Académique Documents

Professionnel Documents

Culture Documents

Nano-Emulsions: New Applications and Optimization of Their Preparation

Transféré par

Yuli CartrinaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Nano-Emulsions: New Applications and Optimization of Their Preparation

Transféré par

Yuli CartrinaDroits d'auteur :

Formats disponibles

Current Opinion in Colloid & Interface Science 13 (2008) 245 251

www.elsevier.com/locate/cocis

Nano-emulsions: New applications and optimization of their preparation

J.M. Gutirrez a,, C. Gonzlez a , A. Maestro a , I. Sol a , C.M. Pey a , J. Nolla b

a

Chemical Engineering Department, University of Barcelona, c/ Mart i Franqus 1, 08020 Barcelona, Spain

b

CSIC/IIQAB, CIBER-bbn, c/Jordi Girona 18-26, 08034-Barcelona, Spain

Received 10 September 2007; received in revised form 29 January 2008; accepted 30 January 2008

Available online 15 February 2008

Abstract

Nano-emulsions, as non-equilibrium systems, present characteristics and properties which depend not only on composition but also on the

preparation method. Although interest in nano-emulsions was developed since about 20 years ago, mainly for nanoparticle preparation, it is in the

last years that direct applications of nano-emulsions in consumer products are being developed, mainly in pharmacy and cosmetics. These recent

applications have made that studies on optimization methods for nano-emulsion preparation be a requirement. This review is focused on the most

recent literature on developments of nano-emulsions as final application products and on the optimization of their preparation.

2008 Elsevier Ltd. All rights reserved.

Keywords: Nano-emulsions; Preparation; Applications; Optimization; Emulsification

1. Introduction

There are two major misunderstandings in the literature

regarding nano-emulsions. One arises from their similarities to

microemulsions. Nano-emulsions are emulsions with an extremely small droplet size [1] which can overlap those of microemulsions. The definition of emulsions by the International

Union of Pure and Applied Chemistry (IUPAC) states: In an

emulsion, liquid droplets and/or liquid crystals are dispersed in

a liquid [2]. Obviously, microemulsions are excluded from this

definition if the word dispersed is interpreted as non-equilibrium and opposite to solubilized, a term that can be applied to microemulsions and micellar systems. Therefore, there

is a fundamental difference between microemulsions and nanoemulsions: microemulsions are equilibrium systems (i.e. thermodynamically stable), while nano-emulsions are non-equilibrium systems with a spontaneous tendency to separate into the

constituent phases. Nevertheless, nano-emulsions may possess a

relatively high kinetic stability, even for several years [1]. The

other source of misunderstandings about nano-emulsions is

Corresponding author. Tel.: +34 934021292; fax: +34 934021291.

E-mail address: josemaria.gutierrez@ub.edu (J.M. Gutirrez).

1359-0294/$ - see front matter 2008 Elsevier Ltd. All rights reserved.

doi:10.1016/j.cocis.2008.01.005

related to the method of preparation. For instance, in Ref. [3], a

review on nano-emulsions, only emulsions with droplet size in

the nanometer range obtained by shear methods are considered

as nano-emulsions. According to these authors, emulsions with

extremely small droplet size (i.e. nano-emulsions) obtained by

the so-called condensation methods (e.g. phase inversion temperature (PIT) or composition (PIC) methods, self-emulsifying

methods, etc.) should not be considered as nano-emulsions.

Evidently, the preparation method influences emulsion properties (e.g. droplet size, stability, etc.), but the nature of the final

dispersion (the constituent phases) is the same whether the

method of preparation uses high shear (external energy, dispersion methods) or the chemical energy stored in the system

(condensation methods). The view expressed in Ref. [3] is based

in a misinterpretation of the mechanisms by which nanoemulsions form by low-energy methods, described, for instance,

in Ref. [5]. Phase transitions involving equilibrium phases,

such as lyotropic liquid crystalline, microemulsion and/or micellar phases, take place during emulsification by condensation

or low-energy methods. However, this does not mean that at

the end of the emulsification process the system is in thermodynamic equilibrium.

As a summary of this point, nano-emulsions are emulsions

(non-equilibrium systems, defined according to [1]) with a

remarkable small droplet size (in the nanometer range, e.g. 20

246

J.M. Gutirrez et al. / Current Opinion in Colloid & Interface Science 13 (2008) 245251

200 nm), regardless of the preparation method. A photography

of an oil-in-water (O/W) nano-emulsion with a schematic example of the structure is presented in Fig. 1.

Evidently the size range may vary depending on the authors.

Some authors consider 500 nm as the upper limit [1,6]. In any

case, the size limit is not a key issue because no qualitative

differences are established by droplet size. The formation,

properties and stability of nano-emulsions are well established in

numerous papers which are reviewed [1,5]. Regarding applications, nano-emulsions were firstly developed, and used for

a long time, to obtain nanoparticles by polymerization [7], the

so-called miniemulsion polymerization method, and more

recently to obtain solid lipid nanoparticles [810], and ceramic

particles [11]. At present, new applications are being developed

to use nano-emulsions as consumer products.

In this review, recent literature on the new applications of

nano-emulsions as consumer products is reviewed and classified

according to the field of application. This direct application of

nano-emulsions requires the optimization with respect to formulation and preparation variables in order to obtain the desired

characteristics. Recent literature on optimization of nano-emulsion preparation is also reviewed and classified according to three

approaches: considerations on phase behavior, selective variation

of parameters and experimental designs.

2. Direct application of nano-emulsions in final products

Practically all original and review papers on nano-emulsions

stress their great potential for applications. However, after more

than 10 years since a growing interest in nano-emulsions was

developed, reports on direct applications of nano-emulsions

are not as numerous as expected. The main limitation for developing applications for nano-emulsions is their stability.

Although practically all papers on nano-emulsions indicate

that nano-emulsions can be stable even by years, the small

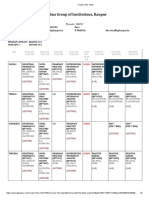

Fig. 1. Visual aspect of an O/W nano-emulsion and structural conformation of

the droplets.

droplet size makes nano-emulsions break by the Ostwaldripening mechanism [1214] in time periods which pose a great

limitation for developing applications different than nanoparticle preparation. In fact, only an extremely low solubility of the

dispersed phase, as presented by silicone oils, would give the

stability needed for most of the applications. In this context,

Mason research group has published several papers studying

nano-emulsions with silicone oils as dispersed phase, [1517].

These nano-emulsions show great stability even for such a high

concentration that droplets are deformed to a foam-like structure

[3], but no applications have been yet developed for these nanoemulsions.

Due to the limitations in the stability of nano-emulsions, a

revision of the most recent literature results in few papers proposing new applications, and in most of them, nano-emulsions

must be prepared shortly before their use.

With respect to agrochemical applications, in a recent

reference [18] nano-emulsions are proposed for solubilizing

water-insoluble pesticides, the classical potential application.

