Académique Documents

Professionnel Documents

Culture Documents

Upgrading The Shear Strength

Transféré par

Chinthaka IddamalgodaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Upgrading The Shear Strength

Transféré par

Chinthaka IddamalgodaDroits d'auteur :

Formats disponibles

Electronic Journal of Structural Engineering, 7(2007)

Upgrading the shear strength of non-ductile reinforced concrete frame

connections using FRP overlay systems

Mohamad J. Terro

Associate Professor. Civil Engineering Department, Kuwait University.

Sameer Hamoush

Associate Professor. Architectural Engineering Department, North Carolina AandT State University.

Moetaz El-Hawary

Research Scientist, Building and Energy Tech. Dept., Kuwait Institute for Scientific Research, PO Box 24885

Safat 13109, Kuwait. Email: mhawary@safat.kisr.edu.kw

ABSTRACT: This investigation presents the use of Fiber Reinforced Polymer (FRP) composite systems in upgrading existing reinforced concrete frames to meet strength and ductility requirements laid out in recent ACI

building codes (ACI-318. 2002). Analytical calculations are presented for the shear behavior of frames strengthened with layers of FRP and an experimental study is carried out to verify the mechanical properties of the proposed FRP systems with various fiber architecture designs. Carbon and fiber glass FRP systems have been analysed. Flat layers and corrugated shapes with rectangular and circular configurations are employed in the

retrofitting systems in addition to various orientations of the fibers which are taken into consideration. The ductility requirement is ensured by controlling the out of plane flexural rigidity of the FRP systems. The desired out

of plane rigidity is obtained by increasing the thickness of the FRP systems or by corrugating the applied FRP

overlays. In conclusion, this study has shown that the use of FRP systems is an efficient and viable repair

method for upgrading concrete frame connections with shear deficiency.

KEYWORDS: shear; FRP; connections; strength; ductility

The study, Gergely et al. (2000), demonstrated the

viability and efficiency of the use of carbon FRP

systems in improving the shear capacity of T-joints.

The analytical and design models used for selecting

the FRP repair systems for improving shear strength,

however, is still the subject of research and requires

significant refinement to ensure optimal repair designs and system performance.

1 INTRODUCTION

Rehabilitation of non-ductile concrete frame joints

to improve strength, confinement, and ductility has

gained considerable attention in recent years (Scott

1996, Hwang and Lee 1999, 2000). Most investigations in the literature aimed at the study of the behaviour of the RC frame connections and their rehabilitation to meet recent design considerations or

provide adequate shear reinforcement after exposure

to seismic loads. A repair method using epoxy injection, removal and replacement of crushed concrete, and RC jacketing of heavily damaged joints

according to the United Nations Industrial Development Organization (UNIDO) manual guidelines

has been proposed, Tsonos (1999). The use of corrugated steel jacketing has also been suggested and

evaluated to upgrade RC frame connections, Bidda

et al. (1997). Strengthening RC T-joints with Carbon FRP systems have been investigated experimentally, Gergely et al. (2000). Design aids for such

joints have been developed in that study. The orientation of the fibres and the surface preparation were

found to affect the efficiency and level of shear

strengthening of the joints.

In this paper, the analysis of rehabilitation systems

using glass and carbon FRP layers to upgrade the

shear strength in deficient concrete frame connections is discussed. The upgrading techniques are

aimed at the strength and ductility requirements laid

out in recent ACI building codes, ACI (2002). An

experimental work is carried out including rectangular and circular corrugated shapes in the retrofitting

systems with different orientations of the fibres. The

out of plane flexural rigidity of the FRP systems ensures the ductility requirement whereas strength requirements are met by increasing the thickness

and/or corrugating the applied FRP overlays.

Electronic Journal of Structural Engineering, 7(2007)

2 SPECIMEN DESIGN

A frame connection is considered in the design of

equivalent FRP retrofitting systems for upgrading

connections with deficiency in shear. The frame

connection is shown in Figure 1(a, b, c and d) in

typical connection with and without spandrel beams

for one and three story structures. The cross section

of the beam is 300 x 600 mm with 2 28 (2 bars of

diameter 28 mm) bottom reinforcement and 4 28

for the top steel. The column has a cross section of

600 x 600 mm with 8 25 reinforcement. Cover to

reinforcement of 40 mm was maintained for all

members. The utilized mix consists of 330 kg of ordinary Portland cement, 640 kg of crushed sand and

1280 kg of quartzite coarse aggregates with water to

cement ratio of 0.5.

