Académique Documents

Professionnel Documents

Culture Documents

Texas Sampling Product Presentation 2013

Transféré par

afroznishatCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Texas Sampling Product Presentation 2013

Transféré par

afroznishatDroits d'auteur :

Formats disponibles

Texas Sampling

Incorporated

Texas Sampling

ISO 9001 Company

Manufactured in Victoria, Texas

Proven Product

Innovative Designs

Large Installed Base

Company Started in 1991

Division of CIRCOR

2

Why take grab samples?

Process Verification

Custody Transfer

Quality Assurance

On-Line Analyzer Verification

Sample Purity

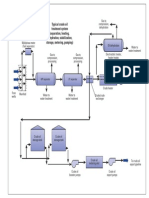

What is closed loop sampling

Texas Sampling specializes in closed

loop sampling systems although

manufacture all types of grab sample

systems.

Closed Loop Sampling: To provide a

method of collecting grab samples in

closed containers without venting to the

atmosphere or exposing the sample

taker to the process liquids or vapors.

4

Why Closed Loop Sampling

Suit up for safety, not for survival

Hygiene/Safety - Benzene and other known carcinogens,

hot samples, Acids, Cyanide, Phosgene,

Organics

Environmental-Reduction in Overall Plant

Emissions

Quality of Sample

- Containment of all Elements in a

Process Stream

To ensure that an accurate and representative

sample is taken every time

5

Scope of applications

Low vapor pressure liquids

High pressure liquids

High vapor pressure liquids

Gases

Slurries

Powders

Etc.

6

Design Elements- Setting TSI apart

Representative samples

Ease of Operation-minimize valve

manipulations

Safety-Zero emissions

Easy to maintain

Engineered to your specific process

requirements

7

Standard TSI products

Manual Continuous

MD, MH

Fixed Volume-

TSI3,MDFV,One-Armed Bandit

LPG-

LSG,LRG,LPG,LSL,LRL,LPL

HF ACID

Custom designed systems-Specials

8

Manual Continuous Sampling

Systems

Fulfills a variety of sampling needs

Lowest-priced basic system

Closed-loop sampler that is ideal for minimal pressure and

temperature applications

Collect emission-free, representative samples of process while

ensuring operator safety

Easy to install and simple to operate

Sample is dispensed into bottle by merely turning a valve

Process pressure forces sample through our patented valve

design into the bottle

With process needle purge, zero dead volume is ensured

throughout the sample valve assembly

Features

and

Easily operated with

one valve

Live load seat

Continual flow

Process needle

matches to seat of

sample valve

Benefits

Very operator friendly

Withstands

temperature

fluctuation

Flow will continue

both in bypass or

sample position

Zero dead volume

10

What is process needle purge

(PNP)?

The system purges needle automatically after

the sample has been collected

Pressurized purge removes the sample from

the process needle

Helps to Eliminate plugging of all components

where process could stagnate

Allows the operator to check the status of the

system to prevent the sample container from

rupturing

Provides a clean, representative sample

11

MH - Manual Continuous

Features a customized,

quarter turn, three-way

ball valve with an orifice

that allows continuous

flow during the sampling

process

Typically used for low

pressure and

temperature applications

with a return of process

12

13

14

MD - Flow Thru

Consists of a sample valve

that allows for continuous

process flow through a or

orifice

The rising stem sample valve

allows the operator to control

the flow of the sample being

dispensed into the sample

bottle

Used for both high and low

pressures and temperatures

where continuous flow is

desired or viscous process is

encountered

Metal Seated Ceramic Ball

Design

15

MD The valve that sets us apart

16

MD

17

MD-Inline

18

MD- Inline with Steam Purge

19

Wafer MD

20

MB - Close Coupled With

Blowback

Very versatile

Capability to blow static

product back into the

process before a sample

is obtained

Tank farms, Batch

processes and pipelines

without sample return

are ideal applications for

this type of sample

system

21

MB

22

MB

23

MR - Close Coupled Ram

Allow process to be

captured in a closed sample

bottle

Upgrade existing ram valves

to meet EPA guidelines

Has PNP available

Can be equipped with flush

and purge to remove any

residual process from the

valve and needle assembly

Can be used in tanks and

pipelines with high viscosity

process streams

24

MR

25

MR

26

Texas Sampling, Inc.