Nano-emulsions are formed before the application by dilution

of a concentrate containing oil, surfactant, the active and 50% of

water. It is claimed that the nano-emulsions obtained show good

stability, but the diameter increases about five times in 14 h,

from 40 to 200 nm. Therefore, application should be carried out

a few hours after preparation for obtaining the advantages

of small droplet size. In this paper, the preparation of nanoemulsions is presented as a novelty when comparing with

commercial microemulsion formulations which also result by

dilution in nano-emulsions. This fact demonstrates that application of nano-emulsions for solubilizing pesticides is not a

potential application but a commercial one.

Concerning the applications in food technology, two recent

reviews about possibilities of nanotechnology [19,20] indicate

that there are potential applications of nano-emulsions, but no

specific applications are given. In Ref. [19], potential applications for nanostructured materials in general are analyzed,

but regarding nano-emulsions, only a mention about their

potential application is made. In Ref. [20], a detailed review on

emulsification techniques is presented but the possible applications that are indicated are not likely to have an important impact

in the future food technology. Finally, nano-emulsification of

carotene containing hexane is described in Ref. [21] although the

final application proposed after evaporation of hexane is a

dispersion of carotene, not a nano-emulsion.

In cosmetics, a generic paper [22] presents the possibilities

for improving stability through using different oils and oil

mixtures. Adequate stability is only achieved by using more

than 50% of such heavy oil as isocetyl isostearate. Cosmetic

properties of nano-emulsions are analyzed and favorable

conclusions are obtained. Other papers presenting studies for

nano-emulsion application on skin were also published [2326].

Pharmacy is the field where more direct applications of

nano-emulsions are proposed. Many of them consist in selfemulsifying systems, so the stability problem is solved by

using the nano-emulsions short after their preparation. Selfemulsifying nano-emulsions for parenteral application [27] or

oral application [2830] have been described. Nano-emulsion

J.M. Gutirrez et al. / Current Opinion in Colloid & Interface Science 13 (2008) 245251

formulations are studied for their application as nanocarriers

which allow the treatment of a variety of diseases. The following

are examples of the most recent proposals of drugs solubilized

in nano-emulsions for disease treatments: anticonvulsant

[27], antihypertensive [28] antibiotic [30]; antinflammatory

applied through skin [26]. There are reports on: drugs solubilized

in nano-emulsions for HIV/AIDS therapy [31]; mechanisms of

atherogenesis studied with cholesterol nano-emulsions [32];

cancer therapy investigated by solubilizing the drug in a

cholesterol rich nano-emulsion [33]; intestinal absorption of

three model drugs solubilized in nano-emulsions [34]; efficacy of

a schistosomicidal compound solubilized in nano-emulsions;

[35]; and application of anthrax vaccine through W/O nanoemulsions [36]. Special magnetic nano-emulsions are also

being studied for medicine applications [3739]. A recent

review [40] shows extensively potential multifunctional

applications of nanocarriers including nano-emulsions in

pharmacy. As stated in the paper, multifunctional nanocarriers

could provide almost unlimited opportunities in producing

highly efficient and specialized systems for drugs, genes and

diagnostic agents. Antimicrobial generic activity of nanoemulsions is also being investigated [41] with W/O nanoemulsions that are diluted in water just before application

reverse to O/W emulsions. More specifically, inactivation of

Ebola virus by nano-emulsion was studied [42] with promising

results. It was concluded that nano-emulsions could be used as

disinfectants.

3. Optimization of nano-emulsion preparation

The properties of nano-emulsions, as non-equilibrium systems, depend not only on composition variables but preparation

variables such as emulsifying path, agitation or emulsification

time. These variables can have a significant influence on the

nano-emulsion final properties. Direct application of nanoemulsions requires optimization studies for achieving the best

properties for specific applications. The most frequent aim for

optimization is to exploit the advantages of nano-emulsions with

respect to conventional emulsions (i.e. macroemulsion): small

size and low polydispersity. Therefore, in general, optimization

is directed to obtain minimum droplet size and/or minimum

polydispersity. Another aim in nano-emulsion optimization is

to improve the stability because, as stated above, stability is

the main problem to overcome to find practical applications

for nano-emulsions. Optimization is also directed to obtain an

optimum in the function for which the nano-emulsions are used

(e.g. drug delivery).

The properties to be optimized, for example droplet size and

polydispersity, will depend, of course, on composition variables,

and could depend on preparation variables, so optimization can be

carried out with respect to these two types of variables. Concerning optimization methods, sometimes the characteristics of

emulsification path allow predicting optimum properties of nanoemulsions, so optimizations are carried out by studying the phase

behavior of the systems. In other occasions, optimization is

experimentally carried out by selective variation of one variable.

Finally, given the high number of variables that can influence the

247

final properties of nano-emulsions, optimization is carried out

by experimental designs which allow reducing the number

of experiments needed. Review of papers about optimization is

presently classified according to these three types of methods.

3.1. Phase behavior studies for optimization

Studies on phase behavior for optimization of nano-emulsion

properties can be important when the so-called condensation or

low-energy emulsification methods are used, because the phases

involved during emulsification are determinant in order to obtain

nano-emulsions of small droplet size and low polydispersity. In

contrast, if shear methods are used, there is not a composition

emulsification path and only phases at the final composition are

important.

The importance of the phase behavior, namely crossing

microemulsion (bicontinuous, D) or lamellar liquid crystalline

phase regions during emulsification is described in detail

in recent reviews [1 ,4,5 ]s. Some recent original works in

which this conclusion is experimentally proved are [4346]

for nano-emulsions obtained by the phase inversion temperature method (PIT); [4749] for nano-emulsions obtained by

phase inversion composition method (PIC), or [18,28,30]

for nano-emulsions prepared by a self-emulsifying method.

Only bicontinuous (D) or O/W microemulsions are considered

appropriate for self-emulsifying while lamellar liquid crystal

compositions do not self-emulsify by dilution, probably due

to viscosity of the lamellar phase [18]. Comparing results

from Refs. [47] and [48] with results from Ref. [18], it can

be concluded that by slow addition of water to a lamellar

liquid crystalline phase nano-emulsions can be obtained,

while emulsions with higher droplet size are obtained by rapid

dilution (as in self-emulsifying methods).

In Ref. [50], nano-emulsions with a very small droplet size are

obtained in an ionic surfactant system by adding aqueous phase

through an emulsification path crossing a micellar cubic liquid

crystalline phase. Other recent not published experimental results

demonstrate that the initial droplet sizes of the nano-emulsions

coincide with the micelle size of the cubic liquid crystalline phase

from which the nano-emulsion is obtained by dilution [Fig. 2].

Actually, conditions for obtaining O/W nano-emulsions with

a minimum in droplet size and consequently low polydispersity

can be summarized as follows: in emulsification by phase

inversion temperature or composition methods an aqueous

continuous phase, O/W or bicontinuous, with all the oil

solubilized must be crossed immediately before reaching the

final two phase region where the nano-emulsions form. These

are composition conditions necessary but not sufficient, because

the kinetics of incorporation of oil to this water continuous phase

or the coalescence can make that nano-emulsion droplet size also

depends on preparation variables such as aqueous phase addition

rate for PIC method or cooling rate for PIT method.

