Académique Documents

Professionnel Documents

Culture Documents

Axially Loaded Columns - Base Plate Design

Transféré par

aomareltayebCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Axially Loaded Columns - Base Plate Design

Transféré par

aomareltayebDroits d'auteur :

Formats disponibles

SCI ADVISORY DESK

AD 252: Axially Loaded Columns - Base Plate

Design - Effective Area Method BS 5950-1: 2000

The empirical method for determining the size of base plates in BS 5950-1:1990 has been

replaced by the effective area method in BS 5950-1:2000. Doubt has been raised as to the

theoretical validity of the empirical method when used with deep UBs or with bases that

have very small outstand dimensions a and b (see Figure 1). The effective area method offers

more economy than the empirical method, while still producing safe designs when compared

to test results.

The effective area method for base plate design may initially seem to be more complex than

the empirical method given in BS 5950-1:1990. However, the approach is much more reliable

and can be used for all column sections. The forthcoming revision of the SCI and BCSA green

book Joints in Steel Construction: Simple Connections will include design procedures for base

plates using the effective area method and will include standard base plates and their

capacities for I, H and hollow section columns.

We have received several questions concerning the effective area method for base plate

design, and in particular what to do when the effective area does not fit on the base plate

selected.

The basic design procedure is set out below.

1. Calculate required area = axial load / 0.6 fcu.

Where:

fcu is the cube strength of either the concrete or the grout, which ever is weaker.

2. Calculate outstand c (see Figure 1) by equating required area to actual area expressed

as a function of c. The expression for the actual effective area of an I or H section

may be approximated to 4c2 + (column perimeter) c + column area.

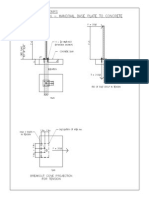

Effective area

c

a

c

Fig. 1

Overlap area

Fig. 2

Effective area

c

c

a

c

Fig. 3

3. Check that there is no overlap of effective area between flanges (see Figure 2). This

will occur if 2c > the distance between the inner faces of the flanges. If an overlap

exists, modify the expression for effective area and recalculate c.

4. Check the effective area fits on the size of base plate selected (see Figure 3). If

effective area does not fit on the base plate, modify the expression for effective area

to allow for the limitations of the plate size and recalculate c, or select a larger base

SCI ADVISORY DESK

plate. For the case shown in Figure 3, the modified expression for the effective area

will be,

4c2 + (column perimeter) c + column area 2 (B+2c) (c a).

5.

If c has been recalculated, step 3 will need to be repeated.

6. Calculate required plate thickness tp using expression below (given in Clause

4.13.2.2):

0.5

3 w

t p = c

p

yp

Where:

w

= 0.6fcu

pyp

is the plate design strength

The expression for the plate thickness can be derived from equating the moment

produced by the uniform load w to the elastic moment capacity of the base plate (both

per unit length).

Moment from uniform load on cantilever

w c2 / 2

w c2 / 2

Rearranging gives

tp

Elastic moment capacity of plate

= py Z (per unit length)

= py tp2 / 6

= c(3 w /py)0.5

When the outstand of the effective area is equal either side of the flange (as in Figure 1

and Figure 4), the cantilevers are balanced and there is no resultant moment induced in

the flange. However, if the cantilevers do not balance either side of the flange, as would

be the case in Figure 3, then theoretically to satisfy equilibrium there is a resultant

moment induced in the flange (see Figure 5 and Figure 6).

c

a

M=(c2-a2)/2

M= a2/2

M= wc2/2

Fig. 4

M= wa2/2

Fig. 5

M= c2/2

M= wc2/2

Fig. 6

It is important to remember that the method given in BS 5950-1:2000 is only a design

model and does not exactly represent what will happen in practice. The remainder of

the plate (not only the effective area) does exist and does carry load. With this in

mind, the moment induced in the column flange due to unbalanced cantilevers does

not need to be explicitly considered in the design of either the column or the base

plate.