Bottle System Application Data Sheet

Date

Name

Phone

Company/Location

PROCESS DATA * Signals Required information

Media

Tag Numbers

Pressure Inlet*

*Pressures over 150psi, Fixed Volume System is recommended

Fast Loop Outlet Pressure*

Vapor Pressure *

*Vapor Pressures>19psiA recommended sampled in Sample Cylinder

Viscosity* (CP)at sample temperature:

Temperature *

* Temperatures over 120F, Process Cooling is recommended

Particles in Sample :

YES

NO Micron Size

/

( %) * if >100micron filter recommended

________________________________________________________________________

MATERIALS OF CONSTRUCTION

*Wetted Parts:

316SS (std.)

Monel400

Hastelloy C276

Other

* specify

* O-Ring Material (Elastomer):

Viton (std.)

Kalrez

Other

* specify

*Valve Packing Material:

Teflon (std.)

Graphoil (Recommended for Temperatures over 350F)

________________________________________________________________________

CONNECTION and MOUNTING

*Sample Inlet/Outlet Connection Size/Type:

(specify tube, NPT, Flange)

*Vent/Flare Pressure

Vent Location:

________________________________________________________________________

SAMPLE CONTAINER

* Type of Container

Customer (sample required)

TSI Bottle

Size Container

* Material of Container

Glass

Plastic

Safety Coated Glass

Metal Can (customer supplied)

* Method of sampling

Septum Bottle (closed loop, captured vent)

Open Top Bottle

________________________________________________________________________

OPTIONS (please check if needed):

Insulated Enclosure

Y

N

Heated Encl.

Y

N *if yes, Steam

or Electric

*if Electric, Area Classification:

Voltage:

Sample Cooler * Additional Data Needed, Please complete Sample Cooler Specification Sheet

PipeStand for mounting system

Process Needle Purge (PNP)

Secondary Sample Isolation Valve before needles/dispense tube

Sample Inlet

Sample Outlet

Both

Process Block Valve

Check Valve on Vent

Non-standard Process Needle (.083 dia.std)

.109

.148

.203

_____________________________________________________________________

Comments/Include sketch if available

27

Fixed Volume Sampling

Sample Sizes From 1cc to 20 litres

Isolates Process Pressure From Sample

Container

Repeatable, Measured Sample Volume

Safe Operation in Emergency

Process needle purge standard

Remote Actuation

28

Features and Benefits

Easily operated with

one handle

Fixed volume

chamber

Sample, bypass,

blowdown, and purge

integrated into one valve

Very operator friendly

Higher pressures (up to

600 psig) are acceptableprocess is isolated in fixed

volume chamber and

blown down with low

pressure purge

Sample bottle will not

overfill

Lab can specify exact

amount of sample needed

29

Manual Fixed Volume Sampling Systems

Closed-loop sample systems designed to take a specified

amount of sample (this amount can be varied according

to the design requirements)

Designed for use in both low and high pressure

applications with a wide variety of viscosities

How it works:

A fixed amount of sample is isolated from the process

Then low pressure purge is used to blow the sample

down into the sample container

PNP removes any residual sample

Can be customized to meet the customers needs

30

TSI3 - Fixed Volume Sampling

System

Designed to take a specified

amount of sample

Can be used in both high and

low pressure applications with a

wide range of viscosities

A fixed amount of sample is

isolated from the process

Low pressure nitrogen is used

to blow the sample down into

the sample container

PNP removes any residual

sample

Entire operation is performed

with a single handle

31

TSI3

32

MDFV - MD Fixed Volume Sampling System

Designed for high

pressure and/or high

viscosity applications

Primary sampling valve

is used to deposit a

sample into the fixed

volume cylinder

Then sample is isolated

from the process and

dispensed into the

sample container with

low pressure purge

33

MDFV

34

All 1/2 FV Systems, Spring Return

35

MRFV - Ram Fixed Volume Sampling System

Uses a ram type valve as

the primary sampling valve

to allow process to fill a

fixed volume cylinder

Then the ram valve is

closed to isolate the

sample from the process

pressure

Low pressure gas blows

the fixed amount of

sample into the sample

container

Can be used in processes

with high viscosity, high

pressure fluids or slurries

36

MRFV

37

Auto Fixed Volume Sample Systems

38

Auto Fixed Volume-Enclosure

39

Auto Fixed Volume Sample System

40

Composite Sample System

41

LPG Systems

High Vapor Pressure (19 psia and over)

TSI Patented Design

Catch Sample Under High Pressure

using sample cylinders

Simplistic Design that is operator friendly

42

LPG Sampling Systems

Enable operators to obtain samples of LP gas or liquids with

high vaporization pressures

Process is captured in a sample cylinder for easy transport to

the lab

Patented cylinder saddles ensure safety, proper alignment, and

prevents leakage when connecting the cylinder

Maximum operator safety

Allows the operator to maintain the proper cylinder outage

System is designed to allow for depressurization of quick

connects before cylinder is removed

Simple operation and easy on/off design

Excellent choice for any high vaporization liquid or gas

application

43

LSL - LPG Liquid Sample System

Take samples of high vaporization

pressure liquids for sample points with

or without a process return

A sight glass is incorporated in the

design to perform two functions

To verify that there is process

flow through the sample system

ensuring that a representative

sample is taken

Visually verify that there is an

outage in the sample cylinder

Any residual process remaining in the

cylinder after analysis can be flushed

back into the process minimizing the

need to clean the cylinder between

samples

44

Features

and

Easily operated with

only 2 valves

Sight flow/level indicator

in panel (liquid system

only) indicates 20%

outage

System pressure gauge

on front of panel

Benefits

Very operator friendly

Equipped with paddle wheel

to provide operator with a

visual check for sample flow

Gives operator status of loop

pressure for proper venting

Informs operator when it is

safe to remove filled sample

cylinder

Verifies no pressure is in

quick connects when station

is in standby

45

Features

and

Cylinder saddles (open/captive)

on front of panel

Double valve Quick Connects

on body and stem

System is mounted on SS plate

- all controls needed for

operation are mounted on front

of panel for easy operator

access

Benefits, cont.

Proper alignment is established

before quick connects join - to

prevent damage to body or

stem of quick connects

Sample cylinder is firmly

secured at sample station for

safe operation

Provides double blocks on both

ends of sample loop after

sample cylinder is removed

Less installation time required

All LPG sample stations will

look and operate uniformly

46

LSG - LPG Gas Sample System

Used to take samples of gases or vapor

The sample cylinder is filled from the top to flush any

liquids or condensed vapors back to the process to

prevent contamination of the fresh sample

A pressure gauge is incorporated in the design to

indicate that process pressure is in the sample

system during sample collection

An armored rotameter can be added to verify flow

through the system as an option

47

48

49

50

LP* - LPG with Purge

*Add L for liquid or G for gas

Used in applications when there is a requirement to

flush the process fluid from the quick connects prior

to disconnecting from the sample cylinder

Compressed air or an inert gas is used to purge the

process fluid from the cylinder connections and out

the vent ensuring that the connections are clean and

dry before the cylinder is removed

There is a separate design for liquids and gases

51

52

53

LPL-Purge with Piggy Back Cylinder

54

Portable LPG

55

Lab Docking Station

56

SPECIALTY APPLICATIONS

HF acid

Lethal service design

Powder applications

Top reactor samplers

Rail car/Tank car applications

57

Texas Sampling, Inc.