3.2. Optimization by selective variation of parameters

Parameters whose influence on nano-emulsion characteristics

can be studied may be classified as composition or preparation

248

J.M. Gutirrez et al. / Current Opinion in Colloid & Interface Science 13 (2008) 245251

Fig. 2. Nano-emulsion obtention by dilution of a cubic liquid crystal.

variables. For emulsification by low-energy methods composition

variables will have a much higher influence than preparation

variables, however for shear emulsification, the influence of

preparation variables will be determinant.

Examples of recent literature about optimization of nanoemulsions obtained by shear include the study of the influence of

different variables and the correlation of droplet size with them

[51]. In this paper two different industrial scale emulsifier

equipments were studied, and the Sauter diameter was correlated

with viscosities, stabilizers, volume fractions and pressure for a

jet mill, number of disc mixers for a static mixer, and passage

number for the two equipments. For both, an equilibrium size is

reach for high number of passages resulting in constant droplet

size.

For other systems, optimum pressure or passage number can

exist if coalescence is facilitated by high pressures or passage

number. In Ref. [52] a food system is studied with a high pressure

microfluidizer to emulsify and using a surfactant and different

polymers for stabilizing the emulsions. The competing phenomena of breaking and coalescence are discussed taking into account

the effect of stabilizers.

In Ref. [53], optimization of nano-emulsion preparation by

submitting a coarse emulsion to subcritical water conditions is

presented. The optimization was studied by selective variation

of composition parameters (surfactant and oil concentration),

and preparation parameter (temperature). For this system small

sizes, 40 nm, are obtained.

For other condensation methods, variables whose effect is

commonly studied are the surfactant oil ratio and the ratio between surfactants when a surfactant mixture is used.

For nano-emulsions prepared by the phase inversion temperature method, optimization by selective variation parameters is

presented in several cited references of recent bibliography. In

[43,46] variation of droplet size is studied with respect to oil

surfactant ratio with the obvious result that the higher the oil

surfactant ratio the greater the droplet size, and in [45] variation

of droplet size with surfactant mixing ratio is studied with the

remarkable result that droplet size does not depend on surfactant

mixing ratio if nano-emulsions are prepared by cooling from the

HLB temperature.

For nano-emulsions prepared by the phase inversion composition method, there are also several studies in recent bibliography. In [54] optimization with respect to preparation

method and variation of droplet size with oil surfactant ratio are

presented. In [49] different routes for emulsification are studied

and droplet size variation with HLB, water fraction and surfactant concentration is also reported. In Ref. [55], effect of

variables HLB and oil surfactant ratio are separately studied with

the expected result that there is an optimum HLB and that the

higher the oil surfactant ratio the greater the droplet size. In Ref.

[56] optimization of W/O nano-emulsion preparation is presented. For different combinations of Span-Tween surfactants,

an optimum surfactant composition presenting a water solubility

maximum is chosen, and droplet size variation is studied with

respect to water concentration. Also with W/O nano-emulsions,

the result is, as expected and coinciding with Ref. [47], that the

higher the water concentration the greater the droplet size.

For nano-emulsions prepared by self-emulsification, there is

a detailed work on optimization [57]. Droplet size variation

with oil, surfactant HLB, and solvents, was studied. The results

indicated that there are optimum values for HLB and proportions

of solvents.

As an example of optimization of nano-emulsion function, in

Ref. [26] the influence of sucrose surfactants on percutaneous

penetration is studied, and in Ref. [35] the efficacy of a

schistosomicidal agent is improved by incorporating the agent

in nano-emulsions.

3.3. Experimental designs for optimization

Experimental designs allow to experimentally study the

influence of several variables with a limited number of

experiments. Statistical analysis of results will allow to know

which variables have a significant influence, and to correlate

desired response with variables by polynomial equations. In

Fig. 3 an example of experimental design is shown, and in Fig. 4

there is an example of response surface.

Not many papers present optimization of nano-emulsion

preparation by experimental designs, and most of them deal about

pharmaceutical formulations for self-emulsification [27,5861].

In Ref. [27] experimental design was used to determine the

influence of two qualitative independent variables: type of oil and

type of lipophilic emulsifier. The other four references correspond

to the same research group. In Refs. [58,59] the incorporation of

retinol to a self nanoemulsifying formulation is studied, being

oil, surfactant and cosurfactant amounts in the formulation the

three independent variables, and mean droplet size, turbidity, and

dissolution rate at 10 and 30 min, the four response variables

studied. Response equations are presented, and system is optimized for dissolution rate at 30 min using the other three

responses as restrictions. In Ref. [60] the surface response

technology explained in a more detailed way and six response

J.M. Gutirrez et al. / Current Opinion in Colloid & Interface Science 13 (2008) 245251

249

Fig. 3. Example of experimental design for the preparation variables agitation and addition rate.

variables are analyzed. In Ref. [61], authors apply the same

methodology to evaluate ultrasonic technique in characterization

of nano-emulsions.

In Ref. [48] a complete explanation of experimental design

application to study the preparation of nano-emulsions is

presented. Methodology is applied to low-energy emulsification

by phase inversion composition method, and effects of composition variables and preparation variables were all together

evaluated. Droplet size as response surface was minimized

separately, first with respect to composition variables, and afterwards with respect to preparation variables. The results confirm

that the higher the oil surfactant ratio the greater the droplet size,

and that there is an optimum surfactant mixing ratio or, what is

the same, an optimum HLB. Concerning the preparation variables, addition and agitation rate have little but significant

influence and an optimum agitation rate is found.

In Ref. [62], optimization methodology by experimental

design is applied to nano-emulsions in an ionic surfactant system

obtained by the phase inversion composition method. Again, the

higher the oil surfactant ratio the greater the droplet size, and

there is an optimum ratio of surfactants in the mixture used.

Concerning the preparation variables, they present again no or

low influence on droplet size. Other not published results of the

authors on nano-emulsions prepared by the phase inversion

temperature confirm that preparation variables such as cooling

rate or agitation do not have a significant influence on droplet

size.

A general conclusion of papers using experimental designs is

that this methodology constitutes a very good tool for studying

preparation of nano-emulsions.

Fig. 4. Example of surface response from the preparation variables agitation and

addition rate.

4. Conclusions

Possible applications of nano-emulsions are strongly

limited by the stability of nano-emulsions, except for nanoparticle preparation when the process of physical or chemical

solidification takes place within the period of stability of nanoemulsions.

Nano-emulsions are proposed for numerous applications

in pharmacy as drug delivery systems because of their capacity of solubilizing non polar active compounds. Due to the

stability problems, most of proposed formulations are selfemulsifying systems and the nano-emulsions are produced

just before their application. Although there have not been

reported too many applications in other fields, there is a great

potential for nano-emulsion applications if Oswald-ripening

destabilization mechanism is limited by using very insoluble

oils.

Concerning optimization in preparation of nano-emulsions

by shear, an optimum shear or time shearing can exist if breaking

and coalescence are competing phenomena during the process.

Concerning optimization in the preparation of nano-emulsions by low-energy methods, recent literature confirms that

crossing bicontinuous or aqueous continuous phases during

emulsification allows obtaining O/W nano-emulsions of small

droplet size and low polydispersity.