The compressive strength of concrete (fc) is 27.6

MPa, and the steel yield stress (fy) 413.7 MPa.

225

428

228

600

300

325

600

600

(c) Typical exterior connection without spandrel beams

for a three-story structure (dimensions in mm).

225

300560 Spandrel Beams

428

228

600

428

300

325

228

600

300

325

600

325

600

600

(a) Typical exterior connection without spandrel beams for

a one-story structure (dimensions in mm).

600

(d) Typical exterior connection with spandrel beams for a

three-story structure (dimensions in mm).

300560 Spandrel Beams

Figure 1. Typical connection designs considered in the analysis

of FRP repair systems.

428 228

225

600

3 SHEAR DESIGN BASED ON ACI-318 (2002)

300

The calculated ultimate moment capacity of the

beam forming the joint is 514 kN.m.

325

Figures 2 (a) and (b) show free body diagrams of

the joints in figures 1 (a) and (c) respectively. A 4.5

m length is considered for columns

600

600

(b) Typical exterior connection with spandrel beams for a

one-story structure (dimensions in mm).

Electronic Journal of Structural Engineering, 7(2007)

T= 1.25 Asfy

Mb =514 kN.m

Ash 0.09 sh hc (

T= 1334 kN

Vc =112.5

Vc =112.5 kN

Vj =1334kN

(4)

Vc =112.5 kN

Where, Ash is total cross-sectional area, sh is the

spacing of transverse reinforcement ,hc is the crosssectional dimension of column core, Ag is the gross

area, Ac is the cross-sectional area of the structural

member and fyh is the specified yield strength of

shear reinforcement.

Mc =514 kN.m

C=1334 kN

Vc =112.5kN

Horizontal section in the joint

Corner equilibrium

f c'

)

f yh

(a) Free body diagram for the joint in Figure 1 (a).

hc = 600 2 ( 38 +12.0 / 2) = 511 mm.

where, 38 mm is the concrete cover and 12 mm is

the stirrup diameter.

Vc2= 112.5 KN T = 1.25Asfy

T = 1334 kN

Mc2= 257 kN.m

Vc2= 112.5 kN

Mb= 514 kN.m

Ac = (600 2 38) 2 = 275000mm 2

Vj = 1223.2 kN

Vc = 56.5 kN

Ash

= 0.3 511 (27.6 / 413.7)

Sh

((600 600 / 275000 ) 1) = 3.16 mm

(6)

Ash

= 0.09 511 (27.6 / 413.7) = 3.07 mm

(7)

Sh

A

Therefore, the value for sh in equation (6) controls.

Sh

Vc = 56.5 kN

Vc1 = 56.5 kN

C = 1334 kN

Mc1= 514/2 = 257 kN.m

Corner equilibrium

Vc = 56.5 kN

Horizontal section in the joint

(b) Free body diagram for joint in Figure 1 (c).

Figure 2. Free body diagrams for typical exterior joints.

Spacing of the hoops sx is the minimum of:

3.1 Shear Calculation of the Joint

of the minimum member dimension

The nominal shear strength of the connection is

given in ACI 318-02 code as:

Vn = ( f c' )1 / 2 b j h

( 0.25 600 = 150 mm )

six times the smallest longitudinal beams bars diameter (628.6 =171.5 mm)

(1)

Where Vn is the nominal shear stress, is the fracture of unbalanced moment, bj is the average dimension and h is the overall thickness.

sx as defined by:

s x = 100 + (350 hx ) / 3

For the joints in Figure 1, is 1, bj is (300+600) =

450 mm, and h is 600 mm.

Vn = 1(27.6)

1/ 2

450 600 / 1000 = 1418.5kN

V j = 1334.4kN

(5)

Where,

hx = 300 38 12.7 / 2 = 255.7 mm

s x = 100 + (350 255.7) / 3 = 131.5 mm

(2)

150 mm, and not less than 100 mm.

where, , Vj is the factored shear force and h = 600

20 bd = 20(31.75) = 571.5 mm.

Based on the above, s x is chosen as 100 mm.

Therefore, the dimension of the joint is acceptable.

Ash = 100 3.16 = 316 mm2

3.2 Design of the Required Transverse Steel

Use hoops of 12mm diameter with three legs in each

direction ( Ash = 339 mm 2 ) as shown in Figure 3.

