Académique Documents

Professionnel Documents

Culture Documents

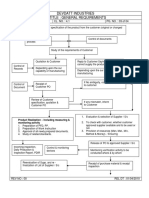

Customer Specific Requirements Matrix

Transféré par

hmp90Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Customer Specific Requirements Matrix

Transféré par

hmp90Droits d'auteur :

Formats disponibles

IMPORTANT NOTE: Customer-specific requirements are regularly updated. Check www.iatfglobaloversight.

org and the Customer's websites for the latest requirements.

Web Link

http://www.iatfglobaloversight.org/

Latest Revision

TS16949 STD #

4.2.3 Control Of documents

4.2.4.1

Records Retention

4.2.4.1

Records Retention

4.2.2 Scope

Aug-09

Sep-08

Ford Reqmt

01/01/2009 (Ed. 06))

GM Reqmnt

Chrysler

Where the organisation uses Ford documents /

Instructions or other documents of external origin, the

organisation ensures that the appropriate revision level is

used. Refer:

http://portal.covisint.com

or as specified by FMC

1.Production part approvals, tooling records, purchase

orders and amendments shall be maintained for the length

of time that the part (or family parts) is active for production

and service requirements plus 1 calender year unless

otherwise specified by FMC.This included all purchasing

documents tooling included.

Formel Q - 01/01/2005 (Rev. 5)

SQAM 19/12/2006

VW

Toyota

Where the organisation uses VW documents /

Instructions or other documents of external origin,

the organisation ensures that the appropriate

revision level is used. Refer:

Suppliers must maintain an ECI

Implementation log to show engineering

change history. May only use alternative

document if it had been approved by TSAM See sec 18-2

Compliance Reference

QOPM 4.2.3

http://www.vwgroupsupply.com

Production part approvals, tooling records,

purchase orders and amendments shall be

maintained for the length of time that the part(or

family parts) is active for productionand service

requirements plus 1 calender year unless

otherwise specified by GM

Production part approvals, tooling

records, purchase orders and

amendments shall be maintained for

the length of time that the part(or

family parts) is active for

productionand service requirements

plus 1 calender year unless otherwise

specified by Chrysler

2. Records of inspection shall be maintained for each

SAME AS FMC

customer specification, unless waived in writing by

STA.These records shall be retained for one calender year

in which they were created.

3.Records of internal quality system audits and

management review shall be retained for three years.

4. Retention

periods longer than those specified above may be

specified by an organisation in its procedures.

same as FMC

Entire facility/plant must be

registered to TS16949: 2002

Entire facility/plant must be

registered to TS16949: 2002

Entire facility/plant must be

registered to TS16949: 2002

QOPM4.2.4.1

Production records must always be completed &

available at the workstation or at the workplace

( pg 96)

Audit records for D/TLDinimum 15 years archiving

Documents must be pref backup on CD rom and

stored in a flame-proof facility

QOPM4.2.4.1

QOPM 4.2.2

QMS certification according to VDA 6.1 and/or

ISO/TS 16949 (pg 123)

Requirements for Formel Q (QPN) implemented.

(incl 2-day production acceptance) (pg 123)

4.2.4 Control of records

APQP, tooling, POs, PPAPs,

and Amendments maintained for active production &

service requirements plus one calendar, unless stated

otherwise by Ford

Mgmnt review and internal audits

retained for 3 years

same as FMC

same

same FMC

QOPM 4.2.4

same

Quality performance records

including inspection, control

charts, test results, maintained

for one Calendar year after they

were created

Same

same

5.2, 8.2.4, 8.5.1

Customer Focus

Shall demonstrate enhanced customer satisfaction through

continuous improvement requirements of Q1 as stated in

QOS. QOS Assessments shall be used in development of

QOS unless otherwise sated by the STA

Trends in Customer

satisfaction must be compared

to that of competitors and

reviewed by top mgmt

Ref: GM publications in 4.2.2

(15 in total)

no requirement

5.5.2.1

Customer Representative

Customer Rep change requires notification within 10

days or any changes in company ownership

No requirement

No requirement

5.5.3

Communication

No requirement

No requirement

No requirement

QOPM 5.1.1

5.6 Mngmt Review

The organization shall hold monthly QOS performance

meetings as specified in in the Q1 manufacturing Site

assessment. The results of these meetings and the Q1

assesment results shall be intergral to the senior

management meetings

No requirement

QOPM 5.1.1

6.2.2.2 Resource

Provision

Only trained & qualified personnel are to be involved in all No requirement

aspects of manufacturing and design of Ford parts.

Personell are to be trained to the current processes and

requirements. Records to be maintained for 3 years from

the date of training.