Optimizations by selective variation of parameters or experimental designs allow to conclude that, with respect to

composition variables, generally there is an optimum surfactant mixture composition, or HLB, and that the higher the oil

surfactant ratio the greater the droplet size. The preparation

variables, as addition, agitation or cooling rate, generally do

not have a significant influence if the system is optimized with

respect to composition.

This last conclusion has a very important derivation: if

preparation variables do not have influence, the system can be

scaled-up, from lab to industrial, and similar results can be

expected.

As a final comment, judging from the most recent literature,

the interest in nano-emulsion preparation and application is

growing, but few of the numerous ideas reported become commercial final applications.

250

J.M. Gutirrez et al. / Current Opinion in Colloid & Interface Science 13 (2008) 245251

Acknowledgment

Financial support from the Spanish Ministry of Science

and Education, MEC (grants CTQ 2005-09063-C03-01/PPQ

and CTQ 2005-09063-C03-02/PPQ) is acknowledged.

References and recommended readings

[1] Solans C, Esquena J, Forgiarini AM, Usn N, Morales D, Izquierdo P,

Azemar N, Garcia-Celma MJ. Nano-emulsions: formation, properties and

applications. Surfactant Science Series 2003;109:52554. First review on

nano-emulsions obtained by low energy methods.

[2] International Union of Pure and Applied Chemistry; Manual of Colloid

Science. London: Butterworth; 1972.

[3] Mason TJ, Wilking JN, Meleson K, Chang CB, Graves SM. Nanoemulsions: formation, structure and physical properties. Journal of Physics

Condensed Matter 2006;18:63566. Review on nano-emulsions obtained

by shear. Authors do not accept as nano-emulsions those obtained by phase

inversion temperature.

[4] Tadros T, Izquierdo P, Esquena J, Solans C. Formation and stability of nanoemulsions. Advances in Colloid and Interface Science 2004;108109:

30318.

[5] Solans C, Izquierdo P, Nolla J, Azemar N, Garcia-Celma MJ. Nano

emulsions. Current Opinion in Colloid and Interface Science 2005;10:

10210. Review on nano-emulsions obtained by low energy methods.

Definitions in this review are questioned in reference [3].

[6] Capek I. Degradation of kinetically-stable O/W emulsions. Advances in

Colloid and Interface Science 2004;107:10210. Review on mechanisms

of destabilization of nano-emulsions. Techniques for increasing stability

are discussed.

[7] Ugelstad J, El-Aaser MS, Vanderhoff JW. Emulsion polymerization.

Initiation of polymerization in monomer droplets. Journal of Polymer

Science Polymer Letters 1973;11:50313. Original paper describing the

utilization of nano-emulsions in polymerization.

[8] Mller RH, Petersen RD, Hommos A, Pandeines RJ. Nanostructured lipid

carriers (NLC) in cosmetic dermal products. Advanced Drug Delivery

Reviews 2007;59:2230. Example of application of solid nanoparticles in

cosmetics.

[9] del Pozo-Rodrguez A, Delgado D, Solins MA, Gascn AR, Pedraz JL. Solid

lipid nanoparticles: factors affecting cells transfection capacity. International

Journal of Pharmaceutics 2007;339:2618. Example of application of solid

nanoparticles in pharmacy.

[10] Teeranaichaideekul V, Souto EB, Junyaprasert VB, Mller RH. Cetyl

palmitate-based NLC for topical delivery of coenzyme Q10: development,

physicochemical characterization and in vitro release studies. European

Journal of Pharmaceutics and Biopharmaceutics 2007;67:1418. Example

of application of solid nanoparticles in pharmacy.

[11] Porras M, Martnez A, Solans C, Gonzlez C, Gutierrez JM. Ceramic

particles obtained using W/O nano-emulsions as reaction media. Colloids and

Surfaces A, Physicochemical and Engineering Aspects 2005;270271:

18994. Example of preparation of solid ceramic nanoparticles.

[12] Lifshitz IM, Slyozov VV. The kinetics of precipitation from supersaturated

solid solutions. Journal of Physics and Chemistry of Solids 1961;19:3550.

The authors propose an equation to describe the Ostwald ripening process.

[13] Wagner C. Theorie der alterung von niederchlagen dursch umlosen (Ostwaldreifung). Zeitschrift fr Elektrochemie 1961;65:58191. The author, independently of [12], proposes an equation to describe the Ostwald ripening process.

[14] Taylor P. Ostwald ripening in emulsions. Colloids and Surfaces A,

Physicochemical and Engineering Aspects 1995;99:17585. The paper

describes the Ostwald ripening as the main destabilization process in emulsions.

[15] Graves S, Meleson K, Wilking JN, Lin MY, Mason TG. Structure of

concentrated nano-emulsions. J Chem Phys 2005;122: 134703. Studies on

concentrate nano-emulsions made from very insoluble silicone oils.

Of special interest.

Of outstanding interest.

[16] Mason TG, Graves SM, Wilking JN, Lin MY. Effective structure factor

of osmotically deformed nano-emulsions. J Phys Chem B 2006;110:

22097102.

[17] Wilking, Mason TG. Irreversible shear-induced vitrification of droplets into

elastic nanoemulsions by extreme rupturing. Physical Review E 2007;75:

041407. Studies on special properties presented by concentrate nanoemulsions made from very insoluble silicone oils.

[18] Wang L, Li X, Zhang G, Dong J, Eastoe J. Oil in water nano-emulsions for

pesticide formulations. Journal of Colloid and Interface Science 2007;314:

2305. Specific self nano-emulsifying formulation proposed for its utilization as pesticide.

[19] Weiss J, Takhistov P, McClements J. Functional materials in food nano

technology. Journal of Food Science 2006;71(9):R10716. Generic nanotechnology in food review.

[20] Sanguasri S, Augustin MA. Nanoscale materials development: a food

industry perspective. Trends in Food Science and Technology 2006;17:

54756. Generic nanotechnology in food review where some very special

applications of nano-emulsions in beverages are proposed.

[21] Tan CP, Nakajima M. -carotene nanodispersions: preparation, characterization and stability evaluation. Food Chemistry 2005;92:66171. Specific

utilization of nano-emulsions for the preparation of nanodispersions as

food additive.

[22] Sonneville-Aubrut O, Simmonet JT, Alloret FL. Nanoemulsions: a new

vehicle for skin care products. Advances in Colloid and Interface Science

2004;108109:1459. Study on stabilization of nano-emulsions for increasing applications in cosmetics.

[23] Yilmaz E, Bolmez HH. Design of a phytosphingosine-containing, positivelycharged nanoemulsion as a colloidal carrier system for dermal application of

ceramides. European Journal of Pharmaceutics and Biopharmaceutics

2005;60:918. Example of concrete application of nano-emulsions in

cosmetics.

[24] Yilmaz E, Bolmez HH. Effect of lipid-containing, positively charged

nanoemulsion on skin hydration, elasticity and erythemaan in vivo

study. International Journal of Pharmaceutics 2006;307:2328.