The required steel area is derived as follows:

Ash 0.3 sh hc (

A

f

) g 1

f yh Ac

'

c

It can be noted that the amount of reinforcement for

joint of Figure 1 (b) is the same as that for joint of

Figure 1(a), since the spandrel beam does not cover

of the joint surface area. The spandrel beam cross

section is 300560 = 168000 mm2. The joint surface

area is 360000 mm2.

(3)

But, not less than:

10

Electronic Journal of Structural Engineering, 7(2007)

D-3039-00) and the remaining eight configurations

in flexural bending (ASTM D-790-92). The evaluated configurations consisted of two fibre materials,

carbon and glass, and two lay-ups of the fibre orientations. The fibre orientations were limited to 0/90o

and 45o.

If a larger section for the spandrel beam is used, the

transverse steel requirement will be cut to half of the

calculated value above. The spacing between the

hoops will be limited to 150 mm.

Three legs of 12 with

100 mm on center

The material properties of the fibers used in the

experimental program are shown in Table1.

300

600

300

The distance between

the top and bottom

steel of the beam is

450 mm. Therefore,

use 5 rows of hoop

steel within the

connection.

The resin used was ATLAC 580-05 Vinyl Ester

in room temperature curing. Summary of the experimental program is shown in Tables 2 (a) and (b).

The fiber balance

Table 1. Properties of the fiber used

600

Composite Materials

Figure 3: Steel reinforcement in the cross section of the

connection (Dimensions in mm).

Carbon W-5-322

1.25 %

1.0 %

Elastic Modulus (GPa)

27.6

48.3

Design Thickness

(mm/layer)

0.2718

0.3302

Ultimate Tension

Strength (MPa)

Ultimate Elongation

4 SHEAR CONNECTIONS REINFORCED

WITH FRP SYSTEMS

In this section, the design is based on the strength

requirements as specified by the hoop steel area provided by the ACI 318-02 Code and the ductility requirements as specified by the hoop steel spacing.

483

was maintained for all specimens of the experimental program. Also, it must be mentioned that the

thickness of the bending test specimens was doubled

to provide extra flexural rigidity for meaningful

tests.

4.1 Strength Requirements

Simple analytical procedures are developed to design the retrofitting system to satisfy the strength requirements of concrete connections using the ACI318-02 Code recommendations. The analysis is

based on the assumption that an equivalent force

generated by the FRP materials (fulstf) replaces

the required confining force exerted by the hoop

steel (Ashfy). The equivalent force in the FRP materials is calculated at a stress level (Ful/SF), where the

Ful is the rupture stress of the FRP materials, and SF

is the safety factor assumed to have a value of 2.

The purpose of the testing program is to evaluate the

elastic modulus of various FRP system configurations (E1) using the direct tension specimens and to

estimate the equivalent moment of inertia using the

flexural testing specimens for each of the proposed

configuration. Each specimen consisted of three FRP

layers (Table 2).

Figures 4 and 5 show results for the stress-strain

and load-deflection relation for typical specimens

sets respectively. In general, three specimens were

used for each set as laid out in Table 2.

The required thickness of the FRP materials over the

s (spacing between the hoop steel) is given by simple mechanics as

tf = 2 Ashfy / ( ful s)

Glass BFG

2532

345

The flexural rigidity for specimens with the fiber architectures identical to those of the specimens used

for the tensile tests was evaluated in the experiments. The purpose of the flexural tests is to establish a relationship between the applied load and the

mid span deflection that results in experimental values for the stiffness (E1I), where E1 is the elastic

modulus along the beam direction and I is the sectional moment of inertia. The flexural tests were performed using two point loads at quarter distance

from the supports.

(8)

Where, tf is the thickness of the FRP materials.

To calculate the equivalent cross sectional area of

the FRP materials for various fibre architectures, an

experimental program was performed to evaluate the

axial and flexural engineering properties of various

FRP fibre architectures. In the testing program, eight

configurations were tested in axial tension (ASTM

11

Electronic Journal of Structural Engineering, 7(2007)

The relationship between the mid-span deflection

(Max) and the applied load (P) is given by

Max = (2.75 P L3 ) /(192 E1I )

(9)

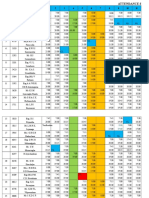

Table 2. Testing Program for the various FRP Configurations

(a) Tensile Tests

(b) Flexural Tests

Set No.

Outer Layers

Inner Layer

Size (mm)

Set No.

