Académique Documents

Professionnel Documents

Culture Documents

2016 Elevator Pressurization in Tall Buildings PDF

Transféré par

adcaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

2016 Elevator Pressurization in Tall Buildings PDF

Transféré par

adcaDroits d'auteur :

Formats disponibles

ctbuh.

org/papers

Title:

Elevator Pressurization in Tall Buildings

Author:

John H. Klote, Smoke and Fire Consulting

Subjects:

Fire & Safety

Vertical Transportation

Keywords:

Fire Safety

Vertical Transportation

Publication Date:

2013

Original Publication:

International Journal of High-Rise Buildings Volume 2 Number 4

Paper Type:

1.

2.

3.

4.

5.

6.

Book chapter/Part chapter

Journal paper

Conference proceeding

Unpublished conference paper

Magazine article

Unpublished

Council on Tall Buildings and Urban Habitat / John H. Klote

International Journal of High-Rise Buildings

December 2013, Vol 2, No 4, 341-344

International Journal of

High-Rise Buildings

www.ctbuh-korea.org/ijhrb/index.php

Elevator Pressurization in Tall Buildings

John H. Klote

Smoke and Fire Consulting, 19355 Cypress Ridge Terrace, Leesburg, VA 20176, USA

Abstract

During a building fire, smoke can flow through elevator shafts threatening life on floors remote from the fire. Many buildings

have pressurized elevators intended to prevent such smoke flow. The computer program, CONTAM, can be used to analyze

the performance of pressurization smoke control systems. The design of pressurized elevators can be challenging for the

following reasons: (1) often the building envelope is not capable of effectively handling the large airflow resulting from elevator

pressurization, (2) open elevator doors on the ground floor tend to increase the flow from the elevator shaft at the ground floor,

and (3) open exterior doors on the ground floor can cause excessive pressure differences across the elevator shaft at the ground

floor. To meet these challenges, the following systems have been developed: (1) exterior vent (EV) system, (2) floor exhaust

(FE) system, and ground floor lobby (GFL) system.

Keywords: Elevator pressurization, Network modeling, Smoke control, Stairwell pressurization, Tall buildings

During a building fire, smoke can flow through elevator shafts threatening life on floors remote from the fire.

To prevent such smoke flow, many buildings have pressurized elevators or enclosed elevator lobbies, but enclosed elevator lobbies are not discussed in this article.

The focus of this article is design of pressurized elevators for tall buildings. The design of pressurized elevators

can be a challenge and it can be more challenging in buildings that also have pressurized stairwells. This article

gives the reasons for this and describes kinds of elevator

pressurization systems that can overcome these challenges.

For extensive information about smoke control, see the

Handbook Smoke Control Engineering (Klote et al. 2012).

Chapter 11 of this handbook is about elevator pressurization, but this chapter does not address tall buildings.

Design Analysis

Network analysis models are often used for design analysis of pressurization smoke control systems. CONTAM

(Walton and Dols 2005) is a network model that was

developed primarily for indoor air quality, but it has been

so extensively used for analysis of pressurization smoke

control systems that it has become the de facto standard.

This article discusses CONTAM, but it should be recognized that analysis with another network model is possible. In CONTAM, a building is represented as a network

of spaces connected by flow paths such as gaps around

closed doors, open doors, and cracks and holes in con

Corresponding author: John H. Klote

Tel: +571-258-0355; Fax: +

E-mail: jklote1111@aol.com

struction. CONTAM is capable of simulating the pressures and flows throughout very large and complex buildings. Because CONTAM is a product of the US National

Institute of Standards and Technology, it can be downloaded

at no cost (www.bfrl.nist.gov/IAQanalysis/CONTAM/download.htm). For specific information about using CONTAM for smoke control applications see Chapter 14 of

the Handbook Smoke Control Engineering.

The primary purpose of CONTAM simulations is to

determine if a particular smoke control system in a particular building is capable of being balanced such that it

will perform as intended. A secondary purpose is to provide information to help size the system components such

as supply fans, exhaust fans, and vents. Design analysis of

elevator pressurization needs to include any other pressurization systems operating together as they would during

a building fire.