[25] Alves MP, Escarrone AL, Santos M, Pohlmann AR, Guterres SS. Human

skin penetration and distribution of nimesulide from hydrophilic gels

containing nanocarriers. International Journal of Pharmaceutics 2007;341:

21520. Study on improvement in properties of active principles by their

application in nano-emulsions.

[26] Calderilla-Fajardo SB, Cazares-Delgadillo J, Villalobos-Garca R, QuintanarGuerrero D, Ganem-Quintanar A, Robles R. Influence of sucrose esters in the

in vivo penetration of octyl methoxycinnamate formulated in nanocapsules,

nanoemulsions and emulsions. Drug Development and Industrial Pharmacy

2006;32:10713.

[27] Kelmann NG, Kuminek G, Teixeira H, Koester LS. Carbamazepine

parenteral nanoemulsions prepared by spontaneous emulsification process.

International Journal of Pharmaceutics 2007;342:2319. Examples of

application of self nano-emulsifying techniques for the development of

applications in medicine for nano-emulsions.

[28] Shafiq S, Shakeel F, Talegaonkar S, Ahmad FJ, Khar RK, Ali M.

Development and bioavailability assessment of ramipril nanoemulsion

formulation. European Journal of Pharmaceutics and Biopharmaceutics

2007;66:22743.

[29] Nielsen FS, Gibault E, Ljusberg-Wahren H, Arleth L, Pedersen JS, Mllertz

A. Characterization of prototype self-nanoemulsifying formulations of

lipophilic compounds. Journal of Pharmaceutical Sciences 2007;96:

87692.

[30] Date AA, Nagarkenser MS. Design and evaluation of self-nanoemulsifying

drug delivery system (SNEDDS) for cefpodoxime proxetil. International

Journal of Pharmaceutics 2007;329:16672.

[31] Vyas TK, Shahiwala A, Amiji MM. Improved oral bioavailability and brain

transport of Saquinavir upon administration in novel nanoemulsions

formulations. International Journal of Pharmaceutics 2008;347(12):93101.

[32] Couto R, Dallan L, Lisboa L, Mesquita CH, Vinagre C, Maranhao R.

Deposition of free cholesterol in the blood vessels of patients with coronary

artery diseases: a new mechanism for atherogenesis. Lipids 2007;42:4118.

[33] Dias M, Carvalho J, Rodrigues D, graziani S, Maranhao R. Pharmacokinetics

and tumor uptake of a derivatized form of paclitaxel associated to a cholesterol-

J.M. Gutirrez et al. / Current Opinion in Colloid & Interface Science 13 (2008) 245251

[34]

[35]

[36]

[37]

[38]

[39]

[40]

[41]

[42]

[43]

[44]

[45]

[46]

[47]

[48]

rich nanoemulsions (LDE) in patients with gynaecologic cancers. Cancer

Chemotherapy and Pharmacology 2007;59: 10511.

Brsewitz C, Schendler A, Funke A, Wagner T, Lipp R. Novel

poloxamer-based nanoemulsions to enhance the intestinal absorption

of active compounds. International Journal of Pharmaceutics 2007;329:

17381.

Caldeira de Araujo SC, Alves de Mattos AC, Ferreira Teixeira H, Zech

Coelho PM, lee Nelson D, Cristina de Oliveira M. Improvement of in vitro

efficacy of a novel schistosomicidal drug by incorporation in nanoemulsions. International Journal of Pharmaceutics 2007;337:30715.

Bielinska AU, Janczak KW, Landers JL, Makidon P, Sower LE, Peterson

JW, Baker Jr JR. Mucosal immunization with a novel nanoemulsion-based

recombinant anthrax protective antigen vaccine protects against Bacillus

antracis spore challenge. Infection and Immunity 2007:40209.

Veyret R, Delair T, Pichot C, Elaissari A. Amino-containing magnetic

nanoemulsions: elaboration and nucleic acid extraction. Journal of

Magnetism and Magnetic Materials 2005;295:15563.

Primo FL, Macaroff PP, Lacava ZGM, Azevedo RB, Morais PC, Tedesco

AC. Binding and photophysical studies of biocompatible magnetic fluid in

biological medium and development of magnetic nanoemulsion: a new

candidate for cancer treatment. Journal of Magnetism and Magnetic

Materials 2007;310:283840.

Primo FL, Michieleto L, Rodrigues M, Macaroff P, Morais PC, Lacava

ZGM, Bentley MV. Tudesco AC. Magnetic nanoemulsions as drug delivery

systems for Foscan : skin permeation and retention in vitro assays for

topical application in photodynamic therapy (PDT) of skin cancer. Journal

of Magnetism and Magnetic Materials 2007;311:3547.

Torchilin VP. Multifunctional nanocarriers. Advanced Drug Delivery

Reviews 2006;58:153255. Review about potential applications including

several functions for formulations.

Teixeira PG, Leite GM, Domingues RJ, Silva J, Gibbs PA, Ferreira JP.

Antimicrobial effects of a microemulsion and a nanoemulsion on enteric and

other pathogens and biofilms. International Journal of Food Microbiology

2007;118:159. Capacity of disinfection of nano-emulsions is evaluated and

discussed.

Chepurnov AA, Bakulina LF, Dalaeva AA, Ustinova EN, Chepurnova TS,

Baker Jr JR. Inactivation of Ebola virus with surfactant nanoemulsion.

Acta Tropica 2003;87:31520.

Morales D, Gutierrez JM, Garcia-Celma MJ, Solans C. A study on the

relation between bicontinuous microemulsions and O/W nano-emulsion

formation. Langmuir 2003;19:7196200. Relation between properties of

nano-emulsions and phases crossed through emulsification path permits to

optimize the preparation of nano-emulsions.

Izquierdo P, Esquena J, Tadros TF, Dederen JC, Feng J, Garcia-Celma MJ,

Azemar N, Solans C. Phase behavior and nanoemulsion formation by the

phase inversion temperature method. Langmuir 2004;20:65948.

Izquierdo P, Feng J, Esquena J, Tadros TF, Dederen JC, Garcia MJ, Azemar

N, Solans C. The influence of surfactant mixing ratio on nano-emulsion

formation by the pit method. Journal of Colloid and Interface Science

2005;285:38894. Optimization of preparation respect to surfactant mixing

ratio is presented.

Morales D, Solans C, Gutierrez JM, Garcia-Celma MJ, Olsson U. Oil/

water droplet formation by temperature change in the water/C16E6/

mineral oil system. Langmuir 2006;22:301420. Mechanism of droplet

formation depending on phases crossed through emulsification path are

discussed.

Uson N, Garcia MJ, Solans C. Formation of water-in-oil (W/O) nanoemulsions in a water/mixed non ionic surfactant/oil systems prepared by

low energy methods. Colloids and Surfaces A, Physicochemical and

Engineering Aspects 2004;250:41521.

Pey CM, Maestro A, Sol I, Gonzlez C, Solans C, Gutierrez JM.