Outer Layers

Inner Layer

Size (mm)

0/90o Glass

45o Glass

25.41.4305

0/90o Glass

45o Glass

25.42.8203

0/90o Carbon

45o Carbon

25.41.4305

10

0/90o Carbon

45o Carbon

25.42.8203

0/90o Glass

45o Carbon

25.41.4305

11

0/90o Glass

45o Carbon

25.42.8203

0/90o Carbon

45o Glass

25.41.4305

12

0/90o Carbon

45o Glass

25.42.8203

45o Glass

0/90o Carbon

25.41.4305

13

45o Glass

0/90o Carbon

25.42.8305

45o Carbon

0/90o Glass

25.41.4305

14

45o Carbon

0/90o Glass

25.42.8305

45o Glass

0/90o Glass

25.41.4305

15

45o Glass

0/90o Glass

25.42.8305

45o Carbon

0/90o Carbon

25.41.4305

16

45o Carbon

0/90o Carbon

150

150

100

Stress (MPa)

Stress (MPa)

200

25.42.8305

Test 1

100

Test 2

50

Test 1

50

Test 2

Test 3

Test 3

0

0

0.000

0.005

0.010

0.015

0.000 0.005 0.010 0.015 0.020 0.025

0.020

Strain (mm/mm)

Strain (mm/mm)

Set 1

Set 3

Figure 4a: Typical stress-strain plots for sets

12

Electronic Journal of Structural Engineering, 7(2007)

200

Stress (MPa)

Stress (MPa)

300

200

Test 1

Test 2

100

150

100

Test 1

50

Test 2

Test 3

0.000

0.010

0.020

0.000

0.030

0.005

0.010

0.015

Strain (mm/mm)

Strain (mm/mm)

Set 8

Set 6

Figure 4b: Typical stress-strain plots for sets 6 and 8.

-1000

-1500

Load (kN)

load (kN)

-800

-600

Test 1

-400

Test 2

-1000

Test 1

-500

Test 2

-200

Test 3

Test 3

10

10

15

Displacement (mm)

Displacement (mm)

Set 9

Set 12

-400

-300

Load (kN)

-300

Load (kN)

-200

Test 1

Test 2

-100

Test 1

-100

-200

Test 3

Test 2

0

Test 3

0

0

5

10

Displacement

(mm)

10

Displacement (mm)

15

Set 16

Set 13

Figure 5: Typical load-deflection plots for sets 9, 12, 13 and 16.

13

15

Electronic Journal of Structural Engineering, 7(2007)

Using Equation (9), an empirical relationship between the applied loads and mid span deflection

was established. This relationship is based on the

experimental results of load and mid-span deflection for sets 9 to 16, as can be seen in Figure 5.

In order for the replacement system to confine the

concrete in the connection core, the maximum out

of plane deflection should be limited to the value Y

defined by Equation (11) under the same applied

loads ( q s ). This can be achieved if the right

stiffness is designed for in the overlaying repair

patch, as shown later. Considering the retrofitting

system as a simply supported beam with a span

equals to Lh. The maximum deflection under the

q s loads is:

4.2 Ductility Requirements

The ductility requirement was achieved by the out

of the plane rigidity of the FRP retrofitting systems. The out of plane rigidity is required to confine the concrete of the connection core. The ACI

381-02 guidelines were used to provide the required rigidity. The equivalent rigidity was evaluated based on the assumption that, under the same

lateral stress, the out of plane deflection of

5 q s L4h

Y=

384

E1 I

Where, E1 I is the equivalent FRP stiffness over

the spacing s.

the hoop steel is the same as the deflection of the

retrofitting systems. The out of plane deflection of

the steel was calculated based on the following

analytical procedures.

Equating the deflection for both conditions, the

stiffness E1I is found to be as

5 2

( Lh Ash f y )

(12)

48

By incorporating the stiffness of Equation (12)

with the experimental flexural tests results, keeping in mind that the FRP systems elastic modulus

is determined from the direct tension tests, the

stiffness for various FRP architectures and configurations can be evaluated.

E1 I =

Considering hoop steel with a spacing s between

the hoops subjected to out of plane uniform stress

q, the total linear load on one hoop is (q s).

Based on the free body diagram in Figure 6, and

with a moment at either end of the hoop steel, the

following relationship between deflection and applied stress is established:

L2

F Y = q s ( h )

8

Y = qs(

Knowing the width of the FPR systems will be

spread over the distance s (the steps between the

hoop steel), Equation (12) can be used to determine the equivalent thickness of the FRP systems.

(10)

L2h

) /( Ash f y )

8

(11)

In this study, two FRP configurations are investigated:

Where, Y is the maximum deflection, F is the force

in the hoop steel and Lh is the length of the hoop

stirrup.