The flows in CONTAM are calculated as m = CA(2

p)1/2 where m is the mass flow through the path (kg/s),

C is the flow coefficient (dimensionless), A is the flow

area (m2), p is the pressure difference across path (Pa),

and is the gas density in path (kg/m3). The user inputs

values of C and A for flow paths, and the CONTAM

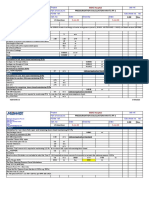

calculates the pressure differences and the flows. Table 1

lists values of C and A for doors. The flow areas are

relatively leaky so that calculated supply air would be

conservatively large, but other values may be appropriate

for some projects.

Table 2 lists some values of C and A for some other

flow paths with various leakage classifications. An engineer cannot exactly know the flow areas in a particular

building, but an educated guess can be made that allows

CONTAM simulations to determine if a specific smoke

342

John H. Klote | International Journal of High-Rise Buildings

Table 1. Flow coefficients and flow areas of doors

Flow

Coefficient

0.65

0.35

0.65

0.35

0.65

0.65

Flow Path

Single door (closed)

Single door (opened)

Double door (closed)

Double door (opened)

Elevator door (closed)

Elevator door (opened)

Flow

Area1 (m2)

0.023

2.0

0.045

3.9

0.06

0.56

Relatively leaky flow areas for closed doors were chosen so

that calculated supply air would be conservatively large.

Table 2. Flow areas and flow coefficients of leakage paths

Flow Path

Walls

Floor

(or roof)

Curtain

wall gap

Leakage

Classification

Tight

Average

Loose

Very Loose

Tight

Average

Loose

Tight

Loose

Flow

Coefficient

0.65

0.65

0.65

Flow Area

(m2 per m2)*

0.5010-4

0.1710-3

0.3510-3

0.1210-2

0.6610-5

0.5210-4

0.1710-3

(m2 per m)**

0.00061

0.0061

*This is m2 of leakage per m2 of wall, floor, or roof.

**This is m2 of leakage per m length of curtain wall gap.

Table 3. IBC Pressure difference criteria

System

Pressurized

Elevators

Pressurized

Stairwells

Minimum p (Pa)

Maximum p (Pa)

25

62

25

87

control system in the building is capable of being balanced such that it will maintain acceptable pressurization.

For more information about flow areas and flow coefficients, see Chapter 3 of the Handbook of Smoke Control

Engineering.

Acceptable pressurization of elevator and stairwell pressurization systems happens when the pressure differences from the elevator shaft to the lobby are between minimum and maximum pressure differences, and the IBC requirements for these pressure differences are listed in

Table 3.

Outdoor temperature and wind data are needed for the

design and analysis of smoke control systems, and Chapter 2 of the Handbook Smoke Control Engineering provides such data and barometric pressures for 1663 locations

throughout the world. Temperature and pressure decrease

with altitude above sea level as described in the U.S.

Standard Atmosphere (NASA 1976) (Fig. 1). For analysis

of smoke control systems for tall buildings, a feature in

CONTAM can be used to account for density to decrease

Figure 1. The US Standard Atmosphere shows temperature

and pressure decreasing with altitude.

with (see Simulation - Airflow Numerics Properties of

the help or user manual).

Shaft Temperature

Elevator equipment has a typical range of operating

temperature. Often there is no effort to maintain this temperature for passenger elevators during building fires, because the elevators are taken out of service. In some locations the elevator equipment may need to be maintained

to give the fire service the option of using elevators

during building fires.

Often supply air to elevator shafts is untreated such that

the temperature in pressurized shafts is close to the outside temperature. The use of untreated air has the benefit

on minimizing the adverse impact of stack effect. The

shaft temperature can be expressed as TS = TO + (TB TO)

where TS is the temperature in the shaft, TO is the temperature outdoors, TB is the temperature in the building,

and is a dimensionless heat transfer factor. As with pressurized stairwells, there has been little research conducted on the heat transfer factor for elevator shafts. For

supply air that is conditioned to the building temperature,

the heat transfer factor is one. For untreated supply air, a

heat transfer factor of 0.15 is suggested as being conservative regarding the impact of stack effect.