Optimization of nano-emulsions prepared by low energy emulsification

methods at constant temperature using experimental designs. Colloids

and Surfaces A, Physicochemical and Engineering Aspects 2006;288:

14450. Complete description of experimental design application to

study nano-emulsion preparation. Effect of variables and response

surfaces are obtained.

251

[49] Sajjadi S. Nanoemulsion formation by phase inversion emulsification: on

the nature of inversion. Langmuir 2006;22:5597603.

[50] Sol I, Maestro A, Pey CM, Gonzlez C, Solans C, Gutierrez JM. Nanoemulsions preparation by low energy methods in an ionic surfactant system.

Colloids and Surfaces A, Physicochemical and Engineering Aspects

2006;288:13843. Preparation of nano-emulsions by crossing a water

continuous cubic liquid crystal phase through emulsification path is described.

[51] Seekkuarachchi IN, Tanaka K, Kumazawa K. Formation and characterization of submicrometer oil-in-water (O/W) emulsions, using high energy

emulsification. Industrial and Engineering Chemistry Research 2006;45:

37290. Extensive and detailed work studying the influence of relevant

variables on the preparation of nano-emulsions by shear.

[52] Jafari SM, He Y, Bhandari B. Optimization of nano-emulsions production

by microfluidization. European Food Research and Technology 2007;225:

73341.

[53] Katagi S, Kimura Y, Adachi S. Continuous preparation of O/W nanoemulsion by the treatment of a coarse emulsion under subcritical water

conditions. LWT 2007;40:137680.

[54] Sadurn N, Solans C, Azemar N, Garca-Celma MJ. Studies on formation of

O/W nano-emulsions, by low energy methods, suitable for pharmaceutical

applications. European Journal of Pharmaceutical Applications 2005;26:

43845.

[55] Liu W, Sun D, Li C, Liu Q, Xu J. Formation and stability of paraffin oil-inwater nano-emulsions prepared by the emulsion inversion point method.

Journal of Colloid and Interface Science 2006;303:55763. Results of this

paper clearly show the dependence of droplet size on HLB in surfactant

mixture.

[56] Porras M, Solans C, Gonzlez C, Martnez A, Guinart A, Gutierrez JM.

Studies on W/O nano-emulsions. Colloids and Surfaces A, Physicochemical and Engineering Aspects 2004;249:1158. Studies about influence of

relevant variables on droplet size of W/O nano-emulsions.

[57] Bouchemal K, Brianon S, Perrier E, Fessi H. Nano-emulsion formulation

using spontaneous emulsification: solvent, oil and surfactant optimization.

International Journal of Pharmaceutics 2004;280:24151.

[58] Taha E, Al-Saidam S, Samy AM, Khan MA. Preparation and in vitro

characterization of self-nanoemulsified drug delivery system (SNEDDS)

of all-trans-retinol acetate. International Journal of Pharmaceutics

2004;285:10919.

[59] Taha E, Samy AM, Kassem AA, Khan MA. Response surface methodology

for the development of self-nanoemulsified drug delivery system (SNEDDS)

of all-trans-retinol acetate. Pharmaceutical Development and Technology

2004;10:36370. Complete optimization is presented for a self-emulsifying

system, with experimental design, analysis of response surfaces and

optimization.

[60] Zidam AS, Sammour OA, Hammad MA, Megrab NA, Habib MJ, Khan

MA. Quality by design: understanding the formulation variables of

cyclosporine a self-nanoemulsified drug delivery system by Box

Behnken design and desirability function. International Journal of

Pharmaceutics 2007;332:5563. The same group that in reference [55]

presents similar treatment of other system through surface response, but

now named the method Quality by design (QBD). A more detailed

explanation of methodology is presented.

[61] Shah RB, Zidam AS, Funck T, Tawakkul MA, Nguyenpho A, Khan MA.

Quality by design: characterization of self-nanoemulsified drug delivery

systems (SNEDDSs) using ultrasonic resonator technology. International

Journal of Pharmaceutics 2007;341:18994. The same group again utilize

experimental designs and response surface methodology, but this time

using them to evaluate a new characterization ultrasonic technique.

[62] Sol I, Maestro A, Gonzlez C, Solans C, Gutierrez JM. Optimization of

nano-emulsion preparation by low energy methods in an ionic surfactant

system. Langmuir 2006;22:832632. Complete study showing influence

of phases crossed through emulsification path and influence of relevant

variables as determined by experimental designs.

Vous aimerez peut-être aussi

- Introductory Chapter: From Microemulsions To Nanoemulsions: Koh Kai Seng and Wong Voon LoongDocument7 pagesIntroductory Chapter: From Microemulsions To Nanoemulsions: Koh Kai Seng and Wong Voon LoongHoàngPas encore d'évaluation

- Ankur Gupta, 2020Document14 pagesAnkur Gupta, 2020Dimi lira santa rosaPas encore d'évaluation

- Land Fester 2001Document4 pagesLand Fester 2001Sreedevi KrishnakumarPas encore d'évaluation

- Emulsion Polymerization ThesisDocument7 pagesEmulsion Polymerization Thesisstephaniewilliamscolumbia100% (2)

- Self Study Reort 2Document30 pagesSelf Study Reort 2ashPas encore d'évaluation

- Nanoemulsions in Cosmetics S OzgunDocument14 pagesNanoemulsions in Cosmetics S OzgunLabhnesh JindalPas encore d'évaluation

- Role of Polymers As Gelling Agents in The Formulation of EmulgelsDocument17 pagesRole of Polymers As Gelling Agents in The Formulation of EmulgelsDina Maretta WulandariPas encore d'évaluation

- Applications and Use of Microemulsions: Kai Lun LEEDocument6 pagesApplications and Use of Microemulsions: Kai Lun LEEjagruthimsPas encore d'évaluation

- Microemulsion Technology Potential and Regulations in Indonesian Food IndustryDocument13 pagesMicroemulsion Technology Potential and Regulations in Indonesian Food Industrydiah putriPas encore d'évaluation

- Mesoporous Zeolites: Preparation, Characterization and ApplicationsDocument4 pagesMesoporous Zeolites: Preparation, Characterization and ApplicationsbhrPas encore d'évaluation

- Nanoemulsion Characterisation Techniques and Formulation MethodsDocument10 pagesNanoemulsion Characterisation Techniques and Formulation MethodsEditor IJTSRDPas encore d'évaluation

- Surfactant Role and ClassificationDocument24 pagesSurfactant Role and ClassificationshagagPas encore d'évaluation

- Role of Surfactants in Nanotechnology and Their ApplicationsDocument24 pagesRole of Surfactants in Nanotechnology and Their ApplicationsHumaira RazzaqPas encore d'évaluation

- Polymer Nanotubes Nanocomposites: Synthesis, Properties and ApplicationsD'EverandPolymer Nanotubes Nanocomposites: Synthesis, Properties and ApplicationsPas encore d'évaluation

- Journal of Petroleum Science and Engineering: Narendra Kumar, Amit Verma, Ajay MandalDocument24 pagesJournal of Petroleum Science and Engineering: Narendra Kumar, Amit Verma, Ajay MandalАхрор АхроровPas encore d'évaluation