The first system is assumed to be applied flat over

the connection (constant thickness). The thickness

is controlled by either the strength or ductility requirements. Table 3. Shows the results of obtaining the thickness based on the strength requirement

(Equation 8) and the ductility requirement (Equation 12) for all 8 fibre architectures tested experimentally. It should be noted that Table 3 is calculated for the connection shown in Figure 2. The

distance Lh is assumed to be 500 mm, while the

steps between the hoop steel (s) is considered to be

100 mm. The hoop steel area (Ash) is 3 legs of diameter 12 mm bars, that is 339 mm2. The yield

stress on the hoop steel is 413.7 MPa.

The bond stress between the hoop steel and concrete is ignored due to the symmetrical configuration of the hoop steel.

F hoop steel force = Ashfy

Ax

deflection Y

Ay

Applied load = qs

Bx

By

The second FRP configuration consists of corrugated systems. The thickness of the system is determined by the thickness required for the strength

requirements and the out of plane moment of iner-

Lh

Figure 6: The free body diagram for a deflected hoop steel

14

Electronic Journal of Structural Engineering, 7(2007)

tia is supplied by the stiffness provided by the corrugated shapes (see Table 4). The proposed corru-

gated shapes are shown in Figure 7 (a) and (b).

Table 3. The thickness of the overlay systems for various FRP architectures.

Set No.

Outer Layers

1,9

0/90o Glass

2,10

3,11

4,12

5,13

6,14

7,15

8,16

0/90o Carbon

0/90o Glass

0/90o Carbon

45o Glass

45o Carbon

45o Glass

45o Carbon

45o Glass

Design

stress

ful (MPa)

172

Elastic

Modulus E1

(GPa)

17.2

Thickness

Based on

Strength* (mm)

16.3

Thickness

Based on

Ductility** (mm)

29.7

45o Carbon

45o Carbon

45o Glass

0/90o Carbon

0/90o Glass

0/90o Glass

0/90o Carbon

296

131

186

172

186

152

193

43.1

17.2

29.0

18.6

17.9

14.5

32.4

9.7

21.3

15.2

16.3

15.2

18.8

14.5

21.8

29.7

24.9

29.0

29.2

31.5

24.1

Inner Layer

* Using equation 8

** [ E1 I /( E1 s )] (where E1 I is calculated from eq. 12)

The distance z is determined based on the ductility

shown in Equation (12). For this system, the conrequirements. Attaching pre-fabricated FRP stripes

finements requirements (stirrup spacing and cross

to connection can ensure the corrugated shapes.

sectional areas) as outlined in the ACI -318-02

The required z distance defines the thickness of the

must be used to find the thickness of the FRP overstrips. The FRP will be lay-up on the top surface of

lays (Figure 8).

the strips.

Table 4. Required thickness and step for various corrugated

1/ 3

FRP architectures

The circular shape shown in Figure 7 (b) is desirable for ensuring a continuous bond between the

FRP systems and the concrete. Also, the use of circular shapes eliminates the difficulty of applying

the FRP to the corners.

Set

No.

0/90o

Glass

0/90o

Carbon

0/90o

Glass

0/90o

Carbon

45o

Glass

45o

Carbon

45o Glass

Inner

Layer

FRP

Thickness

(mm)

16.3

Step Z*

(mm)

50.8

45o

Glass

2,10

9.7

45.7

45o

Carbon

21.3

48.3

3,11

45o

Carbon

15.2

44.5

4,12

45o

Glass

16.3

43.2

0/90o

5,13

Carbon

15.2

44.5

6,14

0/90o

Glass

0/90o

18.8

49.5

7,15

Glass

8,16

14.5

33.0

0/90o

45o

Carbon

Carbon

* For a given thickness and E1 values, z can be derived

using the parallel line theory.

1,9

s

z

s

(a) Rectangular

Outer

Layers

(b) Circular

Figure 7: Proposed corrugated shapes for the FRP retrofitting

systems

5 PROPOSED STRENGTHENING

OVERLAYS

5.1 Type II joints

Multi-layered corrugated FRP system with two fiber layouts 1, 90 and 45. The thickness of the

system will be evaluated based on the required

equivalents strength (area of the stirrups) and

depth coupled with the configuration of the corrugation will be established based on the confinement requirements (stirrup spacing),(Figure 9).