Vous aimerez peut-être aussi

- Base Plate DesignDocument1 pageBase Plate DesignmadodandembePas encore d'évaluation

- Design of Base Plate by EurocodeDocument13 pagesDesign of Base Plate by EurocodeBharati MajlekarPas encore d'évaluation

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part2-Breakout Strength in TensionDocument6 pagesConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part2-Breakout Strength in TensionVenu GopalPas encore d'évaluation

- The Flexure and Shear Design of Corbel (Bracket)Document12 pagesThe Flexure and Shear Design of Corbel (Bracket)Girum MindayePas encore d'évaluation

- AD 360 - Movement Joints in Steel-Framed BuildingsDocument1 pageAD 360 - Movement Joints in Steel-Framed Buildingssymon ellimacPas encore d'évaluation

- AISC LRFD Column DesignDocument4 pagesAISC LRFD Column Designwinlugue3059Pas encore d'évaluation

- Flitch Plate BeamDocument1 pageFlitch Plate Beamdnl_vicarsPas encore d'évaluation

- Base Plate & Anchor BoltDocument40 pagesBase Plate & Anchor BoltSiva baalanPas encore d'évaluation

- Structural dimensions and propertiesDocument4 pagesStructural dimensions and propertiesOlanrewaju OkunolaPas encore d'évaluation

- Design of CorbelsDocument30 pagesDesign of CorbelsSafiurrehmanPas encore d'évaluation

- Design Parameters For Longitudinal Bars (Beams - BS 8110)Document4 pagesDesign Parameters For Longitudinal Bars (Beams - BS 8110)Lavanyan Satchithananthan100% (1)

- Access Steel Data Sheets BindedDocument154 pagesAccess Steel Data Sheets BindedblueswanPas encore d'évaluation

- GF SlabDocument8 pagesGF Slabcheligp1981Pas encore d'évaluation

- Broadway Hilti - Handrail BaseDocument4 pagesBroadway Hilti - Handrail Basexpertsteel100% (1)

- Shear WallDocument238 pagesShear Wallri olPas encore d'évaluation

- Tying Resistance of A Fin Plate ConnectionDocument9 pagesTying Resistance of A Fin Plate ConnectionSam Samoura0% (1)

- Steel Cap Plate Connections DesignDocument18 pagesSteel Cap Plate Connections DesignVinoth KumarPas encore d'évaluation

- Wind Load Calculation 29-08-2018Document4 pagesWind Load Calculation 29-08-2018mbhanusagar.keynesPas encore d'évaluation

- COLUMN BASE PLATE DESIGN CALCULATIONS (BS5950-1:2000Document7 pagesCOLUMN BASE PLATE DESIGN CALCULATIONS (BS5950-1:2000Shakil Akhter100% (1)

- Corbel BS8110Document3 pagesCorbel BS8110Nugraha BintangPas encore d'évaluation

- PROKON - Plane Frame - Analysis - Example - BeamDocument44 pagesPROKON - Plane Frame - Analysis - Example - BeamJames RamPas encore d'évaluation

- Minimum Thickness of Solid Slab According To ACIDocument1 pageMinimum Thickness of Solid Slab According To ACImuhanned100% (1)

- Composite Beam Simply Supported DesignDocument12 pagesComposite Beam Simply Supported DesignMario FeghaliPas encore d'évaluation

- Base Plate Design As Per BS5950 PDFDocument2 pagesBase Plate Design As Per BS5950 PDFpawanPas encore d'évaluation

- Portal Frame Practice ProblemsDocument10 pagesPortal Frame Practice ProblemsBoyzz ChinPas encore d'évaluation

- Typical Anchor BoltsDocument33 pagesTypical Anchor BoltslucianduPas encore d'évaluation

- Drop Panel CalculationDocument2 pagesDrop Panel Calculationsandiok86Pas encore d'évaluation

- Base Plate Cal PDFDocument5 pagesBase Plate Cal PDFMyunSu GooPas encore d'évaluation

- COMPARISON OF COMPOSITE BEAM DESIGNDocument8 pagesCOMPARISON OF COMPOSITE BEAM DESIGNMohamed Abo-ZaidPas encore d'évaluation

- Design of tension member calculationDocument1 pageDesign of tension member calculationchaPas encore d'évaluation

- Vertical Loads On Building Frames: Assumptions For The Analysis of Girders Using Approximate AnalysisDocument10 pagesVertical Loads On Building Frames: Assumptions For The Analysis of Girders Using Approximate AnalysisNeven Ahmed HassanPas encore d'évaluation