- Non-Newtonian FluidDocument15 pagesNon-Newtonian FluidAlaa AskPas encore d'évaluation

- Controlled Production of Emulsion and Particles by Milli and Microfluidic TechniquesDocument11 pagesControlled Production of Emulsion and Particles by Milli and Microfluidic TechniquesSlamet Hadi KusumahPas encore d'évaluation

- 2007 12 20 Foam Engl 03Document48 pages2007 12 20 Foam Engl 03Rajesh Kumar100% (3)

- Nanocapsules in Drug Delivery and Others ApplicationsDocument10 pagesNanocapsules in Drug Delivery and Others ApplicationsPerlitha11Pas encore d'évaluation

- J Memsci 2017 06 075 PDFDocument36 pagesJ Memsci 2017 06 075 PDFAndresa Viana RamosPas encore d'évaluation

- Biodegradable Injectable in Situ Forming Drug Delivery System1Document20 pagesBiodegradable Injectable in Situ Forming Drug Delivery System1thanaPas encore d'évaluation

- Nanocellulose in Polymer Composites and Biomedical ApplicationsDocument8 pagesNanocellulose in Polymer Composites and Biomedical ApplicationsMuhammad Fauzan LubisPas encore d'évaluation

- SPE-188174-MS Green EOR Utilizing Well-Defined Nano-Cellulose Based Nano-Fluids From Flask To FieldDocument13 pagesSPE-188174-MS Green EOR Utilizing Well-Defined Nano-Cellulose Based Nano-Fluids From Flask To FieldJosé Manuel UsuriagaPas encore d'évaluation

- Emulsion Polymerization Process for VeoVa Monomer Latex ProductionDocument7 pagesEmulsion Polymerization Process for VeoVa Monomer Latex ProductionA MahmoodPas encore d'évaluation

- 12 Practical Applications of Paper Chemistry: J. C. Roberts (Ed.), Paper Chemistry © Blackie & Son LTD 1991Document2 pages12 Practical Applications of Paper Chemistry: J. C. Roberts (Ed.), Paper Chemistry © Blackie & Son LTD 1991SalehPas encore d'évaluation

- Emulsion Suspension PolymerizationDocument5 pagesEmulsion Suspension PolymerizationGosa harikrishnaPas encore d'évaluation

- Batch Emulsion PolymerizationDocument166 pagesBatch Emulsion PolymerizationShubham CholePas encore d'évaluation

- Analysis of The Role of Stripping Agents in Polymer DevolatilizationDocument14 pagesAnalysis of The Role of Stripping Agents in Polymer DevolatilizationyamakunPas encore d'évaluation

- Teoria Emulsion PolymerDocument7 pagesTeoria Emulsion PolymerSantos de PradosPas encore d'évaluation

- Articulo 1 Seminario EmulsionesDocument13 pagesArticulo 1 Seminario Emulsioneslaura quicenoPas encore d'évaluation

- Ding-2019-Double Emulsions Prepared by Two-SteDocument19 pagesDing-2019-Double Emulsions Prepared by Two-Ste旭康 鲁Pas encore d'évaluation

- Nanoemulsion: A Pharmaceutical ReviewDocument9 pagesNanoemulsion: A Pharmaceutical ReviewfikriPas encore d'évaluation

- Critical Reviews in Food Science and Nutrition - Mcclements2011Document47 pagesCritical Reviews in Food Science and Nutrition - Mcclements2011Dana NicutaPas encore d'évaluation

- Pickering Emulsions - Preparation Processes, Key Parameters Governing Their Properties and Potential For Pharmaceutical ApplicationsDocument31 pagesPickering Emulsions - Preparation Processes, Key Parameters Governing Their Properties and Potential For Pharmaceutical ApplicationsEsteban MalamboPas encore d'évaluation

- 2018 Liu Yang Self-Stabilized Precipitation PolymerizationDocument12 pages2018 Liu Yang Self-Stabilized Precipitation PolymerizationTay HuiaPas encore d'évaluation

- Chemical Engineering Journal: February 2018Document9 pagesChemical Engineering Journal: February 2018saeasdPas encore d'évaluation

- New Resins For Dental Composites - PMCDocument13 pagesNew Resins For Dental Composites - PMCJefferson RegentePas encore d'évaluation

- Ghasemi2020 Article PreparationOfStableMultipleEmuDocument9 pagesGhasemi2020 Article PreparationOfStableMultipleEmuDaffa RamadhaniPas encore d'évaluation

- 30 BR Emulsion 14Document2 pages30 BR Emulsion 14ionut ivanPas encore d'évaluation

- San Miguel 2006Document11 pagesSan Miguel 2006Ricardo Gómez LoaPas encore d'évaluation

- PolynanocompDocument14 pagesPolynanocompKrishnan AnanthanarayananPas encore d'évaluation

- New Methods For Lipid Nanoparticles PrepratonDocument13 pagesNew Methods For Lipid Nanoparticles PrepratonMohit BawaPas encore d'évaluation

- Pharmaceutics 12 01223 v2Document21 pagesPharmaceutics 12 01223 v2Lina WinartiPas encore d'évaluation

- Factos Affecting The Properties of Nitrocellulose Emulsion A Comparative StudyDocument23 pagesFactos Affecting The Properties of Nitrocellulose Emulsion A Comparative Studyshikaru7114Pas encore d'évaluation

- Nanoemulsion: A Novel Platform For Drug Delivery System: February 2018Document12 pagesNanoemulsion: A Novel Platform For Drug Delivery System: February 2018mwdhtirahPas encore d'évaluation

- Solid Lipid Nanoparticles (SLN) For Controlled Drug Delivery A Review of The State of The ArtDocument17 pagesSolid Lipid Nanoparticles (SLN) For Controlled Drug Delivery A Review of The State of The ArtNhat Dinh DoPas encore d'évaluation

- 10.1515 - Biol 2020 0013Document11 pages10.1515 - Biol 2020 0013nabeelkhaliq323Pas encore d'évaluation

- Nanoparticles Effect On FRP Filament-Winded Composites PerformanceDocument13 pagesNanoparticles Effect On FRP Filament-Winded Composites PerformanceUday MavooriPas encore d'évaluation

- Recent Advances in SemisolidsDocument11 pagesRecent Advances in SemisolidsRajuPas encore d'évaluation

- Review Preparation of Methacrylate Monoliths: Institute of Macromolecular Compounds, St. Petersburg, RussiaDocument13 pagesReview Preparation of Methacrylate Monoliths: Institute of Macromolecular Compounds, St. Petersburg, RussiasuryaPas encore d'évaluation

- Insulation Materials of Transformer Using Moisture Absorption MechanismDocument5 pagesInsulation Materials of Transformer Using Moisture Absorption MechanismInternational journal of Engineering worksPas encore d'évaluation

- Nano FiltrationDocument8 pagesNano FiltrationEman El DsoukyPas encore d'évaluation

- 7 KrisTriBasukiDocument26 pages7 KrisTriBasukiLoraPas encore d'évaluation

- Sjoblom, J. - Handbook of Emulsion Technology PDFDocument731 pagesSjoblom, J. - Handbook of Emulsion Technology PDFdcharlies92% (13)