Cylinder System Application Data Sheet

Gas and Liquid

(Vapor Pressure>19psiA )

Date

Name

Phone

Email

Company/Location

________________________________________________________________________

PROCESS DATA *Signals Required Information

Media

Gas

Liquid

Vapor Pressure *

Tag Numbers

Pressure Inlet*

Fast Loop Outlet Pressure*

(**System available with and without Process Return)

Viscosity* (CP)at sampling temperature

Temperature *

* Temperatures over 120F, Process Cooling is recommended

Particles in Sample

YES

NO Micron Size

/

(%) * if >100micron filter recommended

________________________________________________________________________

MATERIALS OF CONSTRUCTION

*Wetted Parts:

316SS (std.)

Monel400

Hastelloy C276

Other

* specify

* O-Ring Material (Elastomer):

Viton (std.)

Kalrez (**recommended in H2S service)

Other

*Valve Packing Material:

Teflon (std.)

Graphoil (Recommended for Temperatures over 350F)

________________________________________________________________________

CONNECTION and MOUNTING

*Sample Inlet/Outlet Connection Size/Type:

(specify tube,NPT,Flange)

*Vent/Flare Pressure:

Vent Location:

________________________________________________________________________

SAMPLE CONTAINER

* Cylinder:

TSI Supplied

Customer Supplied

*Size Sample Cylinder:

300cc

500cc

Other

(specify)

*Cylinder Quick Connect Brand/PN#

Dip Tube

*Cylinder Accessories:

Rupture Disk

________________________________________________________________________

OPTIONS (please check if needed):

Y

N

Heated Encl.

Y

N *if yes, Steam

or Electric

Insulated Enclosure

*if Electric, Area Classification:

Voltage:

Sample Cooler * Additional Data Needed, Please complete Sample Cooler Specification Sheet

PipeStand for mounting system

Quick Connect Purge **recommended in H2S service

Process Block Valve

Sample Inlet

Sample Outlet

Both

Check Valve on Vent

Special Configurations Available (** please contact your local representative for information): Detector Tube

System, Corrosion Strip Cylinder, Lab Docking Station, ASTM Moisture Test Port, Special Coatings

_____________________________________________________________________

Comments/Include sketch if available

58

HF Acid Sampler

59

Optional Equipment

Coolers

Process Needle Purge (PNP)

Bottles, Caps, and Septas

Sample Cylinders

Materials of Construction

Activated Carbon Absorbers

Gauges, Rotameters

Enclosures

60

61

62

Coolers

Tube-in-Tube Design

Highly efficient

Up to 40 coils available

Includes Temperature Gauge and

Throttling Valve to achieve proper

sample temperatures

63

Texas Sampling Accessories

Bottles, Caps, Septas

Sample Cylinder Assemblies

Service Contracts

Custom Panels

Pipe Stands

64

65

Materials of Construction

316 SS Standard

PTFE

Hastelloy

Alloy 20

Monel

Titanium

Zirconium

Others Available

66

67

Emission Filter with Indicator

68

Niche Applications

Natural Gas

Cryogenics

LPG - High Sulphur content-fully lined internals

HF and other Acid sampling

Flare Gas

Steam Heated Ram Valves

Automated Composite Samplers with

Refrigerators

Draeger tube samplers

Heavy residuals

69

Tank-Multi Point

70

Tank-Multi Point

71

Hot Tar - INLINE

72

Hot Tar- Steam Cool

73

Hot Tar- Steam Cool

74

Reactor Sample System

75

MD- 2 systems on 1 panel

76

Detector/LPG System

77

Thank you to

Vous aimerez peut-être aussi

- TSI-Manual Closed Loop Grab Sampling SystemsDocument49 pagesTSI-Manual Closed Loop Grab Sampling SystemsdogantPas encore d'évaluation

- Process Flow Diagram Ethylene OxideDocument2 pagesProcess Flow Diagram Ethylene Oxideheri100% (1)

