Académique Documents

Professionnel Documents

Culture Documents

EMINENT - Quick Release Hooks

Transféré par

J.SIVIRACopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

EMINENT - Quick Release Hooks

Transféré par

J.SIVIRADroits d'auteur :

Formats disponibles

Quick Release mooring Hooks

Document No.: #E0601

Rev .: B

2006

Shanghai Eminent Enterprise Development Co., Ltd

The copyright for the information and displays contained within this document is retained by Shanghai

Eminent Enterprise Development Co., Ltd and is therefore to be considered proprietary. It is intended for

the sole and discreet use of the party for whom it was prepared. With the exception of published technical

references, literature and brochures the information and displays shall not be disclosed to a third Party

without the prior written consent of Shanghai Eminent Enterprise Development Co., Ltd

Shanghai Eminent Enterprise Development Co.,Ltd

Tel:

+86 (0)13905134168

Fax:

+86 (21) 5794 1569

Shanghai

China

Email:

Web:

info@china-eminent.com

www.china-eminent.com

Quick Release Hook

Quick Release Mooring Hook

1. GENERAL DESCRIPTION

Installed at dock, Quick release hooks are

special equipments for winding and tying of

ships. They are the update products of

mooring dolphins. Compared with cleat, they

reduce working intensity, increase working

efficiency and improve safety and reliability.

Quick release hook consists of integrated

electrical winch and release systems. They

are suitable for large tonnage ships mooring

harbors that require fewer workers and quick

releasing and winding of the hawser under

heavy storm or other dangerous status.

Eminent is a professional manufactory for design,

production, installation and service of Quick

Release Hook(QRH). We learned about different

design philosophies from various manufacturers

drawed on the pick of the basket and we have put

Quick Release Hook

the client's valuable comments into the basket together with our own experience.

Eminent Quick Release Hook as an excellent product came out to the world. Especially,

our designers with a solid experience continue to update in new material and new

technical process in evey year. We have own 38pc patents only for Quick Release

Hooks.

We can supply you various type QRH(single, double, triple or quadruple hooks as

required by the layout of the terminal, although other

configurations, e.g. back-to-back,)with local manual hook

release, electric, hydraulic and pneumatic remote release

systems for the hooks, with the activation devices completely

integrated into the hook assembly.

And also can supply

you the all type QRH installed mooring load monitoring

system. We named it "Eminent Intelligent Hook".

We can produce custom-made quick release hooks base on your requirement.

Quick Release Hook

Each hook is proof tested to 150% of its rated load, and the release mechanism

is tested at full load rating at our own test facility and is witnessed

by

surveyor

from

an

independent

Classification Society LRDNVBVABS

etc.. If remote release is incorporated the

hooks can be released from a remote

location (generally the control room or jetty

office) as well as by activating a button on

the control panel mounted on the side of

the hook. Local displays of the mooring load tensions and audible and visual alarms

can also be incorporated into the hook.

2. STANDARDS

OCMIF Mooring Equipment Guidelines

TMXW1-2004 QRH (Shanghai Enterprise Standard)

ASME, Section IXWelding Qualifications

ASTM A283 (Grade C) Standard

Specification for Low

and

Intermediate Tensile Strength Carbon Steel Plates

ASTM A148 Standard Specification for Steel Castings, High Strength for Non

Structural Purposes

ASTM A572 Standard

Specification for

High Strength Low

Alloy

Columbium-Vanadium Structural Steel

IEC: National Electrical Code,

Intrinsically

Safe Process

Control Equipment for

Use in Class I Hazardous Locations International Electrotechnical Commission

Chinese Standards and the specification from the clients.

Quick Release Hook

3. Capstan Assembly

In order to save time and to ensure maximum safety,Each mooring unit is equipped with

an integrated electric capstan motor assembly, the mooring ropes are lifted up to the

mooring hooks by using the integrated electrical capstan. The capstan which is

reversible is operated from a foot switch.

Capstans are integrally mounted to the hook units and

are certified for Ex area where applicable.