- Design of Steel BeamDocument19 pagesDesign of Steel BeamAnonymous tBhJoH5wgMPas encore d'évaluation

- Beam DesignDocument7 pagesBeam DesignKasi ViswanathanPas encore d'évaluation

- Slab With OpeningDocument16 pagesSlab With OpeningTomislav Šimag100% (1)

- AISC Design Guide 1 Table 3.2 PDFDocument1 pageAISC Design Guide 1 Table 3.2 PDFamine ayari100% (1)

- PurlinDocument1 pagePurlinCe WinPas encore d'évaluation

- Section properties and load capacity analysis of steel beamDocument17 pagesSection properties and load capacity analysis of steel beamSourabh Das100% (1)

- Anchor BoltDocument7 pagesAnchor BoltChris OngPas encore d'évaluation

- Load Case, Load Combination, Modal Case Options. Choose The Load Case To Be DisplayedDocument5 pagesLoad Case, Load Combination, Modal Case Options. Choose The Load Case To Be DisplayedLivia15Pas encore d'évaluation

- Rectangular Spread Footing DesignDocument42 pagesRectangular Spread Footing DesignJedidiah MelakuPas encore d'évaluation

- Z PurlinDocument48 pagesZ PurlinleroytuscanoPas encore d'évaluation

- As Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKDocument1 pageAs Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKNaresh KumarPas encore d'évaluation

- Calculation NoteDocument10 pagesCalculation NoteJay EvansPas encore d'évaluation

- RCC12 Bending and Axial ForceDocument4 pagesRCC12 Bending and Axial ForceAbdul KarimPas encore d'évaluation

- Corbel DesignDocument6 pagesCorbel Designasvenk309Pas encore d'évaluation

- Bondek I - Calculation Note - 1 Row of SupportDocument7 pagesBondek I - Calculation Note - 1 Row of Supporttrung1983Pas encore d'évaluation

- Design of Floor JoistDocument5 pagesDesign of Floor JoistXDXDXDPas encore d'évaluation

- Manual: Engineering Calculation TemplateDocument8 pagesManual: Engineering Calculation TemplateHamiPas encore d'évaluation

- Eccentric Shear Connection Analysis of Bolt GroupDocument4 pagesEccentric Shear Connection Analysis of Bolt GroupjaffnaPas encore d'évaluation

- Stiffner Design For Beam Column ConnectionsDocument84 pagesStiffner Design For Beam Column ConnectionsfabnamePas encore d'évaluation

- Clean Copy Metal Building Foundation Rev 2.1Document14 pagesClean Copy Metal Building Foundation Rev 2.1jurieskPas encore d'évaluation

- Super Composite ColumnDocument2 pagesSuper Composite ColumnCheng Por EngPas encore d'évaluation

- Model Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionD'EverandModel Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionPas encore d'évaluation

- Strap Footing TheoryDocument4 pagesStrap Footing TheorySwopnilOjhaPas encore d'évaluation

- Lecture 11-1 Bases by H.J. MtyanaDocument29 pagesLecture 11-1 Bases by H.J. MtyanaHarold Jackson Mtyana100% (1)

- Time Saving-Two Way2Document9 pagesTime Saving-Two Way2Wanda Beasley100% (1)

- Pages From Foundation Analysis and Design, Joseph E. BowlesDocument4 pagesPages From Foundation Analysis and Design, Joseph E. BowlesakankwasaPas encore d'évaluation

- Archive of SID: Design of A Double Corbel Using The Strut-And-Tie MethodDocument13 pagesArchive of SID: Design of A Double Corbel Using The Strut-And-Tie Methodreloaded63Pas encore d'évaluation

- PT EconomicsDocument53 pagesPT EconomicsaomareltayebPas encore d'évaluation

- Chapter 9 Bearings and Expansion Joints: WSDOT Bridge Design Manual M 23-50.18 Page 9-I June 2018Document40 pagesChapter 9 Bearings and Expansion Joints: WSDOT Bridge Design Manual M 23-50.18 Page 9-I June 2018aomareltayebPas encore d'évaluation

- PLN V000000 06 00004 PDFDocument114 pagesPLN V000000 06 00004 PDFaomareltayebPas encore d'évaluation