The following two systems were considered for

Type II joints:

Multi-layered FRP system with two fibre layouts

1, 90 and 45. The thickness of the system can

be evaluated based on the ductility requirements as

15

Electronic Journal of Structural Engineering, 7(2007)

F.R.P. wrapping around the column.

F.R.P. Wrap

To hold the multi-layered

system and to increase the joint core

F.R.P. Multi-layered system 0/90

and 45

F.R.P. Wrapping around

the column.

Thicknesses will be determined

based on the requirements of the

confinement.

Figure 8: Multi-layered system for upgrading type II joints.

tf = Thickness of the multi-corrugated F.R.P. cover

F.R.P. corrugated cover

Wrapping around the column

Epoxy Injection

to fill voids

F.R.P. WRAP

S

Thickness of the strips to be

determined by the requirements of the

confinement

S: Spacing between strips

Wrapping around the column.

ts = Thickness of the strips.

Section A-A

Details of the retrofitting system

Figure 9: Multi-layered corrugated system for upgrading type II joints.

It is anticipated that the second system will results

in a more efficient design. The ACI 318-02 Code

requires the concrete of the joint core area to carry

the applied shear force. Therefore, an attempt can

be made to increase the core area by wrapping the

connection beams to a new dimension that ensures

sufficient core area to withstand the applied shear

force

5.2 Type I joints

Type I joints also proposed to have two configurations.

Joints with insufficient confining spandrel beams

and sufficient hoop steel. In this type of joints,

FRP wrap will be constructed around the spandrel

beams to satisfy the code requirements for considering the confinements due to the spandrel beams.

16

Electronic Journal of Structural Engineering, 7(2007)

The requirement is specified as the of the connection face is covered by the cross-section of the

spandrel beams, (Figure 10).

Joints with insufficient confining spandrel beams

and insufficient hoop steel. A combination of the

above two systems will be investigated to upgrade

the deficiencies of the connection.

Joints with sufficient confining spandrel beams

and insufficient hoop steel. In this type of joints,

strips or rods are inserted through the spandrel

beams after drilling holes as required to satisfy the

transverse steel confinements. The rods or strips

are epoxy injected and connected at the ends by

wraps around the joint beams, (Figure 11).

The beams connecting the joints must be also investigated in terms of the core concrete area

needed to provide the shear strength of the joints.

In the case of any deficiency, beams wrapping may

be required for increasing the core area.

Wrapping around the column

FRP Wrap

To hold the multi-layered system and to

increase the joint core area typical for all

beams

FRP Multi-layered system

0/90 and 45. typical for all for

beams

Wrapping around the column

Figure 10: The multi-layered system for upgrading of type I joints with sufficient hoop steel.

Wrapping around the column

F.R.P. wrap

Strips go through the

spandrel beams

Thickness of the stripes to be determined by the

requirements of the confinement

Wrapping around

the column

S: Spacing between strips.

Figure 11: The multi-layered system for upgrading of type I joints with insufficient hoop steel.

In all of the above-recommended upgrades, both

ends of the FRP systems must be rigidly fixed to

beams to satisfy the fixed support conditions as-

sumed in the analysis. The end of the FRP system

support conditions can be ensured by either FRPwrapping, mechanical fasteners or both.

17

Electronic Journal of Structural Engineering, 7(2007)

8 REFERENCES

6 CONCLUSIONS AND

RECOMMENDATIONS

ACI 318. 2002. Building Code Requirements for

Structural Concrete (ACI 318-02) and Commentary (ACI 318R-02), American Concrete Institute.

Bidda, A., Ghobarah, A. and T.S.Aziz, T.S. 1997. Upgrading of Non ductile Reinforced Concrete Frame

Connection, Journal of structural engineering,

ASCE, Vol. 123, No. 8. pp. 1001-1010.

Gergely, J., Pantelides, C. and Reaveley, L. 2000. Shear

Strength of RCT-Joints Using CFRP Composites,

Journal for Composites for Construction, Vol. 4, No.

2, pp. 56-64.

Hwang, S. and Lee, H. 1999. Analytical Model for Predicting Shear Strength of Exterior Reinforced Concrete Beam-Column Joints for Seismic Resistance,

ACI, Structural Journal, Vol. 96, No. 5, pp. 846-857.

Hwang, S. and Lee, H. 2000. Analytical Model for Pre

dicting Shear Strength of Interior Reinforced Concrete Beam-Column Joints for Seismic Resistance,

ACI, Structural Journal, Vol. 97, No. 1, pp. 35-44.