This capstan complies with following specifications:

Starting pull:

40KN = max line pull

Running pull: 15KN-30KN = normal line pull

Line speed:

20 m/min-25m/min

Back-stop:

1.5 times normal line pull

The capstan gear box is a self locking device to prevent the capstan head from turning in

the opposite direction due to the weight of the mooring line at power off.

The mounting model for motor is suggested: Horizontal.

4. STRUCTURE DESIGN

MATERIAL LIST:

PART

STANDARD

REMARK

Hook

GB-ZG35CrMo

Equal to JIS SCCrM3

Shaft

GB-40Cr

Equal to ASTM A29 5140

Connector

GB-Q420A

Equal to ASTM A572 Gr.65

Frame

GB-Q420A

Equal to ASTM A572 Gr.65

Quick Release Hook

Mounting base

GB-Q420A

Anchor bolts/nuts

GB-Q345A

Equal to ASTM A572 Gr.65

Equal to ASTM A572 Gr.50

We also can choose the right material and cumstom-made QRH base on

the actual temperature on site(-20)

We will submit the certificates for all material from an independent

Classification Society LRDNVBVABS etc.).If necessary.

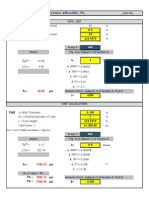

SPECIFICATION AND PERFORMANCE DATA

Each hook will be tested as follows: Test load =1.5 times the SWL

Release load = 1.0SWL

Manual release force for release bar < 170N@SWL

The movement range of hooks:

Vertical: -15(MLMS model), -5,0 to 45, 55.

Horizontal:

Single hook unit:

90/90

Double hook unit:

90/45 (left hook)

45/-90 (right hook)

Triple hook unit:

90/ 45 (left hook)

45/ -45(Middle hook)

-45/-90 (right hook)

Quadruple hook unit: Same as Triple hook unit.

MOUNTING BASE METHODS

Concrete embedment

Quick Release Hook

Bolted to steel deck

Welded onto steel deck

HOOK ARRANGEMENT

Different arrangements available

Hooks can be installed on both sides of post

Hook post delivered with or without capstans

Free standing capstans

5. INTELLIGENT HOOK

Eminent Intelligent hook includes Remote Release System, Status Sensors and Mooring

Load Moritoring System. It is possible to performe Quick Release hooks release,

monitoring out of the dock in emergency. Ensure the Security of Jettyand operators.

Remote Release System and Status Sensors

To operate the release system from the remote location,

a central remote control

panel is included in the delivery. The panel includes:

Hook release indicator

Hook release push button

A master release push button

An emergency release push button

A power on/off indicator lamp

A power on/off switch

Quick Release Hook

Digital display

Display of hook loads

Alarm indication

Hook status (locked/unlocked)

Failed release

The remote quick release panel RQRP is

connected via the LAN/Ethernet cabling to

the hook stations. Functionality of the hooks

is controlled from the network dedicated

processor LAN Micro Sensor (LMS) built into

the

RQRP.

Control

of

the

hooks

open/close functions is separated from the central computer system due to safety

reasons. Furthermore a special coded message protocol between the RQRP and

the hook station LAN/Ethernet unit is made to avoid accidental release of the

hooks.

The design of the RQRP allows to have multiple RQRPs connected both for

hazardous and safe area.

Mooring Load Monitoring System.

(1) The Load Pin:

The load pin is manufactured as a direct replacement for the hook swivel shafts.

The load pin shall have the same safe

working load as the corresponding mooring

hook.

The load pins are made of stainless steel

17-4PH, which is a special quality of

stainless steel with an extreme high strength.

Quick Release Hook

(2) The Amplifier and Control Uint

A dedicated amplifier module LM4 that is integreted into the control panel for capstan

has been designed to protect the load cells from

the cable network to aviod damage in case of

induction caused by lightening. The amplifier module

is equipped with a proceesor unit that will track of

the loads. This means that the load values are

memorized in this amplifier module keeping track

of about 1year of data. Should the central computer

for some reason fail, the history is always available in the amplifier unit.Temperature

ranging from -40 to 85

(3) Load Monitoring on Central Computor

The load information is in real-time sent to the central computor for visualization.