- Concrete Expansion JointsDocument80 pagesConcrete Expansion JointsDiana Sekar Sari100% (1)

- Optimum Design of Resilient Sliding Isolation SystemDocument12 pagesOptimum Design of Resilient Sliding Isolation SystemaomareltayebPas encore d'évaluation

- Technology Paper Report CSI 31-03-09Document98 pagesTechnology Paper Report CSI 31-03-09aomareltayebPas encore d'évaluation

- Who Invented Youngs ModulusDocument6 pagesWho Invented Youngs ModulusaomareltayebPas encore d'évaluation

- 0510 S 15 Ms 43Document16 pages0510 S 15 Ms 43aomareltayebPas encore d'évaluation

- Vibration Analysis ReportDocument13 pagesVibration Analysis ReportaomareltayebPas encore d'évaluation

- Sika FRP Design Program ManualDocument10 pagesSika FRP Design Program ManualYoshua Yang100% (1)

- Who Invented Youngs ModulusDocument6 pagesWho Invented Youngs ModulusaomareltayebPas encore d'évaluation

- Control of Crack WidthsDocument55 pagesControl of Crack WidthsMahmood Mufti100% (1)

- Soil Structure InteractionDocument16 pagesSoil Structure InteractionEmad Ahmed Khan67% (3)

- JORDAHL Catalogue Jda PDFDocument6 pagesJORDAHL Catalogue Jda PDFIoan SosaPas encore d'évaluation

- Power Virtual Collaboration in Project Management FinalDocument38 pagesPower Virtual Collaboration in Project Management FinalTerrence GargiuloPas encore d'évaluation

- Hollowblockandribbedslabs 130702183359 Phpapp01Document38 pagesHollowblockandribbedslabs 130702183359 Phpapp01aomareltayebPas encore d'évaluation

- المرشد في الإسعافات الأولية PDFDocument75 pagesالمرشد في الإسعافات الأولية PDFbentaharPas encore d'évaluation

- AbuDhabi LowDocument1 pageAbuDhabi LowaomareltayebPas encore d'évaluation

- Damping and Energy DissipationDocument14 pagesDamping and Energy DissipationAlex da SilvaPas encore d'évaluation

- Diaphragm Wall Specifications R 0Document10 pagesDiaphragm Wall Specifications R 0aomareltayebPas encore d'évaluation

- Design of Shear Walls Using ETABS PDFDocument97 pagesDesign of Shear Walls Using ETABS PDFEmanuelRodriguezElera100% (1)

- Example Buildings KL Aug 2002Document25 pagesExample Buildings KL Aug 2002aomareltayebPas encore d'évaluation

- Damping and Energy DissipationDocument14 pagesDamping and Energy DissipationAlex da SilvaPas encore d'évaluation

- Diaphragm Wall SpecificationsDocument8 pagesDiaphragm Wall SpecificationsaomareltayebPas encore d'évaluation

- BurjDocument39 pagesBurjarjunmurali1993Pas encore d'évaluation

- Abacus FoundationsDocument9 pagesAbacus FoundationsNath GunasekeraPas encore d'évaluation

- Diaphragm Wall SpecificationsDocument8 pagesDiaphragm Wall SpecificationsaomareltayebPas encore d'évaluation

- Structure Modelling ChecklistDocument4 pagesStructure Modelling ChecklistaomareltayebPas encore d'évaluation

- Risk Register TemplateDocument1 pageRisk Register TemplateaomareltayebPas encore d'évaluation

- 4608 - 160214 - Structural Design Data SheetDocument9 pages4608 - 160214 - Structural Design Data SheetaomareltayebPas encore d'évaluation

- Quality Management Project On Quality Tools of "Ford Motors"Document6 pagesQuality Management Project On Quality Tools of "Ford Motors"Anuj SharmaPas encore d'évaluation

- Adf Interview Questions and AnsewrsDocument85 pagesAdf Interview Questions and Ansewrsleninbabus100% (2)

- 9040 - User ManualDocument236 pages9040 - User ManualWallie Billingsley77% (13)