- 10.2.2 PCS Phosphate's New 4500 STPD Sulfuric Acid Plant in AuroraDocument20 pages10.2.2 PCS Phosphate's New 4500 STPD Sulfuric Acid Plant in AuroraCarlosPas encore d'évaluation

- Techno-Economic Assessment About Sodium HydroxideDocument3 pagesTechno-Economic Assessment About Sodium HydroxideIntratec SolutionsPas encore d'évaluation

- The Purpose of Sulfur Guard BedDocument1 pageThe Purpose of Sulfur Guard BedAlia Khan100% (1)

- Shantanu DasDocument10 pagesShantanu DasarunkdevassyPas encore d'évaluation

- Decomposition of Sodium ChlorateDocument3 pagesDecomposition of Sodium Chlorateعبد القادر حدادPas encore d'évaluation

- GACL Aluminum Chloride ExpansionDocument6 pagesGACL Aluminum Chloride ExpansionashwinikrishnaPas encore d'évaluation

- BF-9201 US F-200 DatasheetDocument3 pagesBF-9201 US F-200 DatasheetNguyễn Kim HùngPas encore d'évaluation

- 05 V PattabathulaDocument16 pages05 V Pattabathulapcorreia_81Pas encore d'évaluation

- Enotec2 PDFDocument6 pagesEnotec2 PDFamk2009Pas encore d'évaluation

- Belco Edv Wet Scrubbing System: Best Available Control Technology (Bact) For Fccu Emission ControlDocument16 pagesBelco Edv Wet Scrubbing System: Best Available Control Technology (Bact) For Fccu Emission ControlBharavi K S100% (1)

- Topsoe Tk-575 BrimDocument2 pagesTopsoe Tk-575 Brimcraigorio616Pas encore d'évaluation

- Shimadzu LC 2010Document20 pagesShimadzu LC 2010Cooordinación Metrologia Nutermía sas100% (1)

- SiCl4 PreparationDocument5 pagesSiCl4 PreparationAdam FlynnPas encore d'évaluation

- Generic Design Assessment - Step 4 - Assessment of Westinghouse AP1000 - Civil Engineering and External Hazards PDFDocument244 pagesGeneric Design Assessment - Step 4 - Assessment of Westinghouse AP1000 - Civil Engineering and External Hazards PDFKhan SalimPas encore d'évaluation

- Paraffin DispersantDocument11 pagesParaffin DispersantWael FaragPas encore d'évaluation

- When Nameplate Is Not EnoughDocument9 pagesWhen Nameplate Is Not Enoughgreenisin100% (1)

- NAC&SACDocument5 pagesNAC&SACEngr. Asif malikPas encore d'évaluation

- Emergency Safety Shower Project DetailsDocument1 pageEmergency Safety Shower Project DetailsTrimitraPas encore d'évaluation

- Electrochemistry ChloralkaliDocument10 pagesElectrochemistry ChloralkaliAnonymous y7dpcKfKxMPas encore d'évaluation

- Chlorine CylinderDocument9 pagesChlorine Cylinderjoseph_mscPas encore d'évaluation

- Axens Catalysts and Adsorbents: Advanced Solutions and ServicesDocument9 pagesAxens Catalysts and Adsorbents: Advanced Solutions and ServicesMo OsPas encore d'évaluation

- Lean Amine Filtration Package XX-001 Precoating TeamDocument3 pagesLean Amine Filtration Package XX-001 Precoating TeamAliPas encore d'évaluation

- PDHG - Methyl Isobutyl Ketone - Nov-2011Document6 pagesPDHG - Methyl Isobutyl Ketone - Nov-2011thomas_v501925Pas encore d'évaluation

- Uhde Brochures PDF en 10Document24 pagesUhde Brochures PDF en 10Jhon Ramirez100% (1)

- Understanding and Eliminating Pressure Fluctuations in 2010 Process SafetyDocument6 pagesUnderstanding and Eliminating Pressure Fluctuations in 2010 Process SafetyandriPas encore d'évaluation