The following discussions are specifically for systems

that use untreated supply air, and it is recommended that

systems that use treated supply air be analyzed with

CONTAM.

Elevator Piston Effect

The motion of an elevator car causes transient pressures

that are called elevator piston effect, and elevator pressurization systems should be designed so that this piston

effect does not adversely impact the system performance.

An analysis of piston effect was developed and verified

with experimental data by Klote (1988). Fig. 2 shows the

pressure differences due to piston effect of an ascending

elevator car in a 15 story building. From this figure it can

Elevator Pressurization in Tall Buildings

343

pressurization needs to operate with a number of exterior

doors open. If the system cannot also operate as intended

with all exterior doors closed, some of these doors may

need to open automatically before the elevators are pressurized. At locations where the fire service does not prop

open exterior doors, a different approach to open exterior

doors may be appropriate.

Basic System

Figure 2. Pressure differences due to piston effect of an

ascending elevator car.

be seen that the pressure difference dropped suddenly as

the car passes the eighth floor where measurements were

taken. For elevators in multiple car shafts with car velocities less than 5 m/s, piston effect should not adversely impact the performance of elevator pressurization. For elevators in single car shafts with car velocities less than 2.5

m/s, piston effect should not adversely impact the performance of elevator pressurization.

System Concepts

The simplest elevator pressurization systems consist of

only providing pressurization air supplied to the elevator

shaft at one or more locations. This kind of system is

referred to as the basic system. Other elevator pressurization systems discussed below are: exterior vent (EV)

system, floor exhaust (FE) system, and ground floor lobby

(GFL) system. Regardless of the system used, any vent to

the outdoors at the top of the elevator shaft needs to be

closed during elevator pressurization, or the impact of such

an open vent must be accounted for in the calculation of

supply air to the elevator.

The design of pressurized elevators can be challenging,

and it can be more so for buildings that also have pressurized stairwells. Typically pressurized elevators require

three or four times as much supply air pressurized stairwells. The reasons for these challenges are: (1) often the

building envelope is not capable of effectively handling

the large airflow resulting from elevator pressurization,

(2) open elevator doors on the ground floor tend to increase the flow from the elevator shaft at the ground floor,

and (3) open exterior doors on the ground floor can cause

excessive pressure differences across the elevator shaft at

the ground floor.

In most large cities, the fire service props open exterior

doors when they get to a fire to speed up mobilization,

and the International Building Code (IBC) (ICC 2012)

considers that elevator pressurization is with open exterior

doors. Occupants also open some exterior doors during

evacuation. In this article, it is considered that elevator

For the basic system, the building envelope often is not

capable of effectively handling the large airflow resulting

from both elevator and stairwell pressurization. This can

result in unacceptable pressure difference at lower floors

as shown in Fig. 3. In this figure, acceptable pressurization was only achieved with very leaky exterior walls.

However for some buildings it may be possible to achieve

acceptable pressurization with other exterior walls, but

this should be evaluated with a CONTAM analysis.

Exterior Vent (EV) System

The idea of the EV system is to increase the leakage of

the building such that successful pressurization can be

achieved. For an open plan office building, this can be

done by the use of vents in the exterior walls. These vents

open automatically on activation of the elevator pressurization system so that the pressure differences become

similar to those of the building with very leaky exterior

walls (Fig. 3). These vents need to be large enough so that

successful pressurization will be achieved. The vents need

to be larger on transfer floors than on other floors.

For a building that is not open plan, the EV system needs

unobstructed flow paths to the outdoors. These flow paths

can consist of ducts above a suspended ceiling from the

elevator lobby to vents located in exterior walls. Duct

penetrations of a fire rated wall may have fire resistance

requirements depending on code requirements.

To minimize the impact of the wind, the vents in exterior walls should be located on four sides of the building.