At least once per year

No Requirement

QOPM 5.2.1

Customer Rep change requires notification

within 10

Only trained & qualified personnel are to be

involved in all aspects of manufacturing and

design of VW parts. Personnel are to be trained to

the current processes and legal requirements. This

includes any foreign nationals (pg 134 & 5)

QOPM 5.1.1

QOPM 6.1.1

Recources must be be accounted for at RFQ stage

6.3.1 Lean

Evidence of LEAN principles must be entrenched in the

process as specified in the Q1 manufacturing site

assessment

Recources including substitute opertors must be

be accounted for at RFQ stage ( pg 97 & 136)

No Requirement

No requirement

QOPM 6.3.1

http://web.lean.ford.com/

6.3.2 Contingency

Notification of Buyer and STA engineer and assembly

within 24 hours of any plant interuption and contingency

plans activated to continue supply

No requirement

No requirement

6.4.2 Cleanliness

Part dunnage is included

No requirement

No requirement

7.1 Product

Realization Planning

GPDS users must use must use APQP/PPAP Readiness

Assessment schedule on Ford Portal - See page 11

See GM publications

QOPM 6.1.1

Use AQP requirements as defined in AQP/PSO DOC

Supplier shall develop Production Prep Plan

(PPP) Updatedto TSAM by 4th each month

7.1.4 Change

control

As per Ford SR's in table A & B on Pg 24 & 25

no requirement

No requirement

no requirement

No requirement

Report materials noted in

PPAP instructions

no requirement

No Requirement

7.2.2.1 Review of requirement - Product

Authorization can be obtained from buyer or Ford

Engineering where appropriate

no requirement

No Requirement

7.2.2.2 Feasibility

Include all supplier and Ford

organizations as appropriate

20% volume increase requires

full feasibility study

no requirement

no requirement

7.3.1.1, 7.3.3.2

Family parts may be covered by

No requirement

Need CP for all three build phases.

FMEAs, Control Plans

One FMEA or CONTROL PLAN

This must be approved by FORD

STA (Ford 4.2)

emphasis on prevention

7.3.3.3, 7.3.3.2 Multidisciplinary approach

Assistance in CP3 or legacy data systems availabe

through website

http://webc3p.ford.com/index.html

FMEA & CP approval is required for parts supplied

DFMEA & PFMEA required for all parts supplied to Ford

QOPM 7.1

Shall proactively communicate

changes

Shall notify SQ Manager and

Purchasing agent of changes to

material, process and manuf.

location.

Also supplier issues and

capacity issues

7.2.1 Environmental

requirement - materials

7.2.3.1 Customer

Communication

QOPM 7.1

See TSAM production Trial requirements Sec

12 pg 1 - 7

The organization shall meet meet requirements of

"Statement of Work" available on the Ford website

Report APQP status as defined on website

Use prototype data for production

Use prototype data for production planning

7.1.2 Acceptance criteria

QOPM 6.2.3

Contingencies for ongoing supply of parts must be

inplace

Supplier must submit Process change request

when ECI affects any approved production

process - see Sec 18-2

QOPM 7.1.4

QOPM 7.2.1

QOPM 7.4.1.1

Materials, substances & component must comply

with EU regulations (pg102)

Lists for declarable substances are to be

considered and documented (pg 125)

Information be be updated on IMDS

QOPM 7.2.2.1

Need CP for both build phases. ( pg 94)

PFMEA must be updated for project changes with PFMEA & MQC shall be submitted to TSAM 8

implemented actions (pg 94)

weeks prior to 1A trials

Shall manage MQC of sub-suppliers and

submit to TSAM on request

Electronic dat tranfer systems for GM's North

operations and CX for SA

no requirement

Establish electronic communication with Chrysler on Covisint

through Global Supplier Portal

Forever Req. - The organization shall communicate any changes

that may impact on quality on FRF on webCN

Cross-functional teams must be used to to

develop Manufacturing Quality Charts (MQC)

& PFMEA

no requirement

As per GM key characteristic Designation (KCDS)

Ref GM 1805 QN

7.3.2.3 Special

Characteristics

also 7.2.2.1

Critical and Special

characteristics guidelines only

Changes to monitoring of SC must be approved by STA

7.3.4, 7.3.6.1

Design & Development review

Must use GPDS for review of product,

design and development stages - Pg15

No requirement

All design changes including those proposed by suppliers

must have written Chrysler approval or waiver of such approval

prior to implementation refer to OSO/TS cl 7.3.7 & PPAP manual

7.3.5 Design

Verification

Design verification required to show conformance with

Ford VDS & SDS

No requirement

must be performed

before PSO can be completed

Continuing conformance

inspection/test shall be

Use GM KCDS

QOPM 7.2.3.1

"shall be knowledgeable of stds" PS-9336<H>

PS-10125<T>, AS-10119<A>

Ref: The Diamond <> 4.2.1.5 for further detail refer to PS-7300

All D/TLD part special characteristics must be

documented including those not identified by VW

but by the supplier (pg 127 & 8 & 131)