This central computor acts as server for the data

recorders located in the hook remote release control

panel cabinet.

The central computor system will also host the

Vessel Docking Aid System Software. Display

screens will be available to the operator thought a

standard MS windows interface and will form an

intergreted package.

Vous aimerez peut-être aussi

- Beginning Digital Electronics through ProjectsD'EverandBeginning Digital Electronics through ProjectsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Mampaey Mooring Hooks - Capstans PDFDocument16 pagesMampaey Mooring Hooks - Capstans PDFMarceloPas encore d'évaluation

- 1Document13 pages1RPDeshPas encore d'évaluation

- FRC Davit 3 Tech DescriptionDocument5 pagesFRC Davit 3 Tech DescriptionSamo SpontanostPas encore d'évaluation

- 382.002 Tank Cleaning Equipment (Instructions & Spare Parts)Document72 pages382.002 Tank Cleaning Equipment (Instructions & Spare Parts)Andrew100% (1)

- OIL CBM Brochure 2015Document3 pagesOIL CBM Brochure 2015prasetyoPas encore d'évaluation

- 02 - Operation Instructions - Stern RollerDocument15 pages02 - Operation Instructions - Stern Rollermiguel100% (1)

- Launching Appliance of Free-Fall Lifeboat Operation Instruction Yzf55Document11 pagesLaunching Appliance of Free-Fall Lifeboat Operation Instruction Yzf55Danial AbdullahPas encore d'évaluation

- Flyer TL-FADocument20 pagesFlyer TL-FAmingo622Pas encore d'évaluation

- Safety Working Load Calculation of Panama ChocksDocument5 pagesSafety Working Load Calculation of Panama ChocksMeleti Meleti MeletiouPas encore d'évaluation

- CAR 35 Release Hook 27-07-2009Document10 pagesCAR 35 Release Hook 27-07-2009Ramin Soad0% (1)

- Iom1338 2Document127 pagesIom1338 2isaavedracastroPas encore d'évaluation

- APPENDIX 4 Statement On Telescopic Spout Operation Fraser Surrey Docks DTCF AmendmentDocument8 pagesAPPENDIX 4 Statement On Telescopic Spout Operation Fraser Surrey Docks DTCF AmendmentRestuPas encore d'évaluation

- Crane Load Chart-D-008 R2 (2) 52Document1 pageCrane Load Chart-D-008 R2 (2) 52sdPas encore d'évaluation

- 3t Monorail Provision CraneDocument21 pages3t Monorail Provision CranesridharPas encore d'évaluation

- Boskalis Heavy Lift Vessels BrochureDocument10 pagesBoskalis Heavy Lift Vessels BrochureRalf TholenPas encore d'évaluation

- LH 185 DS 0062 6Document6 pagesLH 185 DS 0062 6Primelift Safety Resources LimitedPas encore d'évaluation

- ZP10-1430 Stinger Winch Operator's ManualDocument22 pagesZP10-1430 Stinger Winch Operator's ManualIvan MaltsevPas encore d'évaluation

- PALFINGER Provision and Life Boat PDFDocument42 pagesPALFINGER Provision and Life Boat PDFMuhammad AndhikaPas encore d'évaluation

- HF-4 Emergency Towing System (Including Instruction Book)Document43 pagesHF-4 Emergency Towing System (Including Instruction Book)MUKUL100% (1)

- GL Type CraneDocument2 pagesGL Type Cranehelmi_surya2003Pas encore d'évaluation

- Procedures For USARI FADocument27 pagesProcedures For USARI FAKenaia Adeleye100% (2)

- Sea Horizon SpecificationDocument2 pagesSea Horizon SpecificationSyafiq HalimPas encore d'évaluation

- SW 52 DS 0069 2Document6 pagesSW 52 DS 0069 2sssssPas encore d'évaluation

- Liebherr Offshore Cranes Product Range enDocument20 pagesLiebherr Offshore Cranes Product Range enCarlos Gonzalez Torres0% (1)

- TTS Hose Handling CranesDocument4 pagesTTS Hose Handling CranesCaptIsqanPas encore d'évaluation

