Scientific Isotemp muffle furnace was used for the LOI determinations

and the preparation of ignited samples.

A Perkin Elmer Optima 7300 DV ICP-OES spectrometer was used to collect the

data. The operating parameters used on the spectrometer are shown in Table 1.

TABLE 1: Optima 7300 DV operating parameters

Nebulizer

1.

2.

3.

Gem Tip Cross flow

Spray chamber

Scott

Injector

Alumina 2 mm i.d.

RF

1500 W

Argon flow

Sample flow rate

Plasma: 16 L/min

Nebulizer: 0.8 L/min

Auxiliary: 0.4 L/min

1.0 mL/min

TABLE 2: Method detection limit obtained by wavelength used and type of view

Elements

Wavelength

(nm)

View

MDL

(mg/L)

Elements

Wavelength

(nm)

View

MDL

(mg/L)

Al

237.313

Axial

0.07

Na

589.592

Radial

0.05

Ba

413.065

Axial

0.006

177.434

Axial

0.03

Ca

422.673

Radial

0.1

181.975

Axial

0.06

Fe

238.863

Axial

0.02

Si

252.851

Radial

0.07

766.490

Axial

0.002

Sr

460.733

Axial

0.002

337.279

Axial

0.002

213.857

Axial

0.003

Mg

279.077

Axial

0.007

Ti

Mn

293.305

Axial

0.001

Zn

ICP-OES APPLICATION

Accuracy and Precision

Recovery

The following tables show the precision and accuracy obtained in coal and fly ash with

three different certified reference materials (CRMs) (10 replicates for each CRM). The

precision expresses the closeness of the results obtained in a series of 10 measurements

made with the same sample while the accuracy is the proximity of measurement results to

the true value. Both were calculated based on the certified values of the following certified

reference materials: EOP-12-1-02, NCS FC28127 and VS 7177-95.

Table 6 shows the recovery values obtained in different matrixes. Recovery was calculated

on five replicates in each of the certified reference materials used.

Certified values

(%)

Experimental values

(%) n=10

Precision t0,975;9

(%)

Accuracy

(%)

RSD

(%)

Al

16.1

16.3

0.1

98.7

0.5

Ca

1.49

1.44

0.04

96.5

3.9

Fe

5.17

5.21

0.02

99.2

0.5

0.651

0.630

0.011

96.7

2.4

Mg

0.581

0.623

0.002

93.0

0.5

Na

0.361

0.37

0.01

97.6

3.5

Si

22.9

23.8

0.4

96.3

3.7

Ti

3.61

3.44

0.01

95.3

0.5

TABLE 4: Precision and accuracy in coal ash with reference material NCS FC28127

Elements

Certified values

(%)

Experimental values

(%) n=10

Precision t0,975;9

(%)

Accuracy

(%)

RSD

(%)

Al

3.47

3.37

0.03

97.1

1.2

Ca

1.88

1.89

0.04

99.3

2.8

Fe

1.02

1.05

0.01

97.4

1.0

0.29

0.281

0.005

97.0

2.5

Mg

0.28

0.294

0.002

94.7

0.8

Na

Si

0.052

5.61

0.052

6.05

0.001

0.06

99.6

92.2

2.2

1.3

Ti

0.18

0.173

0.002

96.4

1.4

NCS FC28127

(Coal ash)

VS 7177-95

(Coal)

Spiked values Recovery RSD Spiked values Recovery RSD Spiked values Recovery RSD

(mg/L)

(%)

(%)

(mg/L)

(%)

(%)

(mg/L)

(%)

(%)

Ba

102

0.4

102

103

91

102

91

Mn

102

100

0.7

104

0.6

99

103

101

97

100

96

Sr

96

100

0.9

98

Zn

100

0.7

101

0.9

101

CONCLUSIONS

The results presented in the previous tables indicate that sample preparation by borate

fusion followed by ICP-OES analysis is an effective method to analyse coal and fly

ash. The accuracy obtained (between 91.0 and 99.6%) combined with an excellent recovery

(100% 3% for most elements with a relative standard deviation below 3% for all

elements, except for two of them) show that the method is highly efficient. The method

also showed good precision, thus proving its receptivity. This demonstrates that the use of

LeNeo fusion instrument leads to reproducible and efficient methods, despite the sample

dissolution to reduce its salt content.