Critical characteristics must be discussed &

agreed to withTSAM QCE Sec 8 pg4

QOPM 7.2.1.1

All design/process changes including those

proposed by suppliers must have written

TSAM approval or waiver of such approval at

least 3 months prior to the proposed change Sec 18

QOPM 7.3.1

performed during the model

year.

7.3.7 Design

Changes

No requirement

All changes shall have

written approval or waiver

All changes shall have Chrysler approval or waiver of such approval

prior to production implementation

QOPM 7.3.1

7.3.6.2 Prototypes

shall request confirmation of the

need for prototypes

Ref: GP4

No ref

QOPM 7.3.1

7.3.6.3 PPAPs

1) Shall comply with AIAG PPAP

process

2)Subcontractors must meet PPAP

requirements

3) All design changes shall have

approval per PPAP and made

through WERS or SREA process

4) Run-at-rate is satisfied by

demonstrating "Prod. Verification"

Same as Ford plus,

PPAP's required from suppliers inaccordance with Chrysler's

requirements - see pg 1

PPAP requirements for assembly centres shall

from a specified prod run of saleable pilot vehicles

As specified in TRL requiremnts see Pgs 137 141)

Off Tool Sample evaluation must meet TSAM

evaluation requirements -see sec 13 p1 - 3

QOPM 7.3.6.3

Trial & changed parts must be clearly labelled

in accordance with TSAM requirements - See

Sec 18-3

7.4.1.1 Regulations

no requirement

All applicable including internations regulation shall apply

as specified by Ford as specified on Ford portal on covisint

no requirement

Materials/substances must comply with REACH

regulations

Written confirmation of compliance to legal

requirements are required

7.4.1.2, 7.4.1.3

Subcontractor QMS Development

Supplier Quality Management System Development to

When sub suppliers are too small to certify to

minimum ISO9000 level. When required, subcontactors to ISO/TS or ISO 9000 the organization shall have a

be approved by Ford

decision criteria for designating small suppliers.

Such decision criteria shall be in writing, applied

consistently in the application and verified by the

third part auditor. Refer guidelines on pg 17

When sub suppliers are too small to certify to ISO/TS or ISO 9000

the organization shall have a decision criteria for designating small

suppliers. Such decision criteia shall be in writing, applied

consistently in the application and verified by the third part auditor.

Refer guidelines on pg 5

Subcontractors for which influence the

characteristics of mandatory documents must be

audited to ensure that the requirements are

verified (pg 130)

Sub supplier quality must be simular to Tier 1

supplier quality assurance activities. Tier 1

supplier is responsible for all production &

quality issues. TSAM must be notified of any

sub-supplier change at 3 months prior to

change. Sec 9 pg 2

QOPM 7.4.1.2

7.4.3.1 Incoming

Need incoming quality measures, unless waived

No ref

Need incoming quality measures

QOPM 7.4.3.1

Product Quality

in writing by Ford STA

Any inspection shall be commensurate with the risk and

quality of the subcontractor

CGI fully responsible for Quality of incoming

materials including that of VW assured suppliers

(pg 99)

Only approved & qualified subcontractors to be

used (pg 99)

Only approved suppliers as listed on the

approved supplier's list can be used - See

Sec 09 pg 1

Ref: GM 1746

QOPM 7.4.1.1

QOPM 7.4.3.2

7.4.3.2 Scheduling

Subcontractors

100% on time delivery from subcontractors

Monitor and minimise premium freight.

7.5.1.2 Job (work) Instructions

Operators shall use most current WI's unless authorised in No ref

writing

See element 10 Operating instructions

QOPM 7.5.1.2

7.5.1.3 Verification of Job set ups

Set up records shall be

maintained for 1 year.

No ref

No ref

QOPM 7.5.1.3

7.5.1.4.

Preventive

Maintenance

1) Documented system for

preventive maintenance

Includes timely review and

documented action plan

2) Action plans to be included

in management review

3) Records kept for 1 year

No ref

Refer requirements as per Element 19

QOPM 7.5.1.4

No requirement

No requirement

PSO shall be completed by

product team to verify readiness

prior to PPAP submittal.