- COSLBoss PDFDocument2 pagesCOSLBoss PDFDenny HermawanPas encore d'évaluation

- DSV - 110-120mDocument109 pagesDSV - 110-120mmahudin58Pas encore d'évaluation

- Norsafe Tor Mk2 Next Generation On-Load Release Equipment For LifeboatsDocument2 pagesNorsafe Tor Mk2 Next Generation On-Load Release Equipment For LifeboatsokandandinPas encore d'évaluation

- Technical Specification: For NPT40R Rescue BoatDocument3 pagesTechnical Specification: For NPT40R Rescue BoatThomas SellersPas encore d'évaluation

- Nautilus Marine Cranes PesentationDocument25 pagesNautilus Marine Cranes Pesentation魏永涛Pas encore d'évaluation

- PPL-PVS-023 - Rev1 - Barge Calculation During Transportation On SeaDocument80 pagesPPL-PVS-023 - Rev1 - Barge Calculation During Transportation On SeaThanh Anh MaiPas encore d'évaluation

- BS MA 55 Lifeboat WinchesDocument8 pagesBS MA 55 Lifeboat WinchesZohair AftabPas encore d'évaluation

- JR2010010 Marine Warranty Surveyors CoP PDFDocument14 pagesJR2010010 Marine Warranty Surveyors CoP PDFhiyeonPas encore d'évaluation

- 337TO 003 World's Largest FLNG PreludeDocument9 pages337TO 003 World's Largest FLNG PreludeRamPas encore d'évaluation

- Ship EquipmentDocument3 pagesShip EquipmentviahulPas encore d'évaluation

- DP3 Multi-Purpose Offshore Construction Vessel: Toisa ProteusDocument2 pagesDP3 Multi-Purpose Offshore Construction Vessel: Toisa Proteuslmorsal01Pas encore d'évaluation

- Comissionamento Do Sistema de Pull in PDFDocument65 pagesComissionamento Do Sistema de Pull in PDFrfelippe8733Pas encore d'évaluation

- Proposal Single Point Mooring 2Document1 pageProposal Single Point Mooring 2opahPas encore d'évaluation

- Design Criterions For Crane PedestalsDocument5 pagesDesign Criterions For Crane PedestalsRPDeshPas encore d'évaluation

- Procedure For LoadoutDocument17 pagesProcedure For Loadoutnaeimeslami100% (2)

- Schat-Harding Group PresentationDocument44 pagesSchat-Harding Group Presentationbaaziz2015100% (1)

- User Manual: (Capacity 6 Passengers)Document50 pagesUser Manual: (Capacity 6 Passengers)FAR_A_DAY100% (1)

- H2021s Final Drawing For Rescue Boat and Davit PDFDocument35 pagesH2021s Final Drawing For Rescue Boat and Davit PDFBuster HTC desirePas encore d'évaluation

- (Package-2-Mech Works) : Clean Fuels ProjectDocument15 pages(Package-2-Mech Works) : Clean Fuels ProjectsarangpunePas encore d'évaluation

- Havila Venus PDFDocument5 pagesHavila Venus PDFFrds123Pas encore d'évaluation

- 6 10K Favco Operating Maintenance Parts Manual Book 1 of 3Document256 pages6 10K Favco Operating Maintenance Parts Manual Book 1 of 3Anonymous 1ykzuaxWgY100% (1)

- Scaldis - Installation VesselDocument18 pagesScaldis - Installation VesselJoel GancedoPas encore d'évaluation

- Tandem Mooring & OffloadingDocument12 pagesTandem Mooring & OffloadingJim StrakerPas encore d'évaluation

- Comparison Between Lattice Boom and Knuckle BoomDocument2 pagesComparison Between Lattice Boom and Knuckle BoomG.SWAMI100% (2)

- MacGregor HH Crane PDFDocument1 pageMacGregor HH Crane PDFrinaldy fernandaPas encore d'évaluation

- Section 4: Specifications Specifications For Quick Release HookDocument17 pagesSection 4: Specifications Specifications For Quick Release HookAnonymous iM2totBrPas encore d'évaluation