The supply intakes need to be located away from the

vents to minimize the potential for smoke feedback into

Figure 3. Typical pressure differences across elevator shaft

for a basic pressurization system.

344

John H. Klote | International Journal of High-Rise Buildings

the supply air. These vents may need fire dampers depending on code requirements.

The pressurization air per floor needed for a shaft in a

building with the EV system can be estimated as

2pEL

V = (1 + )CAEL -------------

(1)

= pressurization airflow to elevator shaft per floor

(m3/s),

C

= flow coefficient, dimensionless,

= factor for other elevator shaft leakage (dimensionless),

AEL = flow area of all elevator doors on the floor (m2),

pEL = pressure difference from elevator shaft to lobby

(Pa),

= gas density in path (kg/m3)

For the EV system, the pressure difference from elevator shaft to lobby, pEL, is larger than the minimum pressure difference but less than the maximum pressure difference. The factor for other elevator shaft leakage, , depends on the specific shaft design, construction materials,

and quality of workmanship. A value of = 0.15 seems

to be a reasonable allowance.

For example, consider a 27 story building with four elevator shafts that serve all floors. Each shaft has four elevator cars. The flow area of an open elevator door is 0.56

m2, and that of a closed elevator door is 0.06 m2. The

elevators are open on the ground floor, and AEL = 4(0.56)

= 2.24 m2. On floors 2 to 27, the elevator doors are closed,

and AEL = 4(0.06) = 0.24 m2. The other parameters are C =

0.65, = 0.12, pEL = 35 Pa, = 1.2 kg/m3. For the ground

floor, V = 12.5 m3/s of supply air. For the other floors, V

= 1.33 m3/s. The estimated supply air to each of the four

elevator shafts is 12.5 + 26(1.33) = 47 m3/s.

Floor Exhaust (FE) System

The FE system deals with the building envelope issue

by reducing the amount of supply air used. In the FE

system, a relatively small amount of air is supplied to the

elevator shafts, and the fire floor is exhausted such that

acceptable pressurization is maintained on the fire floor

where it is needed. It is common to also exhaust one or

two floors above and below the fire floor. Fig. 4 shows

pressure differences across an elevator shaft for a floor

exhaust (FE) pressurization system. Because the FE system only maintains pressurization at some floors, it may

need to be approved by the authority having jurisdiction.

The exhaust can be through a shaft with a fan located

in a mechanical floor or on the roof, and dampers between the shaft and the floors are closed on all floors when

the system is not operating. On system activation, the

dampers open on the floors to be exhausted. The exhaust

inlet needs to be in the elevator lobby or a space open to

the elevator lobby. The outlet of the exhaust fan needs to

be located away from the inlets of the supply fans to mi-

Figure 4. Typical pressure differences across elevator shaft

for a floor exhaust (FE) pressurization system.

nimize the potential for smoke feedback into supply air.

Ground Floor Lobby (GFL) System

This system has an enclosed elevator lobby on the ground

floor, but the other floors do not have any enclosed elevator lobbies. This system is the complete opposite of the

normal practice of having enclosed elevator lobbies on all

floors except the ground floor, but it has the potential for

successful elevator pressurization.

An enclosed elevator lobby can reduce the pressure

differences across the lower floors of the elevator shaft.

The GFL system often has a vent between the enclosed

ground floor lobby and the building with the intent of

preventing excessive pressure differences across the lobby

doors. The lobby doors are the doors between the enclosed lobby and the building.

The pressure difference across the lobby door and the

elevator door depend on the area of the vent, and this vent

needs to be adjustable to allow for balancing during commissioning. The flow area between floors (floor leakage

and curtain wall gap) is especially important for the performance of the GFL system.

References

ICC. (2012). International Building Code, International Code

Council, Country Club Hills, IL.

Klote, J. H., et al. (2012). Handbook of Smoke Control

Engineering. ASHRAE, Atlanta, GA.

Klote, J. H. (1988). An analysis of the influence of piston

effect on elevator smoke control. NBSIR-88-3751.

National Bureau of Standards, Gaithersburg, MD.