Parts that have been out of

production for 12 months or more

shall have production led PSO - Refer Element 21

QOPM 7.5.2

7.5.2

Process Validation

No ref

Identification, Traceability, preservation Storage &

inventory

No ref

Shall conform to Chrysler Packing, shipping and labelling

instructions

Key requirements are compliance to MMOG/LE

specified by Fords MMOG/LE manual on covisint

Ref 4.340 Cust Specifics

Ref: GM 1731

7.6.1. MSA

In accordance with AIAG manual

Family gauge studies must

be approved by STA

No ref

7.6.3, 7.6.3.2 Laboratory requirements

Independent laboratories shall be approved prior to use

The acceptance criteria should be based on ISO/IEC

17025 or national equivalent, shall be documented other

approval from Ford STA is required

Independent laboratories shall be approved prior to No Ref

use The acceptance criteria should be based on

ISO/IEC 17025 or national equivalent, shall be

documented other approval from GM is required

7.5.3, 7.5.4, 7.5.5

7.5.5.1

All tooling shall be clearly identified & correctly stored

Packaging & ID of containers, data exchange

must comply with requirements set out in B2BPlatform (pg 122)

Shall establish a system to assure Toyota

packing specs are maintained - see sec 11 pg

1-3

QOPM 7.5.3,QOPM 7.5.5

Packaging, ID of containers & VW interphase

communications (CX)shall comply with VW

requirements as set out in B2B Platform

Refer requirements listed in Element 18

3rd Party cal lab certified to ISO/IEC 17025

The acceptance criteria should be based on

ISO/IEC 17025 or national equivalent.

QOPM 7.6.3.2

8.1.1, 8.1.2 Statistical tools

Latest edition of AIAG manual for SPC, MSA VDA must be No ref

applied. Capability Index must include Cpk & Ppk studies

to determine possible sources of variation

8.2.1.1, 5.2 Customer

Shall notify 3rd party in 5 days

Notify within 5 days

Satisfaction

in writing if Q1 revoked.

Shall monitor performance metrics

as per Q1 and updates to FSP

2) Shall communicate customer

satisfaction to all employees

twice a year.

after being placed on

"New business hold - Quality"

For details ref 4.2.8 GM

specifics

8.2.2 Internal Audits & Auditors

Internal audit reviews conducted at least anually

Internal auditors qualified and competent in all core tools,

and process approach.

5 internal audits in the company

of a trained auditor covering all

aspects relating to Ford

Process and product audits

can be performed by process

specialists without full auditor

training.

Internal auditors trained as per ISO 19011 1st

edition

No ref

Short-term process capability Cmk/Ppk values >/=

1.67: Long-term process capability >/= 1.33

Capability regarding Mandatory documentation

characteristics must be proven & fully documented

(pg 132)

in 5 working days if

placed in the "Needs

Improvement" category.

Perform at least once per year

QOPM 8.1.1

Production & Mass production trila must be

conducted to meet TSAM quality & delivery

requirements See sec 12 pg 1 - 7

Customer satisfaction must be measured which

should included packaging and delivery processes Supplier shall have documenred

(pg 122)

countermeasure sytem to analyze and

improve quality concerns through waranty dat

and customer returns

D/TLD-parts & additional legal requirements to be

evaluated by regular internal audits

QOPM 8.2.1

QOPM 8.2.2.4

Auditors must be qualified & competent in process The organization shall complete the self-assessment audit 1/year

approach, core tools & customer specifics

commencing 7 Jan 2008 using Elements O Manufacturing Basics see pg 7

The organization shall conduct LPA & provide evidence of LPA being

conducted on production parts

8.2.3.1. Monitoring & measurement of manufacturing 1) Need to reduce variability using

process

Six Sigma or other similar

techniques

no requirement

No requirement

8.2.4

Monitoring and

measurement of product

ES test failures shall be the cause to stop

shipments. Ford shall be informed

All suspect must be reworked.

Test frequency requirements

shall be noted in the control plan and FMEA

Revisions to frequencies need STA approval

no requirement

No requirement

8.3.4 Customer Waiver

Approval is required before the use of non conforming or

changed process

Approval is required before the use of non

conforming or changed process

Approval is required before the use of

non conforming or changed process

QOPM 8.3.4

8.2.4.1 Layout Inspection

Shall be be performed annually and the measurements

shall be documented on the PPAP Dimensional Results

sheet. Reference AIAG PPAP Manual

No requirement

Same as Ford

QOPM 8.2.4.1

8.2.4.2 Appearance Items

Where processes or environmental could affect the

product the organization shall implement measures such

as Ford Global Craftmanship. This should be covered in

the CP and APQP reporting. Refer to FSP for further

details

No requirement

No requirement

8.3,8.5.2,8.5.3

Control of NC

product and correctve

action

Shall have systems in place to prevent shipping of non

conforming parts to any Ford company facility

Respond to Ford with 8D within 5 business days

Close out 8D within 10 days

Internal notification system

Communicate results and PPM's

Implement corrective actions

PRR system must be actioned on the GM GQTS

system on GMSupplypower

A written 8 step plan

shall be submitted for

corrective action

e-CIMS - at least two people at

each loc. must be trained in use

and reg. access the system

PSFD0270 to be incorporated

to effectively respond to e-CIMS

issues

Form No.