- K.C. LTD.: 165, Mieumsandan 3-Ro, Gangseo-Gu, Busan 46744, KoreaDocument23 pagesK.C. LTD.: 165, Mieumsandan 3-Ro, Gangseo-Gu, Busan 46744, Koreamarine Shanghai100% (2)

- Heavy Lift Jack UpDocument16 pagesHeavy Lift Jack UpjunhyolPas encore d'évaluation

- OKYC Terminal Information and RegulationDocument57 pagesOKYC Terminal Information and RegulationtuyenbsrPas encore d'évaluation

- Muhammad Ayub Bin Khalid: Personal DataDocument5 pagesMuhammad Ayub Bin Khalid: Personal DataAnwarul Shafiq AwalludinPas encore d'évaluation

- Cwor-Brochure WebDocument8 pagesCwor-Brochure WebMartin McCaffreyPas encore d'évaluation

- Catalogo Jokab Safety - RTDocument18 pagesCatalogo Jokab Safety - RTDavid ZacariasPas encore d'évaluation

- Rele Segurança RT9 PDFDocument64 pagesRele Segurança RT9 PDFericson_schelter100% (1)

- ABS MooringSPM GuideDocument6 pagesABS MooringSPM GuideCaptIsqan100% (1)

- HAT Horiz Vessel VolDocument1 pageHAT Horiz Vessel VolJ.SIVIRAPas encore d'évaluation

- Api 682 Update PDFDocument5 pagesApi 682 Update PDFJ.SIVIRAPas encore d'évaluation

- UHX CalcsDocument5 pagesUHX CalcsJ.SIVIRA100% (2)

- Metering Pumps - The Lowdown On TurndownDocument7 pagesMetering Pumps - The Lowdown On TurndownJ.SIVIRAPas encore d'évaluation

- Ug 28Document3 pagesUg 28J.SIVIRA100% (1)

- Extreme Fiber Elongation Calcs - J.SDocument1 pageExtreme Fiber Elongation Calcs - J.SJ.SIVIRA100% (1)

- Seal Chamber Pressure PDFDocument10 pagesSeal Chamber Pressure PDFJ.SIVIRA50% (2)

- Semi Elliptical Head Specs PDFDocument2 pagesSemi Elliptical Head Specs PDFJ.SIVIRAPas encore d'évaluation

- Tank Heat LossDocument25 pagesTank Heat Lossdanmaltais100% (3)

- Datum Compressor Cut PDFDocument1 pageDatum Compressor Cut PDFJ.SIVIRAPas encore d'évaluation

- Pump AlignmentDocument69 pagesPump AlignmentJ.SIVIRA100% (1)

- UHX CalcsDocument5 pagesUHX CalcsJ.SIVIRA100% (2)

- Centrifugal PumpsDocument82 pagesCentrifugal PumpsMd KalamuddinPas encore d'évaluation

- Taller Comercio C.A. - Punto Fijo, Venezuela : General IndexDocument1 pageTaller Comercio C.A. - Punto Fijo, Venezuela : General IndexJ.SIVIRAPas encore d'évaluation

- Volume of (Any) EllipsoidDocument3 pagesVolume of (Any) EllipsoidJ.SIVIRAPas encore d'évaluation

- Propane Gas and Liquefied GasDocument10 pagesPropane Gas and Liquefied GasJ.SIVIRAPas encore d'évaluation

- Soft Tissue SarcomaDocument19 pagesSoft Tissue SarcomaEkvanDanangPas encore d'évaluation

- Work of Asha Bhavan Centre - A Nonprofit Indian Organisation For Persons With DisabilityDocument10 pagesWork of Asha Bhavan Centre - A Nonprofit Indian Organisation For Persons With DisabilityAsha Bhavan CentrePas encore d'évaluation

- Why Men Want Sex and Women Need Love by Barbara and Allen Pease - ExcerptDocument27 pagesWhy Men Want Sex and Women Need Love by Barbara and Allen Pease - ExcerptCrown Publishing Group62% (34)

- Defects Lamellar TearingDocument6 pagesDefects Lamellar Tearingguru_terexPas encore d'évaluation

- Design and Details of Elevated Steel Tank PDFDocument10 pagesDesign and Details of Elevated Steel Tank PDFandysupaPas encore d'évaluation