REFERENCES

[1] Coal Association of Canada. About Coal. Retrieved from the Website www.coal.ca. Calgary, Alberta. 2015.

TABLE 5: Precision and accuracy in coal with reference material VS 7177-95

Elements

Certified values

(%)*

Experimental values

(%) n=10

Precision t0,975;9

(%)

Accuracy

(%)

RSD

(%)

Al

Ca

Fe

K

Mg

Na

Si

Ti

14.33

3.49

3.83

0.49

0.893

0.10

27.43

0.36

14.0

3.70

3.73

0.446

0.874

0.11

28.6

0.357

0.1

0.06

0.03

0.006

0.009

0.01

0.4

0.003

97.7

94.0

97.3

91.0

97.9

97.6

95.7

99.3

1.3

2.4

1.0

1.9

1.5

3.1

2.1

1.2

[2] Coal Association of Canada. Module 1: Coal Evolution. Retrieved from the official Website at http://www.

coal.ca/wp-content/uploads/2012/04/module1_evolution.pdf. Calgary, Alberta. 2003. 12pp.

[3] PITRE, J. and BDARD, M. Characterization of Coal and its By-products Using Borate Fusion and ICP-OES

Analysis. ICP-OES application note. 2014.

*Measured as Al but reported as Al2O3 on the certificate of analysis provided with material

Claisse Headquarters

350 Franquet St., suite 45

Qubec City, Quebec

G1P 4P3 CANADA

claisse.com

0.2

Phone: +1 418. 656. 6453

Fax: +1 418. 656. 1169

Scan this code to discover

other application notes

V1-R1

Elements

Elements

EOP 12-1-02

(Brown coal fly ash)

Claisse, 2015, All rights reserved. The following trade marks are owned by Claisse : Claisse, Claisse Fluxer, Claisse (design), The First and Finest in fusion and LeNeo.

TABLE 3: Precision and accuracy in brown coal fly ash with reference material EOP 12-1-02

TABLE 6: Recovery obtained in coal, ash and fly ash

Vous aimerez peut-être aussi

- PANalytical CNA CementDocument4 pagesPANalytical CNA CementDhandapani Manoharan100% (1)

- Cement AnalysisDocument2 pagesCement AnalysisDhandapani Manoharan100% (1)

- Gas Turbines A Manual PDFDocument74 pagesGas Turbines A Manual PDFHenry Pannell100% (1)

- Hydro Capacity of World CountriesDocument1 pageHydro Capacity of World CountriesDhandapani ManoharanPas encore d'évaluation

- Boiler Tube Failures Due To Improper CommissioningDocument21 pagesBoiler Tube Failures Due To Improper CommissioningDhandapani ManoharanPas encore d'évaluation

- Electrical EngineerDocument1 pageElectrical EngineerDhandapani ManoharanPas encore d'évaluation

- WHRB BoilerDocument36 pagesWHRB BoilerDhandapani Manoharan100% (1)

- Electrical EngineerDocument1 pageElectrical EngineerDhandapani ManoharanPas encore d'évaluation

- Energy-Based Hybrid Control For The RTAC System: Experimental ResultsDocument6 pagesEnergy-Based Hybrid Control For The RTAC System: Experimental ResultsDhandapani ManoharanPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Quad Encoder Velocity Accel with CRIOLabVIEW FPGADocument5 pagesQuad Encoder Velocity Accel with CRIOLabVIEW FPGAChâu Tinh TrìPas encore d'évaluation

- Journal of King Saud University - Computer and Information SciencesDocument10 pagesJournal of King Saud University - Computer and Information SciencesArunima MaitraPas encore d'évaluation

- PQT MJ07Document6 pagesPQT MJ07Raguraman BalajiPas encore d'évaluation

- ICM User GuideDocument84 pagesICM User Guidewords2zhigang_612545Pas encore d'évaluation