NASA. (1976). U.S. Standard Atmosphere, National Oceanic

and Atmospheric Administration, National Aeronautics

and Space Administration, and the United States Air Force.

Avaliable from the National Geophysical Data Center,

Bolder CO.

Walton, G. N. and Dols, W. S. (2005). CONTAM 2.4 User

Guide and Program Documentation, NISTIR 7251, Revised December 14, 2010. National Institute of Standards

and Technology, Gaithersburg, MD.

Vous aimerez peut-être aussi

- Design Guide For HotelsDocument46 pagesDesign Guide For Hotelsapi-382741692% (170)

- Steam Systems Design - Pipes and ValvesDocument160 pagesSteam Systems Design - Pipes and Valvesgladiatork00794% (53)

- Smoke Ventilation Calculations - M TowerDocument4 pagesSmoke Ventilation Calculations - M TowerMaaz Junaidi80% (5)

- Staircase Pressurisation Calculation Rev-04Document36 pagesStaircase Pressurisation Calculation Rev-04Anish KumarPas encore d'évaluation

- Smoke Extraction System Sample CalculationDocument5 pagesSmoke Extraction System Sample Calculationsmcsaminda100% (3)

- 4 FireSmoke Control Stair Pressurization.95110230Document7 pages4 FireSmoke Control Stair Pressurization.95110230adcaPas encore d'évaluation

- Pressurization CalculationDocument6 pagesPressurization CalculationAbdul HakkimPas encore d'évaluation

- Mechanical Engineering Design Criteria PDFDocument44 pagesMechanical Engineering Design Criteria PDFadca100% (1)

- 4 FireSmoke Control Stair Pressurization.95110230Document7 pages4 FireSmoke Control Stair Pressurization.95110230adcaPas encore d'évaluation

- Smoke MovementDocument13 pagesSmoke Movementzshehadeh100% (2)

- Smoke Control System CalcDocument14 pagesSmoke Control System Calckumar123rajuPas encore d'évaluation

- Staircase Pressurisation CalculationDocument1 pageStaircase Pressurisation CalculationMohammed Faisal Siddiqui100% (1)

- Smoke Ventilation Solutions BrochureDocument48 pagesSmoke Ventilation Solutions BrochureThanh Nguyen NgocPas encore d'évaluation

- 03.pressurisation Calculation Semenyih Blok ADocument3 pages03.pressurisation Calculation Semenyih Blok ABriana JenkinsPas encore d'évaluation

- Staircase Pressurization Fan, What Is The Equation To Calculate The Air Flow and Static Pressure For Fan - Bayt PDFDocument3 pagesStaircase Pressurization Fan, What Is The Equation To Calculate The Air Flow and Static Pressure For Fan - Bayt PDFDesigner ForeverPas encore d'évaluation

- Smoke Management Calc For Shopping Mall PDFDocument1 pageSmoke Management Calc For Shopping Mall PDFSudhir KulkarniPas encore d'évaluation

- Smoke Spill 2Document2 pagesSmoke Spill 2Briana JenkinsPas encore d'évaluation

- Aldesme - Flash25 Stair PressurisationDocument8 pagesAldesme - Flash25 Stair PressurisationjaicektmPas encore d'évaluation

- Pressurization BSIDocument3 pagesPressurization BSIRaja Antony100% (3)

- Smoke Management Calc For Car ParkDocument1 pageSmoke Management Calc For Car ParkSudhir KulkarniPas encore d'évaluation

- Smoke Cal AtriumDocument3 pagesSmoke Cal AtriumBilal Hussein SousPas encore d'évaluation

- Car Park Ventilation DemystifiedDocument12 pagesCar Park Ventilation DemystifieddokundotPas encore d'évaluation

- FireSmoke Control Stair PressurizationDocument10 pagesFireSmoke Control Stair PressurizationMohamed AsifPas encore d'évaluation

- Smoke Movement in Atrium BuildingDocument9 pagesSmoke Movement in Atrium BuildingNguyễn Xuân ĐiệpPas encore d'évaluation