Approved:

QOPM 8.2.3.1

QOPM 8.2.4

No parts can be shipped to TSAM unless

Provisional or final approval has been granted

by TSAM QCE - see Sec 17 Pg 1

Judgement for colour must be evaluated as

per TSAM requirements - see sec 14 Pg 1 - 5

Respond to Quality Improvement Request

Continuous & preventive methods to be applied to (QIR) or QPR by duae date or as specified in

progress towards zero defect demand of customer the SQAM - see Sect 19

8D cause & effect taguchi type sytems must be

considered

QOPM 8.2.4.2

QOPM 8.5.2

Vous aimerez peut-être aussi

- IATF 16949:2016 Audit Guide and Checklist 2nd EditionD'EverandIATF 16949:2016 Audit Guide and Checklist 2nd EditionÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Questoes Core ToolsDocument2 pagesQuestoes Core ToolsMàrcia Neruda69% (13)

- Process-Audit-VDA-6.3 ChecklistDocument10 pagesProcess-Audit-VDA-6.3 ChecklistRambir Kaushik50% (2)

- PFMEA Audit ChecklistDocument2 pagesPFMEA Audit Checklistadnans100% (3)

- Mandatory Documents IATF 16949Document10 pagesMandatory Documents IATF 16949Jm Venki100% (10)

- IATF 16949-2016 Audit ChecklistDocument129 pagesIATF 16949-2016 Audit ChecklistRajeshLSPas encore d'évaluation

- IATF 16949 Documentation Toolkit GuideDocument4 pagesIATF 16949 Documentation Toolkit GuideOscar Solis MartirPas encore d'évaluation

- GM 1927-35 Run at Rate Form - 121049 - 01032010151508Document3 pagesGM 1927-35 Run at Rate Form - 121049 - 01032010151508Jetesh Devgun100% (1)

- VDA Volume Field Failure AnalysisDocument22 pagesVDA Volume Field Failure Analysishmp90Pas encore d'évaluation

- Process Audit Turtle DiagramDocument1 pageProcess Audit Turtle DiagramJoel Alcantara100% (3)

- IATF 16949 Mandatory Documents ListDocument2 pagesIATF 16949 Mandatory Documents ListLuis Alejandro60% (5)

- Internal Audit ChecklistDocument37 pagesInternal Audit ChecklistSumeet Rathee100% (5)

- IATF 16949 QMS Requirements MatrixDocument1 pageIATF 16949 QMS Requirements MatrixJOECOOL67100% (5)

- VDA 6.3 Based Supplier AssessmentDocument11 pagesVDA 6.3 Based Supplier AssessmentGrecu Dragos100% (1)

- Sample ManualDocument17 pagesSample ManualBALAJI83% (6)

- Process Audit Preparation GuideDocument5 pagesProcess Audit Preparation GuideNumpetch Somsw100% (6)

- APQP Check ListDocument17 pagesAPQP Check ListmdjeckelPas encore d'évaluation

- Turtle Diagrams - IATF - 16949 - 2016Document8 pagesTurtle Diagrams - IATF - 16949 - 2016Sathyaprakash Hs100% (1)

- IATF 16949 - 2016: Presented by - Kuldeep TanwarDocument193 pagesIATF 16949 - 2016: Presented by - Kuldeep Tanwarsololips100% (2)

- Iso Iatf Quality System Manual PDFDocument53 pagesIso Iatf Quality System Manual PDFKrishnamoorthyPas encore d'évaluation

- Traceability Audit ChecklistDocument12 pagesTraceability Audit ChecklistFirmino Simplicio0% (1)

- Quality Manual TemplateDocument67 pagesQuality Manual TemplateMohini Marathe100% (4)

- IATF 16949 2016 Mandatory ProcedureDocument1 pageIATF 16949 2016 Mandatory Procedureshivendrakumar100% (3)

- TurtlesDocument15 pagesTurtlesshobhit2310100% (4)