- Spent Acid From Chlorine DryingDocument2 pagesSpent Acid From Chlorine DryingacckypenrynPas encore d'évaluation

- Ozone PDFDocument4 pagesOzone PDFShesharam ChouhanPas encore d'évaluation

- STRATCO AlkylationTechnologyImprovementsDocument23 pagesSTRATCO AlkylationTechnologyImprovementsAli YousefPas encore d'évaluation

- Catalyst MsdsDocument3 pagesCatalyst MsdsJaime MendozaPas encore d'évaluation

- Amine Degradation Chemistry in CO2 ServiceDocument15 pagesAmine Degradation Chemistry in CO2 ServiceZEN MAPas encore d'évaluation

- ENGINEERING MATERIALS DEGRADATION AND SELECTIONDocument18 pagesENGINEERING MATERIALS DEGRADATION AND SELECTIONAli UsmanPas encore d'évaluation

- Prico Process PDFDocument13 pagesPrico Process PDFcorkynhoPas encore d'évaluation

- Ambatovy Site TourDocument41 pagesAmbatovy Site Tourrabbidhaggis100% (1)

- PET flakes recycled into UV-curable resinsDocument10 pagesPET flakes recycled into UV-curable resinsR_M_M_Pas encore d'évaluation

- Ud He TechnologyDocument16 pagesUd He TechnologyBejavada SureshPas encore d'évaluation

- Design and Optimization of A Catalytic Membrane Reactor For The DirectDocument8 pagesDesign and Optimization of A Catalytic Membrane Reactor For The DirectGerardOo Alexander SPas encore d'évaluation

- AcquaconvertionDocument10 pagesAcquaconvertionGreysi N. Moreno CedeñoPas encore d'évaluation

- MERICAT J: A New Kerosene Treating Technology To Meet Jet Fuel SpecificationsDocument13 pagesMERICAT J: A New Kerosene Treating Technology To Meet Jet Fuel SpecificationsRio RinaldiPas encore d'évaluation

- GAPS Guidelines: Electrostatic PrecipitatorsDocument4 pagesGAPS Guidelines: Electrostatic PrecipitatorsAsad KhanPas encore d'évaluation

- Petronet LNG LTD., India: Investment in LNG Terminals & Future For The Downstream IndustriesDocument26 pagesPetronet LNG LTD., India: Investment in LNG Terminals & Future For The Downstream Industriesjan.pa87534Pas encore d'évaluation

- CASE STUDY On Phosphoric Acid Plant ProcessDocument3 pagesCASE STUDY On Phosphoric Acid Plant ProcessIsrael NarvastaPas encore d'évaluation

- Microbial DesulfurizationDocument34 pagesMicrobial DesulfurizationMiguel RazquinPas encore d'évaluation

- N-Propanol - CAS # 71-23-8: Product Handling GuideDocument2 pagesN-Propanol - CAS # 71-23-8: Product Handling Guidesharmi2011Pas encore d'évaluation

- SOP for Safe Quenching of Pyrophoric SubstancesDocument5 pagesSOP for Safe Quenching of Pyrophoric Substancesdhavalesh1Pas encore d'évaluation

- NFPA 45 (2004) Requirements That Apply NowDocument8 pagesNFPA 45 (2004) Requirements That Apply NowCarlos EduardoPas encore d'évaluation

- F10ca004-Gb 0597Document8 pagesF10ca004-Gb 0597gabyorPas encore d'évaluation

- IS-12437 Zirconium PowderDocument8 pagesIS-12437 Zirconium PowderAnuradhaPatraPas encore d'évaluation

- PSA medical oxygen generators presentation for COVID-19 hospitalsDocument10 pagesPSA medical oxygen generators presentation for COVID-19 hospitalsrutujaPas encore d'évaluation

- HSFCCDocument22 pagesHSFCCdonald55555100% (1)

- Optimizing Glycol Dehydration System For Maximum Efficiency A Case Study of A Gas Plant in NigeriaDocument16 pagesOptimizing Glycol Dehydration System For Maximum Efficiency A Case Study of A Gas Plant in Nigeria1412091090Pas encore d'évaluation