- Insulating Oil TestingDocument6 pagesInsulating Oil TestingnasrunPas encore d'évaluation

- Method Statement For Lifting WorksDocument12 pagesMethod Statement For Lifting WorksRachel Flores85% (26)

- Shoulder Joint Position Sense Improves With ElevationDocument10 pagesShoulder Joint Position Sense Improves With ElevationpredragbozicPas encore d'évaluation

- AACO 7th Aviation Fuel Forum: AttendanceDocument3 pagesAACO 7th Aviation Fuel Forum: AttendanceJigisha Vasa0% (1)

- Learning Activity Sheet MAPEH 10 (P.E.) : First Quarter/Week 1Document4 pagesLearning Activity Sheet MAPEH 10 (P.E.) : First Quarter/Week 1Catherine DubalPas encore d'évaluation

- Allison Weech Final ResumeDocument1 pageAllison Weech Final Resumeapi-506177291Pas encore d'évaluation

- ATR4518R6v07: Antenna SpecificationsDocument2 pagesATR4518R6v07: Antenna Specificationsanna.bPas encore d'évaluation

- WCC PSV PDFDocument40 pagesWCC PSV PDFAlejandro RamelaPas encore d'évaluation

- Ams - 4640-C63000 Aluminium Nickel MNDocument3 pagesAms - 4640-C63000 Aluminium Nickel MNOrnella MancinelliPas encore d'évaluation

- 5070 s14 QP 11Document16 pages5070 s14 QP 11OsamaRahimPas encore d'évaluation

- The Aging Brain: Course GuidebookDocument126 pagesThe Aging Brain: Course GuidebookIsabel Cristina Jaramillo100% (2)

- BT HandoutsDocument4 pagesBT HandoutsNerinel CoronadoPas encore d'évaluation

- 1 A Finalexam FNH330 June 2015 Final Review QuestionsDocument6 pages1 A Finalexam FNH330 June 2015 Final Review QuestionsChinley HinacayPas encore d'évaluation

- Jinko 570 Mono Facial Jkm570m-7rl4-VDocument2 pagesJinko 570 Mono Facial Jkm570m-7rl4-VShahneela AnsariPas encore d'évaluation

- Topic 7: Respiration, Muscles and The Internal Environment Chapter 7B: Muscles, Movement and The HeartDocument4 pagesTopic 7: Respiration, Muscles and The Internal Environment Chapter 7B: Muscles, Movement and The HeartsalmaPas encore d'évaluation

- Sithpat006ccc019 A - 2021.1Document34 pagesSithpat006ccc019 A - 2021.1Mark Andrew Clarete100% (2)

- Ural Evelopment: 9 9 Rural DevelopmentDocument17 pagesUral Evelopment: 9 9 Rural DevelopmentDivyanshu BaraiyaPas encore d'évaluation

- B737-800 Air ConditioningDocument7 pagesB737-800 Air ConditioningReynaldoPas encore d'évaluation

- Pure Vegeterian: Kousika (CaterersDocument2 pagesPure Vegeterian: Kousika (CaterersShylender NagaPas encore d'évaluation

- The Human Body: An Orientation: Part ADocument10 pagesThe Human Body: An Orientation: Part ARoi Christoffer Jocson PeraltaPas encore d'évaluation

- 15 UrinalysisDocument9 pages15 UrinalysisJaney Ceniza تPas encore d'évaluation

- Uni of Glasgow Map PDFDocument1 pageUni of Glasgow Map PDFJiaying SimPas encore d'évaluation

- Ethics, Privacy, and Security: Lesson 14Document16 pagesEthics, Privacy, and Security: Lesson 14Jennifer Ledesma-Pido100% (1)

- Guimbungan, Core Competency Module 1 - Part 3 PDFDocument11 pagesGuimbungan, Core Competency Module 1 - Part 3 PDFSharlyne K. GuimbunganPas encore d'évaluation

- 351 UN 1824 Sodium Hydroxide SolutionDocument8 pages351 UN 1824 Sodium Hydroxide SolutionCharls DeimoyPas encore d'évaluation