- Schmidt 2001Document12 pagesSchmidt 2001vineeth loganathanPas encore d'évaluation

- MAALI, 2013 - Prepararea Și Aplicarea Nanoemulsiilor in Ultimul Deceniu (2000-2010)Document15 pagesMAALI, 2013 - Prepararea Și Aplicarea Nanoemulsiilor in Ultimul Deceniu (2000-2010)Dana NicutaPas encore d'évaluation

- 00 Chap Salager 2 FormulationDocument57 pages00 Chap Salager 2 FormulationFernando HenriquePas encore d'évaluation

- Emulsions, Microemulsions, and NanoemulsionsDocument31 pagesEmulsions, Microemulsions, and NanoemulsionsHussein Talal Kenaan100% (3)

- Physicochemical and Rheological CharacteDocument11 pagesPhysicochemical and Rheological CharactegessicapalaoroPas encore d'évaluation

- Floating DDSDocument19 pagesFloating DDSalexpharmPas encore d'évaluation

- Nanoemulsions via Two-Step ProcessDocument8 pagesNanoemulsions via Two-Step ProcessYuli CartrinaPas encore d'évaluation

- ZNL 1333Document9 pagesZNL 1333Yuli CartrinaPas encore d'évaluation

- Hypertension 1988 Frishman II21Document10 pagesHypertension 1988 Frishman II21Yuli CartrinaPas encore d'évaluation

- Hypertension 1988 Frishman II21Document10 pagesHypertension 1988 Frishman II21Yuli CartrinaPas encore d'évaluation

- 2628 762 1 SMDocument9 pages2628 762 1 SMAsrelPas encore d'évaluation

- Abd 88 0396 PDFDocument7 pagesAbd 88 0396 PDFYuli CartrinaPas encore d'évaluation

- Drug-Related Admissions and Hospital-Acquired Adverse Drug Events in Germany: A Longitudinal Analysis From 2003 To 2007 of ICD-10-coded Routine DataDocument9 pagesDrug-Related Admissions and Hospital-Acquired Adverse Drug Events in Germany: A Longitudinal Analysis From 2003 To 2007 of ICD-10-coded Routine DataYuli CartrinaPas encore d'évaluation

- 579Document5 pages579Yuli CartrinaPas encore d'évaluation

- PhenobarbitalDocument2 pagesPhenobarbitalArnzz Agbulos100% (1)

- Class 5Document430 pagesClass 5Subash NeupanePas encore d'évaluation

- Beipackzettel Sinupret-Extract en 2017-07Document2 pagesBeipackzettel Sinupret-Extract en 2017-07Olabie 2009Pas encore d'évaluation

- Homogeinización y HomogeinizadoresDocument9 pagesHomogeinización y HomogeinizadoresOmar Canseco JordaPas encore d'évaluation

- Valdoxan: Product InformationDocument15 pagesValdoxan: Product InformationGastón PacciaroniPas encore d'évaluation

- List of high alert medications at Husada HospitalDocument5 pagesList of high alert medications at Husada HospitalCHRISTINE EriskaPas encore d'évaluation

- WC 500167173Document34 pagesWC 500167173Muhammad AslamPas encore d'évaluation

- Diaper DermatitisjDocument11 pagesDiaper DermatitisjSarah M PanjaitanPas encore d'évaluation

- Triamcinolone (Topical) - Drug InformationDocument5 pagesTriamcinolone (Topical) - Drug InformationMauricio Sv0% (1)

- Nfi 2011Document804 pagesNfi 2011indmale_0070% (1)

- RMP For Drug Establishments - 26 August 2015 PDFDocument88 pagesRMP For Drug Establishments - 26 August 2015 PDFIan FranklinPas encore d'évaluation

- Italian Folk HerbsDocument12 pagesItalian Folk HerbsMelissa Farruggio McNairPas encore d'évaluation

- Mefenamic acid helps relieve moderate to severe painDocument1 pageMefenamic acid helps relieve moderate to severe painsneb1392Pas encore d'évaluation

- Role of RA in PharmaDocument5 pagesRole of RA in PharmaDheeraj JaiswalPas encore d'évaluation

- Gynisol SyrupDocument2 pagesGynisol Syruphk_scribdPas encore d'évaluation

- InterviewDocument3 pagesInterviewHui MinPas encore d'évaluation

- Pci Approved ClgsDocument8 pagesPci Approved ClgsParthshah39Pas encore d'évaluation

- Quiz - Hazmat - Hazard ClassificationDocument3 pagesQuiz - Hazmat - Hazard ClassificationMohamad SannanPas encore d'évaluation

- 16 10 25 Decarboxylation of THCA To Active THC PDFDocument3 pages16 10 25 Decarboxylation of THCA To Active THC PDFRafael Ignacio Leal QuijónPas encore d'évaluation

- A A A A C C C C A A A A D D D D Eeee M M M M IIII C C C C S S S S C C C C IIII Eeee N N N N C C C C Eeee S S S SDocument3 pagesA A A A C C C C A A A A D D D D Eeee M M M M IIII C C C C S S S S C C C C IIII Eeee N N N N C C C C Eeee S S S SnelisaPas encore d'évaluation

- C-10 Ointment, Cream, GelDocument6 pagesC-10 Ointment, Cream, GelAli Uy100% (2)

- Vancomycin Pharmacokinetics GuideDocument5 pagesVancomycin Pharmacokinetics GuidedrblondyPas encore d'évaluation

- Chapter 10 Costing and Pricing of A Drug FormulationDocument10 pagesChapter 10 Costing and Pricing of A Drug FormulationS.Srinivasan ('Chinu'); Renu Khanna81% (16)

- Create B.Pharm 7th Sem Time TableDocument2 pagesCreate B.Pharm 7th Sem Time TableNitish SharmaPas encore d'évaluation

- 6 - The Physical Plant and Its EquipmentDocument26 pages6 - The Physical Plant and Its EquipmentAbdul Basit100% (3)

- Antibiotics: Review of Ceftazidime-Avibactam For The Treatment of Infections Caused by Pseudomonas AeruginosaDocument24 pagesAntibiotics: Review of Ceftazidime-Avibactam For The Treatment of Infections Caused by Pseudomonas AeruginosaVictor Hugo SilveiraPas encore d'évaluation

- Pricelist Produk Ekatalog PT. Mersifarma TM, Thn. 2023 - 2024 UPDATE Feb 23Document3 pagesPricelist Produk Ekatalog PT. Mersifarma TM, Thn. 2023 - 2024 UPDATE Feb 23didikPas encore d'évaluation

- 0208 Sulfa SlideDocument24 pages0208 Sulfa SlidetvvsagarPas encore d'évaluation

- Bandung Pharma Consumer CompaniesDocument3 pagesBandung Pharma Consumer Companiesvale pallenPas encore d'évaluation

- Agenda Prac Draft Agenda Meeting 7 10 February 2022 - enDocument69 pagesAgenda Prac Draft Agenda Meeting 7 10 February 2022 - ennegfbPas encore d'évaluation