Scott, R. H. 1996. Intrinsic Mechanism in Reinforced

Concrete Beam-Column Connection Behavior, ACI

Structural Journal, Vol. 93, No. 3, pp 336-346.

Tsonos, A. G. 1999. Lateral Load Response of

Strengthened Reinforced Concrete Beam-to-Column

Joints, ACI, Structural Journal, Vol. 96, No. 1, pp.

46-56.

Based on the performed research investigation, the

following recommendations can be concluded:

The use of FRP systems is an effective

method for upgrading deficient concrete

connections to enhance the shear strength

and ductility performance.

Architecturally corrugated FRP retrofitting

systems are an efficient option to provide

out of plane rigidity for confining the concrete in the core of the connection. Corrugating of the overlays results in a reasonable thickness of the systems used.

The combinations of 0/90o and 45o for the

orientations of carbon fibres results in the

least thickness of the FRP system. This

combination can be implemented in the

case where the option of architecturally

corrugated FRP systems is obsolete.

To ensure the ductility requirements, the

ends of the FRP systems should be fixed to

the beams forming the connection. This can

be accomplished by wrapping of FRP materials around the FRP retrofitting systems.

The developed work in this project is to be

implemented in actual field applications.

Therefore, more analytical analysis is

needed to evaluate the elastic modulus of

the laminated systems taking in consideration the fibre volumetric ratios and the

layer thickness. This work is still in progress in North Carolina AandT Center of

Composite Material Research.

7 ACKNOWLEDGEMENTS

This work could not have seen light without the

support of North Carolina AandT Center of Composite Material Research. In particular, the authors

wish to acknowledge the guidance of Prof. Naseer

El-Haque whose devotion to academic excellence

and unfailing support to his colleagues is a priceless treasure to all of us at Kuwait University.

18

Vous aimerez peut-être aussi

- Report On Green Project Sobhadham Piyasa: Ministry of Mahaweli Development and Environment Sri LankaDocument34 pagesReport On Green Project Sobhadham Piyasa: Ministry of Mahaweli Development and Environment Sri LankaChinthaka Iddamalgoda100% (1)

- Attendance SheetDocument2 pagesAttendance SheetChinthaka IddamalgodaPas encore d'évaluation

- Great Horn Development Company FZCO: Data Transmittal FormDocument1 pageGreat Horn Development Company FZCO: Data Transmittal FormChinthaka IddamalgodaPas encore d'évaluation

- AttendenceDocument27 pagesAttendenceChinthaka IddamalgodaPas encore d'évaluation

- Designation: Temporary Instructor Organisation: Department of Civil Engineerin, University of Moratuwa Duration: 1991Document22 pagesDesignation: Temporary Instructor Organisation: Department of Civil Engineerin, University of Moratuwa Duration: 1991Chinthaka IddamalgodaPas encore d'évaluation

- Document Transmittal ForamtDocument1 pageDocument Transmittal ForamtChinthaka IddamalgodaPas encore d'évaluation

- Award LetterDocument64 pagesAward LetterChinthaka IddamalgodaPas encore d'évaluation

- Typical Lintel DetailsDocument1 pageTypical Lintel DetailsChinthaka IddamalgodaPas encore d'évaluation

- DGM (Epc-Sc) Office at Jawatte Refurbishment of Proposed Project Director'S OfficeDocument2 pagesDGM (Epc-Sc) Office at Jawatte Refurbishment of Proposed Project Director'S OfficeChinthaka IddamalgodaPas encore d'évaluation

- To Whom It May Concern: Project ManagerDocument1 pageTo Whom It May Concern: Project ManagerChinthaka IddamalgodaPas encore d'évaluation

- Car Parking Code: Development Control Plan No. 18Document33 pagesCar Parking Code: Development Control Plan No. 18Chinthaka IddamalgodaPas encore d'évaluation

- IESL-NEWS LETTER - July August Normal 2014 MailpdfDocument12 pagesIESL-NEWS LETTER - July August Normal 2014 MailpdfChinthaka IddamalgodaPas encore d'évaluation

- Construction Hand BookDocument237 pagesConstruction Hand BookNson Lee100% (1)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Medrano, Rene LynnDocument2 pagesMedrano, Rene LynnRene Lynn Labing-isa Malik-MedranoPas encore d'évaluation

- Green ThumbDocument2 pagesGreen ThumbScarlet Sofia Colmenares VargasPas encore d'évaluation

- UntitledDocument5 pagesUntitledapril montejoPas encore d'évaluation

- Per Dev Dlp-1-2 - 3 SelfDocument6 pagesPer Dev Dlp-1-2 - 3 SelfMonisa SocorinPas encore d'évaluation