- EMF Test Report: Ericsson Street Macro 6701 B261 (FCC) : Rapport Utfärdad Av Ackrediterat ProvningslaboratoriumDocument13 pagesEMF Test Report: Ericsson Street Macro 6701 B261 (FCC) : Rapport Utfärdad Av Ackrediterat Provningslaboratoriumiogdfgkldf iodflgdfPas encore d'évaluation

- CCH Power CalculateDocument4 pagesCCH Power Calculateangga measPas encore d'évaluation

- Engineering Data Sheet: 49187073 E 1145842 1 of 1 October 21, 2016 60HzDocument1 pageEngineering Data Sheet: 49187073 E 1145842 1 of 1 October 21, 2016 60HzGustavo VillarrealPas encore d'évaluation

- ManualDocument14 pagesManualnas_hoPas encore d'évaluation

- EN 12663-1 - 2010 - IndiceDocument6 pagesEN 12663-1 - 2010 - IndiceOhriol Pons Ribas67% (3)

- How To Build A Backyard PergolaDocument15 pagesHow To Build A Backyard PergolaMichael Wilkins100% (1)

- Electrical Power Transmission & DistributionDocument18 pagesElectrical Power Transmission & DistributionMd Saif KhanPas encore d'évaluation

- f094 PDFDocument4 pagesf094 PDFAnshuman SinghPas encore d'évaluation

- 2011 Equipment Packing InstructionsDocument3 pages2011 Equipment Packing InstructionsNidhi MurthyPas encore d'évaluation

- Engineering Mechanics Tutorial Question BankDocument13 pagesEngineering Mechanics Tutorial Question Bankrajeev_kumar365Pas encore d'évaluation

- XPol Panel 806–960 65° 0°–14°TDocument3 pagesXPol Panel 806–960 65° 0°–14°TkenansabPas encore d'évaluation

- NHA 2430 Design Analysis Reporting FEADocument7 pagesNHA 2430 Design Analysis Reporting FEAASIM RIAZPas encore d'évaluation

- Thiourea PDFDocument43 pagesThiourea PDFMohamad EshraPas encore d'évaluation

- Final Page Size: A5 (148mm X 210mm)Document20 pagesFinal Page Size: A5 (148mm X 210mm)RJ BevyPas encore d'évaluation

- Aerodrome Controller (ADC) ExamDocument5 pagesAerodrome Controller (ADC) ExamaxnpicturesPas encore d'évaluation

- FANUC Robot R-2000iB SeriesDocument4 pagesFANUC Robot R-2000iB SeriesChandan KanuPas encore d'évaluation

- Regional Contest Package in EIM NC IIDocument3 pagesRegional Contest Package in EIM NC IIAlPas encore d'évaluation

- Tds G. Beslux Tribopaste L-2-3 S (26.03.09)Document1 pageTds G. Beslux Tribopaste L-2-3 S (26.03.09)Iulian BarbuPas encore d'évaluation

- COMEC Modular Storage SolutionsDocument8 pagesCOMEC Modular Storage SolutionsPedro ChapadoPas encore d'évaluation

- Motivation and Leadership in Engineering ManagementDocument24 pagesMotivation and Leadership in Engineering ManagementChen Marie DyPas encore d'évaluation

- Coal Drying Technology and Plant DesignDocument12 pagesCoal Drying Technology and Plant DesignJigar M. UpadhyayPas encore d'évaluation

- Reading 03 - Iron Lady The Eiffel TowerDocument2 pagesReading 03 - Iron Lady The Eiffel TowerFernando Elías Valderrama GómezPas encore d'évaluation

- NOx Control of Kiln and Preheater Complete AnalysisDocument129 pagesNOx Control of Kiln and Preheater Complete AnalysisAnonymous sfY8T3q0100% (2)

- Silo Fluidizer: Keep Dry Bulk Materials MovingDocument2 pagesSilo Fluidizer: Keep Dry Bulk Materials MovingHùng Thanh NguyễnPas encore d'évaluation

- Sustainable Transport Development in Nepal: Challenges and StrategiesDocument18 pagesSustainable Transport Development in Nepal: Challenges and StrategiesRamesh PokharelPas encore d'évaluation

- Manual WkhtmltopdfDocument5 pagesManual WkhtmltopdfGeorge DiazPas encore d'évaluation

- 4 LoopsDocument30 pages4 LoopsThirukkuralkaniPas encore d'évaluation