- Core Tools PDFDocument1 pageCore Tools PDFsentrakerjaan100% (3)

- AIAG-VDA DFMEA Final ExamDocument10 pagesAIAG-VDA DFMEA Final ExamMoham'medAlthafAs'lam100% (2)

- IATF Process Audit Check Sheet FormatDocument14 pagesIATF Process Audit Check Sheet Formatukavathekar71% (7)

- Process Audit VDA 6.3Document9 pagesProcess Audit VDA 6.3Mike Paruszkiewicz100% (1)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Ford Q1 and QOS Quality Operating System ScheduleDocument1 pageFord Q1 and QOS Quality Operating System Schedulehmp90Pas encore d'évaluation

- Ford Q1 and QOS Quality Operating System ScheduleDocument1 pageFord Q1 and QOS Quality Operating System Schedulehmp90Pas encore d'évaluation

- APQP Check ListDocument17 pagesAPQP Check Listhmp90Pas encore d'évaluation

- Introduction To GemologyDocument286 pagesIntroduction To GemologyEhtesham Siddiqui100% (2)

- Iatf 16949 Clause To Eqms ModuleDocument8 pagesIatf 16949 Clause To Eqms Modulepodrao100% (3)

- IATF 16949:2016 IntroductionDocument20 pagesIATF 16949:2016 IntroductionDisha Shah100% (4)

- 01.IATF 16949 AwarnessDocument48 pages01.IATF 16949 AwarnessMahi Reddy88% (8)

- IATF 16949 Awareness Training-Terms OnlyDocument18 pagesIATF 16949 Awareness Training-Terms Onlysuresh kumar67% (3)

- Free Ts 16949 Audit ChecklistDocument8 pagesFree Ts 16949 Audit ChecklistKumaravel100% (1)

- ISO 9001 Quality Procedure Context of the OrganizationDocument1 pageISO 9001 Quality Procedure Context of the OrganizationKarim HakimPas encore d'évaluation

- Iatf 3year Internal Audit PlanDocument6 pagesIatf 3year Internal Audit Planrajesh sharmaPas encore d'évaluation

- Supplier Quality Assurance Manual - Rev. 06Document40 pagesSupplier Quality Assurance Manual - Rev. 06Sundaramoorthy ArumugamPas encore d'évaluation

- IATF 16949 2016 Gap ToolDocument353 pagesIATF 16949 2016 Gap ToolOziel Cardenas33% (6)

- Turtle Diagram PPAPDocument1 pageTurtle Diagram PPAPDL50% (2)

- Draft Quality Manual IATF 16949 Version 0.0Document67 pagesDraft Quality Manual IATF 16949 Version 0.0Ashish Kumar Dahiya100% (2)

- Iatf 16949 TrainingDocument136 pagesIatf 16949 Trainingpreetam kumar100% (1)

- PRODUCT AUDIT CHECKLIST (WO Schedule)Document7 pagesPRODUCT AUDIT CHECKLIST (WO Schedule)Ranjeet Dongre100% (1)

- Manufacturing Process Audit Checklist: Reference DocumentsDocument4 pagesManufacturing Process Audit Checklist: Reference DocumentsAri Rosyadi100% (1)

- IATF 16949 Awareness Exam TitleDocument1 pageIATF 16949 Awareness Exam Titlenichecon1Pas encore d'évaluation

- Go digital with safety checklistsDocument84 pagesGo digital with safety checklists88No1FanPas encore d'évaluation

- CSR Matrix Iso Ts GM Ford Fca-Regulations-Cqi-111516Document142 pagesCSR Matrix Iso Ts GM Ford Fca-Regulations-Cqi-111516Jose Cepeda80% (5)

- PPAP FundamentalsDocument21 pagesPPAP FundamentalsRajdeep SinghPas encore d'évaluation

- FMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFDocument10 pagesFMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFBonny BonitoPas encore d'évaluation

- IATF 16949 mandatory documentsDocument3 pagesIATF 16949 mandatory documentsOscar Solis MartirPas encore d'évaluation

- IATF 16949 2016 Gap Tool InstructionsDocument11 pagesIATF 16949 2016 Gap Tool InstructionsJosé María Moreno63% (8)

- IATF 16949:2016 Training on Quality Management Systems and Audit ConceptsDocument62 pagesIATF 16949:2016 Training on Quality Management Systems and Audit ConceptsMadhukar Sinha100% (6)

- IATF 16949:2016 Process Audit TrainingDocument4 pagesIATF 16949:2016 Process Audit TrainingisolongPas encore d'évaluation