- Jacobi Tds Colorsorb Hp120a A4 Eng E0116Document2 pagesJacobi Tds Colorsorb Hp120a A4 Eng E0116Alfonso García100% (1)

- 1bottles Group Production of Bisphenol-ADocument112 pages1bottles Group Production of Bisphenol-AJames BelciñaPas encore d'évaluation

- Nalco 72215 (GHS)Document8 pagesNalco 72215 (GHS)Waseem SyedPas encore d'évaluation

- EPD H2O2-Eka ChemicalsDocument4 pagesEPD H2O2-Eka ChemicalsnhangocPas encore d'évaluation

- N16S-GT Package 23x23mm Technical SpecificationsDocument49 pagesN16S-GT Package 23x23mm Technical Specificationsvi aPas encore d'évaluation

- ProjectDocument14 pagesProjectهاجر صالح جبارPas encore d'évaluation

- Chlorine: International Thermodynamic Tables of the Fluid StateD'EverandChlorine: International Thermodynamic Tables of the Fluid StatePas encore d'évaluation

- Tsi 2014 12 04Document15 pagesTsi 2014 12 04afroznishatPas encore d'évaluation

- Texas Sampling MD Flow Thru System PresentationDocument15 pagesTexas Sampling MD Flow Thru System PresentationafroznishatPas encore d'évaluation

- Psi38883 Ambient WebOpt-AKHSDocument4 pagesPsi38883 Ambient WebOpt-AKHSafroznishatPas encore d'évaluation

- Form CCCP Civil Services Prelim Cum Mains 2015Document4 pagesForm CCCP Civil Services Prelim Cum Mains 2015afroznishatPas encore d'évaluation

- Exploration Production TransportDocument28 pagesExploration Production TransportafroznishatPas encore d'évaluation

- Workshop On Global Logistics, Shipping and Forwarding With Time BreakupDocument15 pagesWorkshop On Global Logistics, Shipping and Forwarding With Time BreakupkishorsanapPas encore d'évaluation

- WEB Aerosol-Dust Brochure Design Rv3.3 FINALOptDocument12 pagesWEB Aerosol-Dust Brochure Design Rv3.3 FINALOptafroznishatPas encore d'évaluation

- Process Simulation of Crude Oil StabilizationDocument105 pagesProcess Simulation of Crude Oil Stabilizationafroznishat100% (5)

- Treatments Plants For Oil ProductionDocument38 pagesTreatments Plants For Oil ProductionafroznishatPas encore d'évaluation

- Epf Crude Oil TreatmentDocument1 pageEpf Crude Oil Treatmentafroznishat100% (2)

- A Guide To Accounting ZakahDocument98 pagesA Guide To Accounting Zakahfarhan042Pas encore d'évaluation

- Magnetic PropertiesDocument29 pagesMagnetic PropertiesSiyan ShivaPas encore d'évaluation

- Module I Seminar Skor A Chemistry SPM 2010Document9 pagesModule I Seminar Skor A Chemistry SPM 2010Suriati Bt A RashidPas encore d'évaluation

- Shed BuildingDocument59 pagesShed BuildingdomesPas encore d'évaluation

- Caustic Soda 99 - Aus SdsDocument8 pagesCaustic Soda 99 - Aus SdsThatoPas encore d'évaluation

- Bechem Premium GreaseDocument2 pagesBechem Premium GreaseDinesh babuPas encore d'évaluation

- Practical Design of Vibro Stone Columns: June 2016Document15 pagesPractical Design of Vibro Stone Columns: June 2016Dr Ganesh Kame (Dr Kame)Pas encore d'évaluation

- Reservoir Fluid Sampling & RecombinationDocument9 pagesReservoir Fluid Sampling & Recombinationdrojas70Pas encore d'évaluation

- CHAPTER 8 - Latex DippingDocument79 pagesCHAPTER 8 - Latex DippingZaimr100% (3)