- Door LeakagesDocument1 pageDoor LeakagespsjjoshiPas encore d'évaluation

- Smoke Control Hotels PDFDocument9 pagesSmoke Control Hotels PDFsajuherePas encore d'évaluation

- Fire Report in AtriumDocument22 pagesFire Report in AtriumkarlamoraPas encore d'évaluation

- CPD General Principles of Smoke ControlDocument62 pagesCPD General Principles of Smoke ControlMemento MoriPas encore d'évaluation

- Stairwell CalculationDocument8 pagesStairwell Calculationfarzinshahab100% (1)

- Stairwell PressurisationDocument1 pageStairwell Pressurisationpsjjoshi100% (1)

- Guide To Smoke Extraction in BuildingsDocument76 pagesGuide To Smoke Extraction in BuildingsKc Hon100% (2)

- RJA Smoke Control Modeling Report - Sahara Mall Expansion - 12 August 2010Document44 pagesRJA Smoke Control Modeling Report - Sahara Mall Expansion - 12 August 2010Subharajk100% (1)

- CAL-03 - Staircase Pressurization CalculationDocument4 pagesCAL-03 - Staircase Pressurization CalculationAbdul Sami100% (1)

- Lift Well Pressurization Calculation TOWER C - (G+17)Document4 pagesLift Well Pressurization Calculation TOWER C - (G+17)KoushikPas encore d'évaluation

- Staircase PressurizationDocument8 pagesStaircase PressurizationSimon LawPas encore d'évaluation

- Zoned Smoke Control Applications: Using HVAC Systems To Limit SmokeDocument5 pagesZoned Smoke Control Applications: Using HVAC Systems To Limit SmokeNiong DavidPas encore d'évaluation

- Review On Design Guides For Smoke Management System in An AtriumDocument23 pagesReview On Design Guides For Smoke Management System in An AtriumArgile-assholePas encore d'évaluation

- Smoke Control in Malls PDFDocument4 pagesSmoke Control in Malls PDFmukeshsinghtomarPas encore d'évaluation

- Design Calculation Sheet For Fire Lift Well Pressurisation S.NO. DescriptionDocument1 pageDesign Calculation Sheet For Fire Lift Well Pressurisation S.NO. DescriptionpsjjoshiPas encore d'évaluation

- Flaktwood WTP46a - Fan Applications in Smoke Control SystemsDocument14 pagesFlaktwood WTP46a - Fan Applications in Smoke Control Systemsdokundot67% (3)

- The Effects of Water Ingress Into Fire Fighting Elevator ShaftsDocument7 pagesThe Effects of Water Ingress Into Fire Fighting Elevator ShaftsrewmarinePas encore d'évaluation

- Kazma SMOKE VENTILATION SYSTEMDocument2 pagesKazma SMOKE VENTILATION SYSTEMRoin BanerjiPas encore d'évaluation

- Technical Handbook Air CurtainsDocument13 pagesTechnical Handbook Air Curtainsaca111111Pas encore d'évaluation

- SCA Guide Smoke Control To Common Escape Routes in Apartments 23 Jan 2020 Revision 3Document79 pagesSCA Guide Smoke Control To Common Escape Routes in Apartments 23 Jan 2020 Revision 3Santiago J. ramos jrPas encore d'évaluation

- Value Engineering of Car Park Ventilation SystemDocument8 pagesValue Engineering of Car Park Ventilation SystemmitasyahuPas encore d'évaluation

- Smoke Control and Day To Day Ventilation For Multi-Storey Residential BuildingsDocument20 pagesSmoke Control and Day To Day Ventilation For Multi-Storey Residential BuildingsThanh Nguyen Ngoc100% (1)

- Tower 1 PressurizationDocument12 pagesTower 1 PressurizationRaja Antony0% (1)

- State of The Art Atrium Smoke ControlDocument12 pagesState of The Art Atrium Smoke ControlBasil OguakaPas encore d'évaluation

- DAR Stair Case PressurizationDocument10 pagesDAR Stair Case Pressurizationmansidev100% (3)