- Dpb6013 HRM - Chapter 3 HRM Planning w1Document24 pagesDpb6013 HRM - Chapter 3 HRM Planning w1Renese LeePas encore d'évaluation

- Bilateral Transfer of LearningDocument18 pagesBilateral Transfer of Learningts2200419Pas encore d'évaluation

- Car Parking DesignDocument6 pagesCar Parking Designcharler kinyuajPas encore d'évaluation

- En DAY4 David Chen Building The AI Computing Platform For Pervasive Intelligence enDocument8 pagesEn DAY4 David Chen Building The AI Computing Platform For Pervasive Intelligence endieuwrignPas encore d'évaluation

- Swenson 1 Dan Swenson Printing Press: Part One (Timeline)Document6 pagesSwenson 1 Dan Swenson Printing Press: Part One (Timeline)Dan SwensonPas encore d'évaluation

- Permanent Magnet Motor Surface Drive System: Maximize Safety and Energy Efficiency of Progressing Cavity Pumps (PCPS)Document2 pagesPermanent Magnet Motor Surface Drive System: Maximize Safety and Energy Efficiency of Progressing Cavity Pumps (PCPS)Carla Ayelen Chorolque BorgesPas encore d'évaluation

- (Word 365-2019) Mos Word MocktestDocument4 pages(Word 365-2019) Mos Word MocktestQuỳnh Anh Nguyễn TháiPas encore d'évaluation

- NiftDocument3 pagesNiftMegha Nair PillaiPas encore d'évaluation

- Program of ActivitiesDocument2 pagesProgram of ActivitiesVon Limuel LopezPas encore d'évaluation

- Hydrology Report at CH-9+491Document3 pagesHydrology Report at CH-9+491juliyet strucPas encore d'évaluation

- Empowerment Series Social Work With Groups Comprehensive Practice and Self Care 10Th Edition Charles Zastrow Full ChapterDocument67 pagesEmpowerment Series Social Work With Groups Comprehensive Practice and Self Care 10Th Edition Charles Zastrow Full Chapterruby.levi441100% (5)

- Effect of Minor and Trace Elements in Cast IronDocument2 pagesEffect of Minor and Trace Elements in Cast IronsachinguptachdPas encore d'évaluation

- Antenna Systems - Standard Format For Digitized Antenna PatternsDocument32 pagesAntenna Systems - Standard Format For Digitized Antenna PatternsyokomaPas encore d'évaluation

- Lennox IcomfortTouch ManualDocument39 pagesLennox IcomfortTouch ManualMuhammid Zahid AttariPas encore d'évaluation

- Zener Tester: by MedhatkoDocument6 pagesZener Tester: by Medhatkosaran gulPas encore d'évaluation

- Kunst 1600 Case AnalysisDocument3 pagesKunst 1600 Case AnalysisrakeshPas encore d'évaluation

- JVC tm1010pnDocument4 pagesJVC tm1010pnPer VigiloPas encore d'évaluation

- 19 71 Hydrologic Engineering Methods For Water Resources DevelopmentDocument654 pages19 71 Hydrologic Engineering Methods For Water Resources DevelopmentMartha LetchingerPas encore d'évaluation

- Dayco-Timing Belt Training - Entrenamiento Correa DentadaDocument9 pagesDayco-Timing Belt Training - Entrenamiento Correa DentadaDeiby CeleminPas encore d'évaluation

- William Ury Power of A Positive No Bantam - 2007Document227 pagesWilliam Ury Power of A Positive No Bantam - 2007Tam Jeopardy100% (1)

- TinkerPlots Help PDFDocument104 pagesTinkerPlots Help PDFJames 23fPas encore d'évaluation

- Naca Duct RMDocument47 pagesNaca Duct RMGaurav GuptaPas encore d'évaluation

- GATE Chemical Engineering 2015Document18 pagesGATE Chemical Engineering 2015Sabareesh Chandra ShekarPas encore d'évaluation

- CE-23113-SP-902-R01-00 Asset SpecificationDocument14 pagesCE-23113-SP-902-R01-00 Asset SpecificationСветлана ФайберPas encore d'évaluation

- 74 Series Logic ICsDocument6 pages74 Series Logic ICsanon-466841Pas encore d'évaluation

- Skirmishes Graham Harman PDFDocument383 pagesSkirmishes Graham Harman PDFparaiaPas encore d'évaluation