- Sku 3033 Environmental ChemistryDocument4 pagesSku 3033 Environmental ChemistryNurul AisahPas encore d'évaluation

- Partition WallDocument6 pagesPartition WallVinayak U (RA1911201010039)Pas encore d'évaluation

- Try at Home Make FerrofluidDocument2 pagesTry at Home Make FerrofluidJorge FarinhaPas encore d'évaluation

- Ecological Engineering: Veljko Prodanovic, Belinda Hatt, David Mccarthy, Kefeng Zhang, Ana DeleticDocument11 pagesEcological Engineering: Veljko Prodanovic, Belinda Hatt, David Mccarthy, Kefeng Zhang, Ana DeleticƩńg Mễdĥàť ẌƿPas encore d'évaluation

- Manufacturing Process-Ii: Lab Manual 01Document8 pagesManufacturing Process-Ii: Lab Manual 01Abdul Rehman FaisalPas encore d'évaluation

- Sym Group Crystal Structure Atomic Number Atomic WeightDocument59 pagesSym Group Crystal Structure Atomic Number Atomic WeightBhupesh MulikPas encore d'évaluation

- Safety Data Sheet PrimerDocument4 pagesSafety Data Sheet PrimerJoePas encore d'évaluation

- Natsteel BRCDocument8 pagesNatsteel BRClwin_oo2435Pas encore d'évaluation

- Thermodynamic Considerations in The Interactions of Nitrogen Oxides and Oxy Acids in The AtmosphereDocument5 pagesThermodynamic Considerations in The Interactions of Nitrogen Oxides and Oxy Acids in The AtmosphereKing Ray TabalbaPas encore d'évaluation

- SPE 121182 Selective Water Shutoff in Gas Well Turns A Liability Into An Asset: A Successful Case History From East Kalimantan, IndonesiaDocument7 pagesSPE 121182 Selective Water Shutoff in Gas Well Turns A Liability Into An Asset: A Successful Case History From East Kalimantan, Indonesiahade wantoPas encore d'évaluation

- LintelsDocument18 pagesLintelsBasavaraj hsPas encore d'évaluation

- Material Characterization Lab 2Document7 pagesMaterial Characterization Lab 2siddant vardeyPas encore d'évaluation

- Komatsu Coolant High Performance Long Life Coolant With Low Impact On Global EnvironmentDocument7 pagesKomatsu Coolant High Performance Long Life Coolant With Low Impact On Global EnvironmentDian Wahyu AlfatahPas encore d'évaluation

- JIS C 3316 2000 Polyvinyl Chloride Insulated Wires For Electrical ApparatusDocument14 pagesJIS C 3316 2000 Polyvinyl Chloride Insulated Wires For Electrical ApparatusquochunguicPas encore d'évaluation

- Syngas ProductsDocument98 pagesSyngas ProductsHendriyana St100% (1)

- Thesis FulltextDocument472 pagesThesis FulltextBhaskar ReddyPas encore d'évaluation

- Chapter 2 The Gaseous StateDocument3 pagesChapter 2 The Gaseous StateChai LianPas encore d'évaluation

- 2010-F3-CHEM Final Exam Paper ReviewDocument39 pages2010-F3-CHEM Final Exam Paper Review2E (04) Ho Hong Tat AdamPas encore d'évaluation

- Final ReviewDocument43 pagesFinal ReviewKaththi KathirPas encore d'évaluation

- BEGINNER'S GUIDE TO SURFACTANTSDocument6 pagesBEGINNER'S GUIDE TO SURFACTANTSJuanGuillermoCarmonaOcampoPas encore d'évaluation

- Chem 17 - LE 1 (2nd Sem)Document3 pagesChem 17 - LE 1 (2nd Sem)Aleli ReyesPas encore d'évaluation

- PDS RECECoat FINE GREYDocument2 pagesPDS RECECoat FINE GREYAmira RamleePas encore d'évaluation