- Staircase PressurizationDocument8 pagesStaircase PressurizationKrishna PATEL100% (1)

- Performance Based Smoke Prevention and Extraction System D - 2014 - Procedia EngDocument8 pagesPerformance Based Smoke Prevention and Extraction System D - 2014 - Procedia EngjanainaPas encore d'évaluation

- OVERPRESSURE Neutre PDFDocument50 pagesOVERPRESSURE Neutre PDFIgor SpirovPas encore d'évaluation

- 10-Mechanical Extract System-Car Park VentilationDocument18 pages10-Mechanical Extract System-Car Park VentilationAli Ruhsen Cete100% (1)

- Smoke Control System in High Rise BuildingDocument8 pagesSmoke Control System in High Rise BuildingOmar Al-GubuoryPas encore d'évaluation

- Staircase Pressurization Calculation SheetDocument4 pagesStaircase Pressurization Calculation SheetsmcsamindaPas encore d'évaluation

- Staircase Pressurization Calculations ProcedureDocument40 pagesStaircase Pressurization Calculations Procedurecancer24100% (3)

- Evaluation of Smoke ManagementDocument60 pagesEvaluation of Smoke ManagementdescslamPas encore d'évaluation

- Car Park Ventilation - Jet FansDocument16 pagesCar Park Ventilation - Jet FansMANIKANDAPas encore d'évaluation

- Elevator PressurizationDocument7 pagesElevator PressurizationLaisattrooklai PhisitPas encore d'évaluation

- 2016 Elevator Pressurization in Tall Buildings PDFDocument5 pages2016 Elevator Pressurization in Tall Buildings PDFsiva_nagesh_2Pas encore d'évaluation

- Smoke Control by Pressurization in Stairwells and Elevator Shafts 080808Document12 pagesSmoke Control by Pressurization in Stairwells and Elevator Shafts 080808Neša P MarojevićPas encore d'évaluation

- Clemons Paper With Ex Sum 1008Document12 pagesClemons Paper With Ex Sum 1008Anonymous BbZceWkVnPas encore d'évaluation

- Performance Assessment of Pressurized Stairs in HiDocument11 pagesPerformance Assessment of Pressurized Stairs in Hijoseluis_eng7854Pas encore d'évaluation

- On Elevator Shaft Pressurization System Standards and Codes For Smoke Control in Tall BuildingsDocument5 pagesOn Elevator Shaft Pressurization System Standards and Codes For Smoke Control in Tall BuildingsminiongskyPas encore d'évaluation

- Practical Design of Water Distribution Systems PDFDocument28 pagesPractical Design of Water Distribution Systems PDFadcaPas encore d'évaluation

- Standards FOR Fire Protection Systems: October 2009Document37 pagesStandards FOR Fire Protection Systems: October 2009adcaPas encore d'évaluation

- Military Handbook: Heating, Air Conditioning, Ventiliating, and Dehumidifying SystemsDocument227 pagesMilitary Handbook: Heating, Air Conditioning, Ventiliating, and Dehumidifying SystemsPlainNormalGuy2100% (9)

- Air Pollution Dispersion Modeling PDFDocument6 pagesAir Pollution Dispersion Modeling PDFadcaPas encore d'évaluation

- Good Pratices GAS PIPINGDocument136 pagesGood Pratices GAS PIPINGRui PedroPas encore d'évaluation

- Installation InstructionsDocument6 pagesInstallation InstructionsadcaPas encore d'évaluation

- R102 SystemsDocument7 pagesR102 SystemsadcaPas encore d'évaluation

- Beacon MeadsDocument4 pagesBeacon Meadsangel darioPas encore d'évaluation

- Engineering DataDocument26 pagesEngineering DataadcaPas encore d'évaluation

- Awwa C200Document68 pagesAwwa C200adca100% (1)

- Bulletin Friction Head Loss 3Document1 pageBulletin Friction Head Loss 3adcaPas encore d'évaluation