- The Process Approach QuestionsDocument6 pagesThe Process Approach QuestionsDwinanda SeptiadhiPas encore d'évaluation

- CSR Matrix For RefDocument6 pagesCSR Matrix For RefBard Z8Pas encore d'évaluation

- IATF 16949 - 2016 - List of Mandatory DocumentsDocument3 pagesIATF 16949 - 2016 - List of Mandatory DocumentsSenthil_KPas encore d'évaluation

- CS Customer - Plant Turtle Diagram 07Document1 pageCS Customer - Plant Turtle Diagram 07Alex100% (1)

- Paradise IATF IA Presentation PDFDocument211 pagesParadise IATF IA Presentation PDFSameer SaxenaPas encore d'évaluation

- ISO 9001:2015 To IATF 16949:2016 - QMS Transition Checklist: Blue FontDocument3 pagesISO 9001:2015 To IATF 16949:2016 - QMS Transition Checklist: Blue FontPratik Ardhapurkar100% (1)

- USE GRR DATASHEET AND REPORTDocument8 pagesUSE GRR DATASHEET AND REPORThmp90Pas encore d'évaluation

- Sample Size Control Limit DesignDocument10 pagesSample Size Control Limit Designhmp90Pas encore d'évaluation

- HOSTAFORMC2521Document6 pagesHOSTAFORMC2521hmp90Pas encore d'évaluation

- Plastic Omnium Implements 8D Non-Conformity SolutionDocument1 pagePlastic Omnium Implements 8D Non-Conformity Solutionhmp90100% (1)

- John Deere supplier survey guideDocument68 pagesJohn Deere supplier survey guidehmp90Pas encore d'évaluation

- OutsourcedDocument4 pagesOutsourcedSupri YantoPas encore d'évaluation

- Lean and Accounting: The Role of The CEO and CFO: Orest J. Fiume Retired Vice President - Finance The Wiremold CompanyDocument44 pagesLean and Accounting: The Role of The CEO and CFO: Orest J. Fiume Retired Vice President - Finance The Wiremold Companyjitendrasutar1975Pas encore d'évaluation

- Risk Based Thinking in ISO 9001 2015 PaperDocument5 pagesRisk Based Thinking in ISO 9001 2015 PapersjmpakPas encore d'évaluation

- 4.2.2 Control of DocumentsDocument6 pages4.2.2 Control of Documentshmp90Pas encore d'évaluation

- Quality Management PDFDocument37 pagesQuality Management PDFhmp90100% (1)

- Supplier Environmental Assessment SupplierDocument9 pagesSupplier Environmental Assessment Supplierhmp90Pas encore d'évaluation

- Teste - Inglês - 5 Ano-2biDocument2 pagesTeste - Inglês - 5 Ano-2bihmp90Pas encore d'évaluation

- VDA FMEA Process AnalysisDocument54 pagesVDA FMEA Process Analysishmp90Pas encore d'évaluation

- 4.1QM06 Process Flow ChartDocument2 pages4.1QM06 Process Flow Charthmp90100% (1)

- Process Verification Audit ChecklistDocument6 pagesProcess Verification Audit Checklisthmp90Pas encore d'évaluation

- JDS-G223 Training AidDocument52 pagesJDS-G223 Training Aidhmp90Pas encore d'évaluation

- Supplier Information Survey enDocument68 pagesSupplier Information Survey enhmp90Pas encore d'évaluation

- Red Flags SurveyDocument6 pagesRed Flags Surveyhmp90Pas encore d'évaluation

- DS G223X1Document28 pagesDS G223X1hmp90Pas encore d'évaluation

- Sample Size Control Limit DesignDocument10 pagesSample Size Control Limit Designhmp90Pas encore d'évaluation

- John Deere Process Audit InstructionsDocument10 pagesJohn Deere Process Audit Instructionshmp90Pas encore d'évaluation

- ECR ECR Meeting ECN: PurposeDocument1 pageECR ECR Meeting ECN: Purposehmp90Pas encore d'évaluation

- 32 QS-F-05 Audit Summary Report R1Document1 page32 QS-F-05 Audit Summary Report R1hmp90Pas encore d'évaluation

- An Architect's Core ProcessDocument1 pageAn Architect's Core Processhmp90Pas encore d'évaluation

- DLP Din8Document2 pagesDLP Din8KOUDJIL MohamedPas encore d'évaluation

- PrEN 12271-10 - Factory Production ControlDocument17 pagesPrEN 12271-10 - Factory Production ControlPedjaPas encore d'évaluation

- Language II Module 2 Adjectives and AdverbsDocument25 pagesLanguage II Module 2 Adjectives and AdverbsCarla Arredondo MagnerePas encore d'évaluation