- Data Sheet 6AV6545-0DA10-0AX0: General InformationDocument8 pagesData Sheet 6AV6545-0DA10-0AX0: General InformationSean MorrisonPas encore d'évaluation

- Aqa MM1B W QP Jun07Document8 pagesAqa MM1B W QP Jun07Annan_Faridi_517Pas encore d'évaluation

- Measuring AssignmentDocument3 pagesMeasuring AssignmentArnab BhattacharyaPas encore d'évaluation

- Roll Handling Data Form: Company DetailsDocument1 pageRoll Handling Data Form: Company DetailsAlfredo MinchezPas encore d'évaluation

- Mechanical Technology Concepts: Applied ThermodynamicsDocument45 pagesMechanical Technology Concepts: Applied ThermodynamicsLe0 GamingPas encore d'évaluation

- Class - 8 PT3 - Portion 2023 24 - 1Document5 pagesClass - 8 PT3 - Portion 2023 24 - 1gurdeepbeniwal97Pas encore d'évaluation

- Scalable Analog/Addressable Fire Alarm Control System: IFP-2100ECS / IFP-2100ECSBDocument2 pagesScalable Analog/Addressable Fire Alarm Control System: IFP-2100ECS / IFP-2100ECSBMurali DaranPas encore d'évaluation

- Electrical Circuit Analysis ProblemsDocument14 pagesElectrical Circuit Analysis ProblemsMd Rafiqul IslamPas encore d'évaluation

- Using LD - PreloadDocument4 pagesUsing LD - Preloadmr z3iyaPas encore d'évaluation

- LIFTING PERFORMANCE OF THE SY215C EXCAVATORDocument4 pagesLIFTING PERFORMANCE OF THE SY215C EXCAVATORAkhmad SebehPas encore d'évaluation

- Body Fat PercentageDocument7 pagesBody Fat Percentagegurveer singhPas encore d'évaluation

- The Use and Misuse of SEMDocument30 pagesThe Use and Misuse of SEMPPDTBM renPas encore d'évaluation

- Area Under The CurveDocument3 pagesArea Under The CurveReyland DumlaoPas encore d'évaluation

- Fontargen AJ PDFDocument282 pagesFontargen AJ PDFantonyPas encore d'évaluation

- Manulife VRV System Selection for Philippines OfficeDocument7 pagesManulife VRV System Selection for Philippines Officelucio ruiz jrPas encore d'évaluation

- Blockchain Technology For Cloud Storage - A Systematic Literature ReviewDocument33 pagesBlockchain Technology For Cloud Storage - A Systematic Literature ReviewNgocPas encore d'évaluation

- A Stated-Preference Study of The Willingness-To-Pay To Reduce Traffic Risk in Urban vs. Rural RoadsDocument13 pagesA Stated-Preference Study of The Willingness-To-Pay To Reduce Traffic Risk in Urban vs. Rural RoadsSantanu KumarPas encore d'évaluation

- Smart AntennasDocument40 pagesSmart AntennasMeeraPas encore d'évaluation

- Connection Design Steel Base Plate Bs5950 v2015 01Document4 pagesConnection Design Steel Base Plate Bs5950 v2015 01Anonymous j9PxwnoPas encore d'évaluation

- John Deere 772d 6wd GraderDocument6 pagesJohn Deere 772d 6wd GraderyaserattiaPas encore d'évaluation

- Excel ShortcutsDocument21 pagesExcel Shortcutsrushishinde9797Pas encore d'évaluation

- Laminar Flow Reactor ProblemDocument6 pagesLaminar Flow Reactor ProblemAileen Banua Añonuevo100% (1)

- Effort Distribution On Waterfall and AgileDocument12 pagesEffort Distribution On Waterfall and Agileanandapramanik100% (2)

- 24Document3 pages24sdssdPas encore d'évaluation

- Microelectronic Circuit Design 5th Edition Jaeger Blalock Solution ManualDocument21 pagesMicroelectronic Circuit Design 5th Edition Jaeger Blalock Solution Manualruth100% (23)