- Cold Startup 1Document51 pagesCold Startup 1Vel MuruganPas encore d'évaluation

- Balance of Plant Operation (Power Plant)Document34 pagesBalance of Plant Operation (Power Plant)Aleem UllahPas encore d'évaluation

- NacelleDocument7 pagesNacellecarlitos232067% (3)

- Shaangu For Metalurgical Industry 2013Document49 pagesShaangu For Metalurgical Industry 2013zzgiadinhzzPas encore d'évaluation

- Portable Mancoolers 115vDocument4 pagesPortable Mancoolers 115vEliasPas encore d'évaluation

- Energy Efficiency in Textile Sector of PakistanDocument6 pagesEnergy Efficiency in Textile Sector of PakistanShazia ShabbirPas encore d'évaluation

- Process Control NarrativeDocument28 pagesProcess Control NarrativeGeetha_jagadish30100% (3)

- Ducted Fan ThesisVTOhanian2011Document203 pagesDucted Fan ThesisVTOhanian2011pest619Pas encore d'évaluation

- Subject: Bird Ingestion Certification Standards: Date: 1/19/01 Initiated By: ANE-110 AC No: AC 33.76-1 ChangeDocument8 pagesSubject: Bird Ingestion Certification Standards: Date: 1/19/01 Initiated By: ANE-110 AC No: AC 33.76-1 ChangeBookMaggotPas encore d'évaluation

- Avionic VentilationDocument2 pagesAvionic Ventilationffelipe123Pas encore d'évaluation

- Generator Rotor Insertion DRG 4.5-9913-0002 0410e2p - KranDocument14 pagesGenerator Rotor Insertion DRG 4.5-9913-0002 0410e2p - KranjothipriyadPas encore d'évaluation

- TC 900riDocument2 pagesTC 900riSergio GuimarãesPas encore d'évaluation

- Growing Under Glass Choosing and Equipping A Greenhouse, Growing Plants PDFDocument79 pagesGrowing Under Glass Choosing and Equipping A Greenhouse, Growing Plants PDFAnonymous YQawhbPas encore d'évaluation

- LUNOS Catalogue For Home VentilationDocument68 pagesLUNOS Catalogue For Home Ventilationing urbanPas encore d'évaluation

- Siemens Air Cooled Generators Sgen 100a 2p Brochure enDocument4 pagesSiemens Air Cooled Generators Sgen 100a 2p Brochure enDanfer Huiza De La CruzPas encore d'évaluation

- Axial Fans Main Catalogue InformationDocument19 pagesAxial Fans Main Catalogue InformationAdailton FreitasPas encore d'évaluation

- Bebederos Elkay FD7003Document2 pagesBebederos Elkay FD7003Enver Ernesto Miranda RiosPas encore d'évaluation

- Parboiling Dryer PlantDocument25 pagesParboiling Dryer PlantShivaz SharmaPas encore d'évaluation

- Application and Features of Titanium For The Aerospace IndustryDocument6 pagesApplication and Features of Titanium For The Aerospace IndustryCláudiaCardosoPas encore d'évaluation

- 8Document72 pages8Patri NievasPas encore d'évaluation

- Gas Furnace GuidelineDocument41 pagesGas Furnace GuidelineLisbethMPas encore d'évaluation

- Montaje de Ventilador Cooling TowerDocument3 pagesMontaje de Ventilador Cooling TowerAle HqzPas encore d'évaluation

- Techno Commercial OfferDocument12 pagesTechno Commercial Offert_syamprasadPas encore d'évaluation

- Forced Convection ApparatusDocument3 pagesForced Convection ApparatusAshish VermaPas encore d'évaluation

- Dynapure ApcDocument2 pagesDynapure ApcjupocPas encore d'évaluation

- Application Manual Heating-Ventilation-Air ConditioningDocument60 pagesApplication Manual Heating-Ventilation-Air ConditioningniakinezhadPas encore d'évaluation

- Protected Agriculture in Jamaica Gardening Guidebook For JamaicaDocument109 pagesProtected Agriculture in Jamaica Gardening Guidebook For JamaicaWinter Gardening100% (3)