- U1L2 - Definitions of 21st Century LiteraciesDocument19 pagesU1L2 - Definitions of 21st Century LiteraciesJerry Glenn Latorre CastilloPas encore d'évaluation

- Writing A Spooky Setting DescriptionDocument4 pagesWriting A Spooky Setting DescriptionAayan AnjumPas encore d'évaluation

- MAPEH 6- WEEK 1 ActivitiesDocument4 pagesMAPEH 6- WEEK 1 ActivitiesCatherine Renante100% (2)

- Crafting and Executing StrategyDocument33 pagesCrafting and Executing Strategyamoore2505Pas encore d'évaluation

- 1 s2.0 S1747938X21000142 MainDocument33 pages1 s2.0 S1747938X21000142 MainAzmil XinanPas encore d'évaluation

- Wiley Wesleyan UniversityDocument36 pagesWiley Wesleyan UniversityBirunda SilvaPas encore d'évaluation

- Scedule Maintenance KBN Mill 2020Document9 pagesScedule Maintenance KBN Mill 2020slamet supriyadiPas encore d'évaluation

- Giljang - Bsn2-A10 - Sas 1-3Document7 pagesGiljang - Bsn2-A10 - Sas 1-3Cherylen Casul GiljangPas encore d'évaluation

- Unit 3.1 - Hydrostatic ForcesDocument29 pagesUnit 3.1 - Hydrostatic ForcesIshmael MvunyiswaPas encore d'évaluation

- Chapter 6 - 31-05-2023Document163 pagesChapter 6 - 31-05-2023Saumitra PandeyPas encore d'évaluation

- E Requisition SystemDocument8 pagesE Requisition SystemWaNi AbidPas encore d'évaluation

- Lesson Element Baron-Cohen Et Al. (1997) : Instructions and Answers For TeachersDocument10 pagesLesson Element Baron-Cohen Et Al. (1997) : Instructions and Answers For TeachersSyed SumaiyahPas encore d'évaluation

- Siart, Et. Al (2018) Digital GeoarchaeologyDocument272 pagesSiart, Et. Al (2018) Digital GeoarchaeologyPepe100% (2)

- Stylistic and DiscourseDocument4 pagesStylistic and Discourseeunhye carisPas encore d'évaluation

- A Review On Micro EncapsulationDocument5 pagesA Review On Micro EncapsulationSneha DharPas encore d'évaluation

- Design and Simulation of Programmable AC-DC Converter Using Pulse Width Modulation (PWM) Techniques in MATLABDocument5 pagesDesign and Simulation of Programmable AC-DC Converter Using Pulse Width Modulation (PWM) Techniques in MATLABJeannot MpianaPas encore d'évaluation

- Hackathon Statements V1Document10 pagesHackathon Statements V1AayushPas encore d'évaluation

- Exp-1. Evacuative Tube ConcentratorDocument8 pagesExp-1. Evacuative Tube ConcentratorWaseem Nawaz MohammedPas encore d'évaluation

- CD1 ISO/IEC 17000 Conformity Assessment - Vocabulary and General PrinciplesDocument26 pagesCD1 ISO/IEC 17000 Conformity Assessment - Vocabulary and General PrinciplesMAC CONSULTORESPas encore d'évaluation

- Limits, Fits and Tolerances: Prof. S. S. PandeDocument31 pagesLimits, Fits and Tolerances: Prof. S. S. PandeM PankajPas encore d'évaluation

- Usage Instructions - Hengro PoolProtect 1 - 5Document3 pagesUsage Instructions - Hengro PoolProtect 1 - 5Brian VisserPas encore d'évaluation

- Mindfulness With Collegiate Gymnasts - Effects On Flow, Stress and Overall Mindfulness LevelsNicholas P. Cherupa,, Zeljka VidicDocument13 pagesMindfulness With Collegiate Gymnasts - Effects On Flow, Stress and Overall Mindfulness LevelsNicholas P. Cherupa,, Zeljka VidicGABRIELPas encore d'évaluation

- Math 101Document3 pagesMath 101Nitish ShahPas encore d'évaluation

- AsdfgDocument2 pagesAsdfgTejendra PachhaiPas encore d'évaluation

- Tutorial Sim MechanicsDocument840 pagesTutorial Sim MechanicsHernan Gonzalez100% (4)

- Non-Destructive Examination & Standard CF Acceptance For - Forgsd - Pipe Work Stub PiecesDocument2 pagesNon-Destructive Examination & Standard CF Acceptance For - Forgsd - Pipe Work Stub PiecesveeramalaiPas encore d'évaluation